A high-gloss three-dimensional texture material and its preparation method

A three-dimensional, textured technology, applied in the field of high-gloss three-dimensional textured materials and their preparation, can solve the problems of difficult material recycling, high production efficiency, and low cost, and achieve the goal of reducing the problem of inconsistent orientation, improving scratch resistance, and weakening molding defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

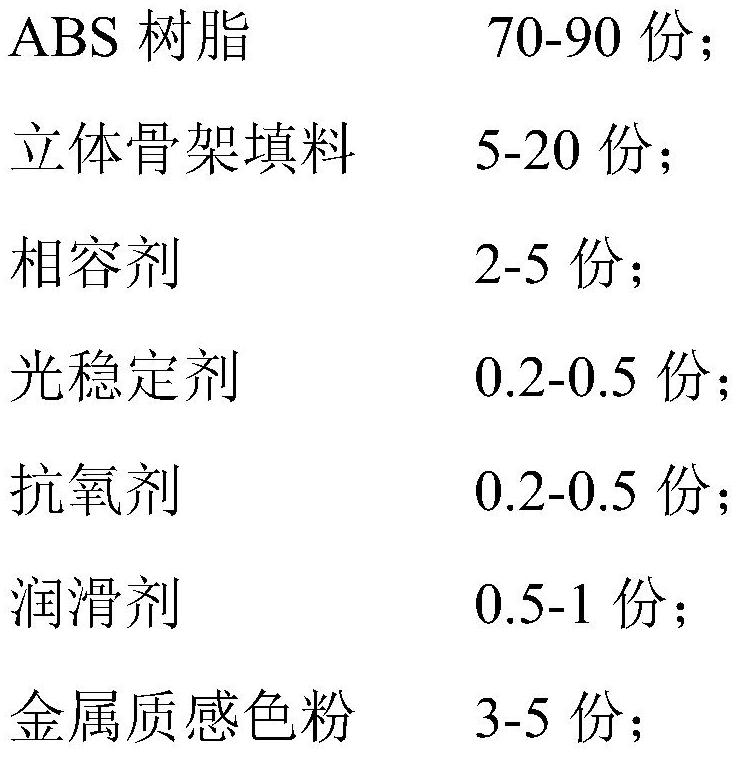

[0042] (1) Add 90 parts of ABS resin, 2 parts of compatibilizer, 0.4 part of antioxidant and 0.5 part of light stabilizer into a high-mixer with a temperature of 70°C and nitrogen protection for 8 minutes;

[0043] (2) According to the ratio, add 5 parts of three-dimensional skeleton filler, 3 parts of metallic toner (3 parts of copper-based metal powder) and 0.7 parts of lubricant into a high-mixer with a temperature of 70 ° C and nitrogen protection for 8 minutes. ;

[0044] (3) Under the protection of nitrogen, add the material in (1) to the main feeding port of the twin-screw extruder, and add the material in (2) to the side feeding port of the twin-screw extruder, and extrude after melt blending After granulation, a high-gloss three-dimensional texture material is obtained; the barrel temperature of the twin-screw extruder is 200-230°C, the screw speed is 500RPM, and the vacuum degree is -0.08MPa.

Embodiment 2

[0046] (1) Add 70 parts of ABS resin, 5 parts of compatibilizer, 0.2 part of antioxidant and 0.4 part of light stabilizer into a high-speed mixer with a temperature of 75 ° C and nitrogen protection for 5 minutes;

[0047] (2) According to the ratio, add 20 parts of three-dimensional skeleton filler, 5 parts of metallic toner (5 parts of copper-based metal powder) and 0.5 part of lubricant into a high-mixer with a temperature of 75 ° C and nitrogen protection for 5 minutes. ;

[0048] (3) Under the protection of nitrogen, add the material in (1) to the main feeding port of the twin-screw extruder, and add the material in (2) to the side feeding port of the twin-screw extruder, and extrude after melt blending After granulation, a high-gloss three-dimensional texture material is obtained; the barrel temperature of the twin-screw extruder is 200-230°C, the screw speed is 450RPM, and the vacuum degree is -0.04MPa.

Embodiment 3

[0050] (1) Add 75 parts of ABS resin, 5 parts of compatibilizer, 0.5 part of antioxidant and 0.2 part of light stabilizer into a high-mixer with a temperature of 65°C and nitrogen protection for 10 minutes;

[0051] (2) According to the ratio, add 20 parts of three-dimensional skeleton filler, 5 parts of metallic toner (3.5 parts of aluminum-based metal powder and 1.5 parts of pearl powder) and 0.8 parts of lubricant into a high-mixing machine with a temperature of 65 ° C and nitrogen protection. Mix in the machine for 10 minutes;

[0052] (3) Under the protection of nitrogen, add the material in (1) to the main feeding port of the twin-screw extruder, and add the material in (2) to the side feeding port of the twin-screw extruder, and extrude after melt blending After granulation, a high-gloss three-dimensional texture material is obtained; the barrel temperature of the twin-screw extruder is 200-230°C, the screw speed is 500RPM, and the vacuum degree is -0.1MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com