Copolymer polyester resin and molded product using same

A polyester resin and copolymer technology, applied in the field of copolymer polyester resin, can solve the problems of reducing shrinkage stress, poor low-temperature shrinkage, etc., and achieve the effects of reducing shrinkage stress, high shrinkage rate, and reducing molding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0048] The present invention can be better understood through the following illustrative examples and comparative examples, which are illustrative and not limiting to the present invention.

[0049] Property measurements were performed in Examples and Comparative Examples according to the following methods.

[0050] ◎Glass transition temperature (Tg): Tg was measured using a differential scanning calorimeter purchased from TA Instruments.

[0051] ◎Heat shrinkage rate: cut a sample into a square with a size of 10 cm × 10 cm, and soak it in warm water for 10 seconds at the temperature shown in Table 1 below under no-load conditions to make it heat shrink, and then Soak in water at 25°C for 10 seconds, then measure the longitudinal and transverse lengths of the sample, and then substitute them into the following formula.

[0052] Thermal shrinkage rate (%) = 100 x (length before shrinkage - length after shrinkage) / (length before shrinkage)

[0053] ◎Solution resistivity (Ωcm...

Embodiment 1

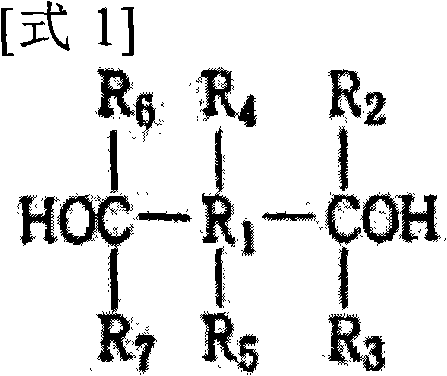

[0060] To prepare the copolymer polyester resin, based on 6 moles of terephthalic acid, 183 g of 1,4-cyclohexanedimethanol, 511 g of ethylene glycol and 183 g of 2-methyl-1,3-propanediol were added to a stirring In a 3-liter reactor with a discharge condenser and a discharge condenser, mixing was carried out, and the reaction was carried out while gradually raising the temperature therein to 255°C.

[0061] Thereby, the generated water is discharged to the outside, thereby performing esterification. After the completion of water generation and discharge, the obtained esterified product was transferred to a polycondensation reactor equipped with a stirrer, a condenser and a vacuum system.

[0062] 0.5 g of tetrabutyl titanate, 0.4 g of triethyl phosphate and 0.5 g of cobalt acetate were added to the esterified product. While the internal temperature of the reactor was raised from 240°C to 275°C, ethylene glycol was removed in a low vacuum atmosphere of 50 mmHg, which was reduc...

Embodiment 2

[0065] A copolymer polyester resin was prepared in the same manner as in Example 1 except that 250 g of 2-methyl-1,3-propanediol was added. Then a heat-shrinkable film was prepared using the resin, and the glass transition temperature, shrinkage initiation temperature, heat shrinkage rate, melt resistivity, and shrinkage stress of the heat-shrinkable film were measured. The results are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com