Preparation method and application of master batch used for polyvinylidene fluoride film

A polyvinylidene fluoride and film technology, which is applied in the field of plastic coloring, can solve problems such as poor processing performance and film defects, and achieve the effects of reducing film forming defects, increasing melt fluidity, and uniform film performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

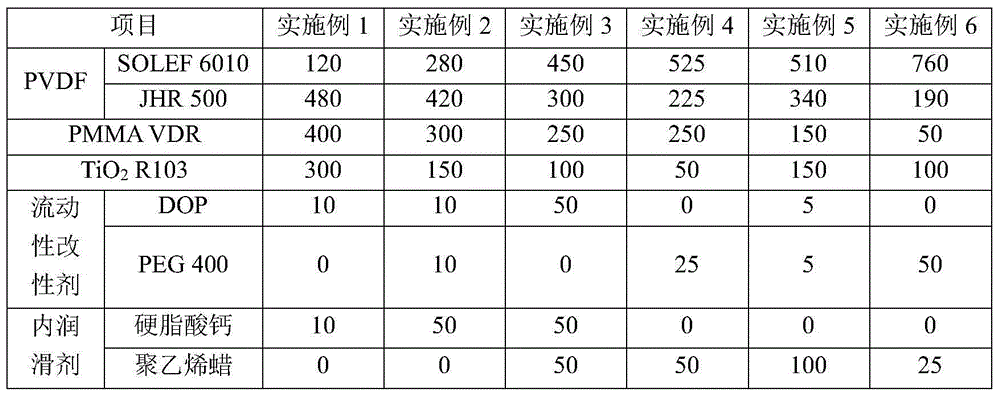

Embodiment 1

[0033] Weigh the raw materials according to the formula in Table 1, and mix them uniformly in a high-speed mixer at room temperature until the materials are uniformly stirred. After cooling, granulation, and drying, a high-melt fluidity color masterbatch for polyvinylidene fluoride film is obtained.

[0034] Add the masterbatch into the single-screw extrusion casting machine for melting and plasticizing, the melting and plasticizing temperature is 190-220 °C, the screw speed is 30 r / min, and then pass through the sheet / film die, the die temperature is 230 °C, and the flow rate is 230 °C. The film is formed by a stretching device, and then the film is subjected to heat treatment at 140° C. to shape, and then the edge is trimmed. After corona treatment, the film is cooled and wound to obtain a polyvinylidene fluoride-based film.

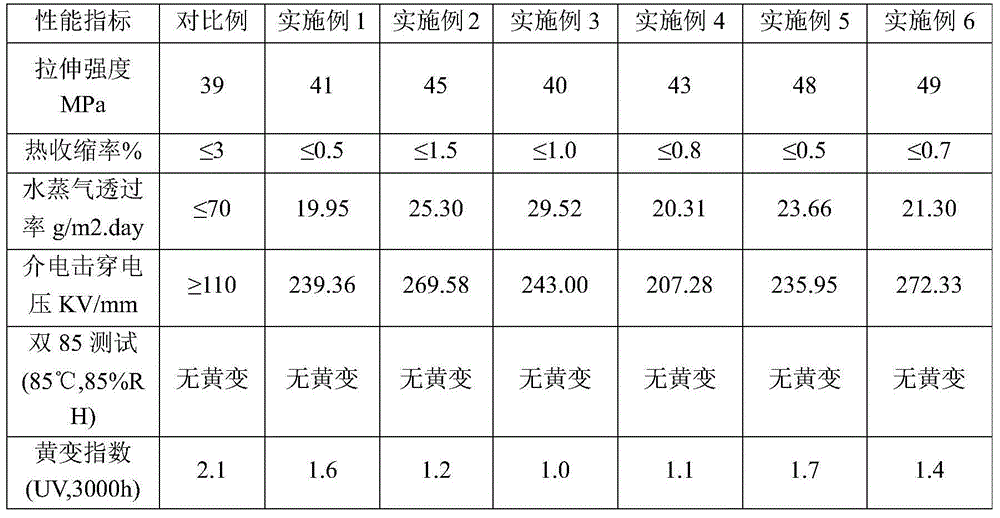

[0035] The above film is made into a 25μm thick film, and its tensile strength is tested according to ASTM D882 standard, its thermal shrinkage rate i...

Embodiment 2

[0037] Weigh the raw materials according to the formula in Table 1, and mix them uniformly in a high-speed mixer at room temperature until the materials are uniformly stirred. After cooling, granulation, and drying, a high-melt fluidity color masterbatch for polyvinylidene fluoride film is obtained.

[0038] Add the masterbatch into the single-screw extrusion casting machine for melting and plasticizing, the melting and plasticizing temperature is 200-230 ℃, the screw speed is 20r / min, and then pass through the sheet / film die, the die temperature is 220 ℃, through the flow The film is formed by stretching and stretching device, and then the film is heat-treated at 150° C. to shape, then trimmed, and cooled and rolled after corona treatment to obtain a polyvinylidene fluoride-based film.

[0039] The above film is made into a 25μm thick film, and its tensile strength is tested according to ASTM D882 standard, its thermal shrinkage rate is tested according to ISO 11501 standard,...

Embodiment 3

[0041] Weigh the raw materials according to the formula in Table 1, and mix them uniformly in a high-speed mixer at room temperature until the materials are uniformly stirred. After cooling, granulation, and drying, a high-melt fluidity color masterbatch for polyvinylidene fluoride film is obtained.

[0042] Add the masterbatch into the single-screw extrusion casting machine for melting and plasticizing, the melting and plasticizing temperature is 210-230 ℃, the screw speed is 50r / min, and then pass through the sheet / film die, the die temperature is 220 ℃, through the flow The film is formed by stretching and stretching device, and then the film is heat-treated at 150° C. to shape, then trimmed, and cooled and rolled after corona treatment to obtain a polyvinylidene fluoride-based film.

[0043]The above film is made into a 25μm thick film, and its tensile strength is tested according to ASTM D882 standard, its thermal shrinkage rate is tested according to ISO 11501 standard, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com