Polylactic acid base composite material and preparation method thereof

A composite material, polylactic acid technology, applied in the field of polymers, can solve the problems of large spherulite size, poor tear strength, lack of branched chain structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

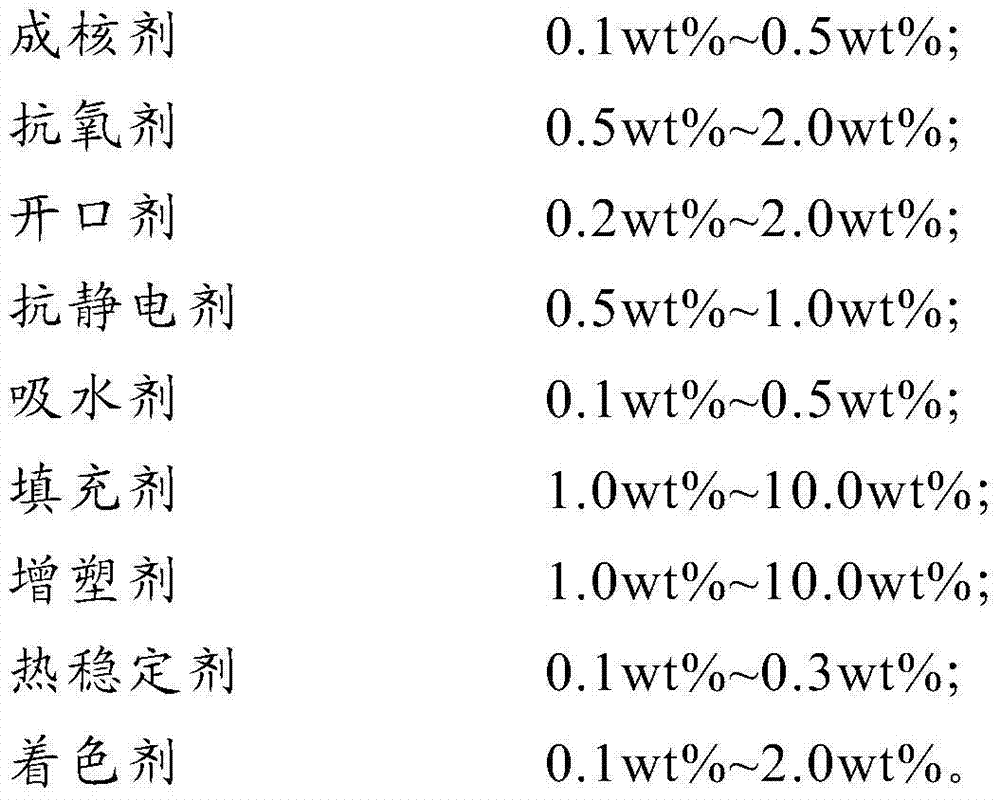

preparation example Construction

[0042] The preparation method of the polylactic acid-castor oil copolymer described in the present application can be prepared according to the following method: under the action of a catalyst, castor oil and lactide are mixed, and the polylactic acid-castor oil copolymer is obtained after reaction. In the above-mentioned process of preparing polylactic acid-castor oil copolymer, the catalyst is preferably stannous octoate. The above reaction is a process in which castor oil initiates the bulk polymerization of lactide, the temperature of the polymerization is preferably 120°C-135°C, and the time of the polymerization is preferably 10-20h. The mass ratio of the castor oil to the lactide is preferably (1-5): 10, and the amount of the catalyst added is 0.1wt% to 0.5wt% of the total amount of the castor oil and the lactide . In order to fully dissolve the castor oil, as a preferred option, the castor oil is first refluxed with toluene to remove water. The number average molecul...

Embodiment 1

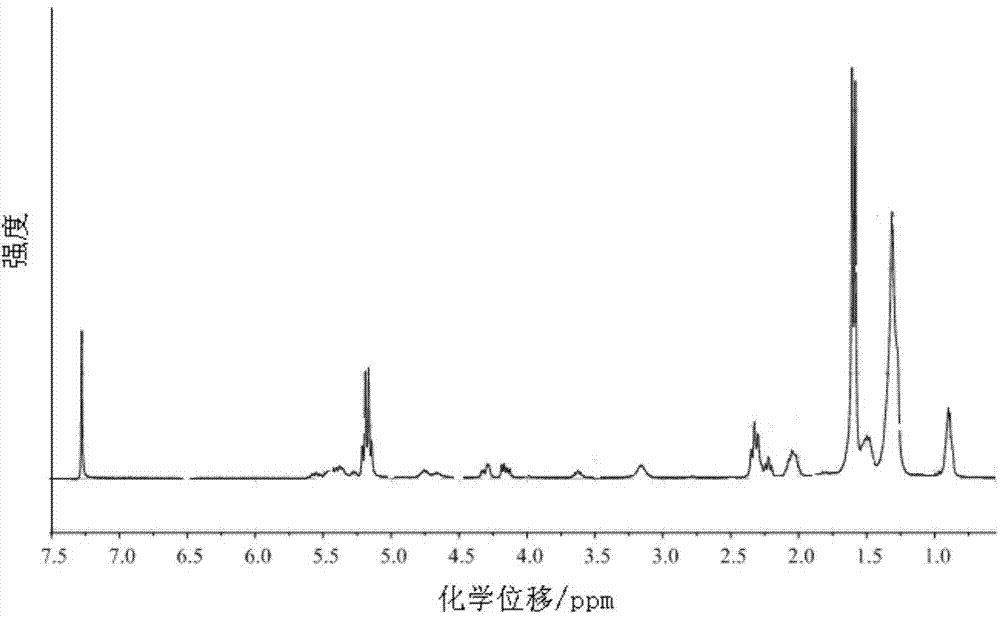

[0060] The preparation of embodiment 1 polylactic acid-castor oil copolymer

[0061] Castor oil and toluene are refluxed to remove water, and then toluene is removed to obtain dry castor oil; 100 g of lactide crystallization is purified, dried, and packed into a reactor; 30 grams of dry castor oil is added, and under the condition of magnetic stirring, Mix well at 100-120°C; add 0.5% catalyst stannous octoate, react at 120-130°C for more than 10 hours to obtain a white solid product, and obtain polylactic acid-castor oil copolymer by sedimentation. The molecular weight of the copolymer measured by GPC was 6300 g / mol. figure 1 Be the HNMR curve figure of the final reaction product of this embodiment, according to figure 1 It was confirmed that the reaction product was a polylactic acid-castor oil copolymer.

Embodiment 2

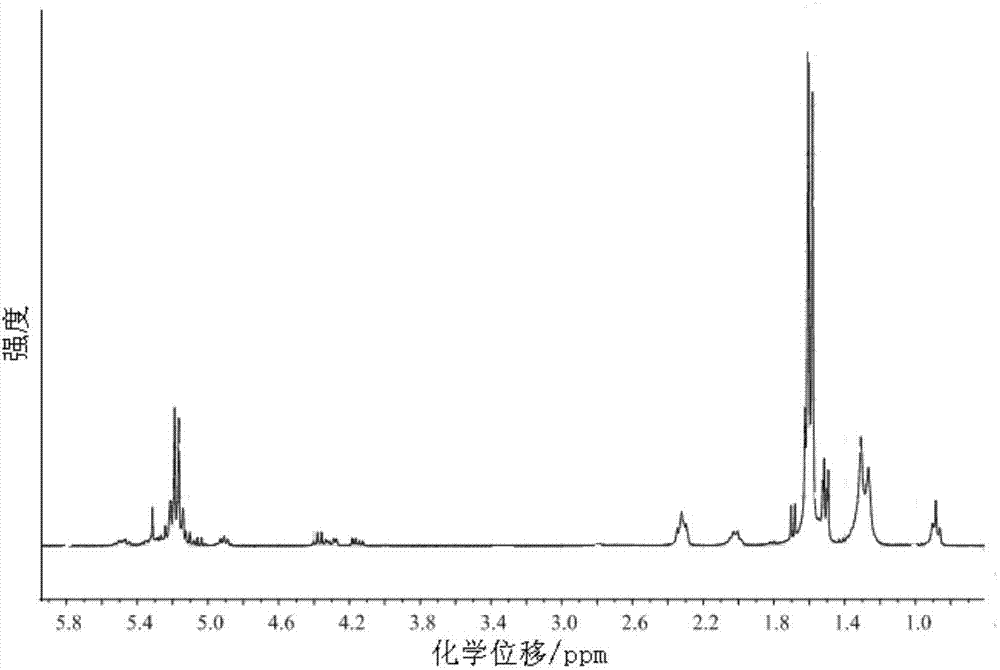

[0062] The preparation of embodiment 2 polylactic acid-polyurethane

[0063] Firstly, polylactic acid with a molecular weight of 15000g / mol was prepared by ring-opening polymerization with isopropanol as an initiator. Take 45g polylactic acid and 10g hexamethylene diisocyanate to fully react at 80-120°C; 180g castor oil and 10g hexamethylene diisocyanate react at 50-80°C for 5-10 hours to obtain a polyurethane prepolymer; The reaction product of polylactic acid and hexamethylene diisocyanate is slowly added dropwise to the polyurethane prepolymer, the reaction temperature is 80-100°C, and the reaction time is 5-10 hours to obtain the polylactic acid-polyurethane copolymer. The molecular weight of the copolymer measured by GPC was 60000 g / mol. figure 2 Be the HNMR curve figure of the final reaction product of this embodiment, according to figure 2 It was confirmed that the reaction product was a polylactic acid-polyurethane copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com