Functional nylon-6 fiber and preparation method thereof

A nylon and fiber technology, applied in the field of functional nylon 6 fiber and its preparation, can solve the problems of poor light resistance and heat resistance, poor antistatic property, low modulus, etc., and achieve the effects of good fluidity, high fluidity and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

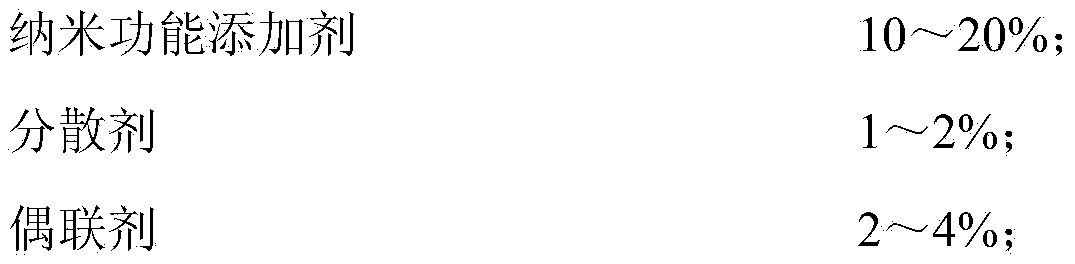

[0038] A functional nylon 6 fiber, which is composed of branched nylon 6 functional masterbatch and conventional nylon 6 chips, and its mass percentage is:

[0039] Branched chain nylon 6 functional masterbatch 6%

[0040] Regular nylon 6 slices margin

[0041] In-situ polymerization is optimally selected, and the polymerized branched nylon 6 functional masterbatch is made of isophthalic acid, caprolactam, molecular weight regulator, deionized water, nano-functional additives, and coupling agent, and is prepared by polymerization reaction under nitrogen protection. Get, take described caprolactam as benchmark, its raw material component mass percent is:

[0042]

[0043] Described molecular weight regulator is acetic acid;

[0044] The nano functional additive is an antistatic agent.

[0045] The coupling agent can be commercially available NDZ-105 as a titanate coupling agent.

[0046] The prepared branched nylon 6 chips have a relative viscosity of 2.3 and a melting p...

Embodiment 2

[0054] A functional nylon 6 fiber, which is composed of branched nylon 6 functional masterbatch and conventional nylon 6 chips, and its mass percentage is:

[0055] Branched chain nylon 6 functional masterbatch 8%

[0056] Regular nylon 6 slices margin

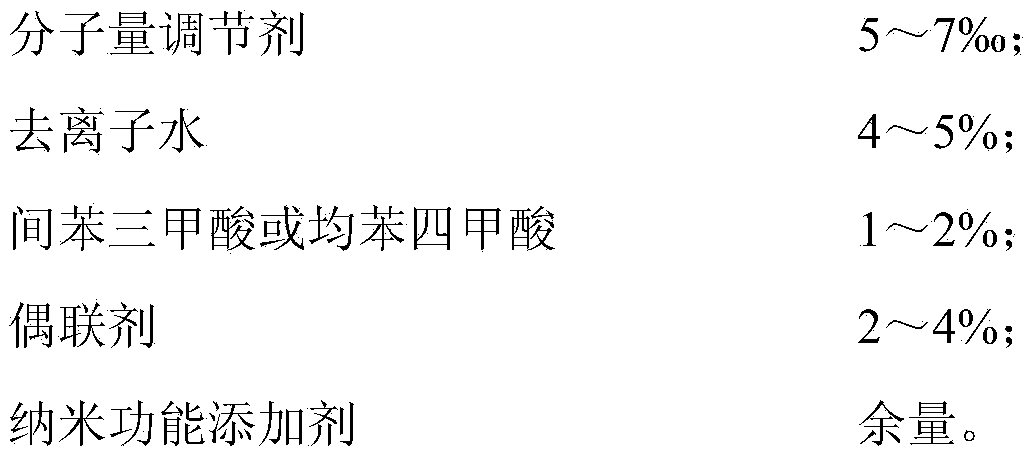

[0057] In-situ polymerization is optimally selected, and the polymerized branched nylon 6 functional masterbatch is made of pyromellitic acid, caprolactam, molecular weight regulator, deionized water, nano-functional additives, and coupling agent, and is prepared by polymerization reaction under nitrogen protection. Get, take described caprolactam as benchmark, its raw material component mass percent is:

[0058]

[0059] Described molecular weight regulator is acetic acid;

[0060] The nano-functional additives are antibacterial agents and far-infrared additives.

[0061] The coupling agent can be silane coupling agent KH560 and titanate coupling agent NDZ-311W.

[0062] The prepared branched nylon 6 chips have a relat...

Embodiment 3

[0070] A functional nylon 6 fiber, which is composed of branched nylon 6 functional masterbatch and conventional nylon 6 chips, and its mass percentage is:

[0071] Branched chain nylon 6 functional masterbatch 10%

[0072] Regular nylon 6 slices margin

[0073] In-situ polymerization is optimally selected, and the polymerized branched nylon 6 functional masterbatch is made of isophthalic acid, caprolactam, molecular weight regulator, deionized water, nano-functional additives, and coupling agent, and is prepared by polymerization reaction under nitrogen protection. Get, take described caprolactam as benchmark, its raw material component mass percent is:

[0074]

[0075] Described molecular weight regulator is adipic acid, acetic acid;

[0076] The nano-functional additive deodorant and far-infrared additive.

[0077] The coupling agent can be titanate coupling agent NDZ-133, NDZ-201.

[0078] The prepared branched nylon 6 chips have a relative viscosity of 2.1 and a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com