Pouring gate structure of injection mold of soft rubber watchband type product and molding method

An injection mold and molding method technology, which is applied to the molding field of soft rubber watch strap products, can solve the problems of difficulty in trimming gates, reduced toughness, waste of manpower, etc., and achieves the effects of saving manpower, improving quality, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

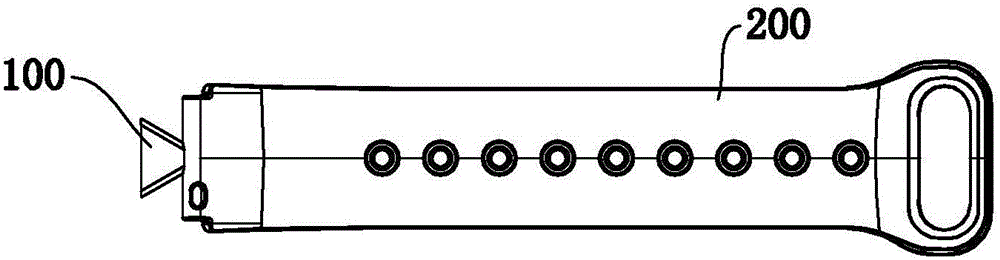

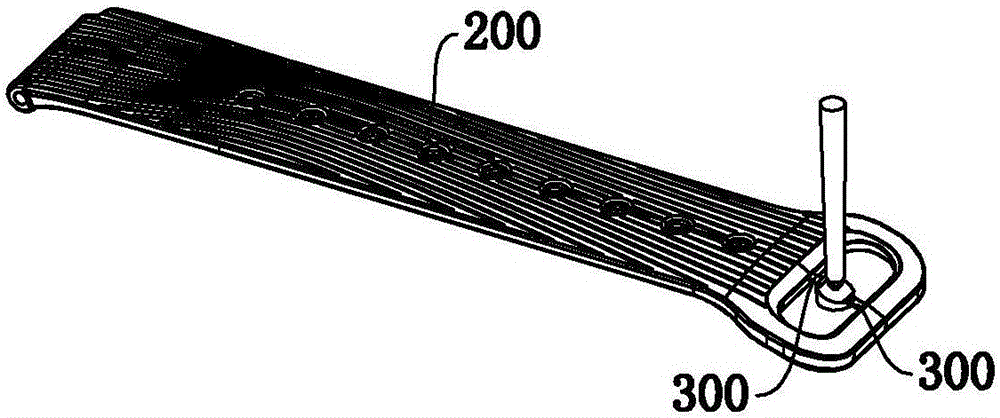

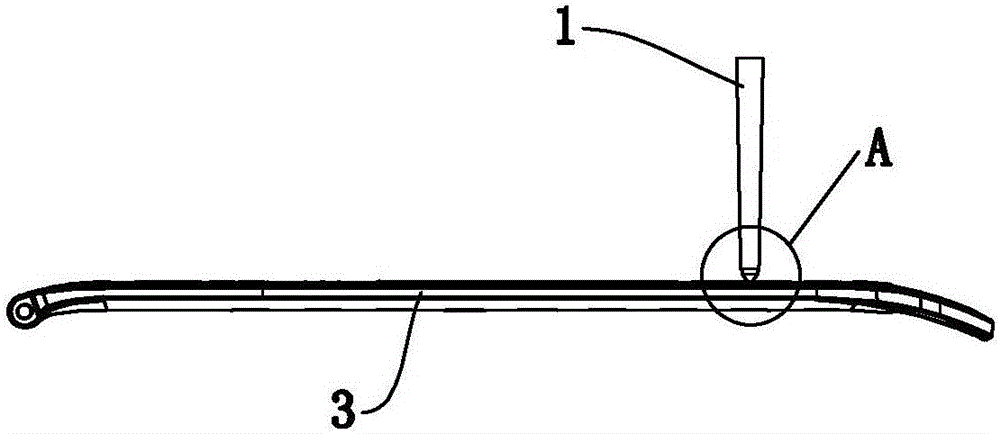

[0038] Such as image 3 , Figure 4 and Figure 5 Commonly shown, a gate structure of an injection mold for soft rubber watch band products includes a runner 1 arranged on the injection mold, and a point gate 2 is provided between the end of the runner 1 and the cavity of the injection mold. The gate 2 is correspondingly arranged at a strap hole 31 of the soft rubber strap 3 . This gate structure is suitable for soft rubber strap products.

[0039] The runner 1 gradually narrows along the flow direction of the molten raw material. The point gate 2 gradually narrows along the flow direction of the molten raw material.

[0040] Since the gate form of the injection mold is changed from the existing side gate to point gate 2 to feed glue, and the point gate 2 is set at a strap hole 31 that is not commonly used for soft rubber watch strap products, point The gate 2 is small, and the mold is automatically broken after the product is formed, and then punched off with a punch wit...

Embodiment 2

[0043] The embodiment of the present invention discloses a method for forming a soft rubber watchband product. Using the gate structure of the injection mold for the soft rubber watchband product provided in the first embodiment above includes the following steps:

[0044] A. Mold closing;

[0045] B. Melting: Heat and melt the raw materials in the barrel of the injection molding machine. The raw materials are TPU materials, and the temperature of the raw materials is 185°C, which can reduce the molding defects of the products;

[0046]C. Injection molding: The molten raw material is injected into the injection mold through the nozzle of the injection molding machine by a multi-stage injection process and kept under pressure to ensure the molding quality of the product. The holding time is 0.5s, the second-stage forming product is 50%, the second-stage holding time is 2s, the third-stage forming product is 95%, the third-stage holding time is 3s, and the rest of the product is...

Embodiment 3

[0051] This embodiment is basically the same as Embodiment 2, the difference is that in step B, the material temperature of the raw material is 175°C; The pressing time is 0.7s, the holding time of the second stage is 1.5s, and the holding time of the third stage is 2.5s; in step D, the cooling time is 8s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com