Light triple-heavy metal circular tube flexion restriction support energy dissipating machine

A buckling restraint, three heavy metal technology, applied in the direction of building components, earthquake resistance, etc., can solve the problems of the production, installation and performance of the energy dissipator, the stable performance of the energy dissipation performance of the energy dissipator, the weight of concrete or mortar, etc. , to achieve the effect of reducing weight, reducing construction difficulty and making it convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] This section describes in detail the specific implementation of the present invention in conjunction with the accompanying drawings

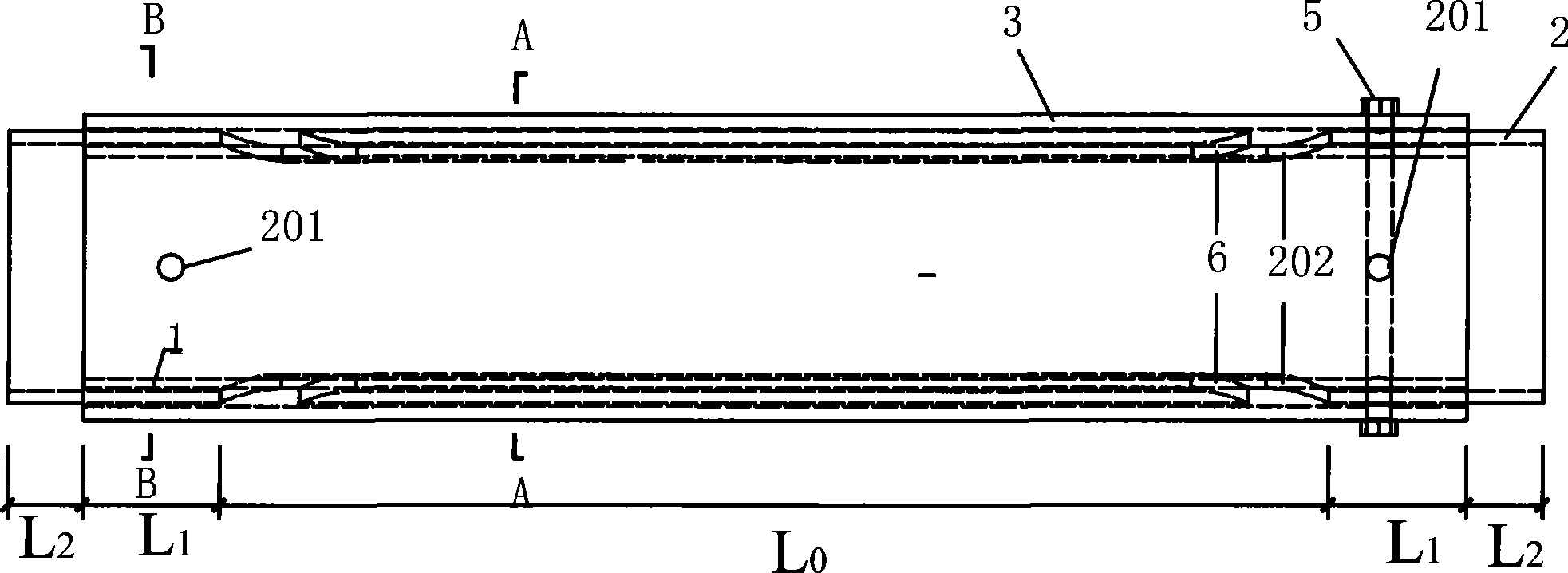

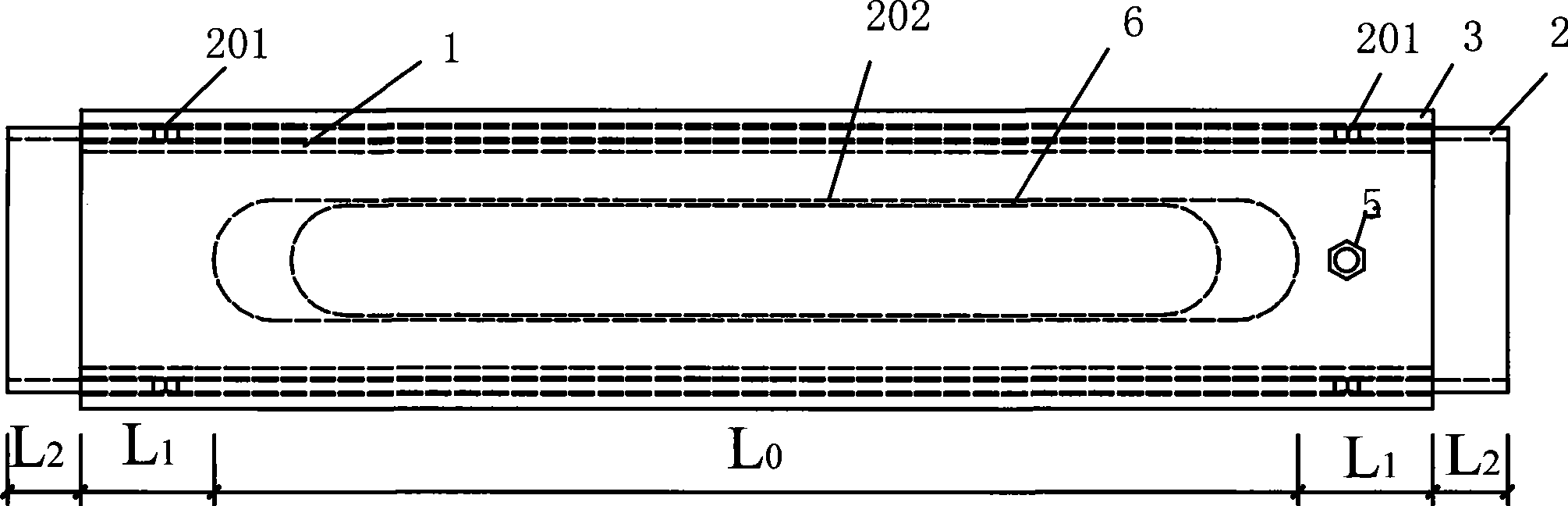

[0032] 1. The buckling-restrained support energy dissipator of light-duty triple metal circular tube is mainly composed of three metal circular tubes, that is, the inner restraint tube 1, the core stress tube 2 and the outer restraint tube 3 from the inside to the outside. The core force-bearing tube is the core force-bearing part of the energy dissipator, and the inner and outer restraint tubes constitute the buckling restraint part of the energy dissipator. The core stress pipe is made of Q235B steel with good ductility, low yield steel or other metal materials with good ductility, while the inner and outer restraint pipes are generally made of steel pipes. The three metal round pipes adopt the positioning bolt 5 arranged at one end to fix relative positions. The buckling-constrained support energy dissipator of the light triple metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com