Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

465results about How to "Reliable connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

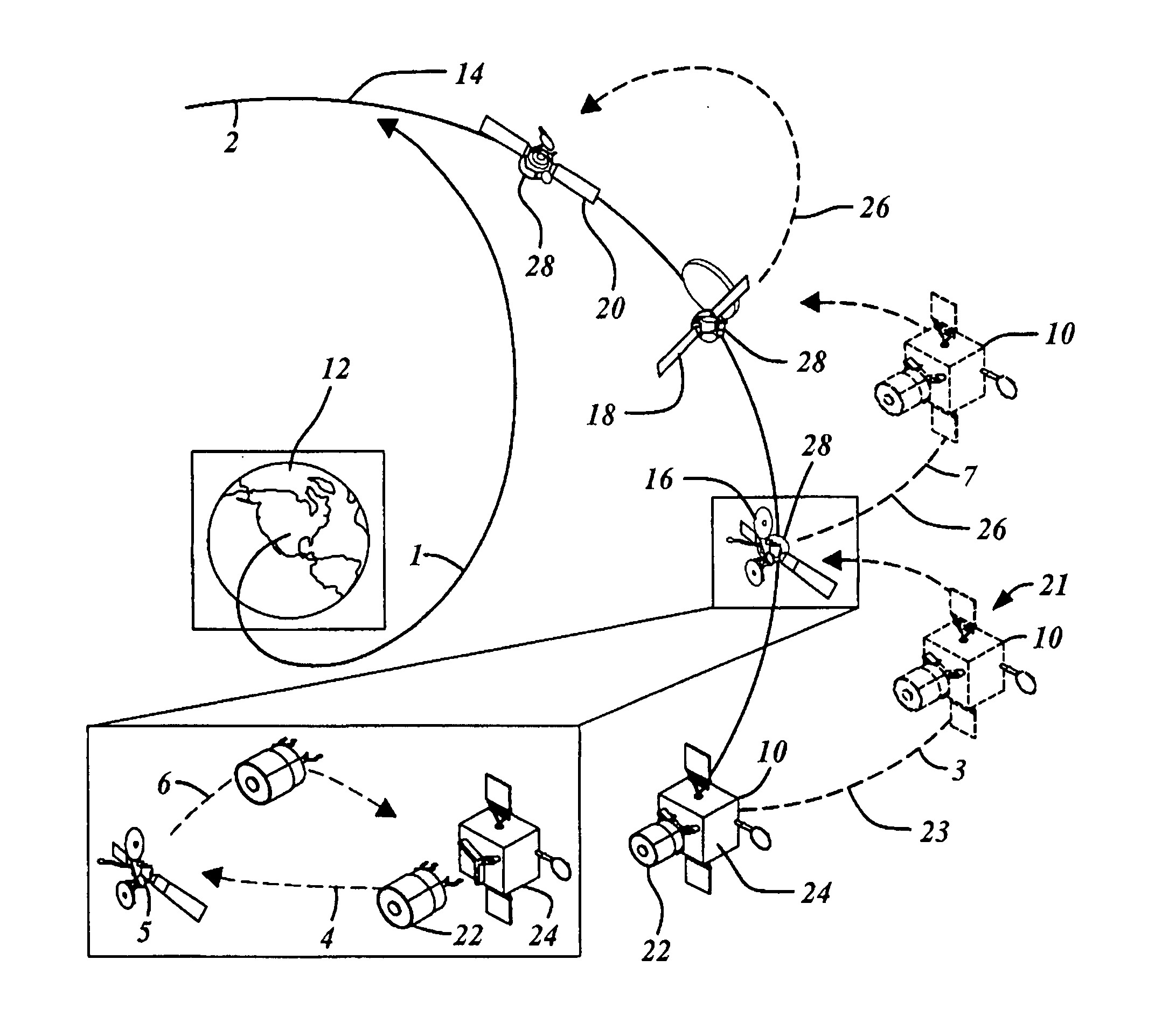

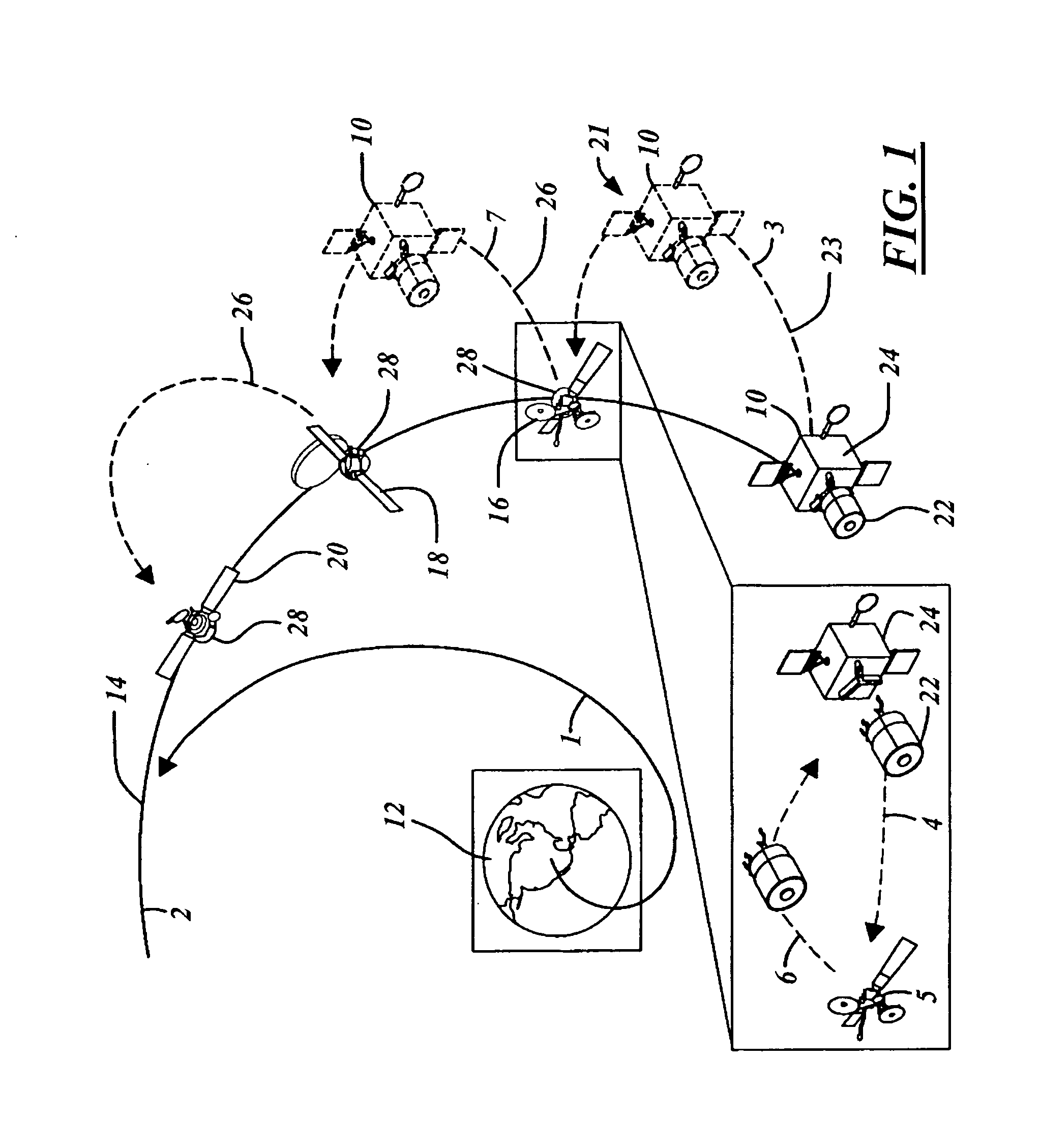

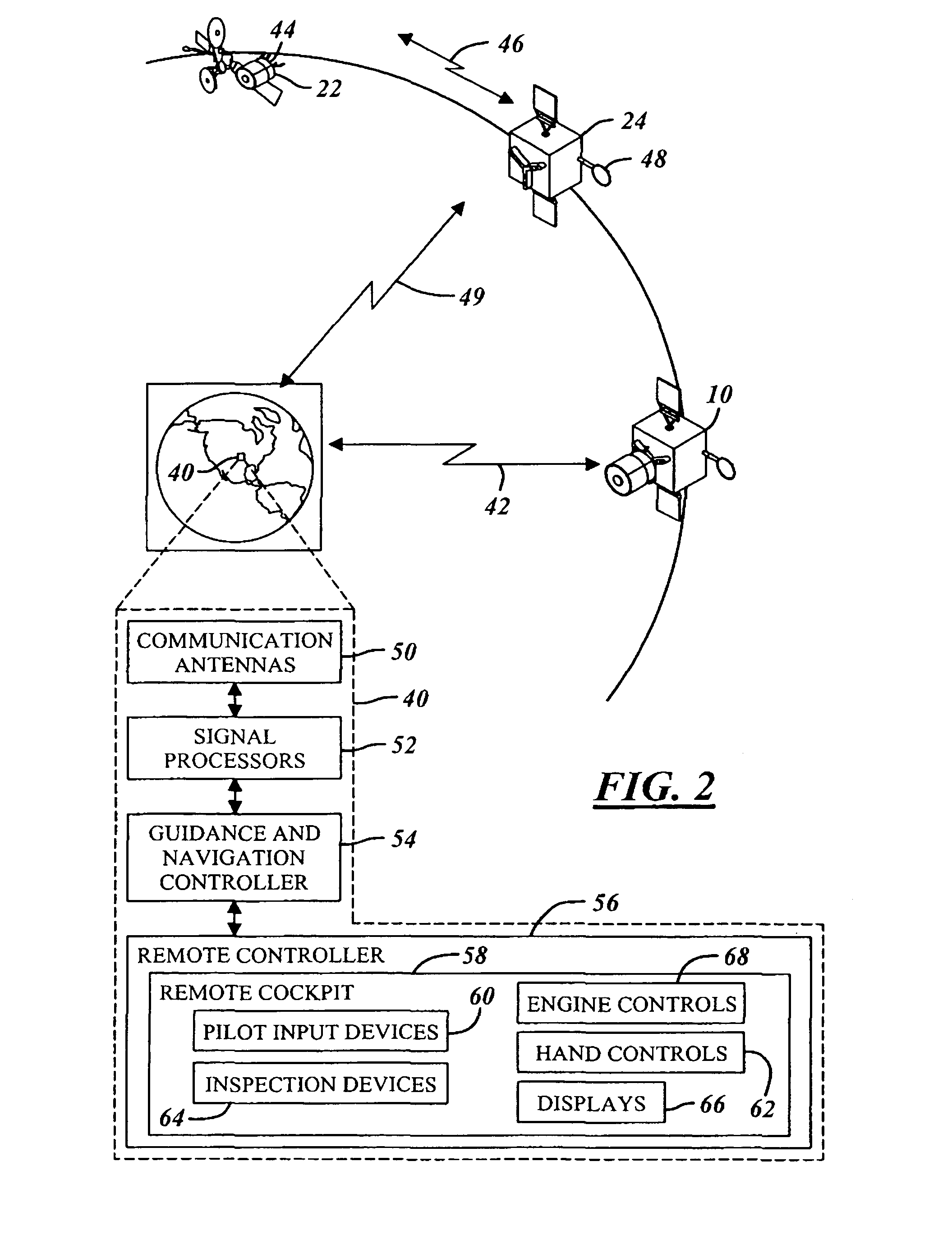

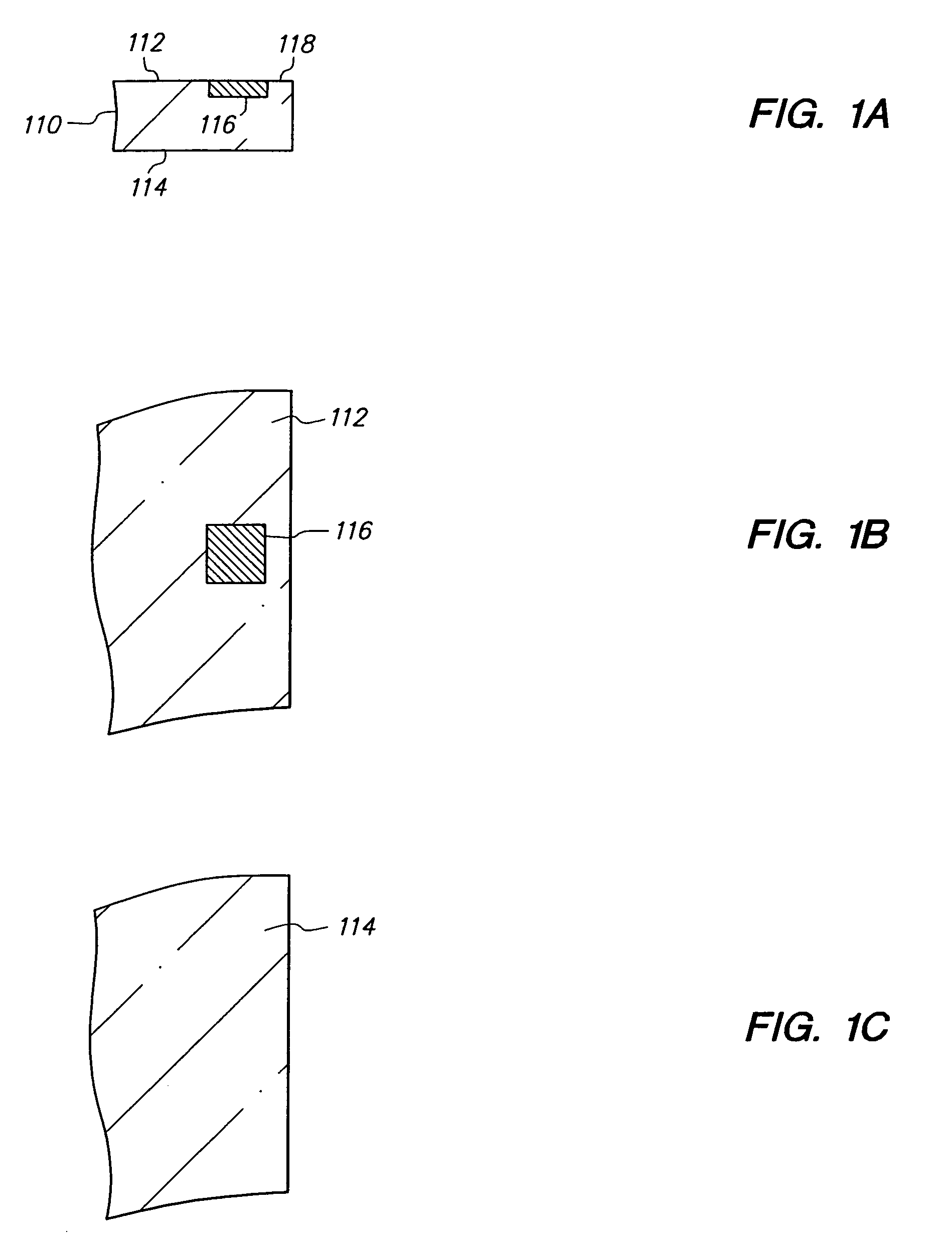

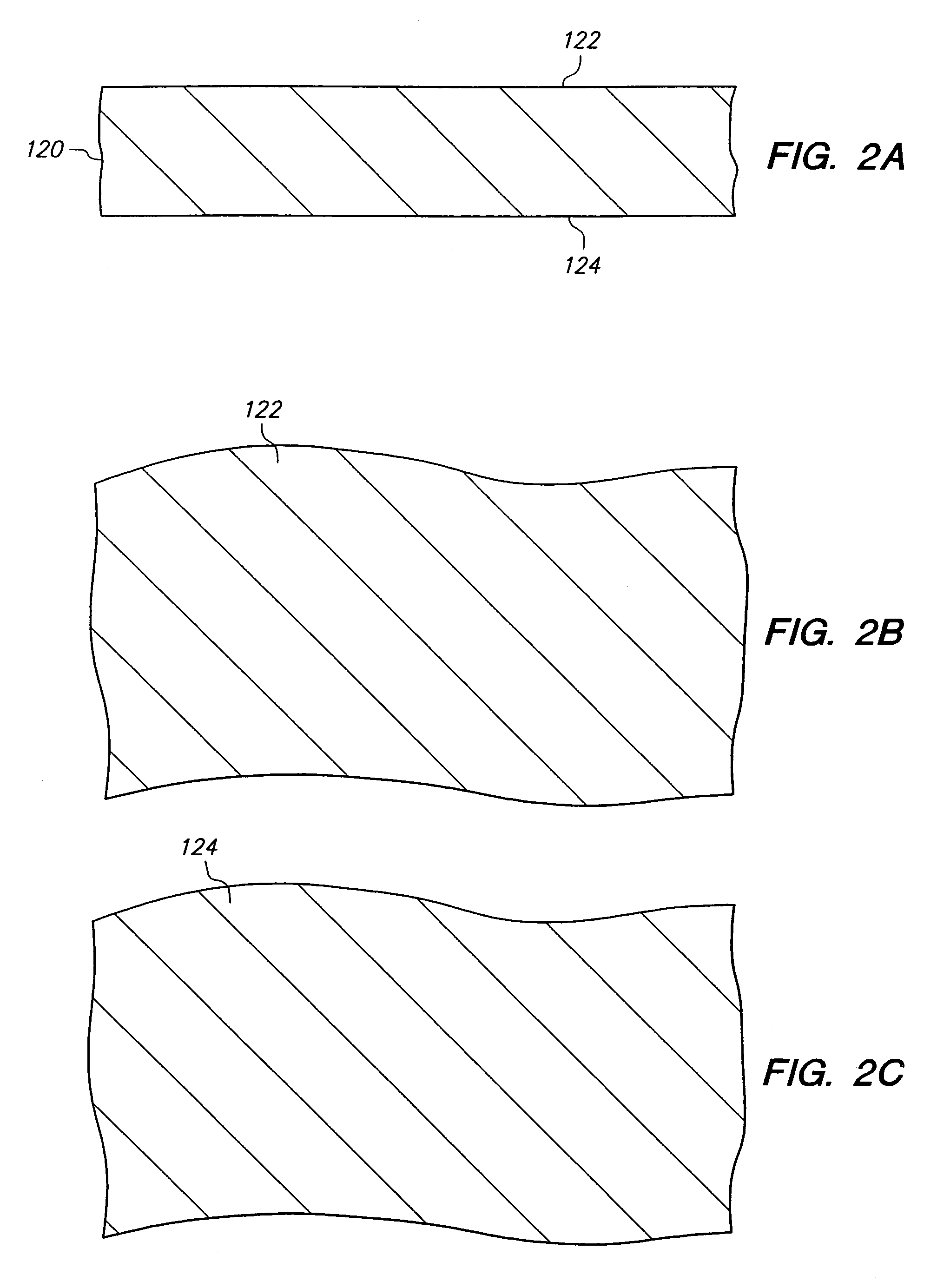

Two part spacecraft servicing vehicle system with adaptors, tools, and attachment mechanisms

InactiveUS20070228220A1Minimize requirementReliable connectionCosmonautic vehiclesCosmonautic component separationService systemFlight operations

Owner:THE BOEING CO

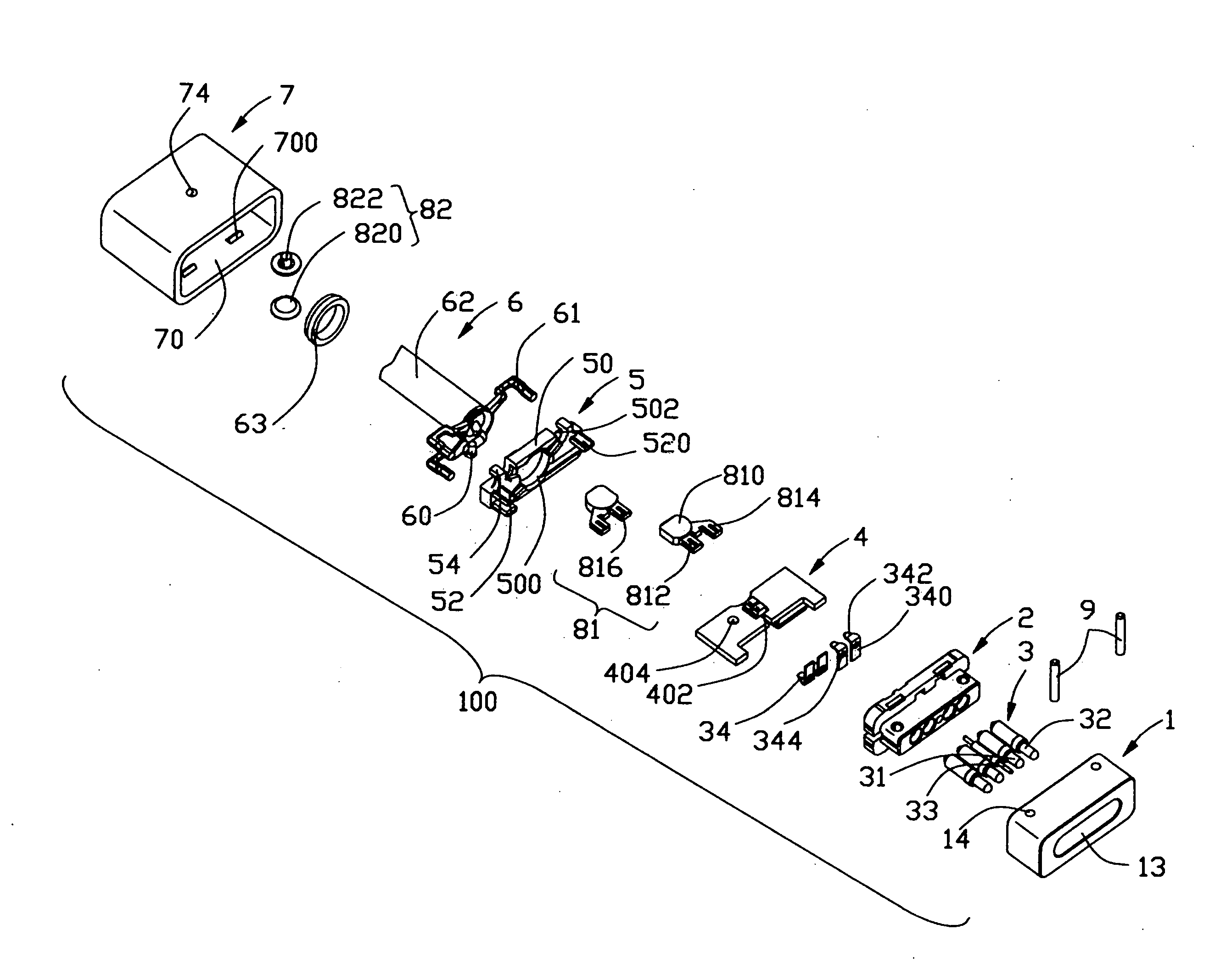

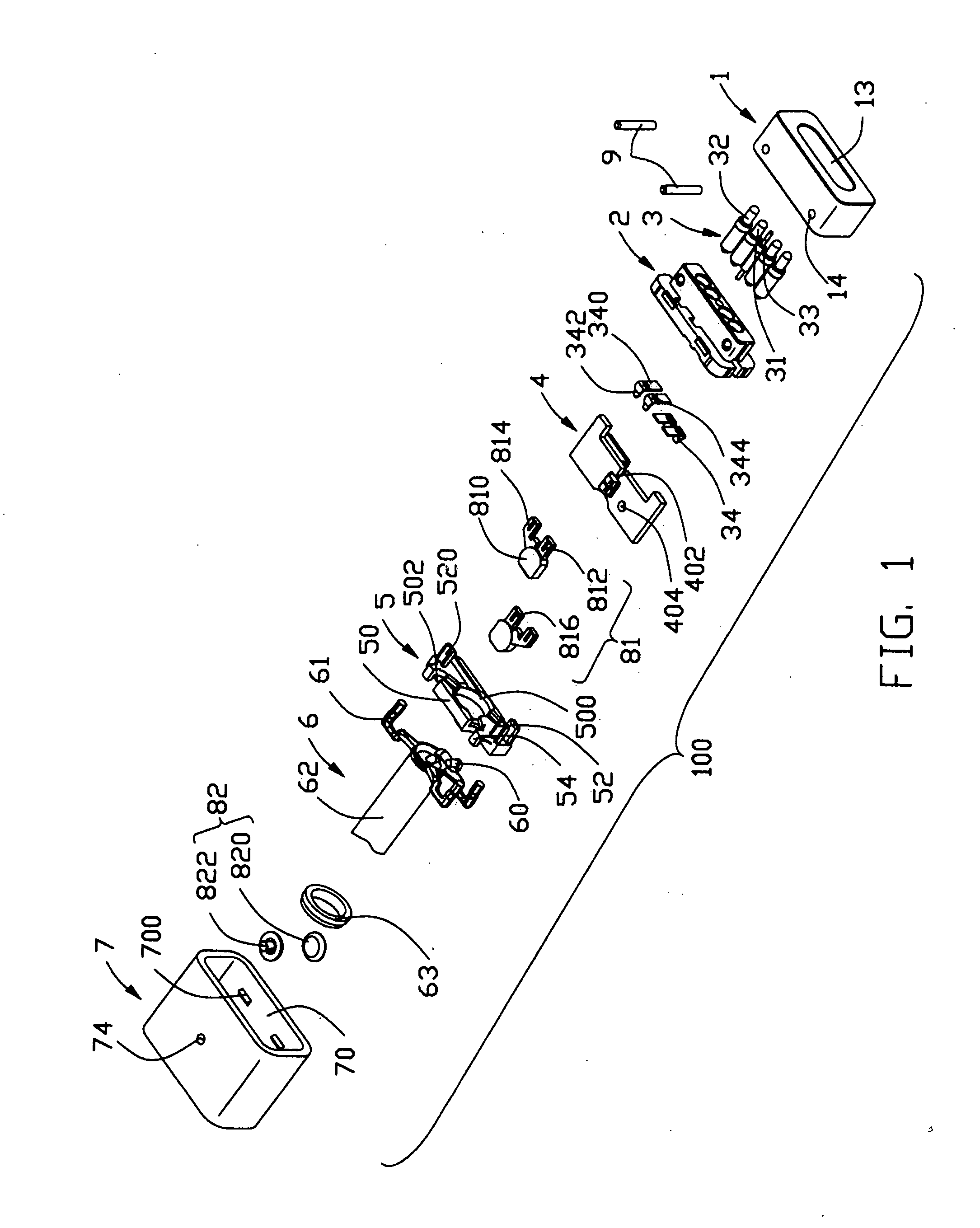

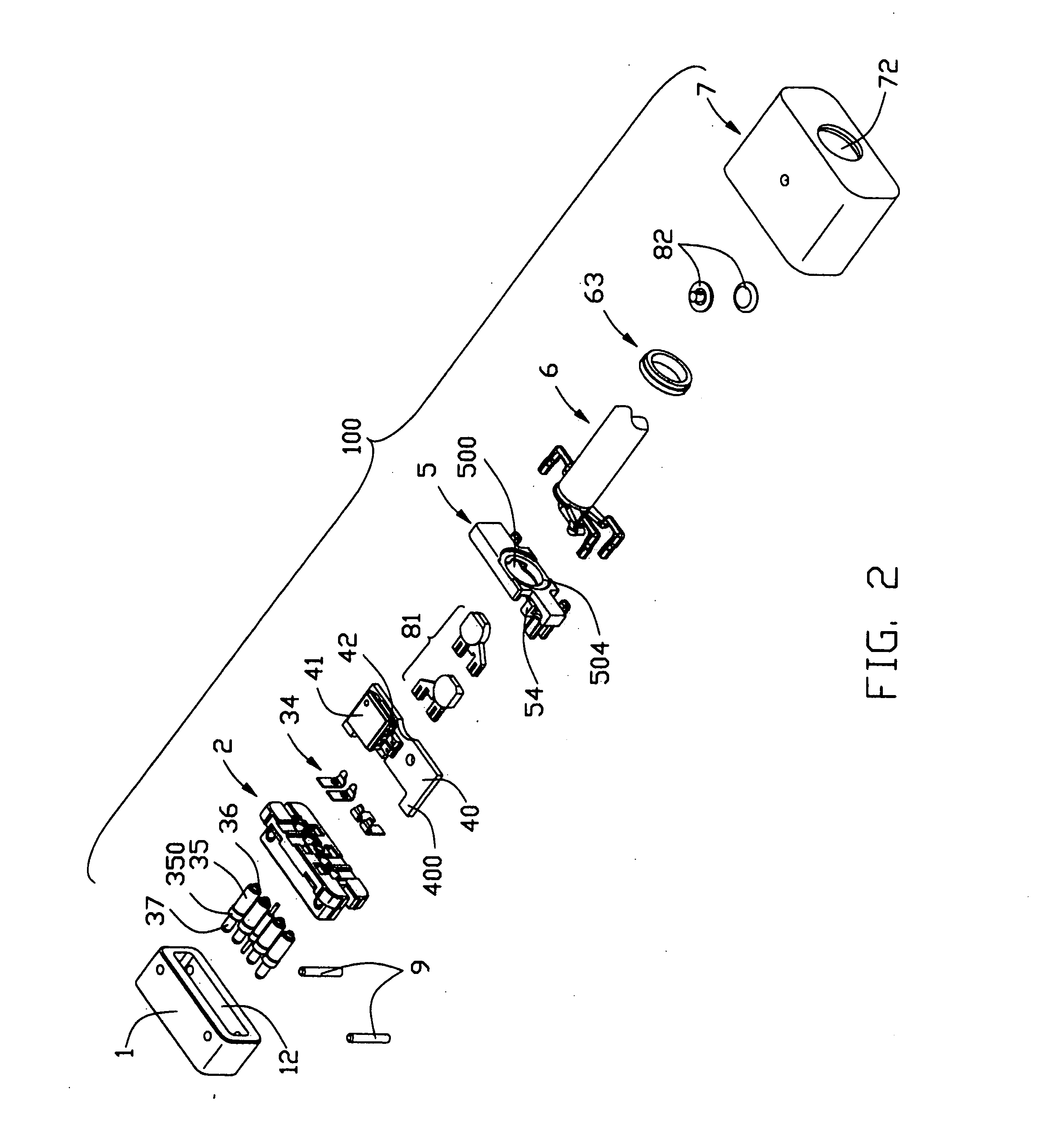

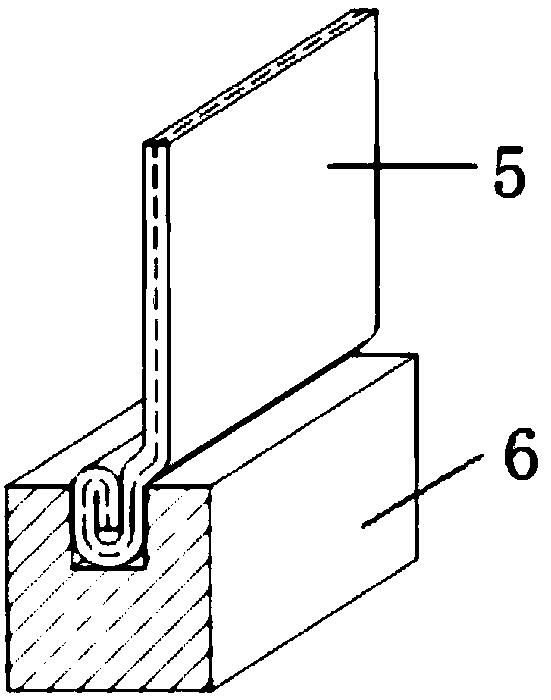

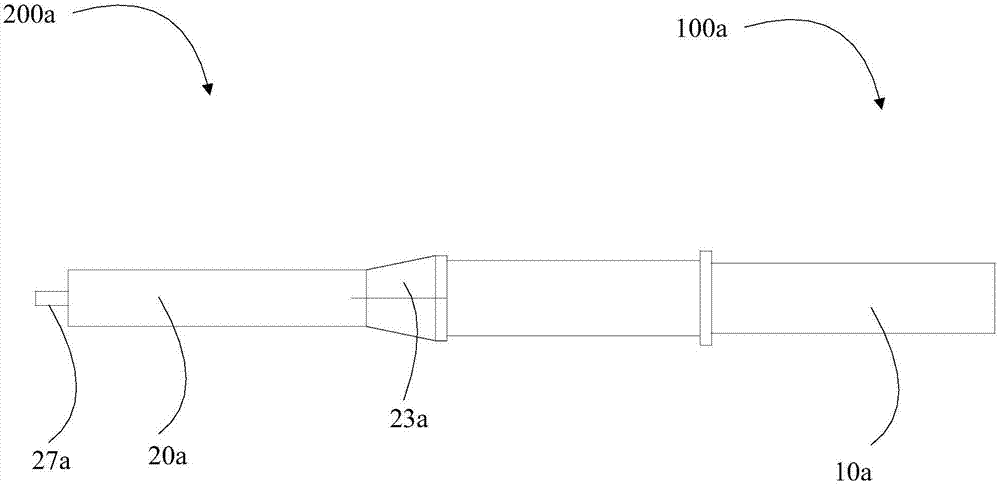

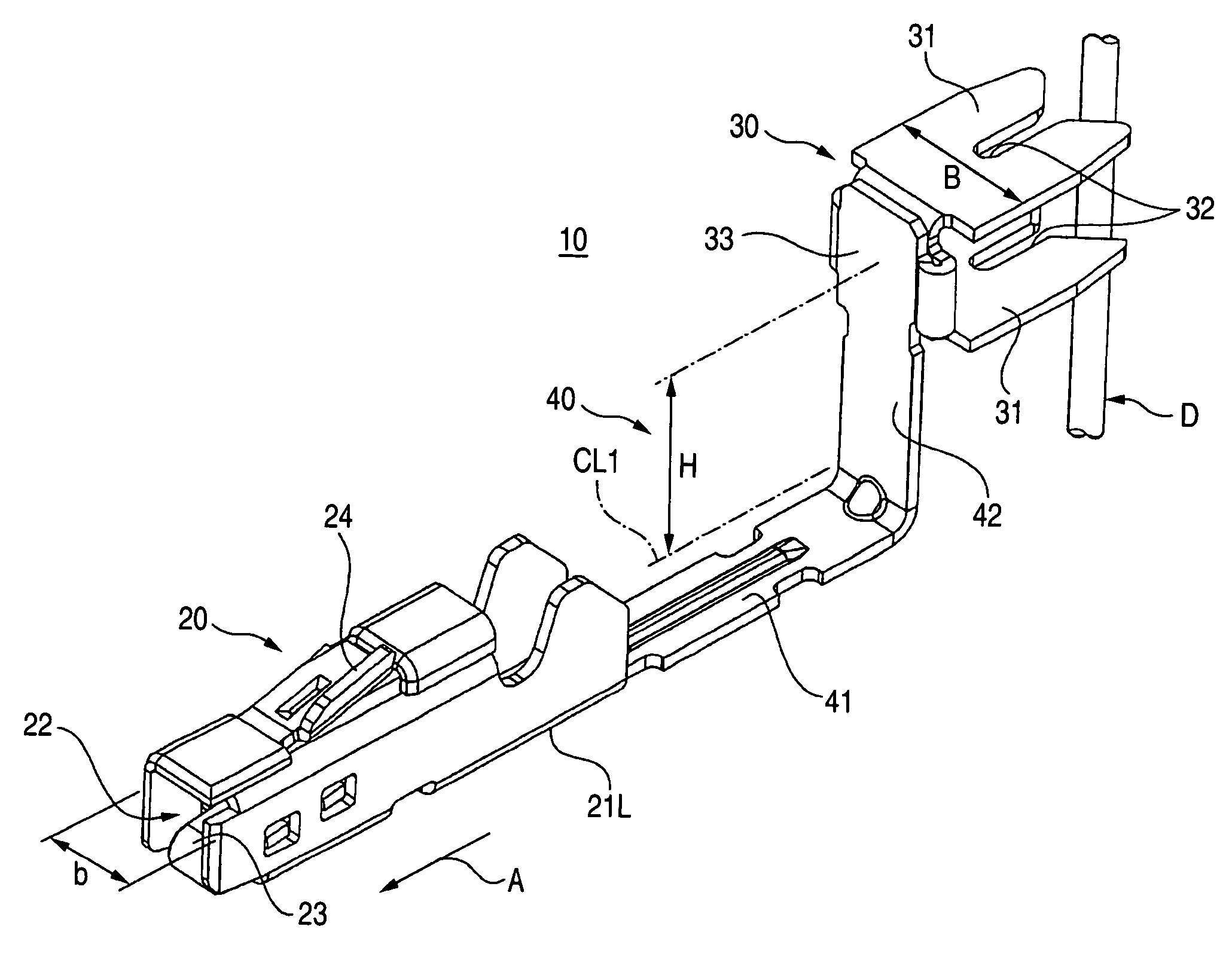

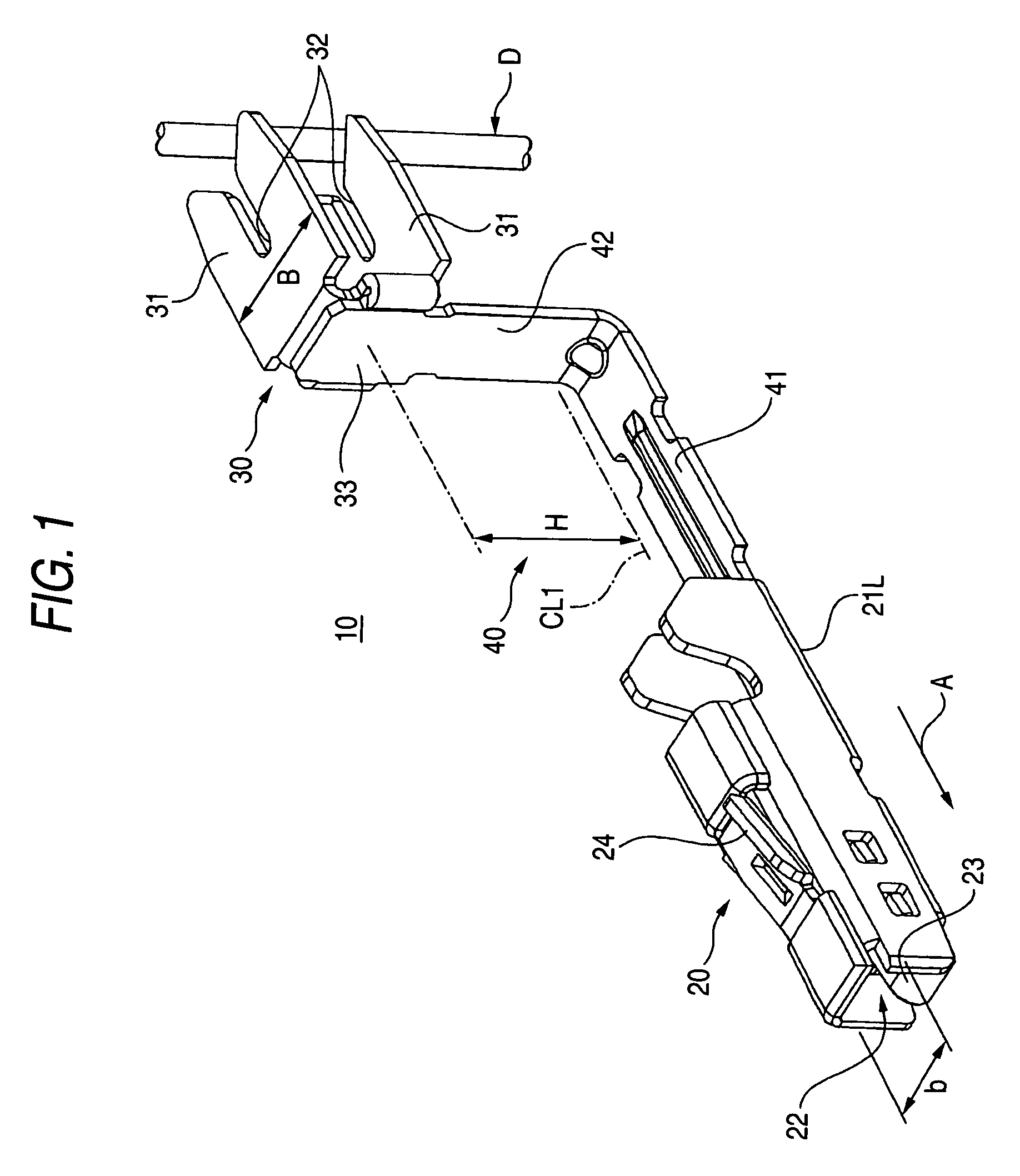

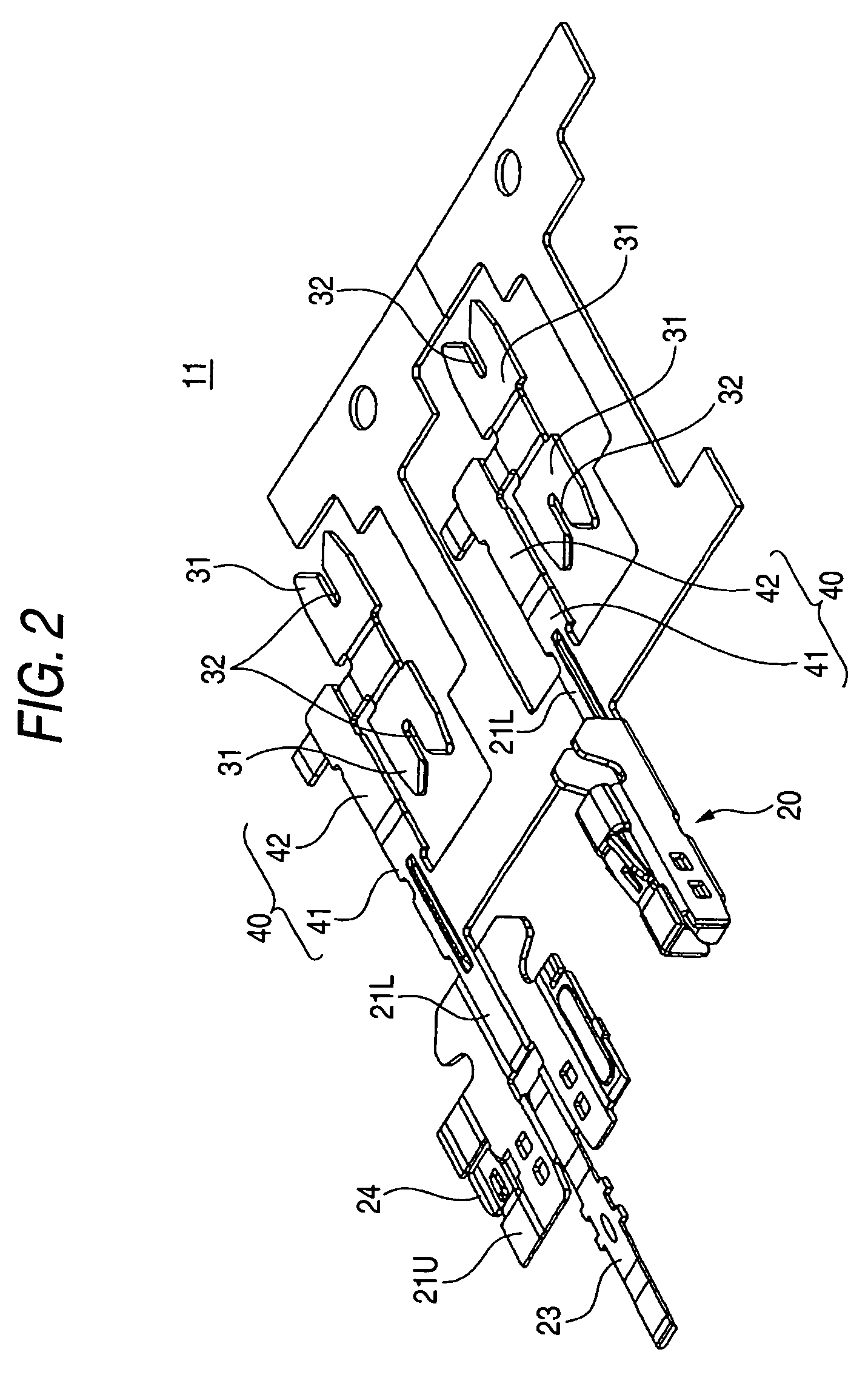

Connector assembly with strain relief member

ActiveUS20080003881A1Reliable connectionImprove structureRelieving strain on wire connectionElectrically conductive connectionsStrain reliefEngineering

A cable connector assembly (100) includes a housing (2), a signal contact (31), a ground contact (32) assembled to the housing, a circuit board (4) assembled to the housing and electrically connecting with the contacts, a cable (6) comprising a conductor (60) directly connecting with the circuit board (4) and a metal braiding layer (61) electrically with a strain relief member (5) which electrically connects with the circuit board, and a rear cover (7) assembled to the housing to enclose the electrical connection among the cable, the strain relief member, the circuit board and the contacts.

Owner:APPLE INC

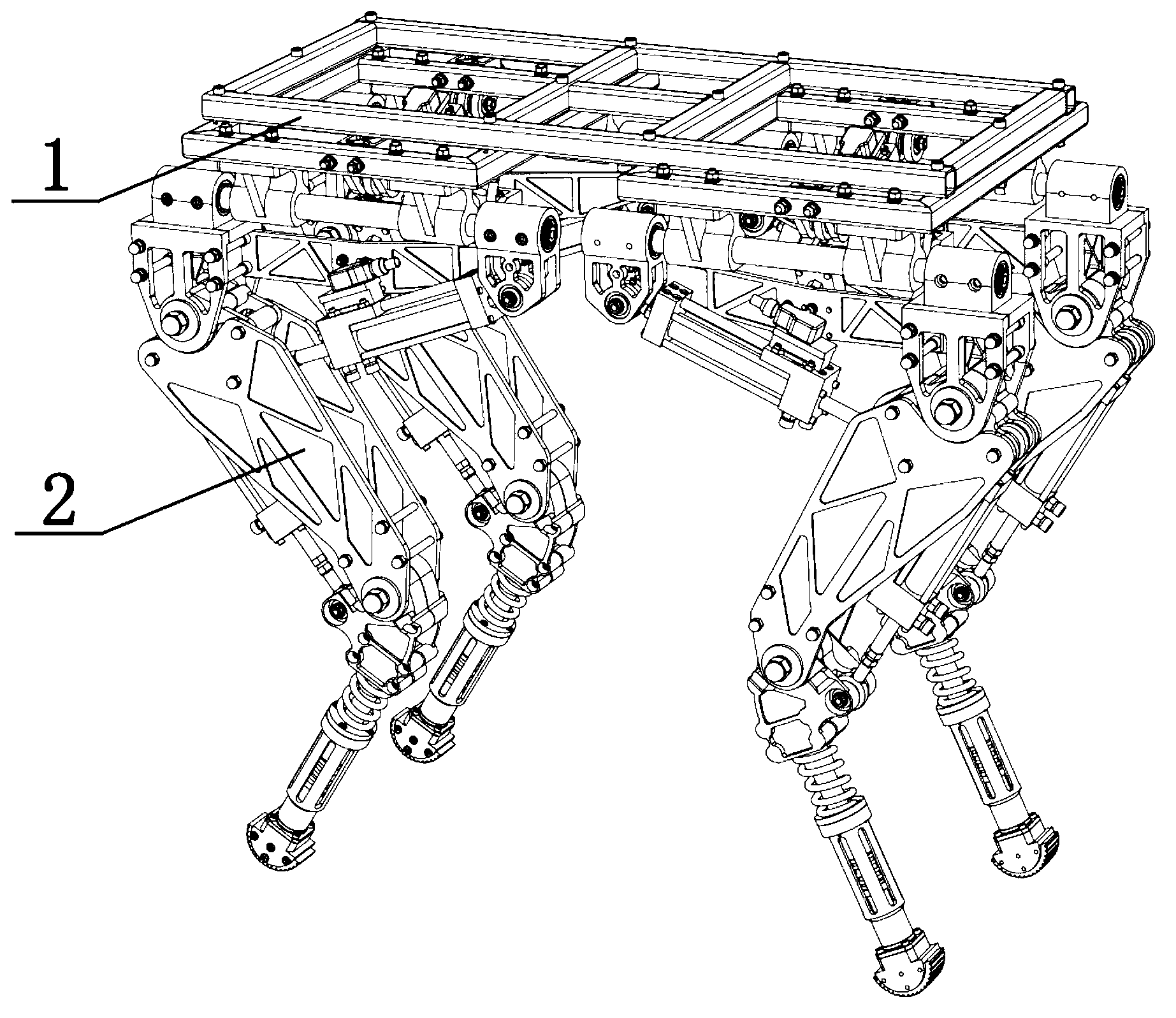

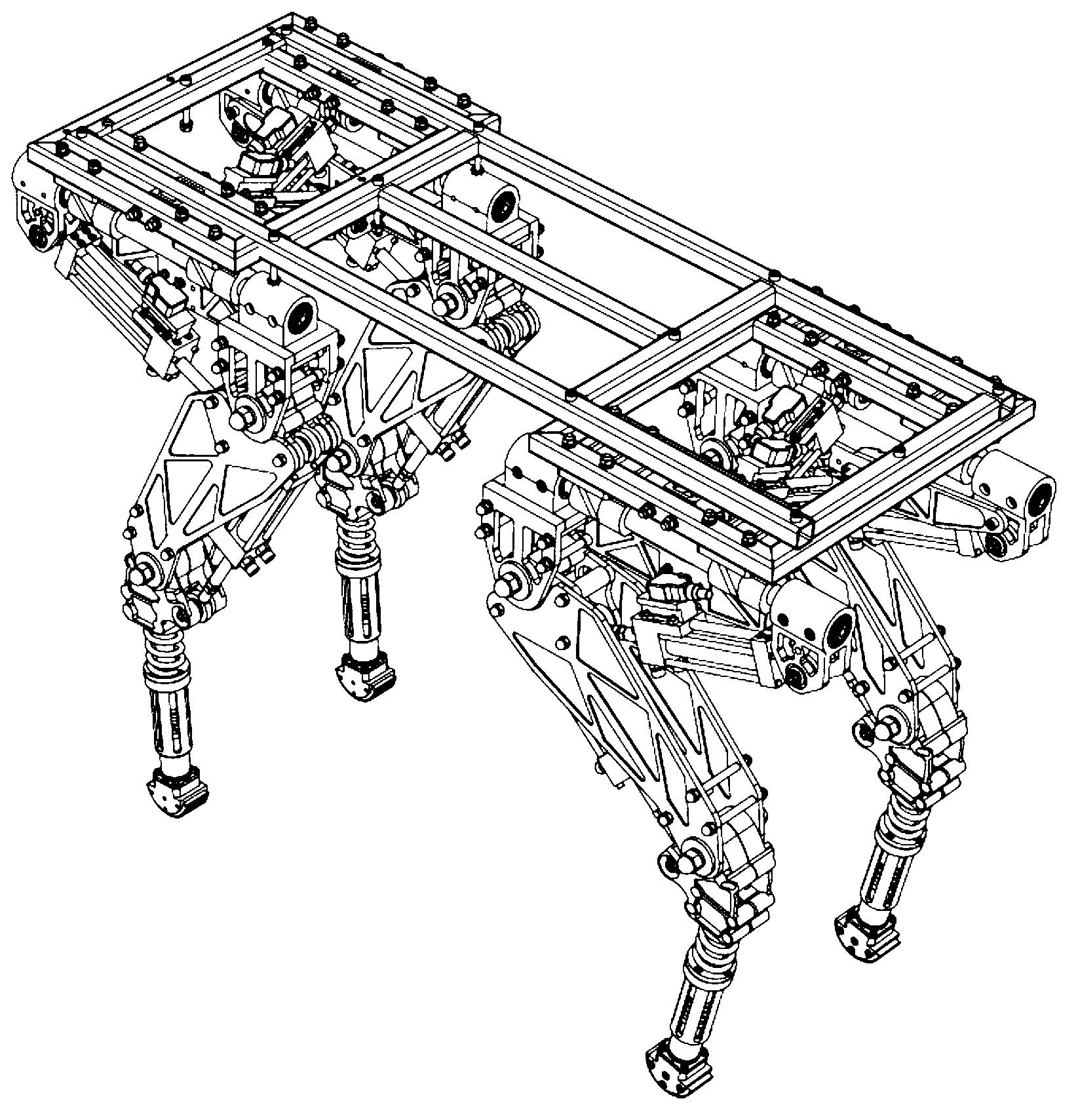

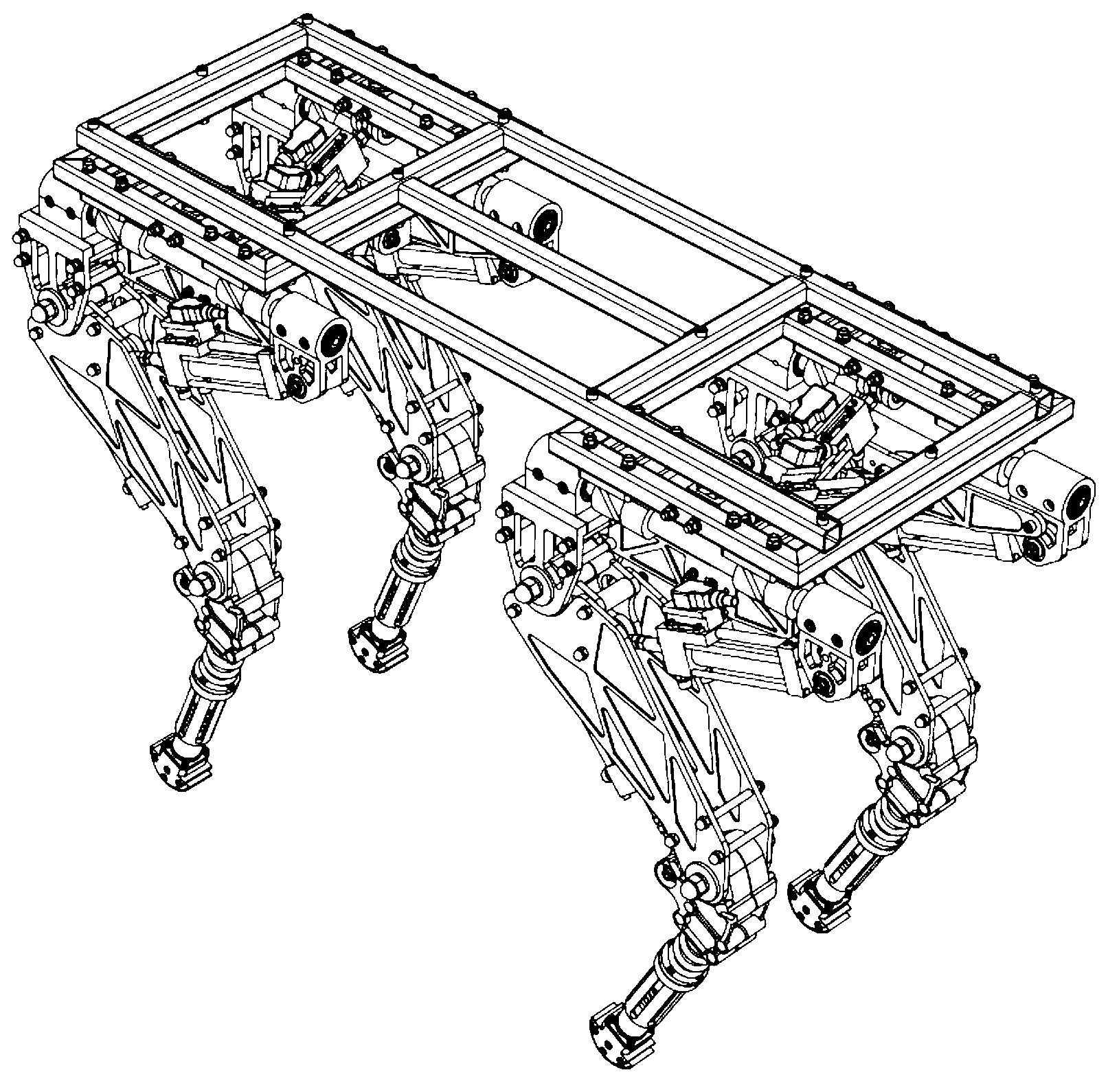

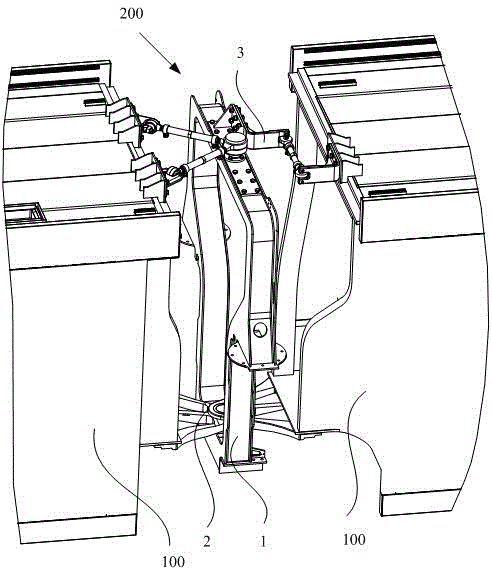

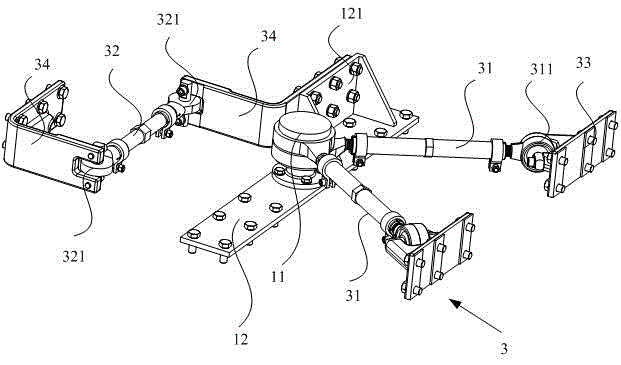

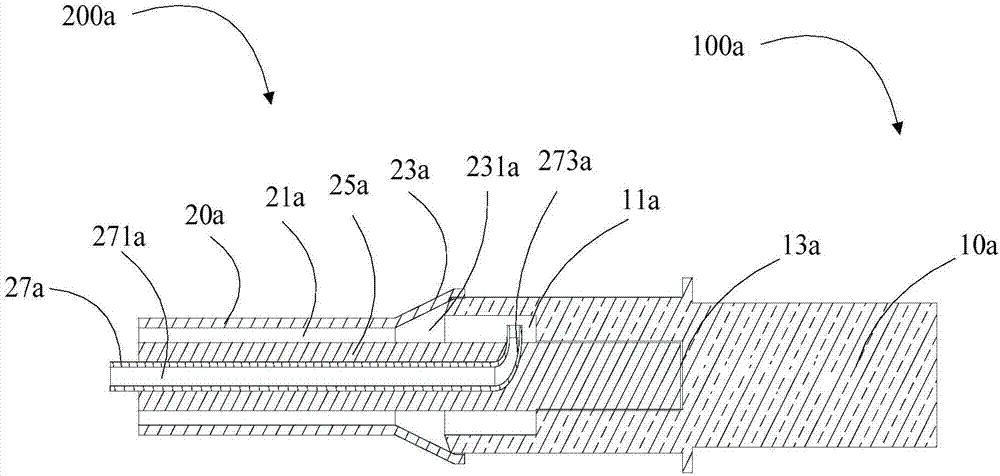

Modular hydraulic-drive four-leg robot with variable leg shape structures

InactiveCN103318289ASolve the lack of spaceImprove terrain adaptabilityVehiclesDynamic balanceKnee Joint

The invention discloses a hydraulic-drive four-leg robot. The modular hydraulic-drive four-leg robot has the advantages that the hydraulic-drive four-leg robot is good in dynamic balance and high in topographical adaptability, loading capacity and cost performance, and is in a modular and bionic structural design, four leg shapes can be switched over by means of quickly assembling and disassembling subassemblies, the modular hydraulic-drive four-leg robot is multipurpose, and merits and shortcomings of various leg shapes are verified by experiments at a physical prototype stage; each single leg is provided with two leg sections, has three degrees of freedom and comprises a hip joint and thigh assembly, a knee joint and shank assembly and a side sway assembly; a side sway and connecting block combining form is adopted for each thigh portion according to a bionic principle, so that sufficient rigidity and strength are guaranteed, the hydraulic-drive four-leg robot can bear a load stably while the weight of the robot is reduced to the greatest extent, and sufficient activity space for hydraulic cylinders is guaranteed; shank portions comprise foot-end rubber pads and passive retractable bidirectional spring shock absorption mechanisms, and instant impact force generated when the robot is in contact with the ground can be effectively buffered and absorbed under multiple shock absorption actions; problems of limited service lives of components and vulnerability of electronic elements such as foot-end force sensors due to the fact that impact force disappears and springs are rebounded quickly when an existing robot leaves the ground can be solved by the aid of the bidirectional spring mechanisms.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

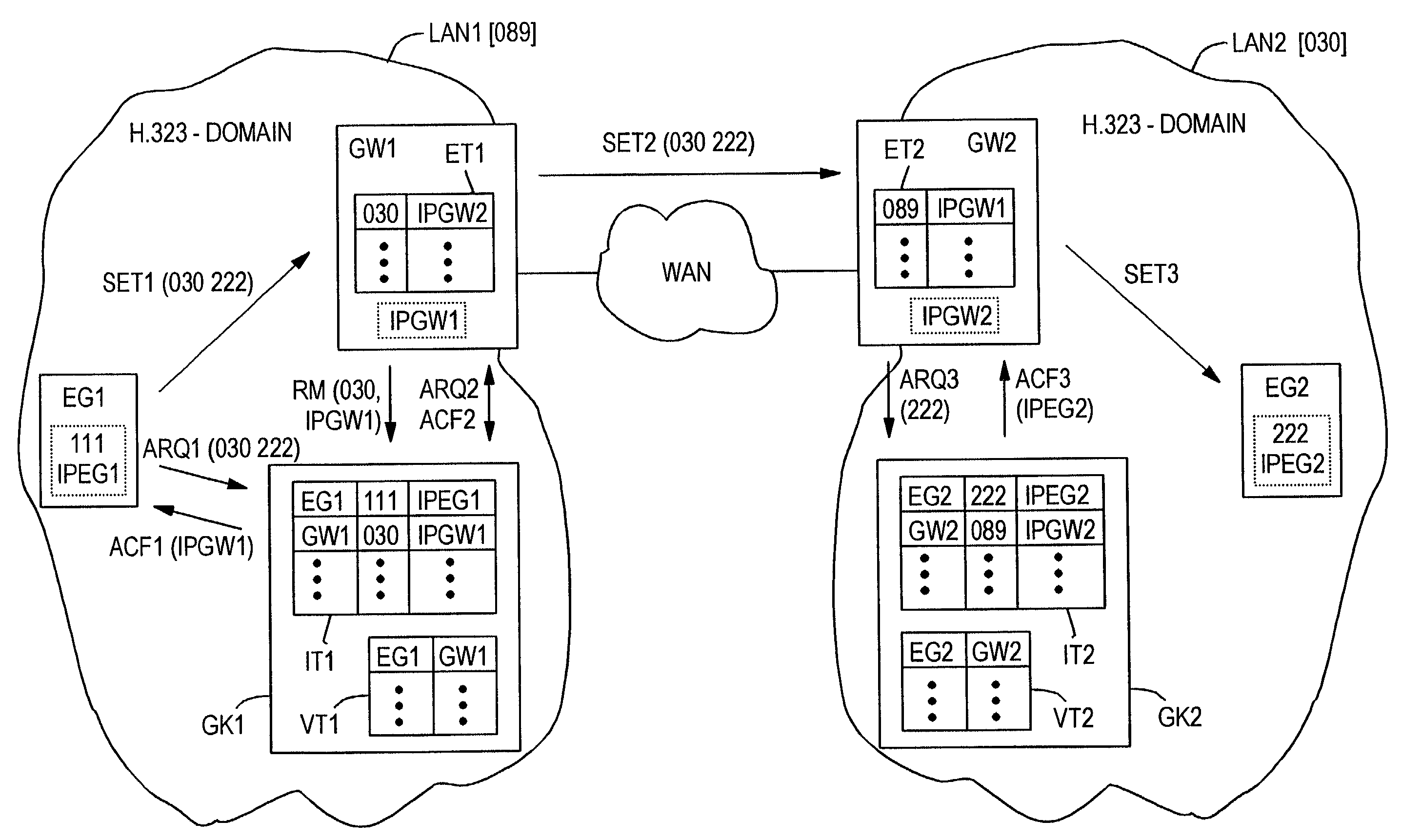

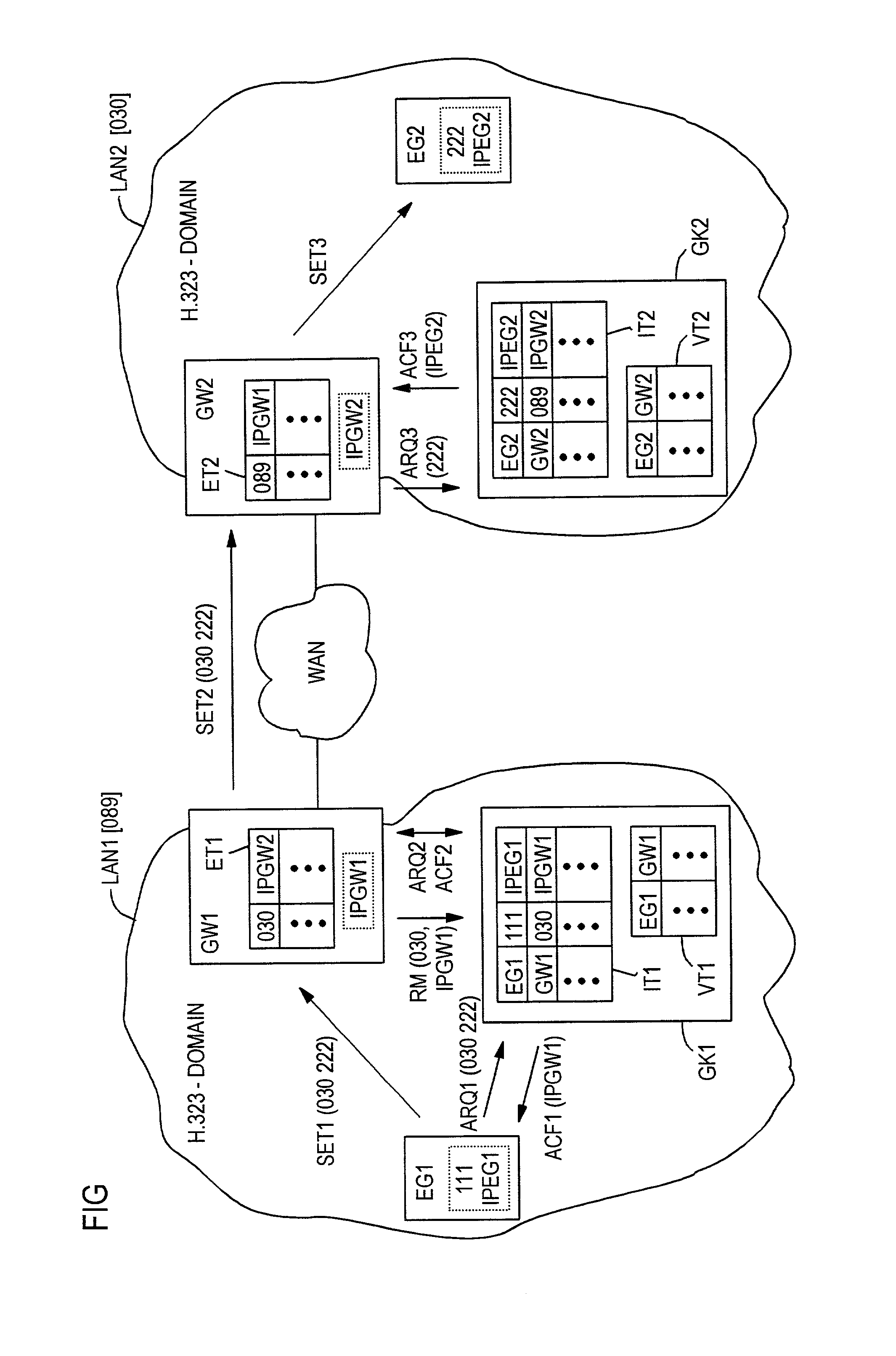

Method for establishing a connection from a terminal of a communication network to a network-external connection destination, and associated apparatus and network

InactiveUS7260084B2Reliable connectionFirmly connectedData switching by path configurationNetwork connectionsLogical addressExternal connection

A method for establishing a connection from a network-internal terminal of a communication network, the network-internal connections of which are managed by a connection controller, to a network-external connection destination, wherein the connection is established via a gateway device which is registered in the connection controller under the logical address of the network-external connection destination, and on the basis of the logical destination address, the connection controller establishes a network-internal connection from the terminal to the gateway device, and in the gateway device itself, a network-externally valid transport address is assigned to the logical destination address, on the basis of which transport address the connection is relayed to the network-external connection destination.

Owner:SIEMENS AG

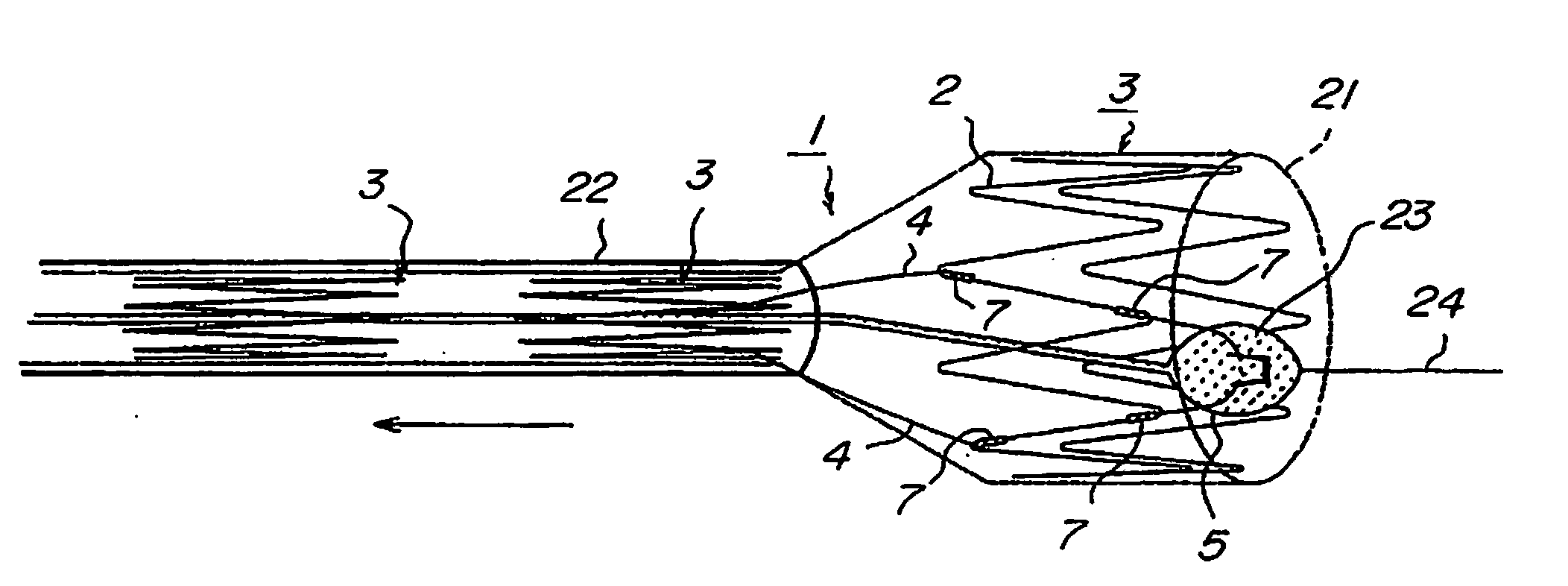

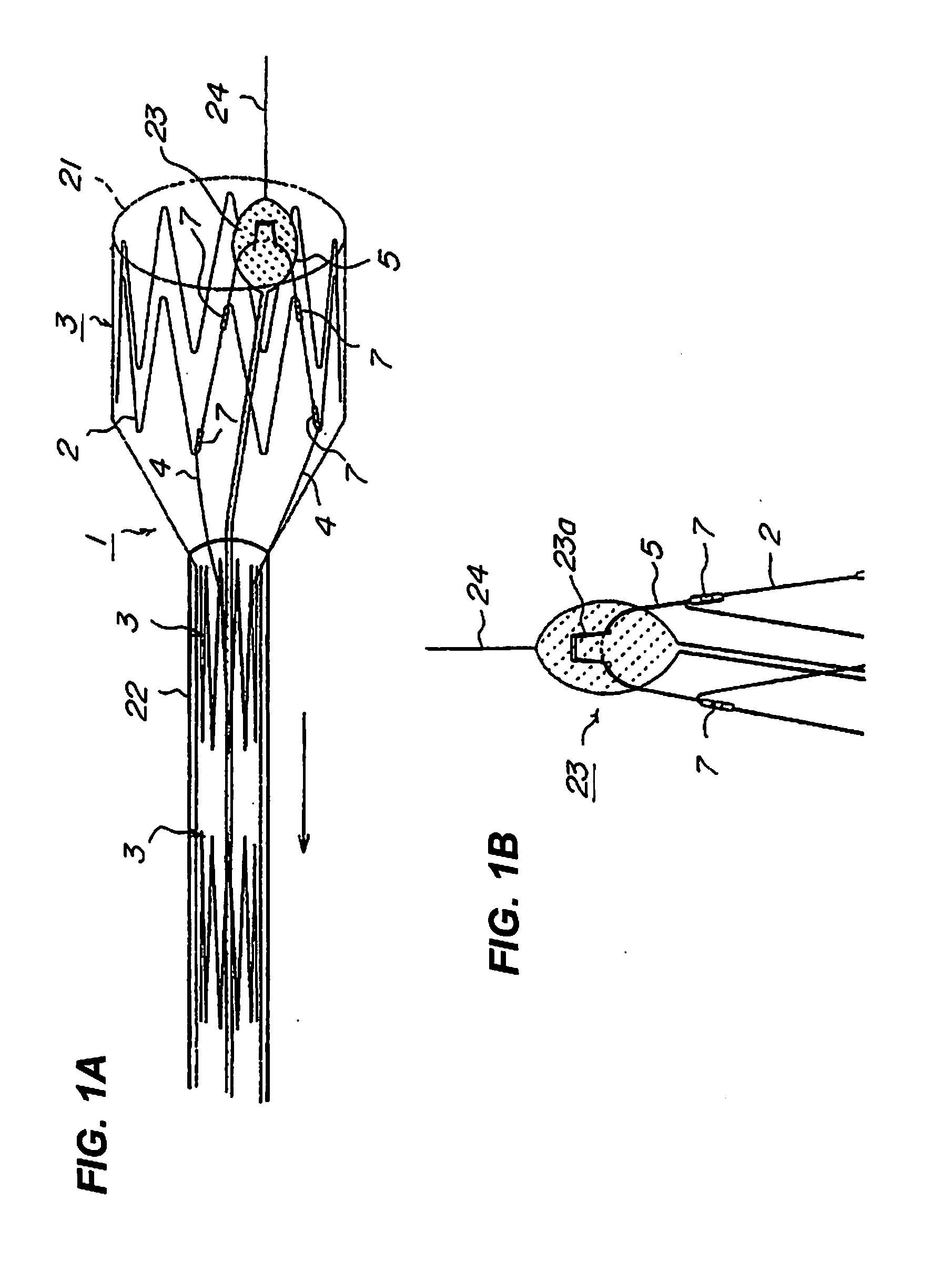

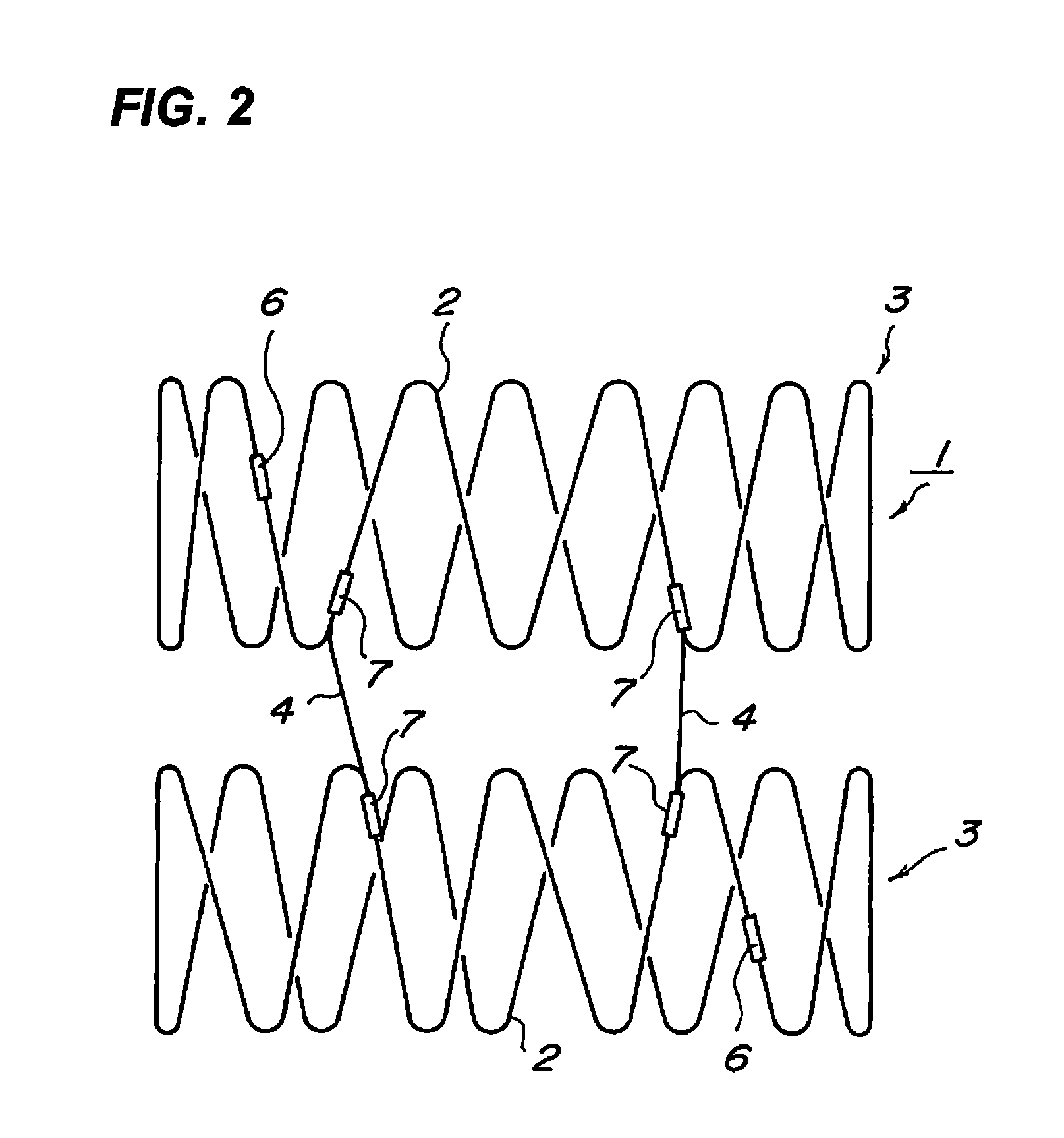

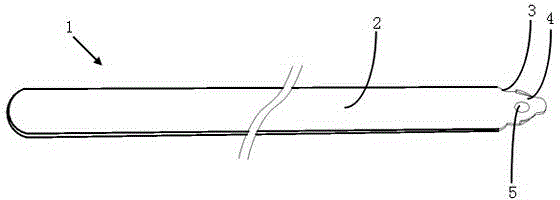

Stent

It is an object of the present invention to prevent a wire part including a stabilizer hook, a strut or the pulling-back member from separating from a connection part even when a force in a tensile direction is applied to a stent.A stent 1 having a connection part in which wire parts including a stent main wire 2, a strut 4 and a stabilizer hook 5 are connected to each other through a junction pipe 7, wherein a locking part which is locked to the junction pipe 7 is formed on the wire part which is inserted into the junction pipe 7.

Owner:MANI INC +1

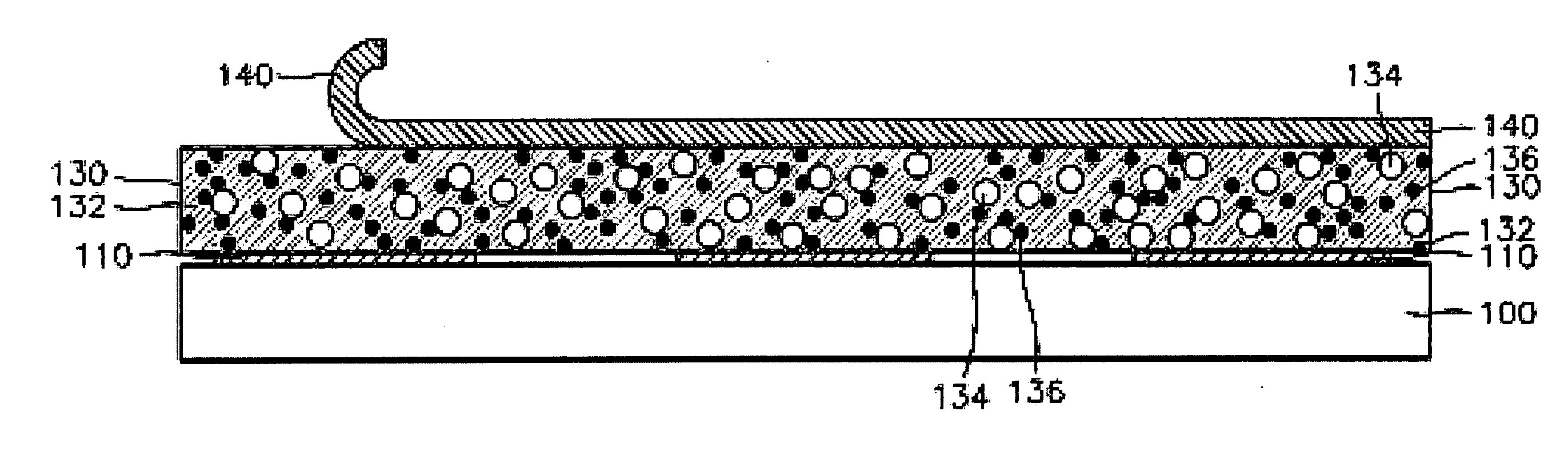

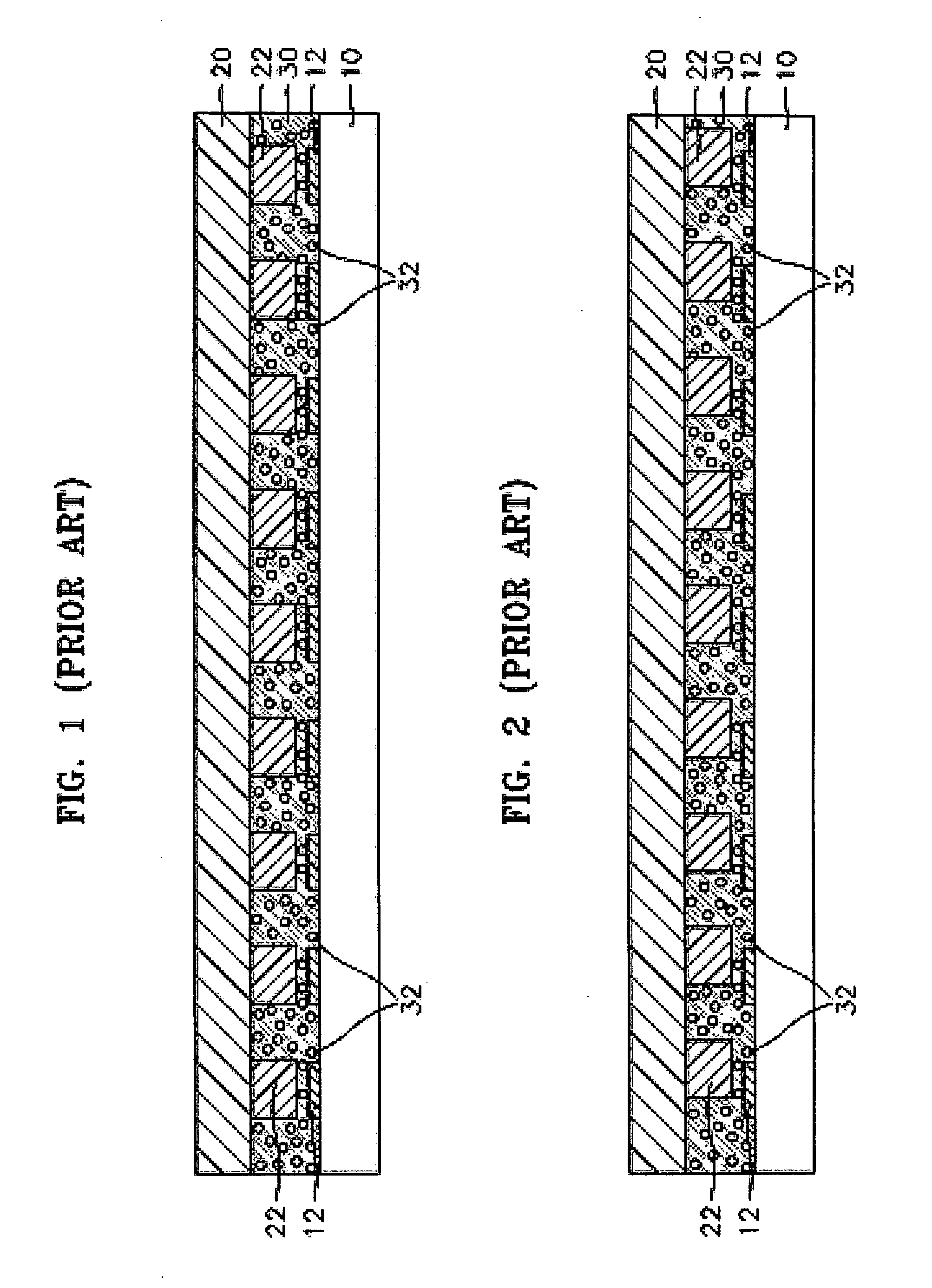

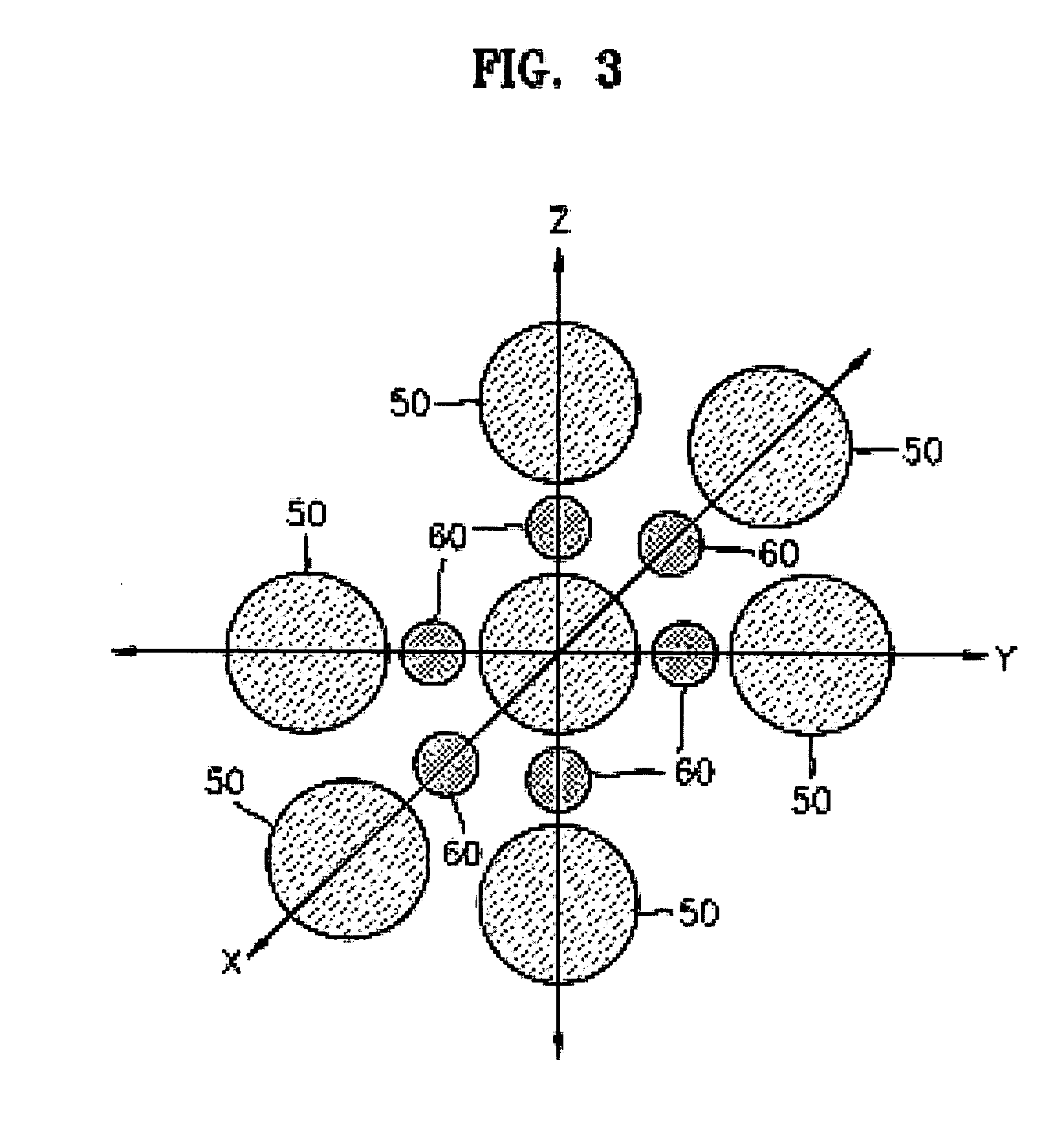

Anisotropic conductive adhesive for fine pitch and COG packaged LCD module

InactiveUS20060035036A1Big sizeReliable connectionLiquid crystal compositionsNon-macromolecular adhesive additivesAverage diameterAnisotropic conductive adhesive

Provided are an anisotropic conductive adhesive (ACA) for a fine pitch including conductive particles and non-conductive particles, and a chip-on-glass (COG) packaged liquid crystal display (LCD) module including the ACA. The sizes of the conductive particles and non-conductive particles in the ACA are adjusted according to a gap between electrodes of fine pitch arranged on a glass substrate of the LCD module. The provided ACA for a fine pitch is used for connecting the IC onto the glass substrate such as to electrically connect the IC to the electrodes. The provided ACA includes a thermosetting resin, a curing agent for curing the thermosetting resin, a plurality of conductive particles having an average diameter of less than half of a gap between the electrodes, the plurality of conductive particles being included at a first dispersion density, and a plurality of non-conductive particles having an average diameter of less than half of the average diameter of the conductive particles, the plurality of conductive particles being included at a second dispersion density that is larger than the first dispersion density.

Owner:TELEPHUS

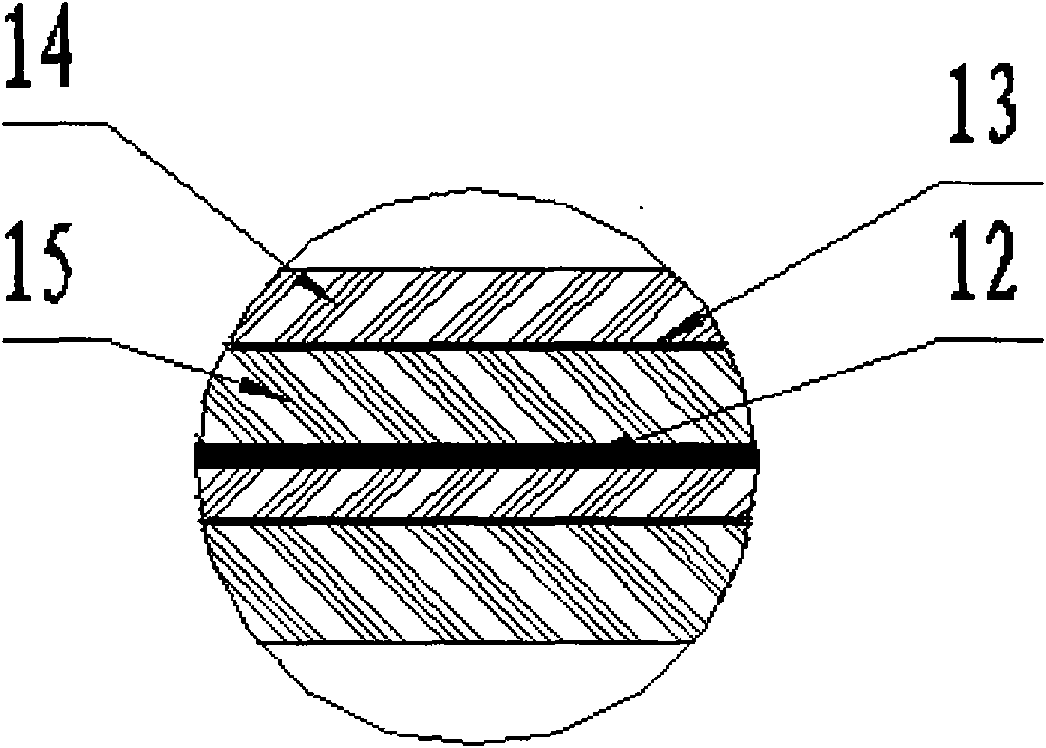

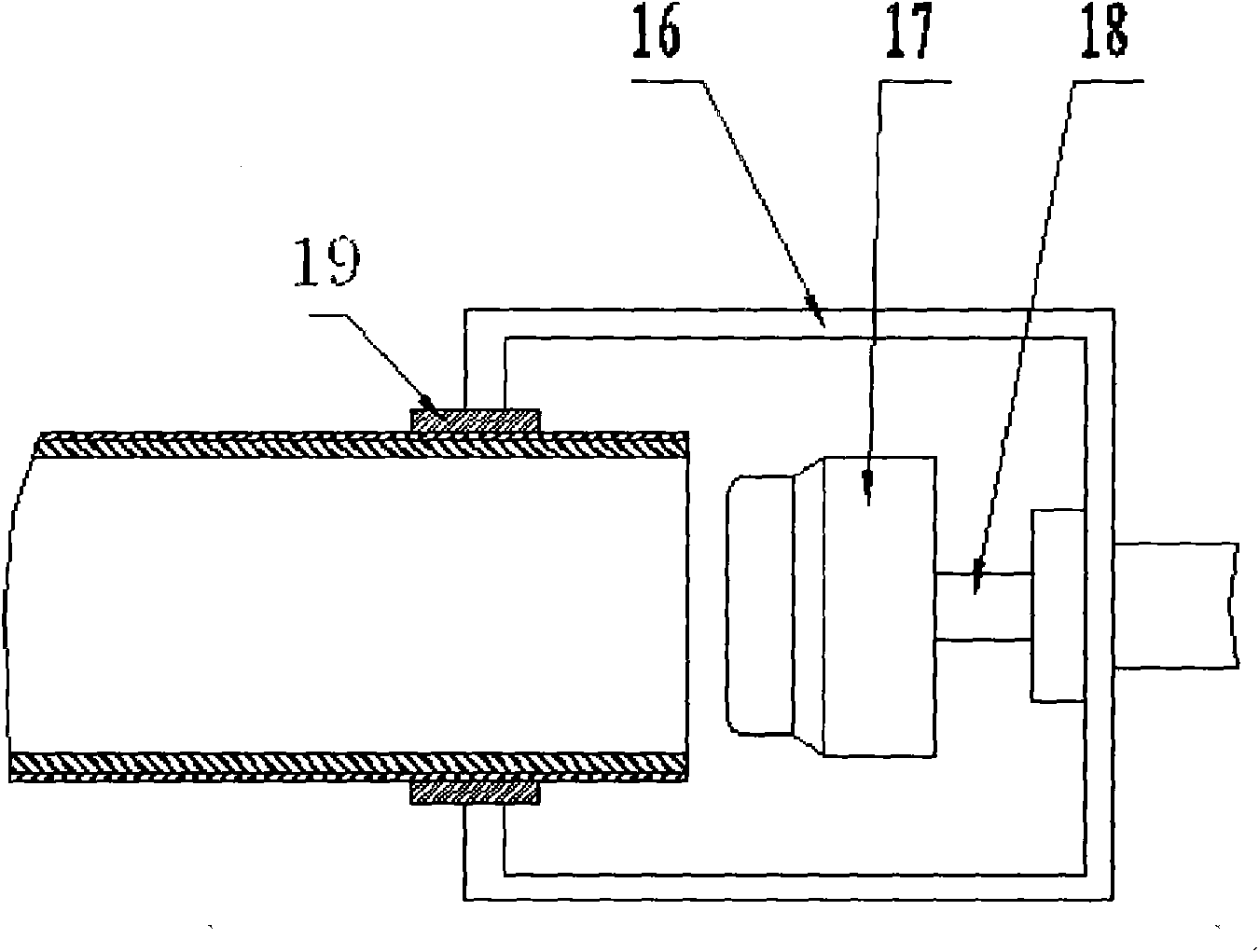

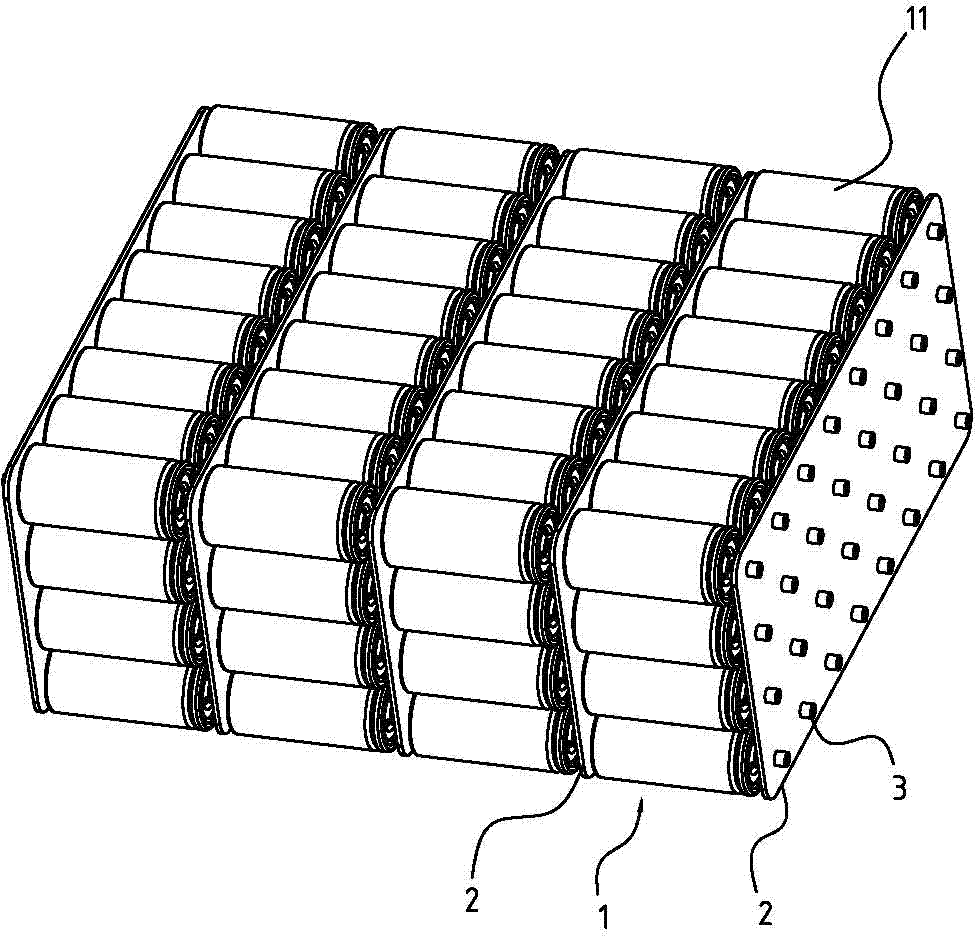

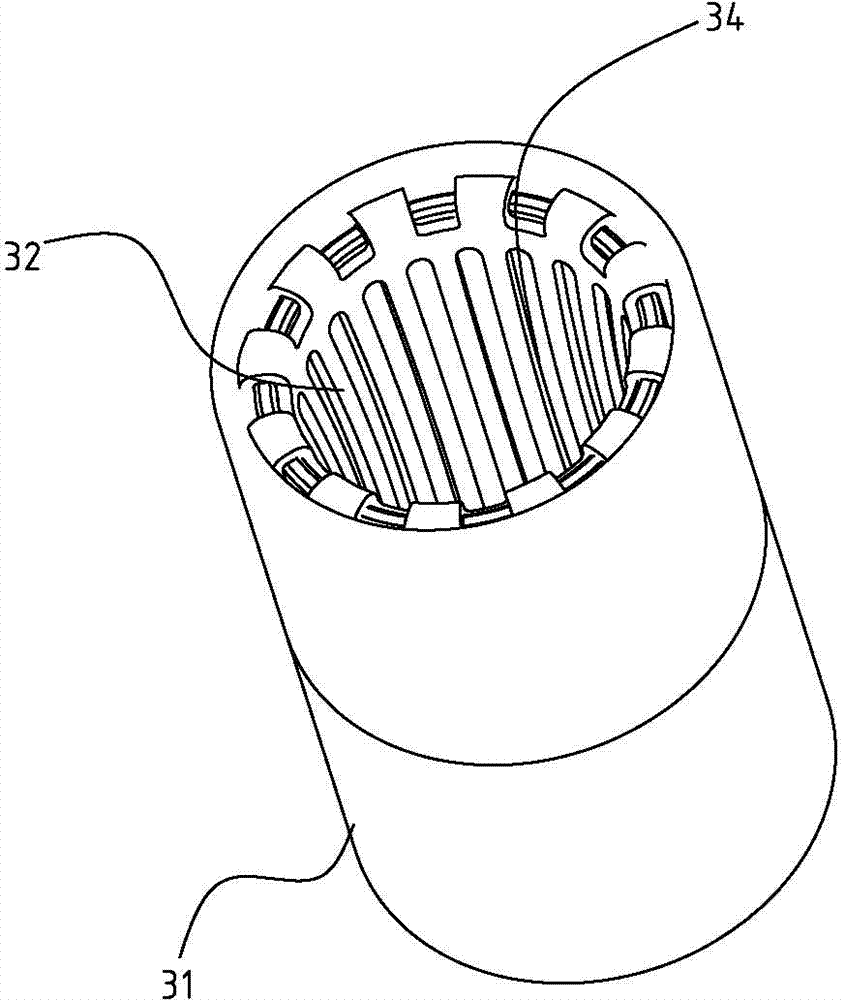

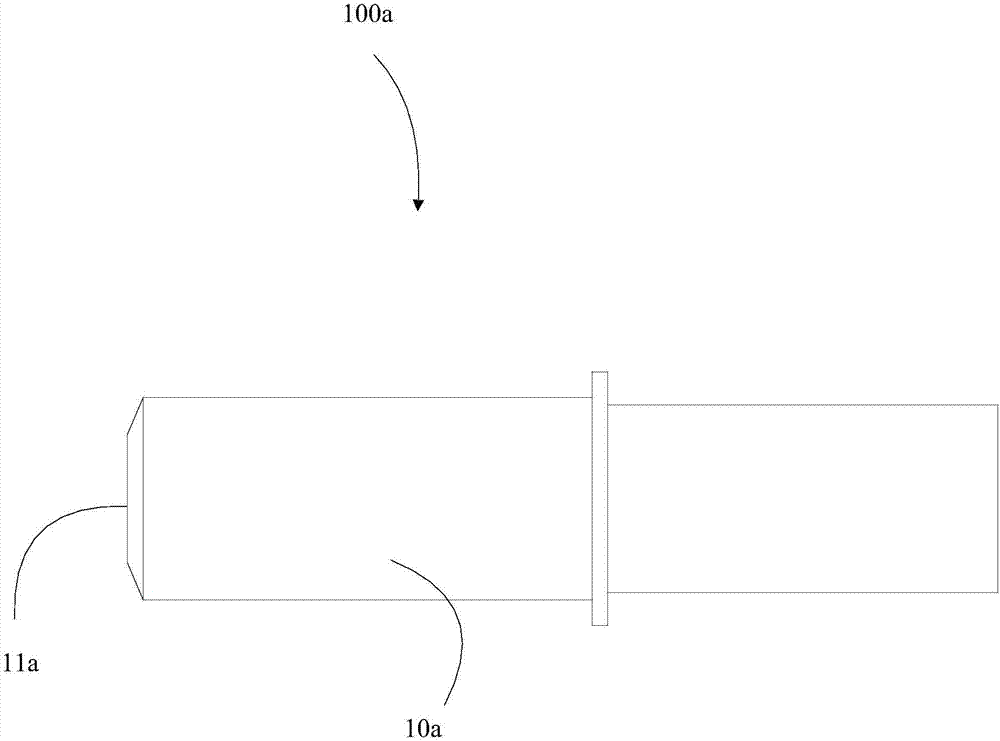

Thermal sensitive ceramic heater and heating body and heating core applied to thermal sensitive ceramic heater

ActiveCN104797015AImprove insulation performanceIncrease productivityOhmic-resistance electrodesHeater elementsHeat conductingHeat sensitive

The invention discloses a thermal sensitive camera heater. The thermal sensitive camera heater comprises a heating portion, a connection wire harness and a mounting frame, the heating portion is formed by a heating body and a radiator, the heating body comprises a heat conducting tube and a heating core, the heating core comprises a heating slice, an electrode slice and insulation paper, and the connection wire harness comprises a connection slice. Not fewer than two semi-circular grooves are formed in the outer lateral side of the heat conducting tube. A heat conducting face of the heat conducting tube is 0-15mm wider than the radiator. The thermal sensitive camera heater has the advantages that by the aid of the connection slice added on the electrode slice, reliable connection point contact and stable connection between the heater and the wire harness and convenience in manufacturing are achieved; by the aid of the heat conducting tube and the radiator which are different in width, the radiator can be combined with the heat conducting tube more stably and more uniform in radiation; by the aid of the semi-circular grooves in the lateral side of the heat conducting tube, the inner wall of the heat conducting tube causes less damage to a heating core insulation film, combination of the heating core in the heat conducting tube is tighter, and safety and heat efficiency are improved greatly.

Owner:SUZHOU GUOWEI CERAMIC ELECTRICAL APPLIANCE CO LTD

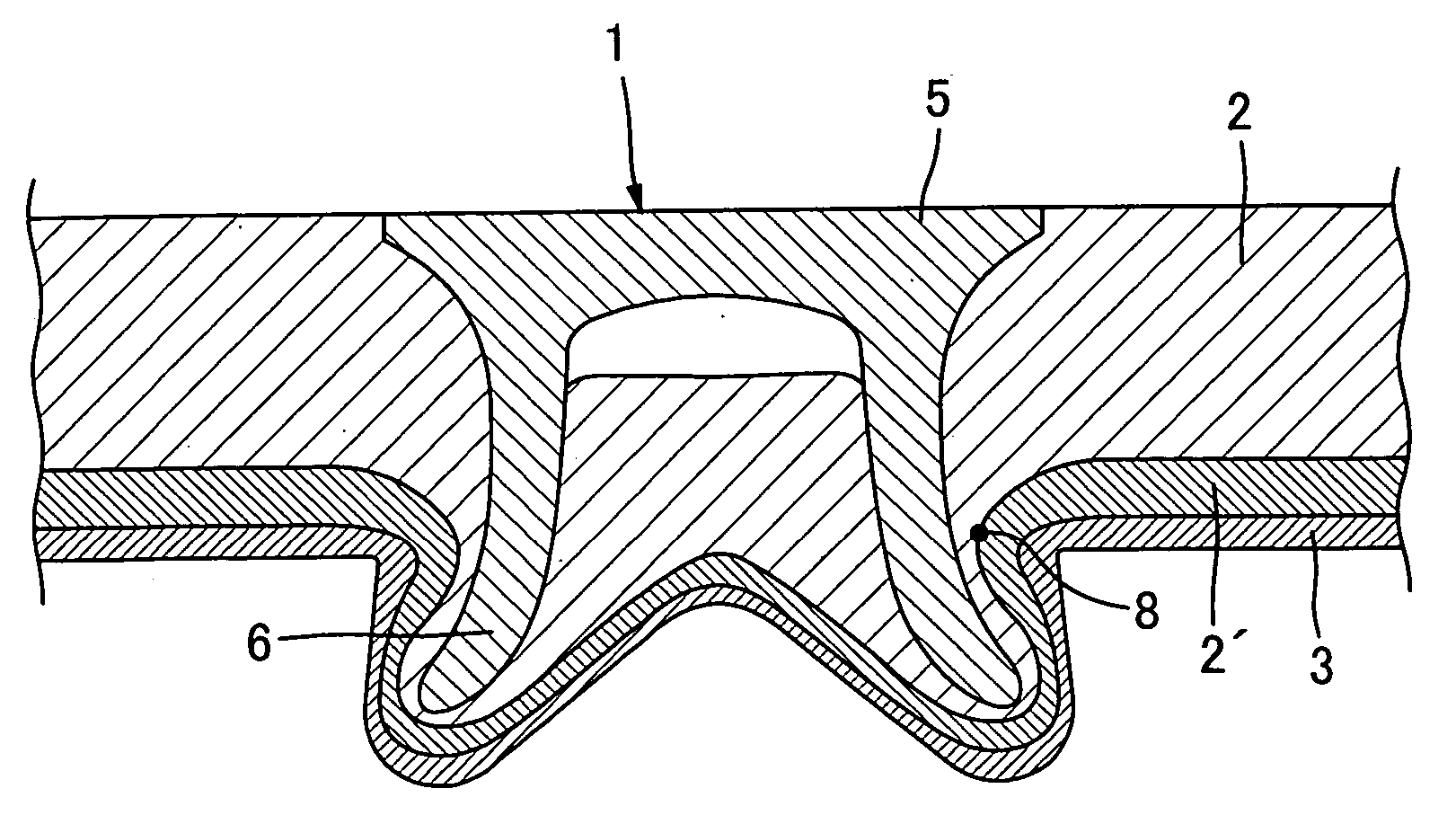

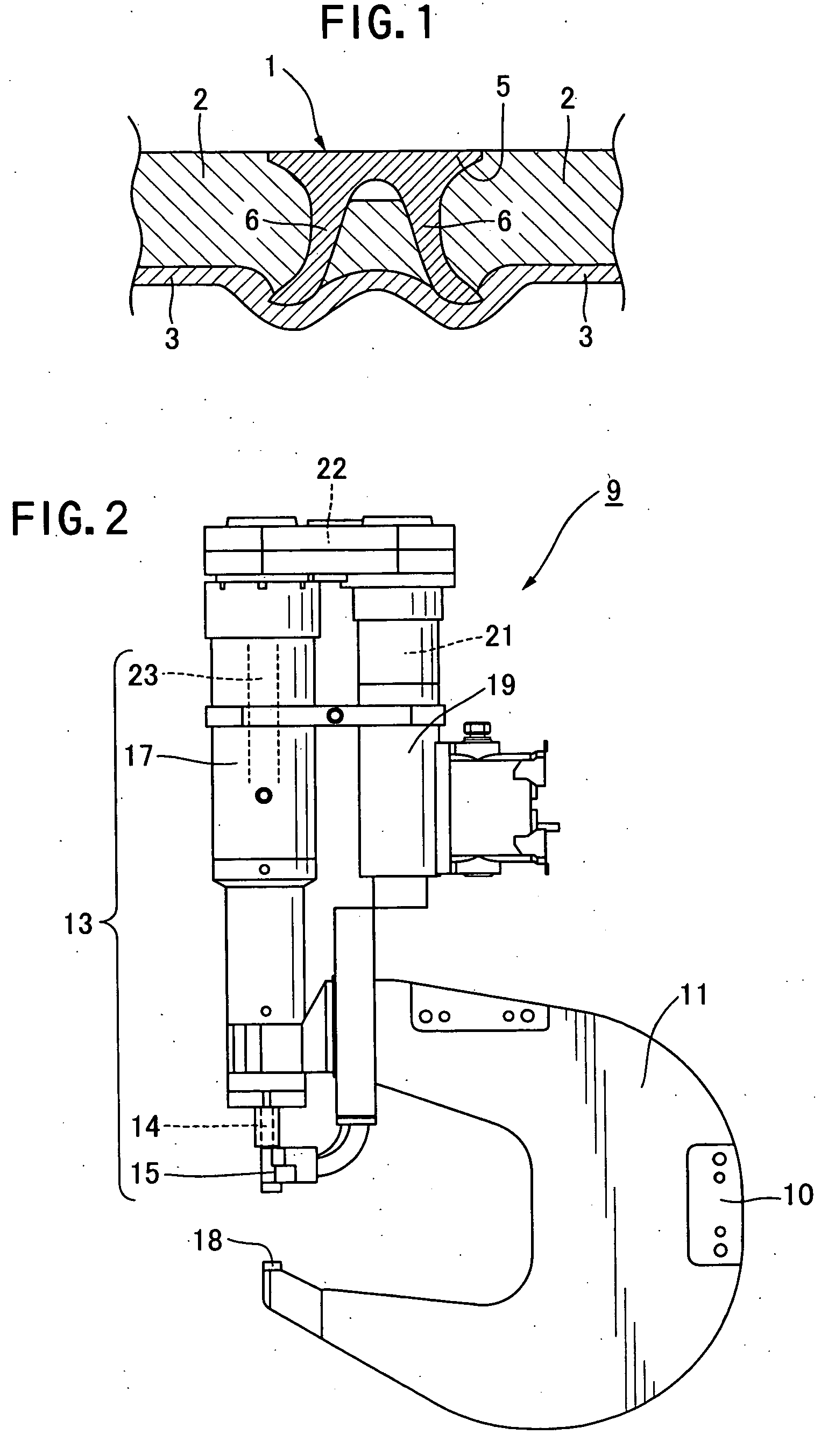

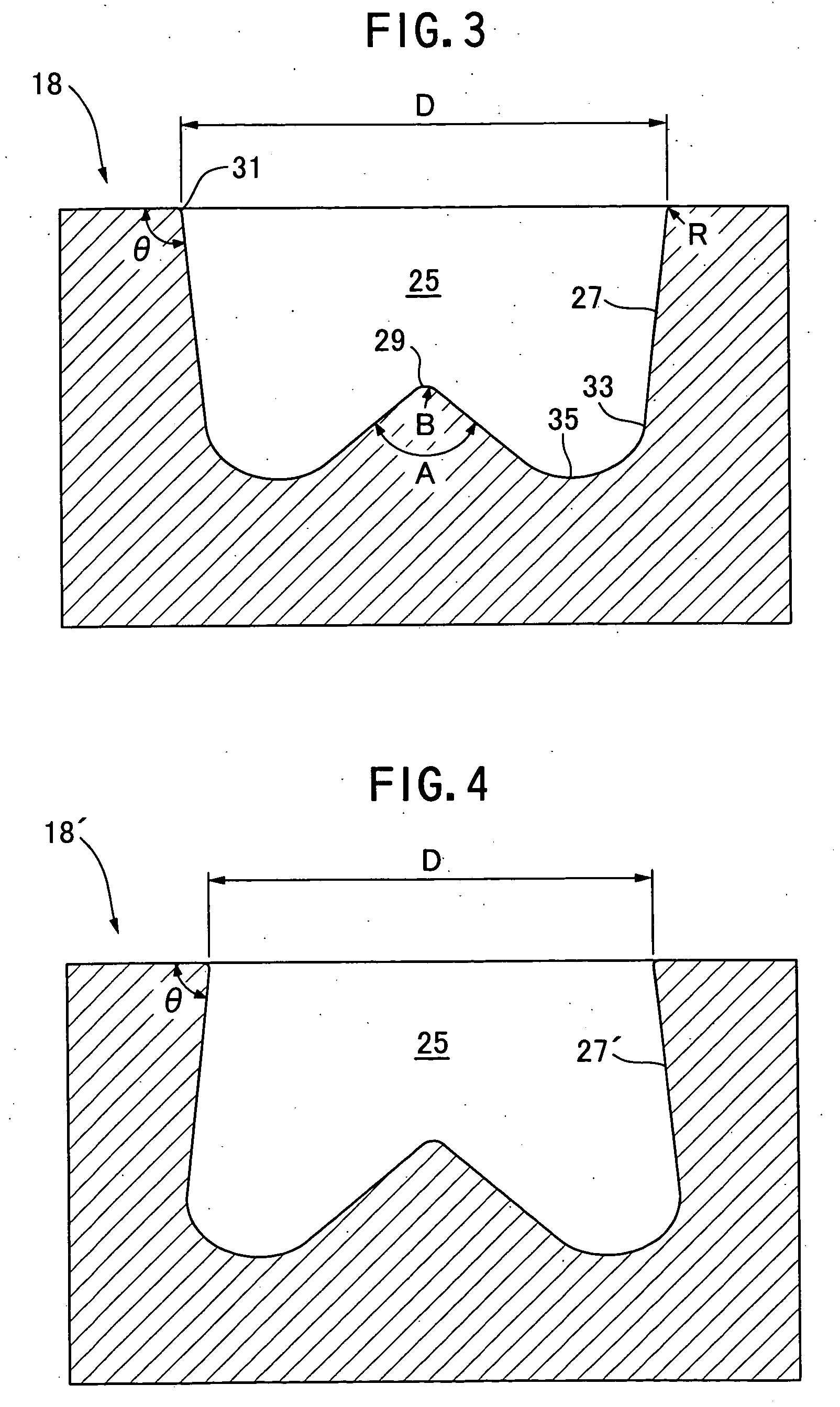

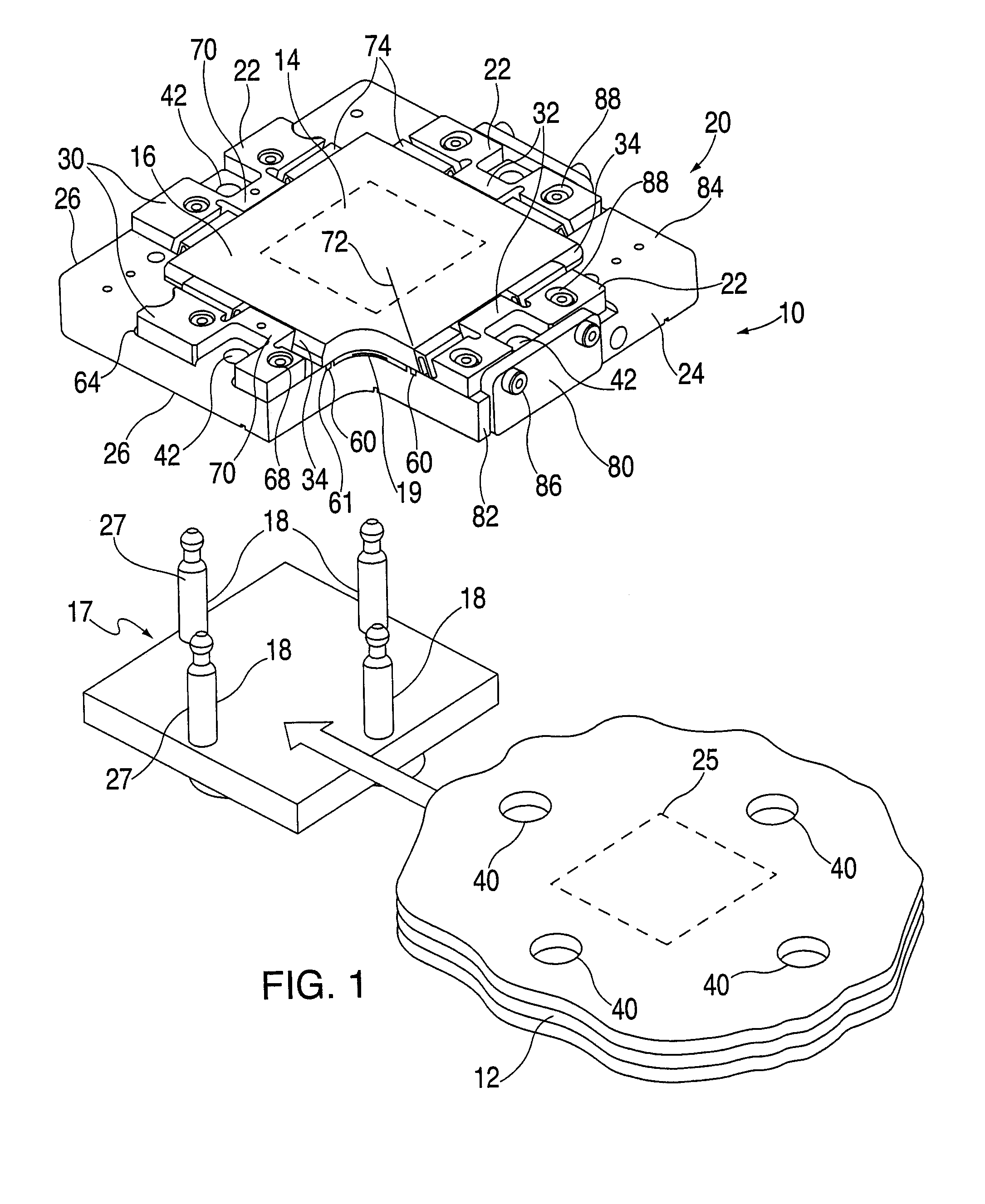

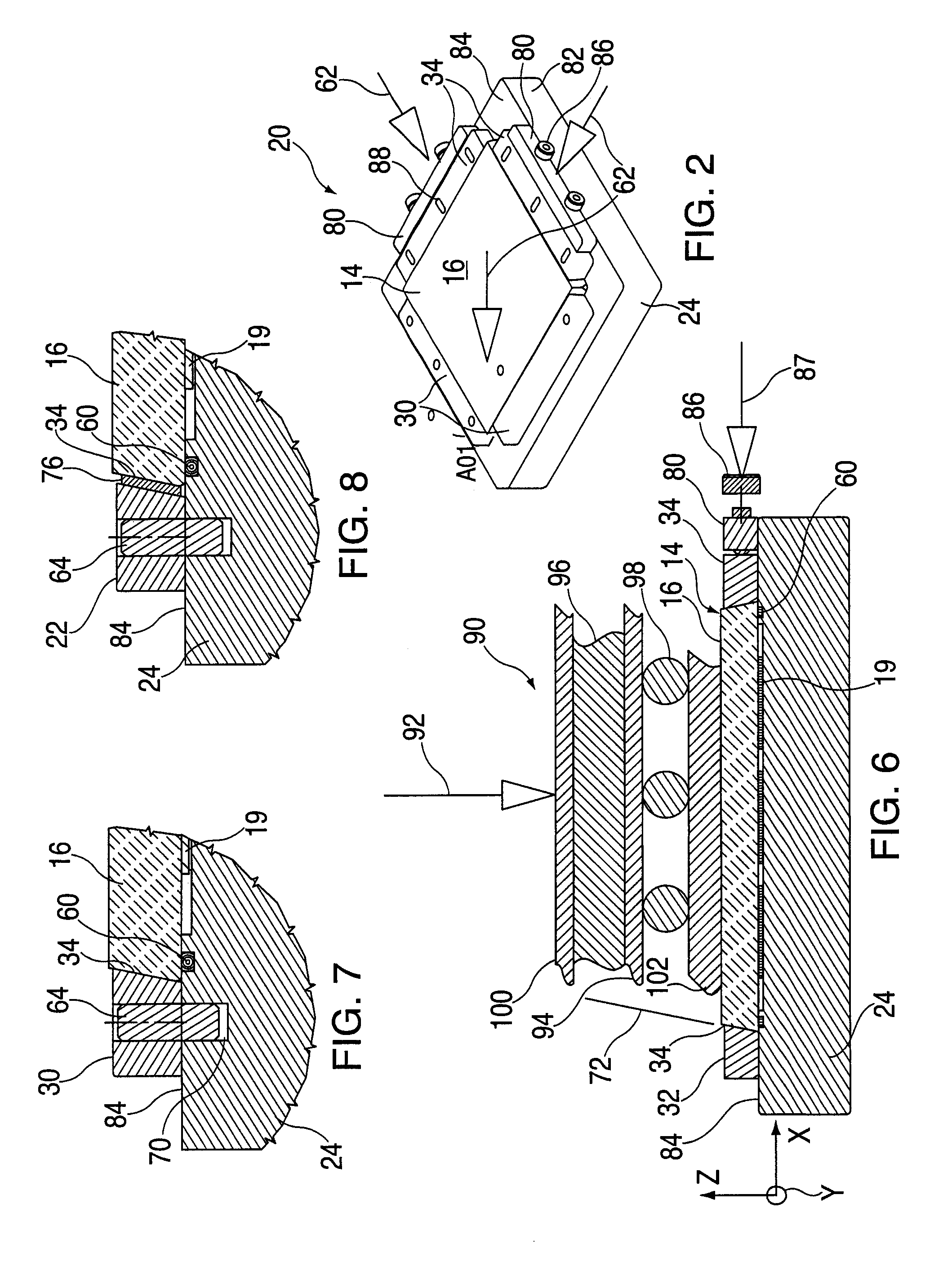

Self-piercing rivet setting die and apparatus

A die (18) for use in a self-piercing rivet setting apparatus comprises a cavity (25) for receiving therein a protruded workpiece zone consisting of respective portions of the workpieces (2, 3) to be protrudingly deformed toward the die through the pressure of the self-piercing rivet (1). The cavity has a bottom surface provided with a central raised portion (29) protruding from the center of the bottom surface toward a punch. The central raised portion of the cavity has a vertical angle in the range of 90 to 160 degrees. Preferably, the central raised portion has a top formed in a spherical shape. The cavity has an approximately cylindrical outer wall (27) in the periphery thereof. The cavity has a curved inner surface extending from the top of the central raised portion to the lower end (33) of the outer wall through the bottom (35) of the cavity.

Owner:KONE CORP +1

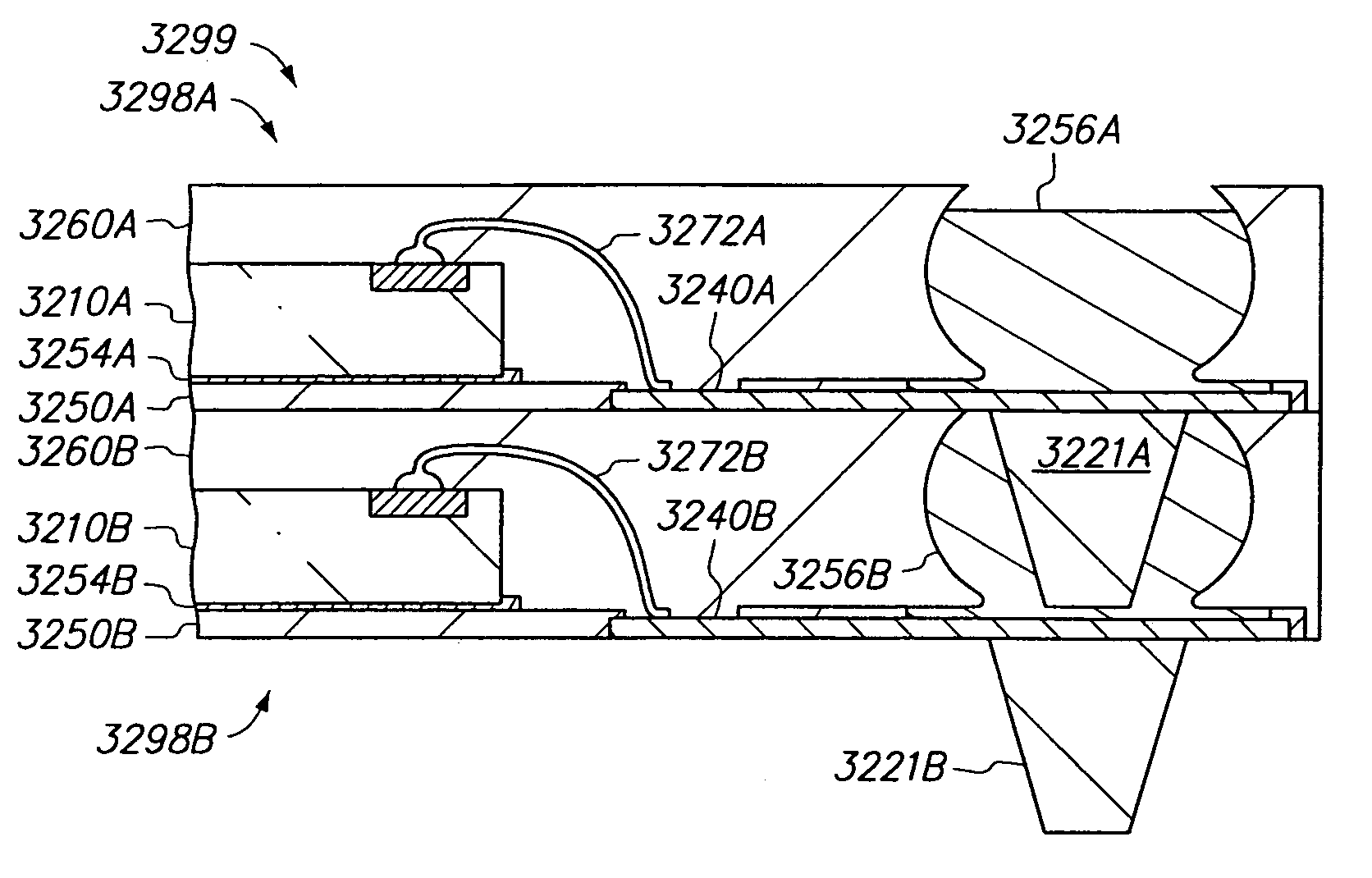

Method of making a three-dimensional stacked semiconductor package with a metal pillar in an encapsulant aperture

InactiveUS7129113B1Reliable connectionImprove uniformitySemiconductor/solid-state device detailsSolid-state devicesSealantMetal

Owner:BRIDGE SEMICON

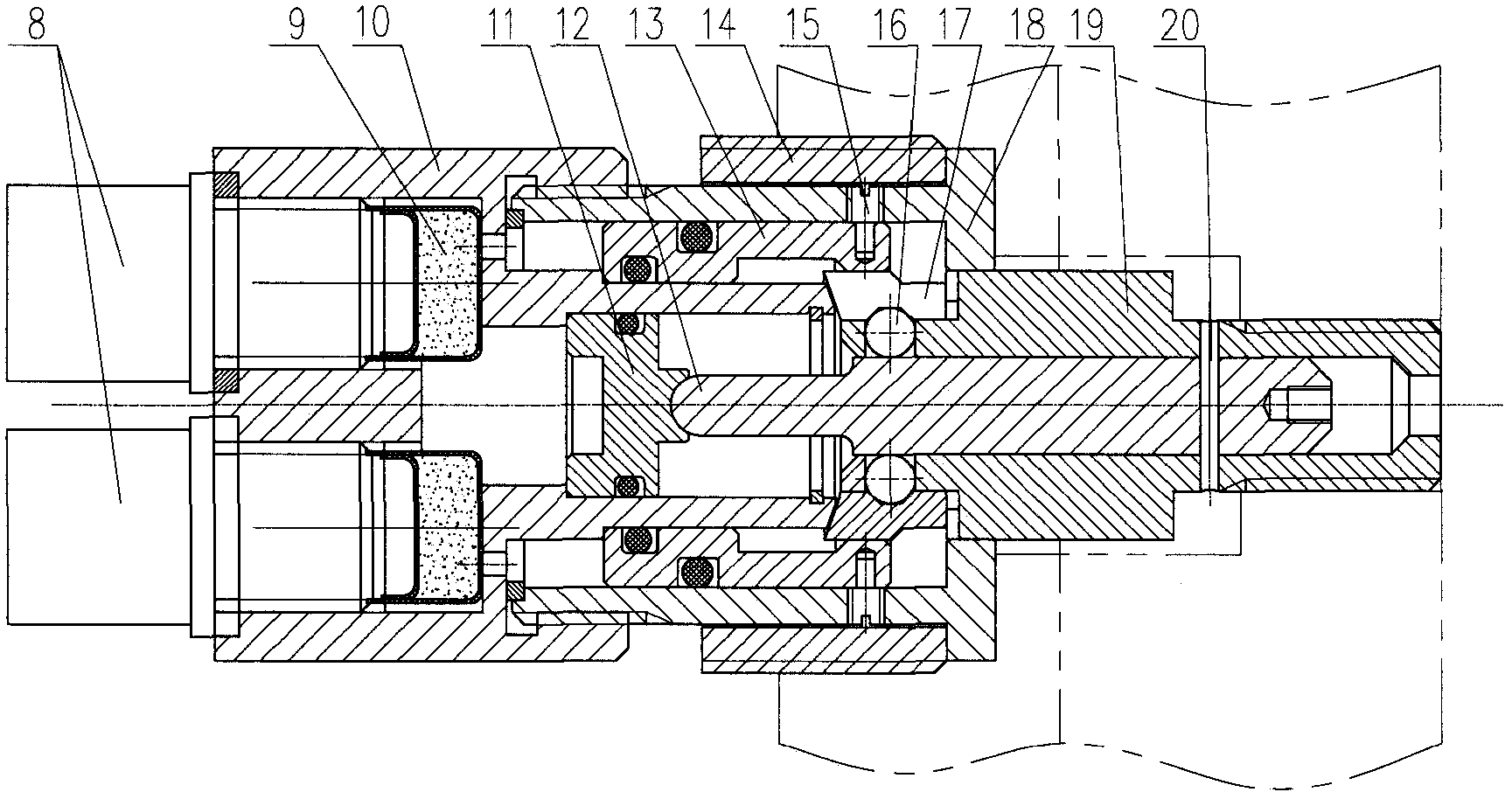

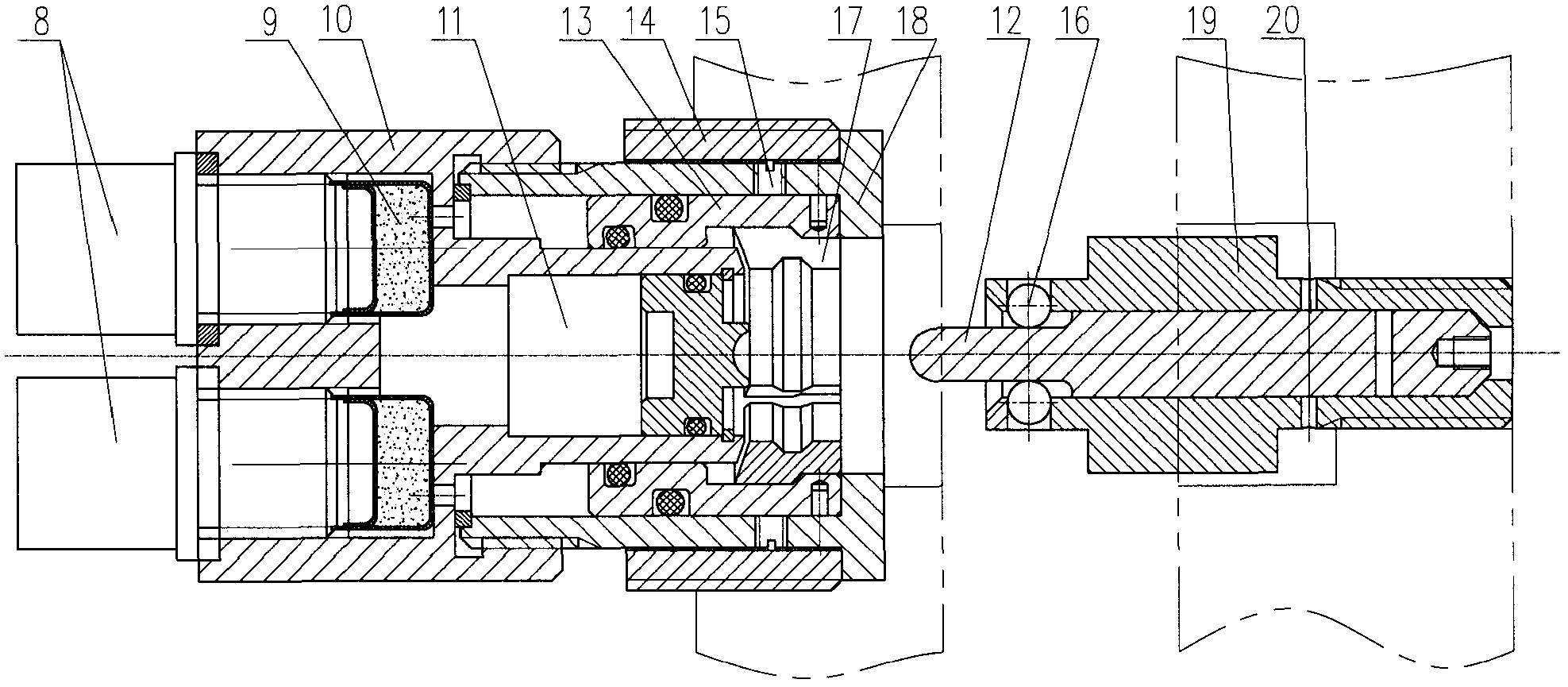

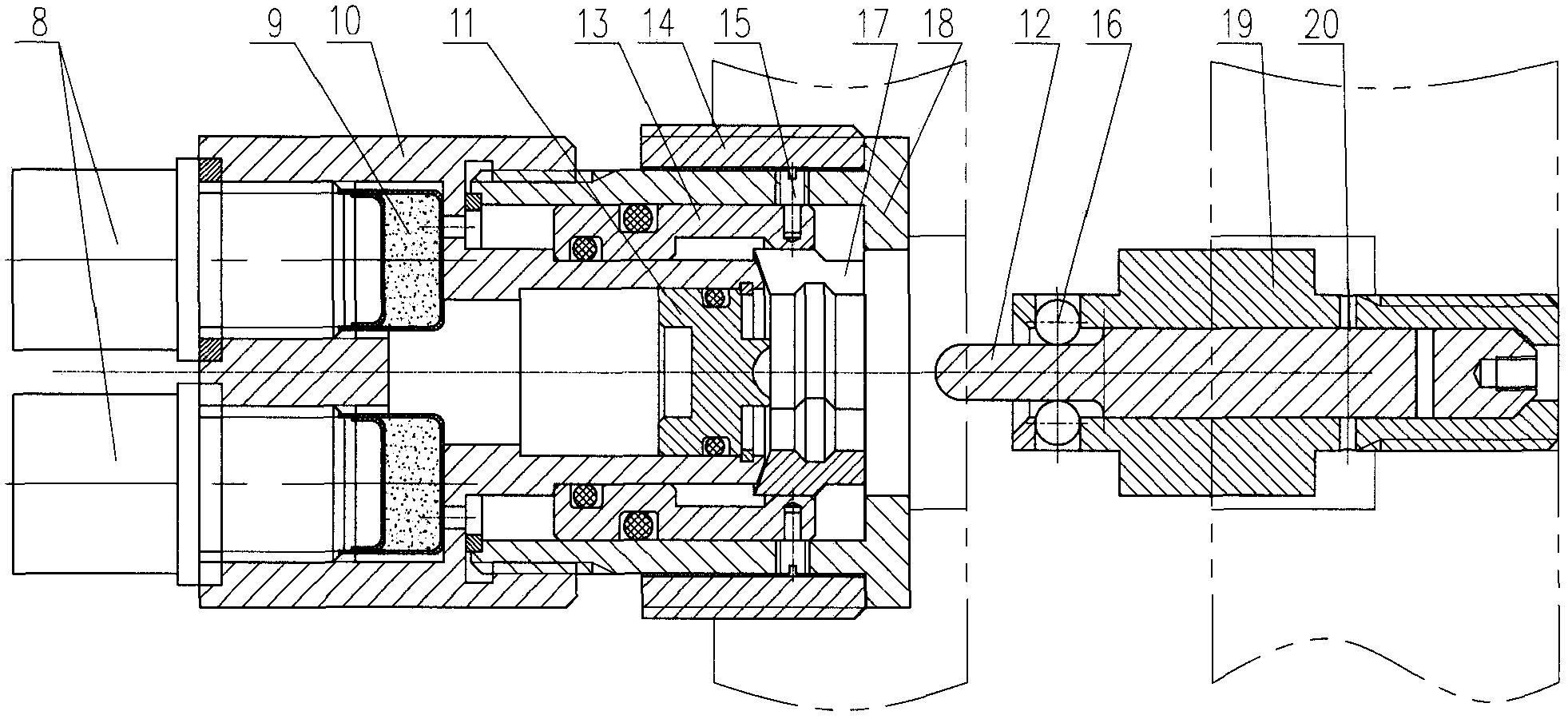

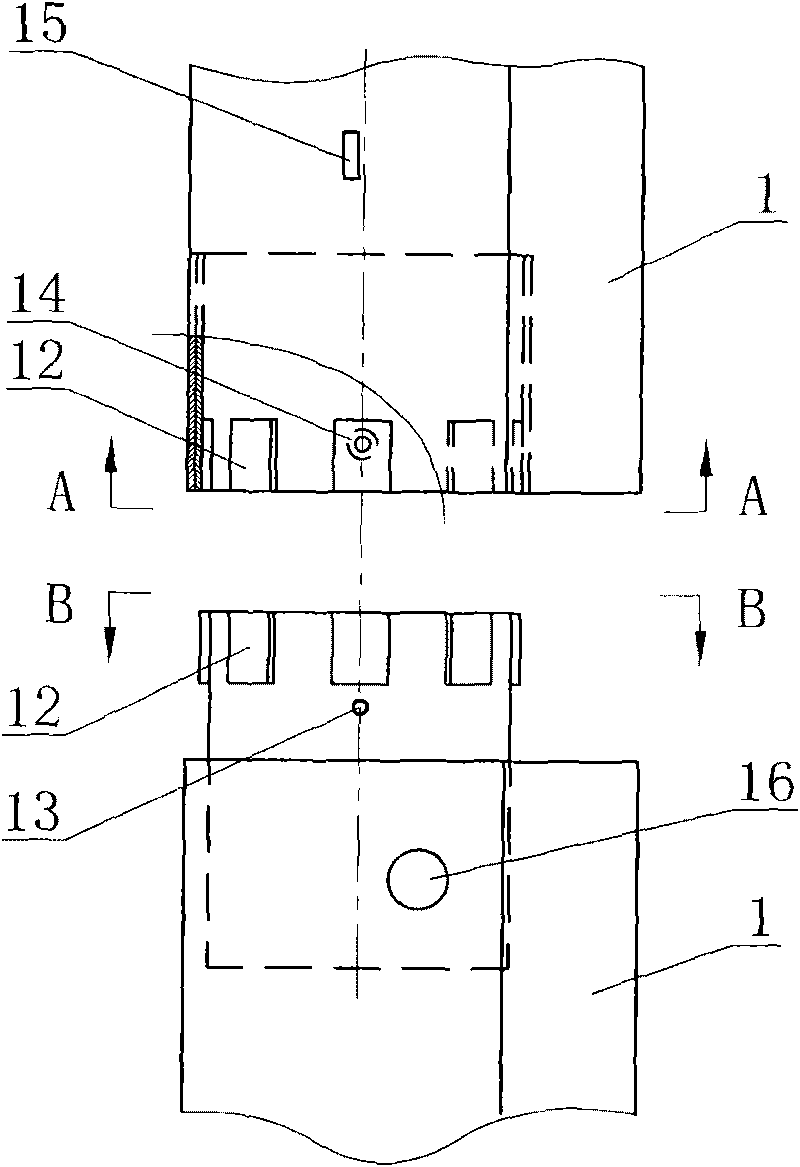

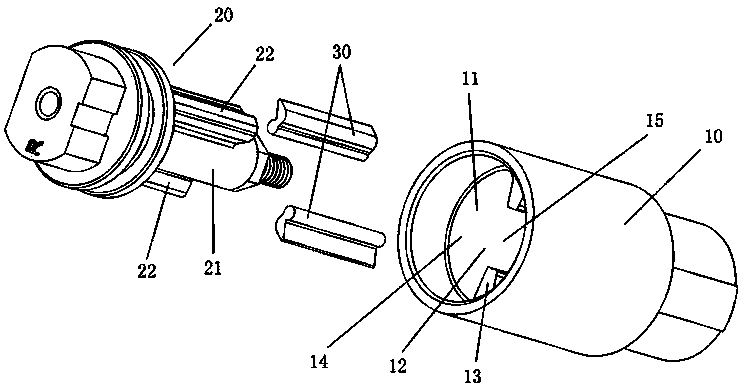

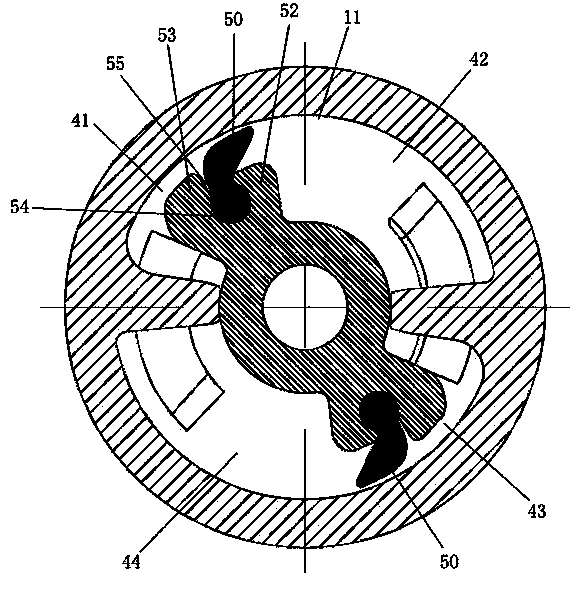

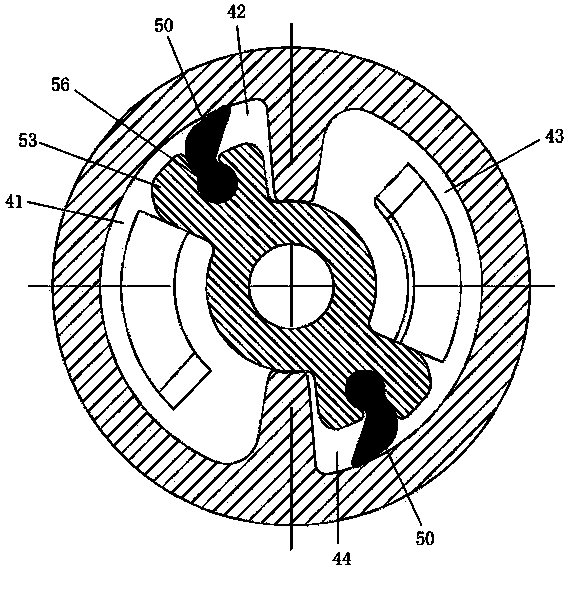

A connection and separation device for spacecraft

ActiveCN105659802BReliable connectionEasy to useCosmonautic component separationSelf-propelled projectilesSpacecraftEngineering

A connection and separation device for spacecraft, which is composed of an initiating element, an inner actuator, an outer actuator, etc., and is screwed together with the first connection object through a lock nut arranged on the casing, and is screwed with the second connection object through a lock rod. connected together, so as to realize the reliable connection of the first and second connection objects. When separating, the high-pressure gas generated after the detonating element is detonated drives the movement of the inner and outer actuators respectively, and then completes the unlocking and separation, and realizes the ejection of the second connection object. The device of the present invention is simple in structure and easy to use. As long as one of the inner and outer actuators acts, the unlocking and separation can be completed. Even if one of the actuators fails, the separation will not fail, so it has the advantage of high reliability. .

Owner:BEIJING INST OF SPACECRAFT SYST ENG

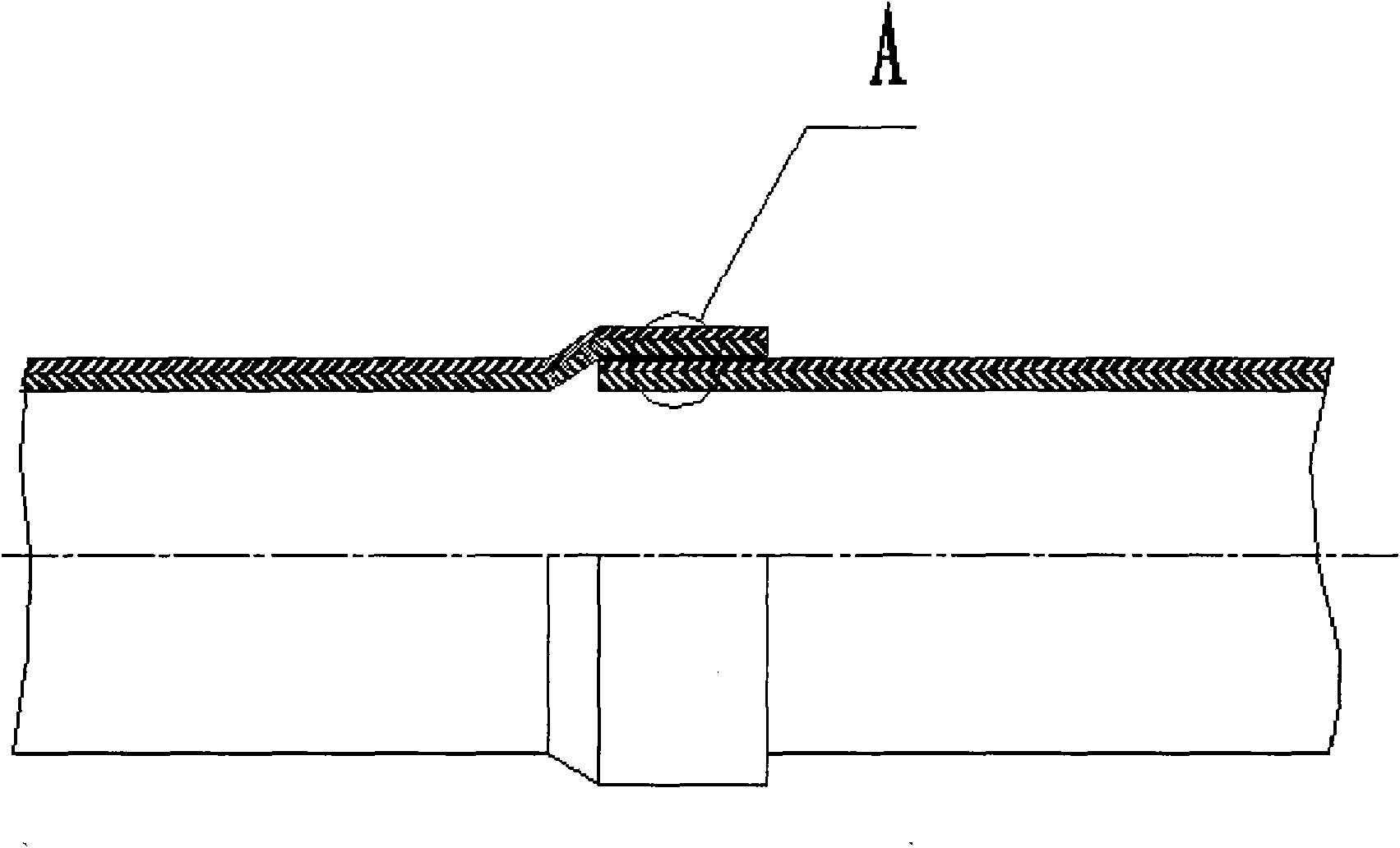

Hot melting connecting method of plastic composite pipe and connecting device used by same

The invention relates to a hot melting connecting method of a plastic composite pipe and a connecting device used by the same. The hot melting connecting method adopts a hot melting socket connectingmode, and comprises the following steps: presetting the pipe mouth inside diameter of one section of plastic composite pipe at a connected end to be equivalent to the pipe mouth outside diameter of the other section of plastic composite pipe; when in connection, heating the outer surface of a minor-caliber pipe mouth and the inner surface of a major-caliber pipe mouth at the connecting end of twosections of composite pipes to be in a fusing state; and removing a heating device, socketing heating surfaces of two sections of composite pipes together and connecting two sections of composite pipes after cooling. The connecting device is sequentially provided with a fixed clamp group, an inner surface hot melter, an outer surface hot melter and a movable clamp group in the same axial directionof clamping the plastic composite pipeline, wherein the fixed clamp group and the movable clamp group are respectively fixed on a plunger piston connecting rack of a hydraulic plunger piston system and an oil cylinder connecting rack, and the inner surface hot melter and the outer surface hot melter are respectively fixed on front side and the back side of a heating plate and fixed together on asuspended movable bracket together. The hot melting connecting method and the connecting device have the advantages of realizing the connection in the flaring and hot melting socket modes, having convenient operation, reliable connection, easy processing and low connecting cost, being suitable for connection of buried pipelines and other long pipelines and particularly according with the connecting requirements of plastic composite pipelines of steel wire frames with the pressure less than 1.6Mpa.

Owner:山东东宏集团有限公司

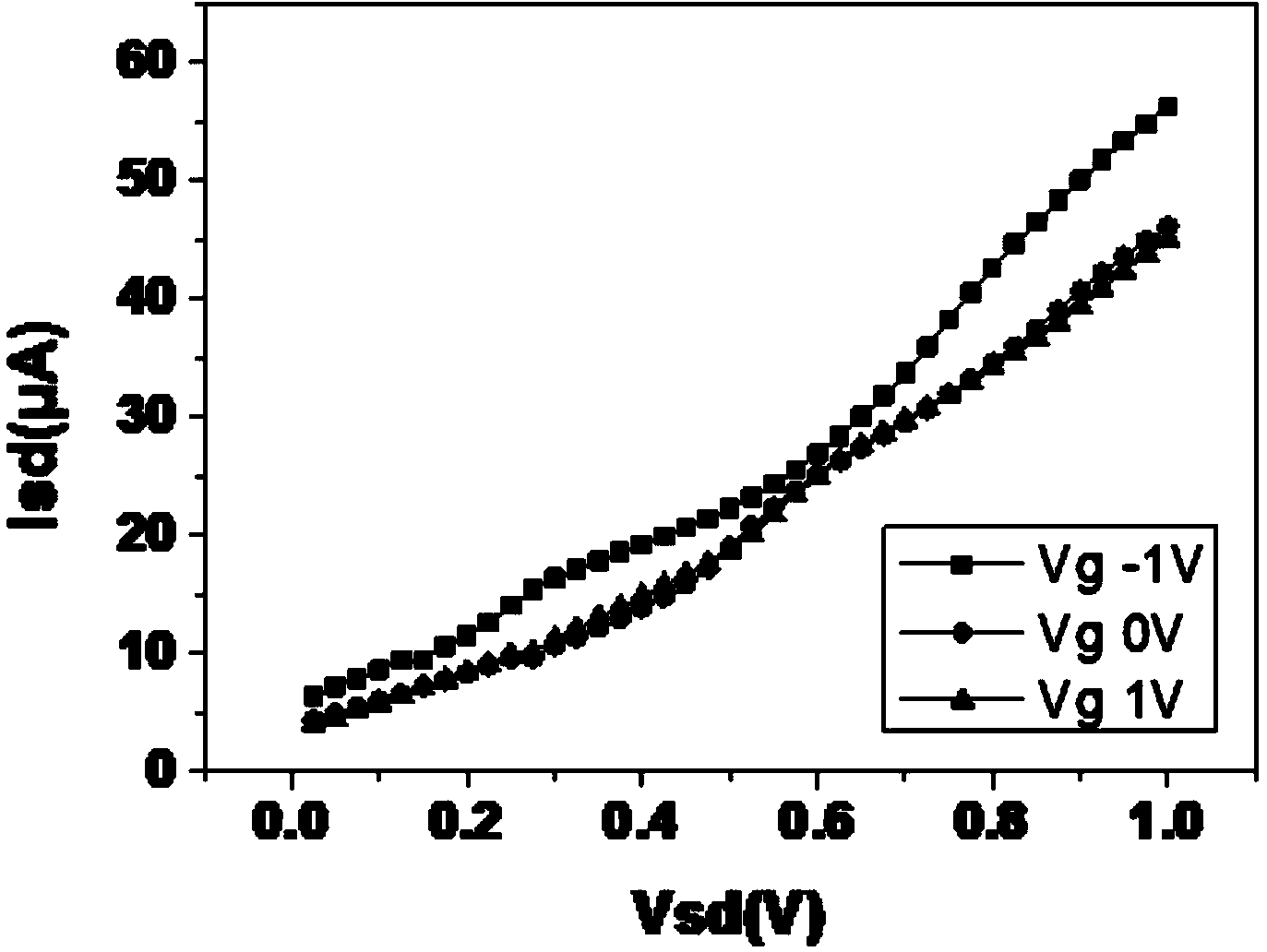

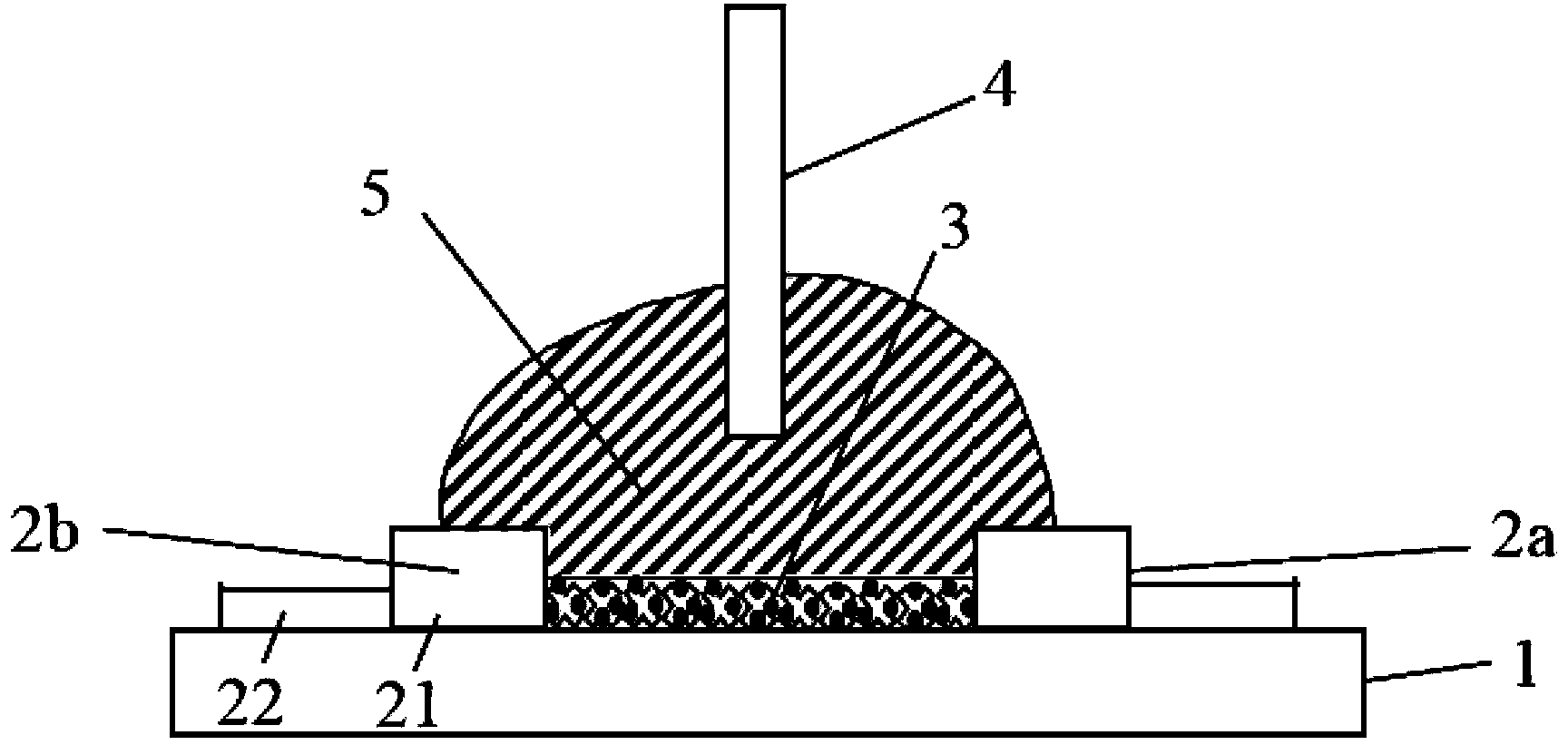

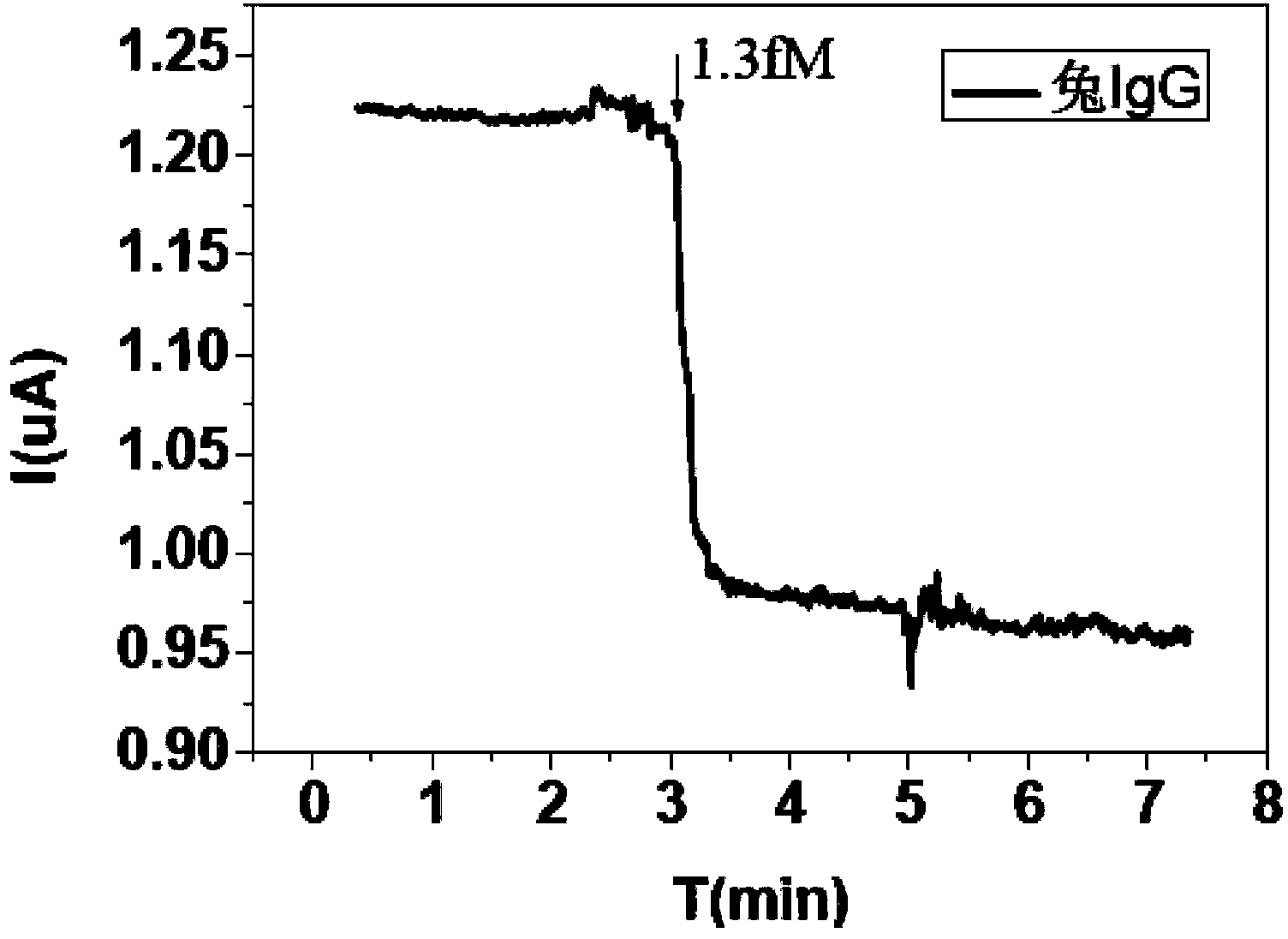

Biological sensor, manufacturing method and detection method thereof

ActiveCN104345082AReliable connectionThe product process is simpleMaterial analysis by electric/magnetic meansPhysicsChemistry

The invention discloses a biological sensor and a manufacturing method and a detection method thereof. The biosensor has a field effect transistor structure, which comprises a flexible substrate, printed silver source drain electrode arranged on the flexible substrate and a printing functionalized nano carbon material layer connected with the source drain electrode. A specific receptor is connected with the functionalized nano carbon material layer as a sensitive material for detecting minute quantity of a specific target material. The source drain electrode is connected with a set of signal detecting system, which cooperates with signal regulation of a suspended grid in a detection liquid to realize the rapid, accurate and sensitive biological diagnosis; therefore, the biological sensor has the advantages of integration, compatibility and portability.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

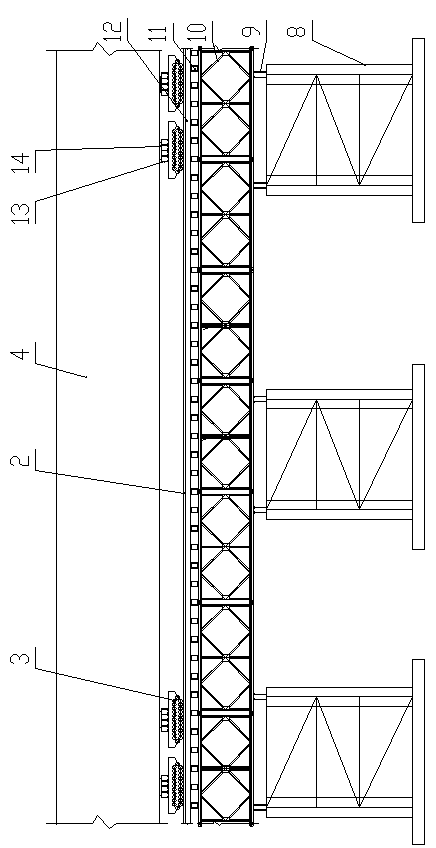

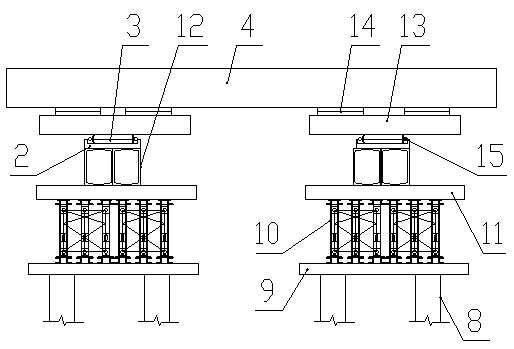

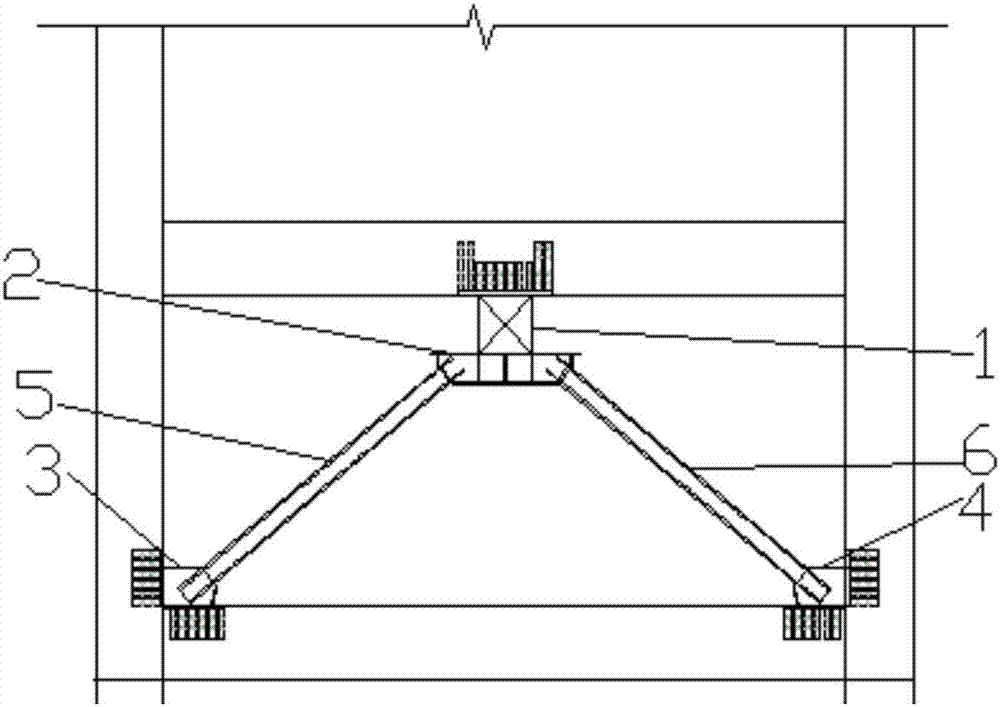

Reverse dragging device for construction of dragging large-span steel braced girder

The invention discloses a reverse dragging device for construction of dragging a large-span steel braced girder. The reverse dragging device comprises a temporary support and a winch, wherein the temporary support is provided with a slide way with a groove-shaped cross section, a crawler-type conveyor capable of sliding along the slide way is arranged in the slide way, the steel braced girder is arranged on the crawler-type conveyor, the upper portion of the front end of the temporary support is provided with a fixed pulley block, and a hauling cable wound on the winch bypasses the fixed pulley block and is connected with the front end of the steel braced girder via a movable pulley block. The reverse dragging device for the construction of dragging the large-span steel braced girder is simple in structure, reasonable in design, good in bearing performance, safe, reliable, high in construction efficiency, high in practicability and worthy of popularization and application.

Owner:中交二公局第四工程有限公司

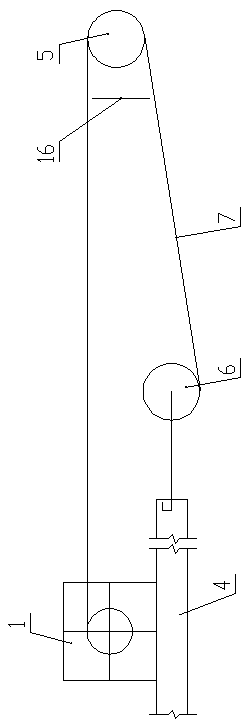

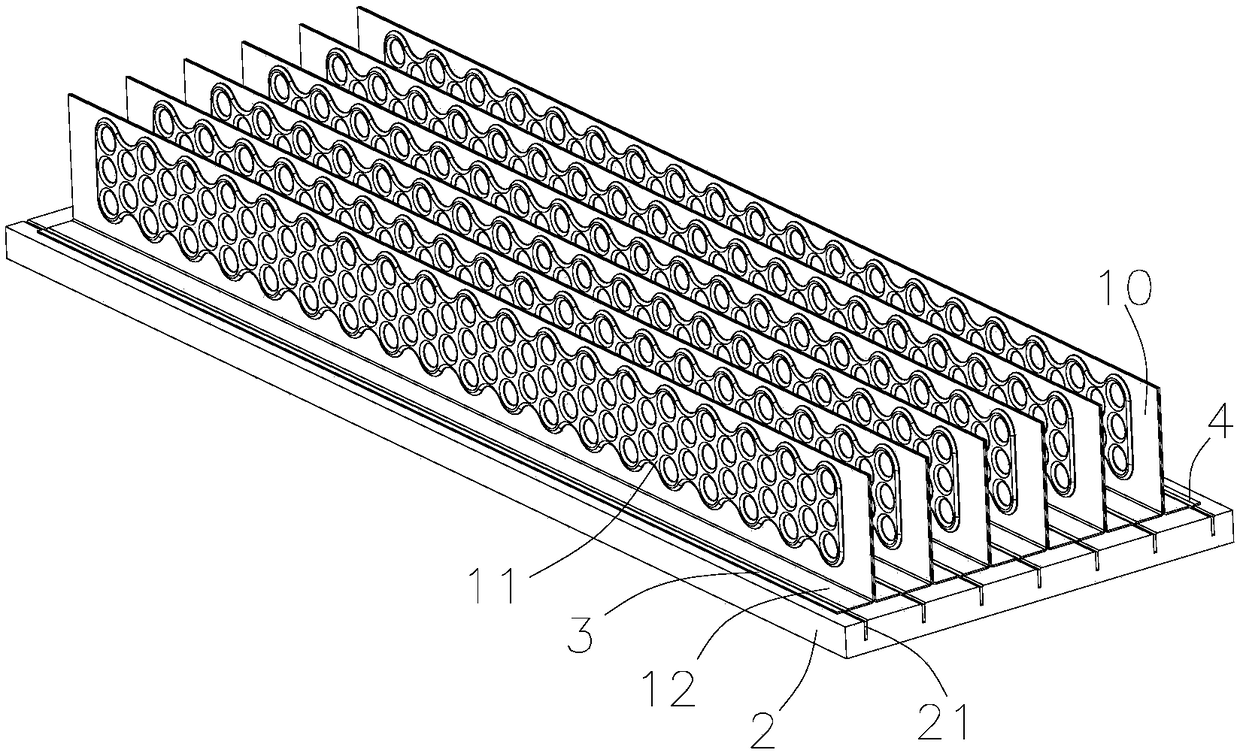

Power cell module connecting structure and connecting method thereof

ActiveCN103035870AAvoid quality problemsStrong vibration resistanceCell component detailsEngineeringPrinted circuit board

The invention relates to a power cell module connecting structure method. A power cell module is composed of a plurality of single cell groups, the adjacent power cell modules are connected through a connecting structure, the connecting structure comprises a PCB (printed circuit board), and the PCB plate is provided with more than one connector; the connector comprises a metal shell the two ends of which are communicated, the shell is internally provided with a spring piece, and a support ring is arranged between the spring piece and the inner wall of the shell and is used for fixing the spring piece and the shell; the PCB plate is provided with through holes, the shell of the connector is electrically connected with the PCB plate, and connecting holes are formed in the connector; and the contact pins of each single cell in a power cell module on the two sides of the PCB are inserted into the connecting holes of the corresponding connector, the contact pins are kept to be electrically connected with a spring piece in the connector, and the monomer cells in the adjacent power cell modules are electrically connected through the connector. According to the invention, the connector is used for replacing a bolted connection, the contact pins and the connector are elastically connected, and the structure can not generate a loose phenomenon because of vibration.

Owner:SHENZHEN BUSBAR SCI TECH DEV

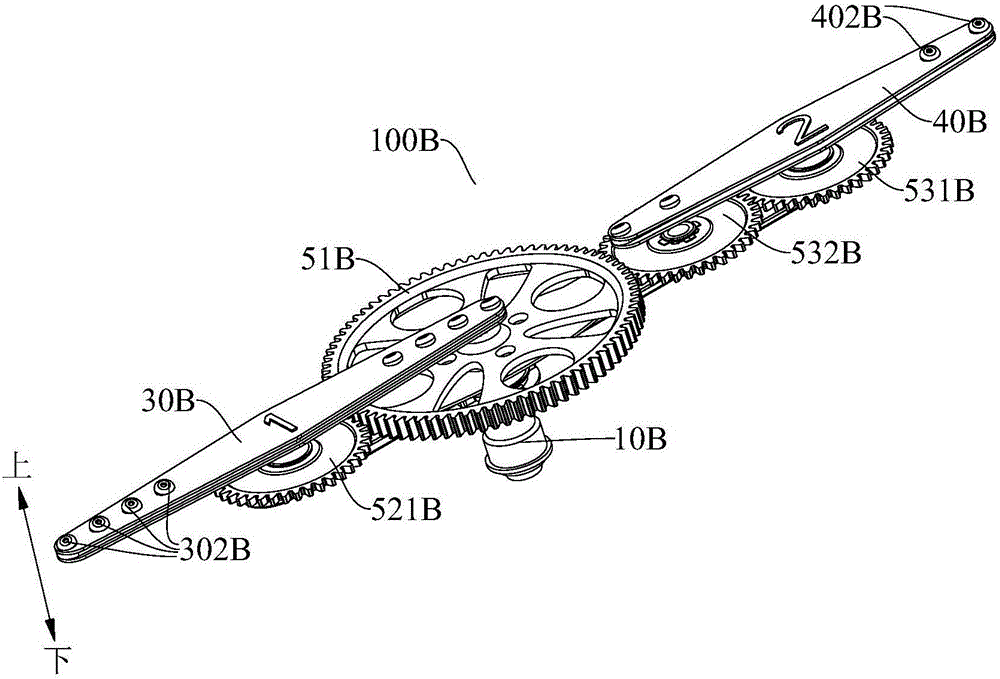

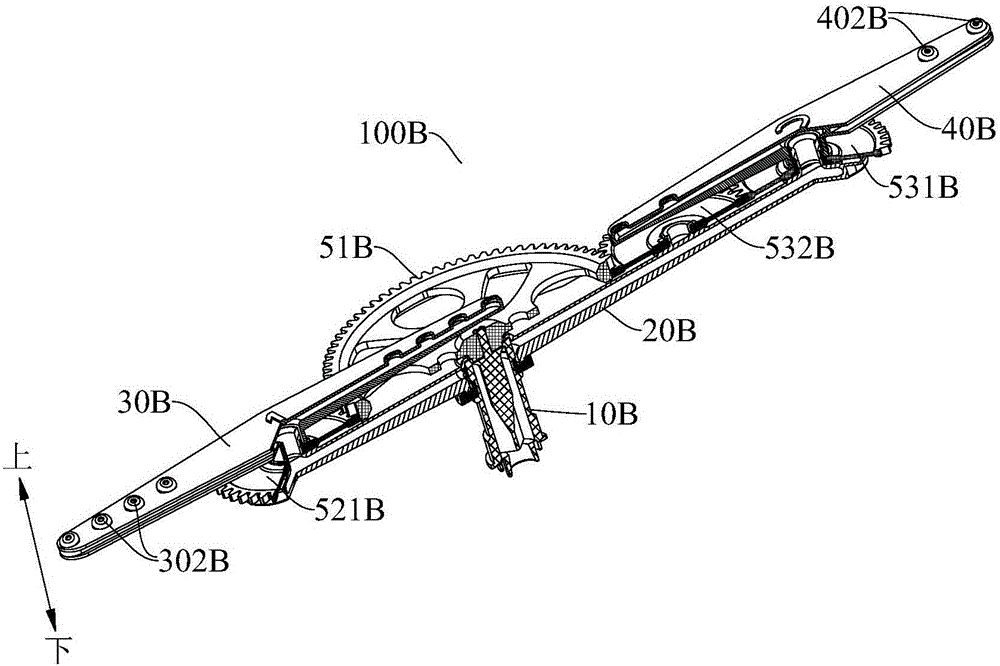

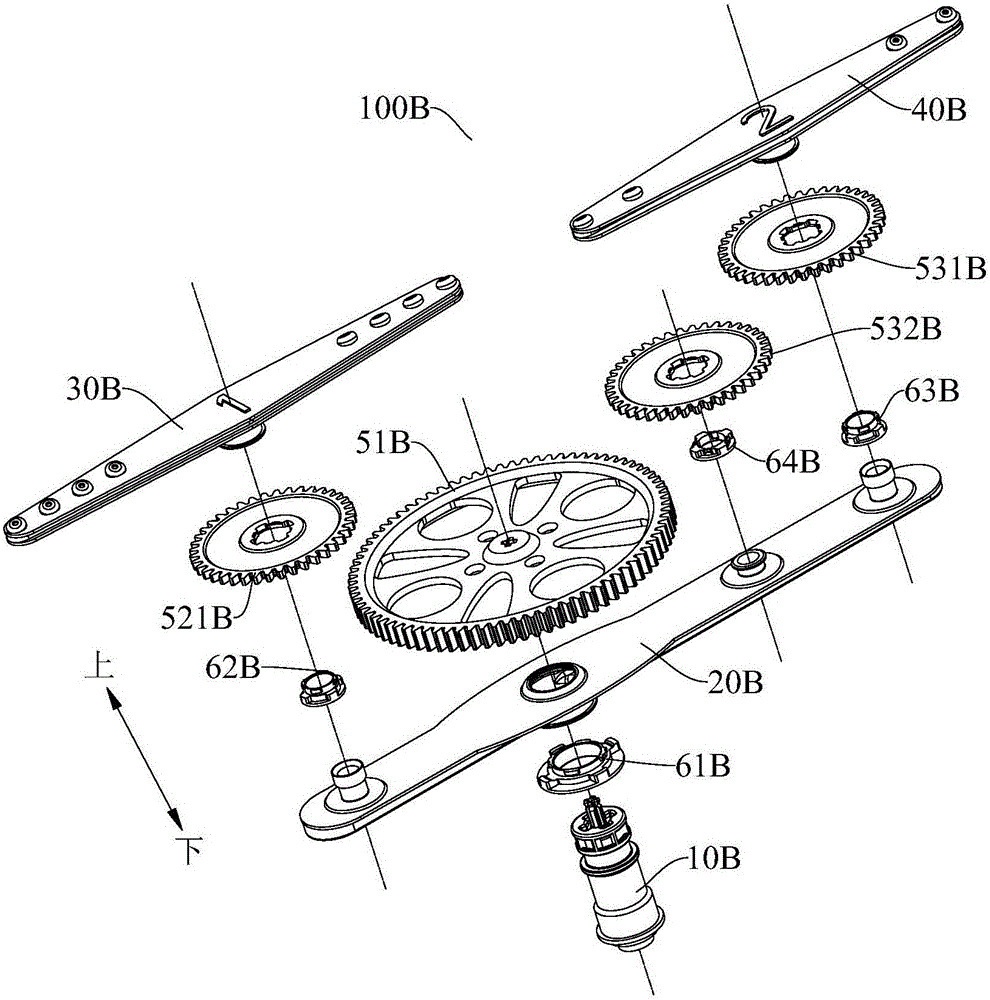

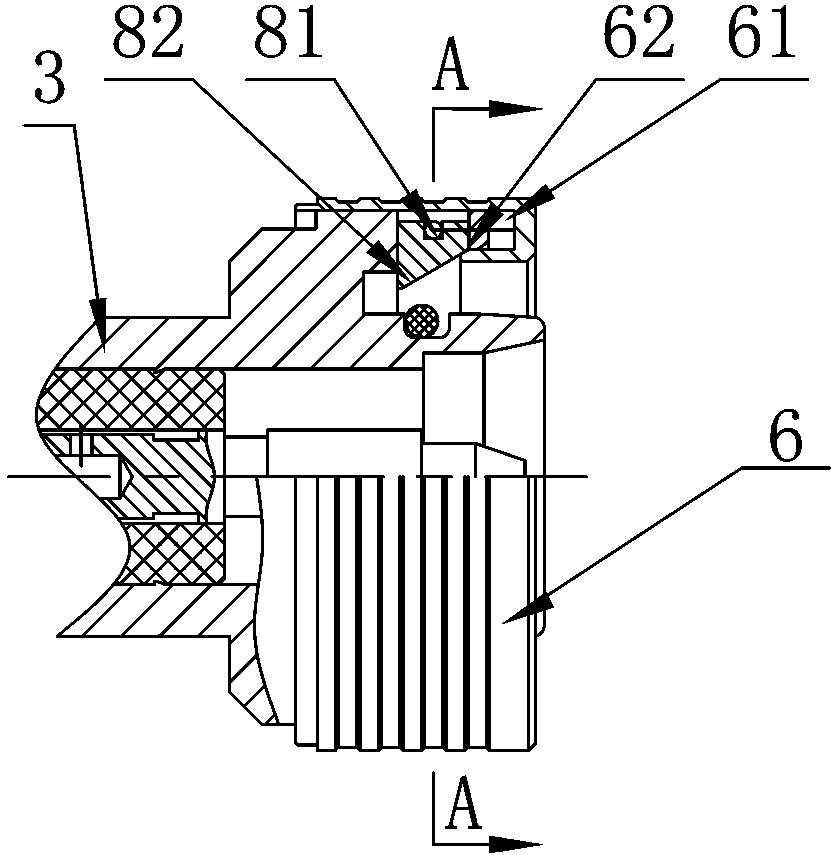

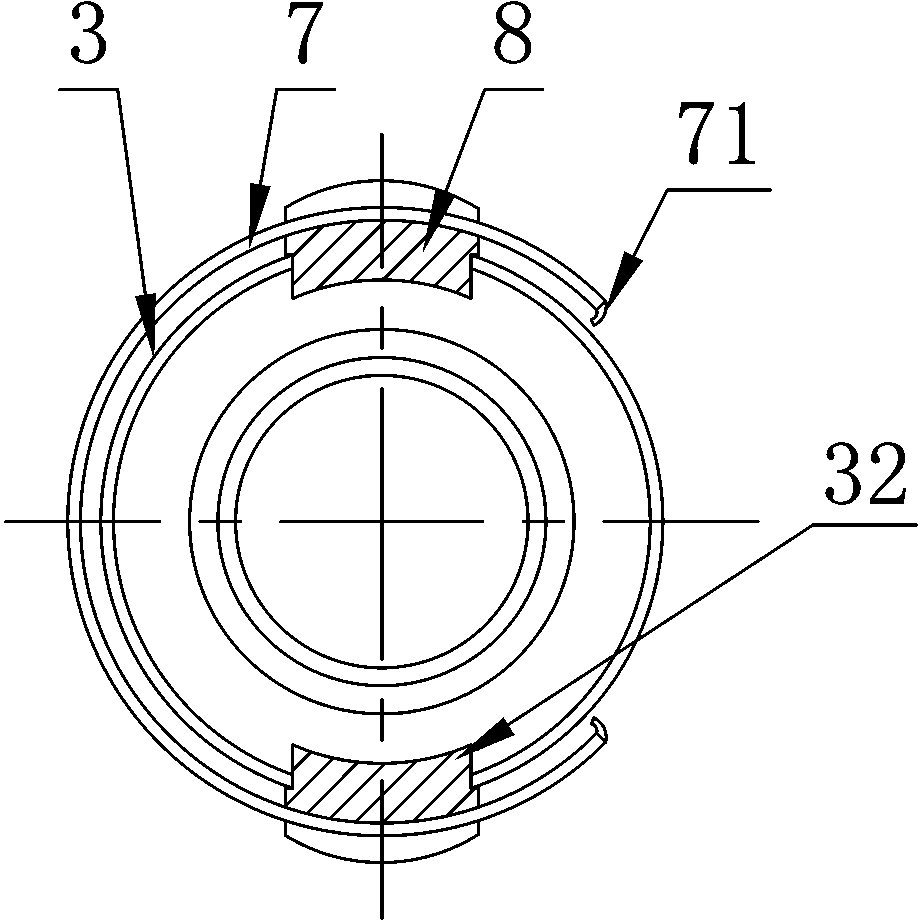

Spraying arm assembly for dish-washing machine and dish-washing machine provided with spraying arm assembly

ActiveCN105942951ASimple structureReliable connectionTableware washing/rinsing machine detailsGear wheelEngineering

The invention discloses a spraying arm assembly for a dish-washing machine and the dish-washing machine provided with the spraying arm assembly. The spraying arm assembly comprises a spraying arm base, a spraying arm main body, a first spraying arm subordinate body, a second spraying arm subordinate body and a gear assembly, wherein the spraying arm main body is arranged on the spraying arm base and is capable of rotating around the central axis of the spraying arm base; a first spraying arm subordinate body rotating shaft and first spraying holes are arranged on the first spraying arm subordinate body, and the first spraying arm subordinate body is capable of rotating around the central axis of the first spraying arm subordinate body rotating shaft; a second spraying arm subordinate body rotating shaft and second spraying holes are arranged on the second spraying arm subordinate body, and the second spraying arm subordinate body is capable of rotating around the central axis of the second spraying arm subordinate body rotating shaft; the second spraying arm subordinate body comprises two spraying arms which are symmetrically arranged; the movement tracks of the first spraying holes and the second spraying holes are superposed, so that a washing region, which is roughly square, is defined; and the gear assembly is capable of driving the spraying arm main body and the spraying arm subordinate bodies to rotate. According to the embodiment, the spraying arm assembly for the dish-washing machine disclosed by the invention can achieve the square washing region, and the spraying arm assembly is good in washing effect and good in user experience.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG +1

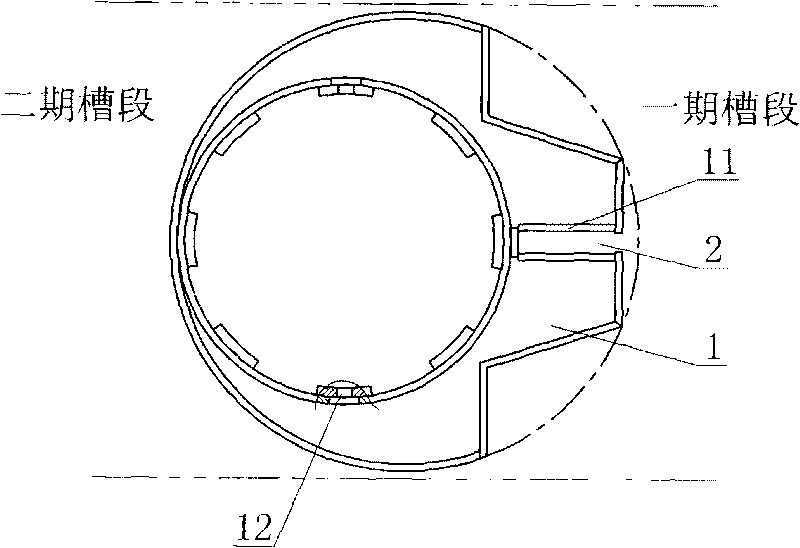

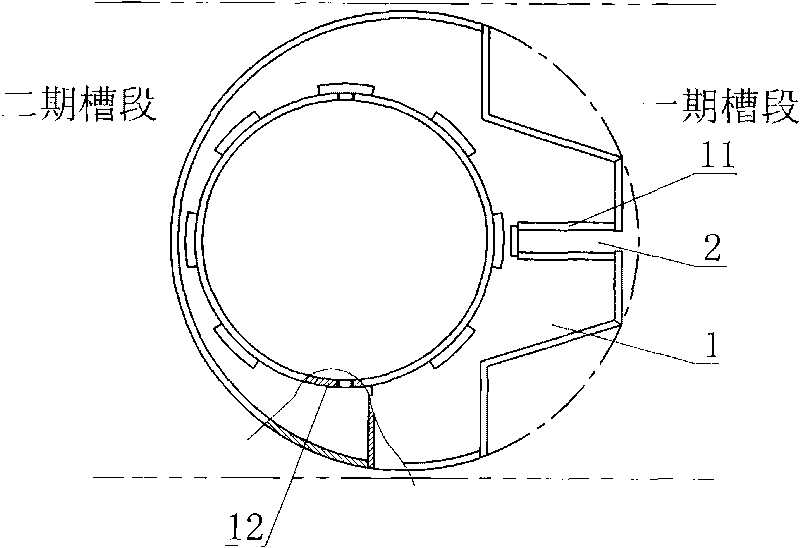

Diaphragm wall joint flexible water stop installing device and method

InactiveCN101705697AEasy to install and removeReliable connectionArtificial islandsUnderwater structuresSteel platesSlurry wall

The invention relates to a diaphragm wall joint flexible water stop installing device and a method. The installing device is a connector pipe structure made of steel plates or profile steel with width-thickness ratio being close to 1, at least one mounting groove capable of installing a rubber water stop is arranged on one side of the installing device in contact with concrete, and the width at an opening of the mounting groove is slightly smaller than that of a groove cavity. Since the width-thickness ratio of the connector pipe is close to 1, one side of the connector pipe in contact with soil is closely stuck with a soil layer, no phenomenon of flow around exists during the concrete pouring process, the subsequent construction of the groove section is greatly facilitated, and the installing device and the installing method have the advantages of the round pipe connector and overcome the defects of the I-shaped steel connector; the installation and the disassembly are convenient; the connection of the connector pipes is reliable, and the installing device and the installing method have sufficient rigidity, further meet the requirements for deformation resistance and connection and provide convenience for lifting the connector pipe; and the installed rubber water stop has good effect, does not drop off, can be completely retained on a concrete interface, and can well be adapted for the deformation caused by long-term dynamic load in the soft soil strata and prevent the seam from leaking due to misplacement.

Owner:GUANGDONG FOUND ENG GRP CO LTD +1

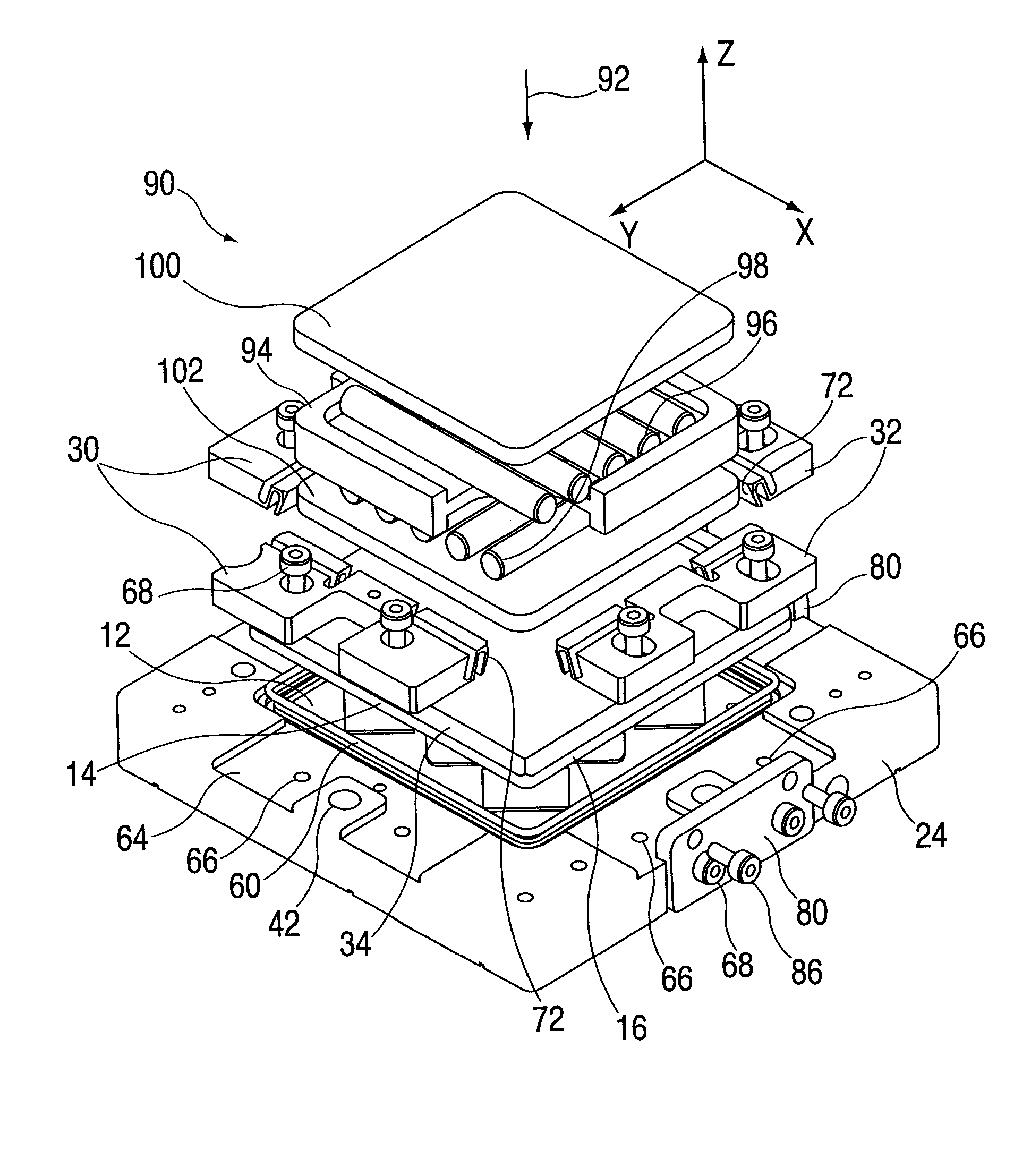

Method and apparatus to form a reworkable seal on an electronic module

InactiveUS20050037640A1Reliable connectionSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic modules

A system and method to form a reworkable compression seal between an electronic module and a cap are disclosed. The system and method include an electronic module having a tapered edge configured on at least a portion of the edge defining a perimeter of the electronic module and the cap configured with an opening to receive the electronic module therein. A compression seal is disposed with the cap and is configured to surround one or more chips or other electronic components on the electronic module to form a seal between the electronic module and the cap. A plurality of side loaders are operably coupled to the cap and aligned to receive the tapered edge on the electronic module. Each side loader is configured to engage the tapered edge and provide sufficient compressive force to the compression seal disposed between the electronic module and the cap.

Owner:INTELLECTUAL DISCOVERY INC

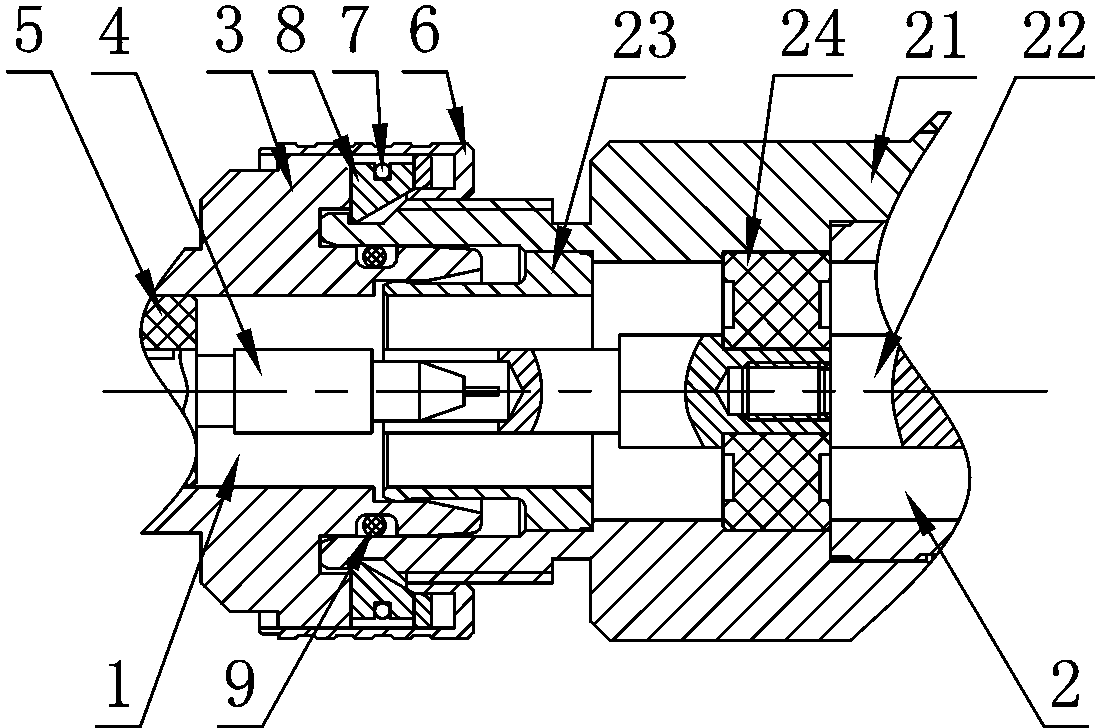

Carriage hinge device and streetcar

ActiveCN105329252AImprove reliabilityHigh torqueRailway couplingsTramway vehiclesEngineeringMechanical engineering

The invention provides a carriage hinge device and a streetcar. The carriage hinge device comprises a loading frame, a lower hinge assembly and an upper hinge assembly. The lower hinge assembly comprises a first oscillating bearing, a second oscillating bearing, a first connecting plate and a second connecting plate, and the connecting plates are hinged to the loading frame through the oscillating bearings. An upper installing shaft is arranged at the upper portion of the loading frame and provided with a rubber bearing. The upper hinge assembly comprises two first connecting rods, a second connecting rod, two first installing bases and two second installing bases; one ends of the first connecting rods are hinged to the loading frame through the rubber bearing, and the other ends of the first connecting rods are hinged to the first installing bases through a third oscillating bearing; the two ends of the second connecting rod are hinged between the two second installing bases through a fourth oscillating bearing, and one of the second installing bases is fixed to the upper portion of the loading frame. The reliability of the streetcar is improved.

Owner:青岛中车四方轨道车辆有限公司

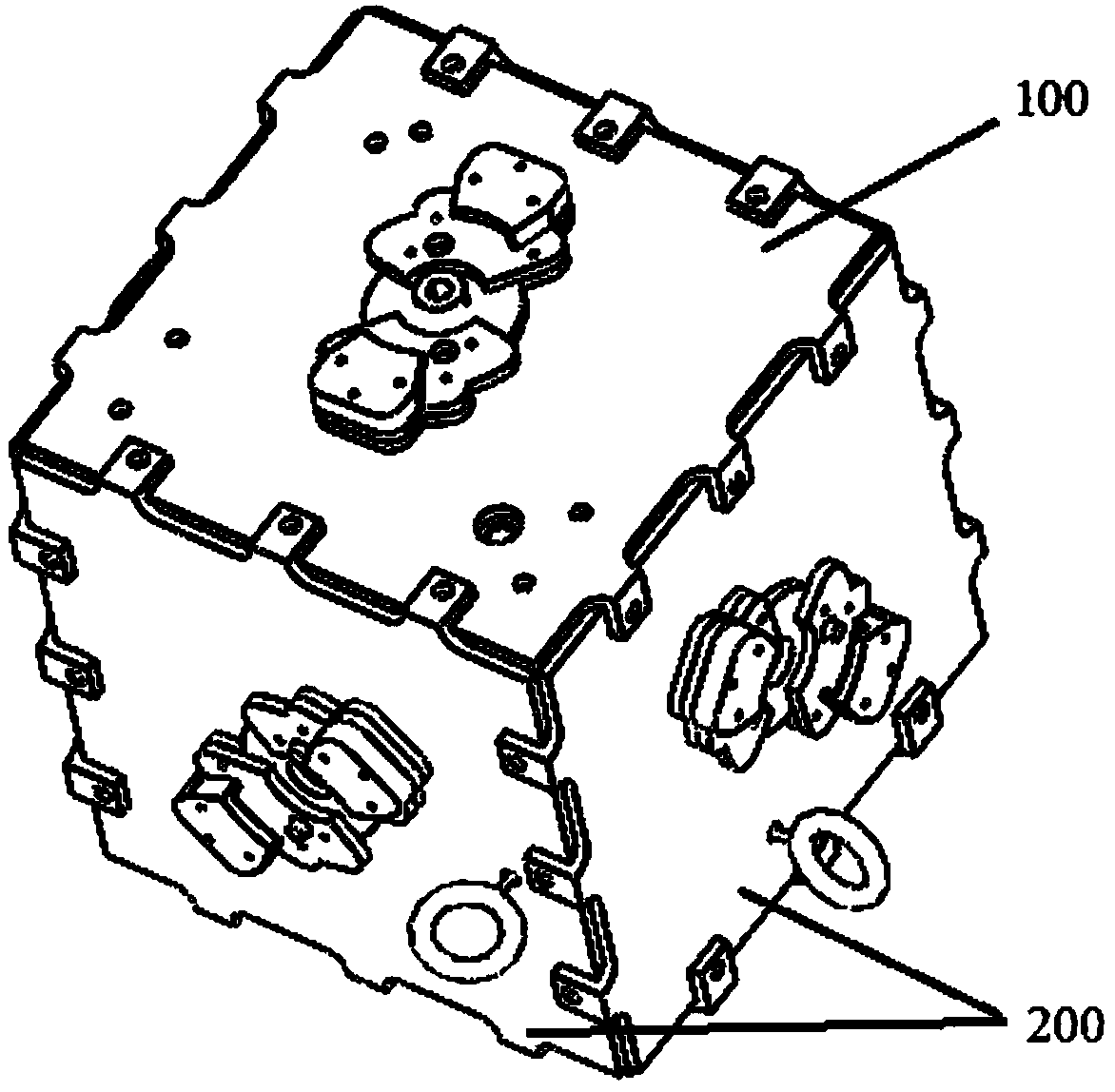

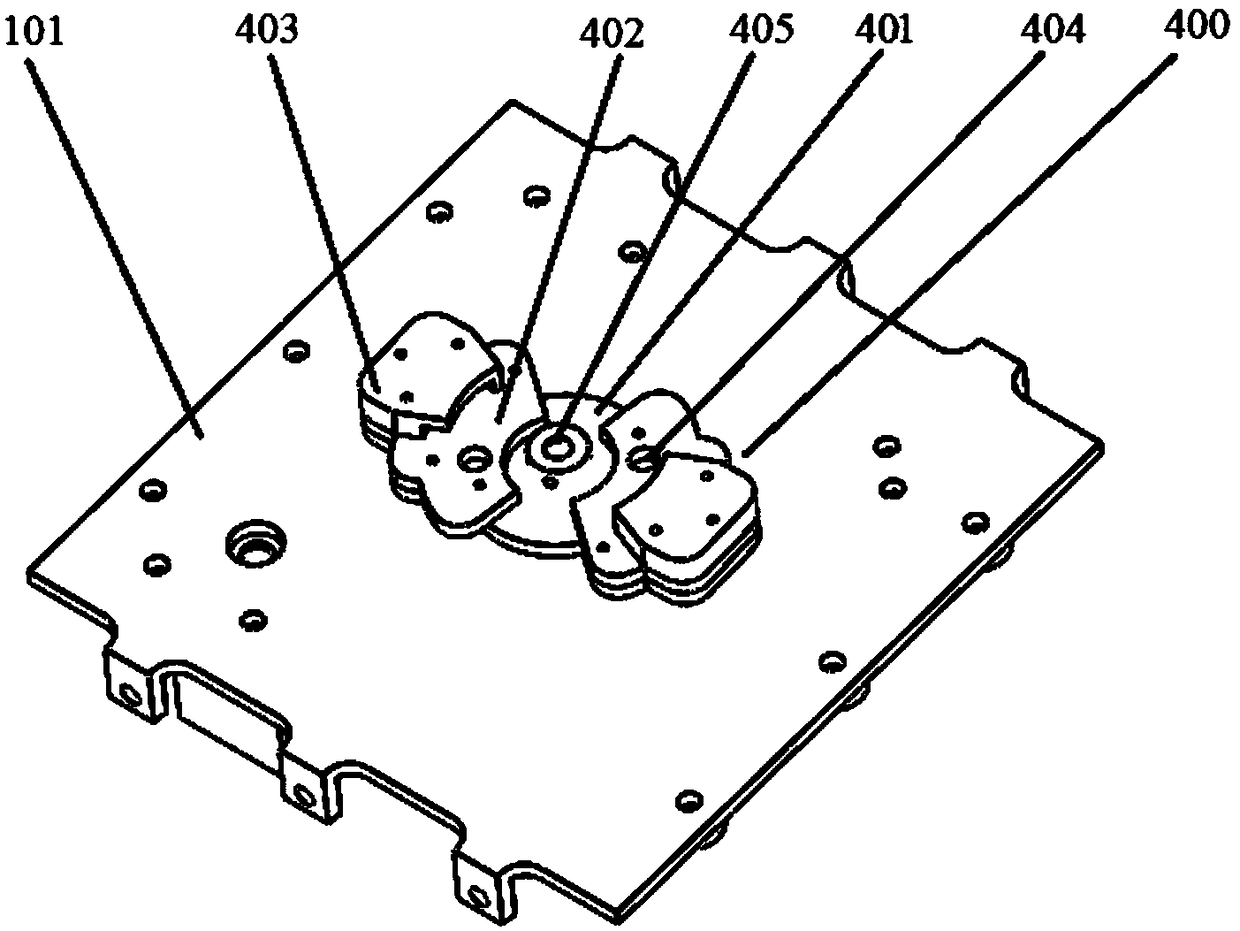

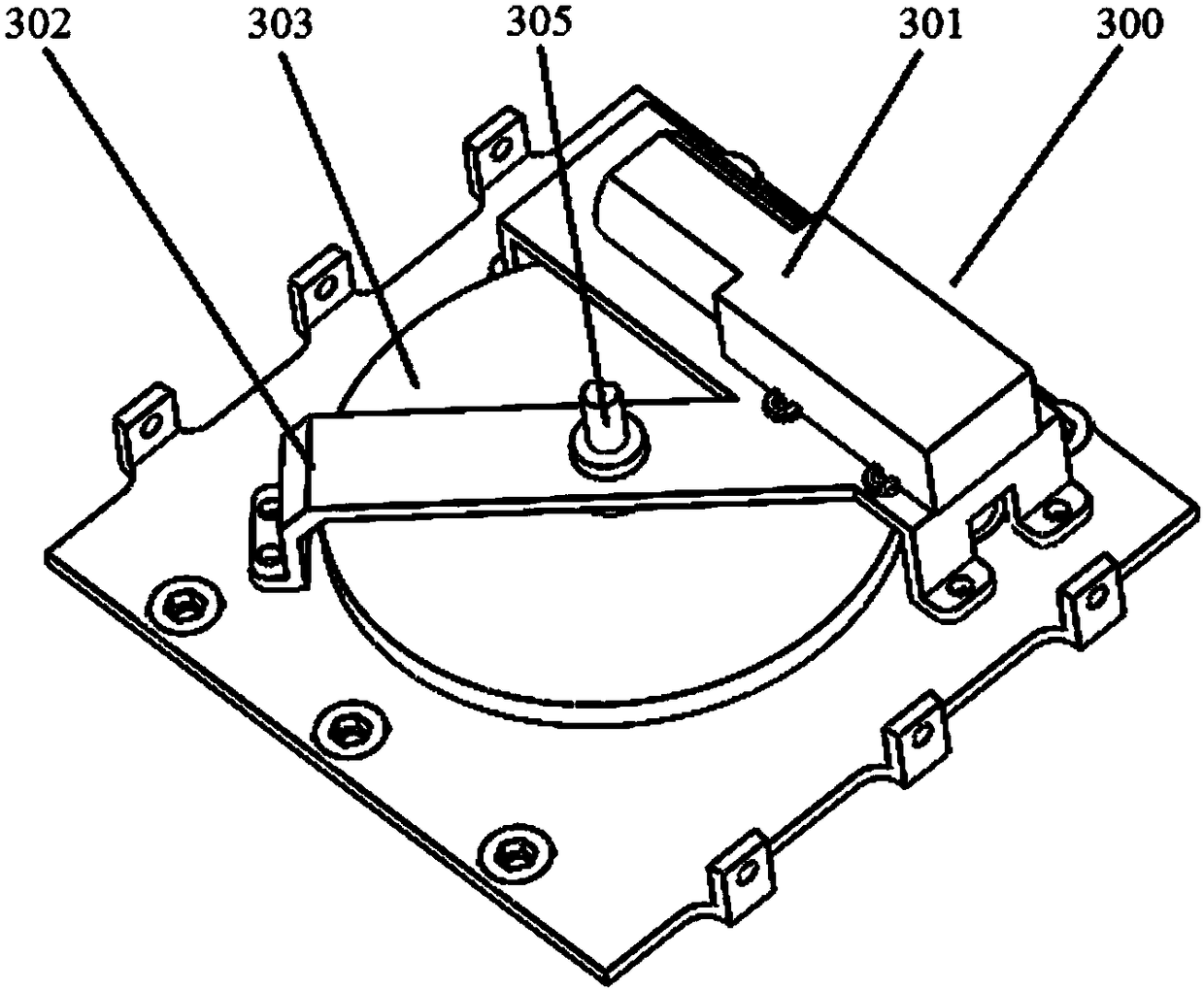

Cubic modular reconfigurable robot unit and robot

ActiveCN108527350ASimple structural designReliable connectionProgramme-controlled manipulatorModularityModular structure

The invention provides a cubic modular reconfigurable robot unit which comprises three driving surface modules and three driven surface modules. The driving surface modules comprise drive mechanisms and driving surface rotating fastener mechanisms, the driven surface modules comprise stop pin control mechanisms and driven surface rotating fastener mechanisms, and the unit has three degrees of freedom. The invention further provides a modular reconfigurable robot formed by assembling a plurality of units. The units can be assembled into the modular reconfigurable robot with different degrees offreedom and capable of meeting requirements of different application places by different topological connection modes, the units are conveniently disassembled and assembled, and the maintenance costof a modular robot system can be greatly reduced. The cubic modular reconfigurable robot unit with a module structure has the advantages of connection reliability, convenience in disassembly and assembly, movement flexibility and the like and can be widely applied and not limited to the fields of industry, aerospace, education, rescue and the like.

Owner:SHANGHAI MINGCHEN MOLDING TECH

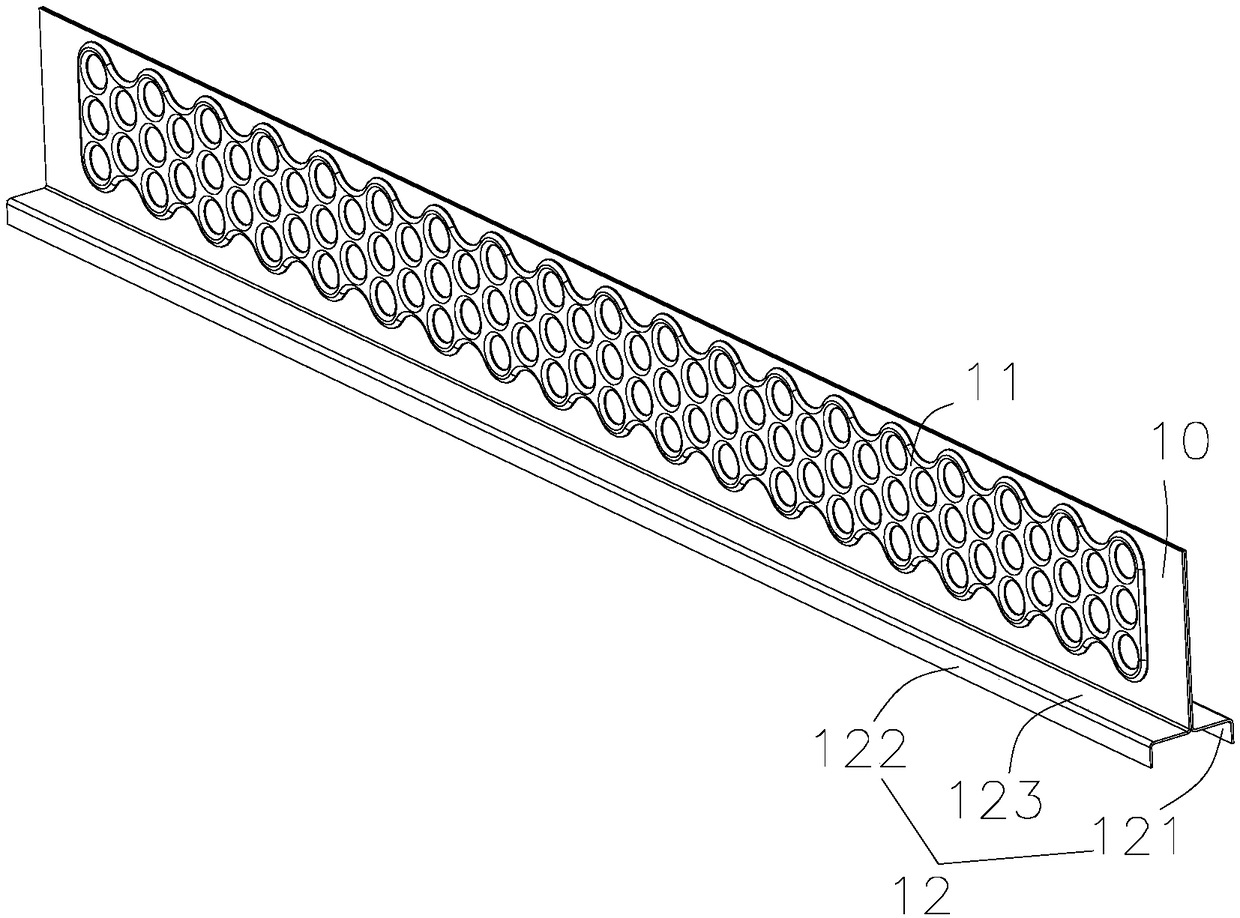

Cooling fin and cascaded caulking groove radiator

PendingCN109341401AEasy to operateFirmly assembledIndirect heat exchangersLaminated elementsHeat resistanceEngineering

The invention belongs to the technical field of radiators, and particularly relates to a cooling fin and a cascaded caulking groove radiator. The cooling fin comprises a fin body and a bent part. At least one side edge of the fin body is provided with the bent part. The bent part comprises a first bent section, a second bent section, and a connecting section for connecting the first bent section with the second bent section. The first bent section and the second bent section are mutually separated, and the first bent section and the second bent section are mutually parallel. The cooling fin and the cascaded caulking groove radiator have the beneficial effects that according to the cascaded caulking groove radiator, as a first bent section of one fin is arranged in a mounting groove, when asecond bent section of the other fin is extruded into the same mounting groove, the second bent section achieves the effect of a wedge, the second bent section, the inner wall of the mounting grooveand the first bent section are extruded tightly, the mounting operation is convenient, and assembly is reliable and not likely to loosen; and according to the cascaded caulking groove radiator, the contact area of the fins and a base is large, transfer heat resistance is small, and therefore better cooling performance is achieved.

Owner:常州恒创热管理有限公司

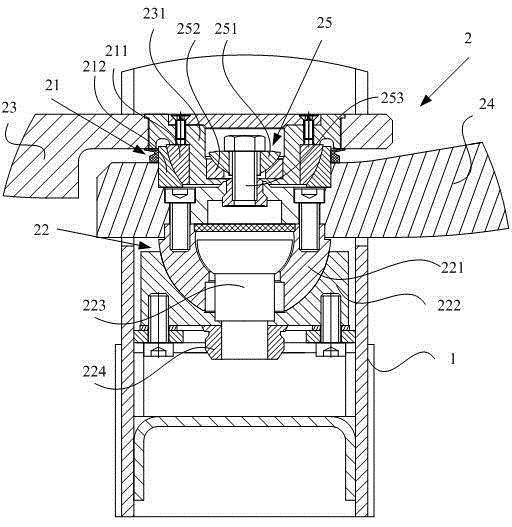

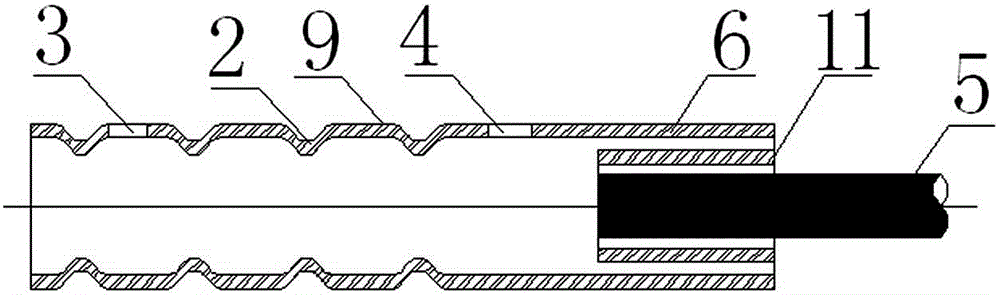

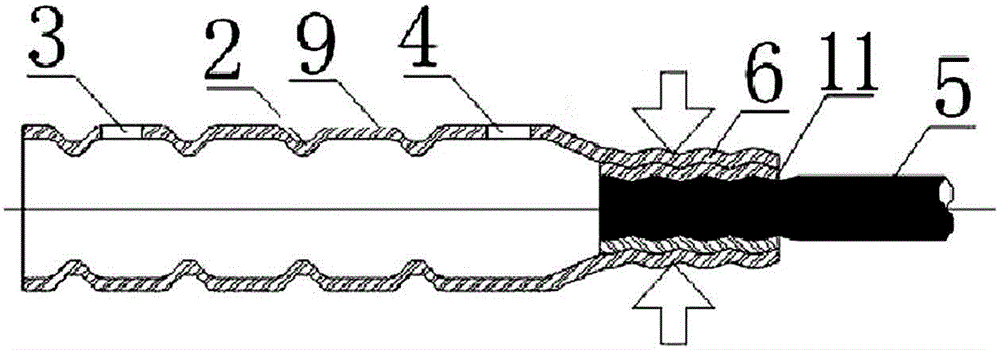

Contact pin, connection structure of contact pin and liquid cooling cable and charging gun

PendingCN107516775AReliable connectionReliable coolingElectrically conductive connectionsElectric vehicleElectrical and Electronics engineering

The invention provides a contact pin, a connection structure of the contact pin and a liquid cooling cable and a charging gun with the contact pin. The contact pin is used for connecting the liquid cooling cable to the charging gun and comprises a contact pin body, one end of the contact pin body is axially and sequentially provided with a first storage groove and a second storage groove, the first storage groove is communicated with second storage groove, and the diameter of the first storage groove is larger than that of the second storage groove. Reliability and stability in connection between the contact pin and the liquid cooling cable can be guaranteed, and heat generated in charging operation of the contact pin can be quickly taken away through the liquid cooling cable, so that the contact pin can be cooled reliably, and current carrying capacity of the charging gun can be improved to realize high-power charging of electric devices (such as electric vehicles).

Owner:SHENZHEN WOER NEW ENERGY ELECTRICAL TECH CO LTD +2

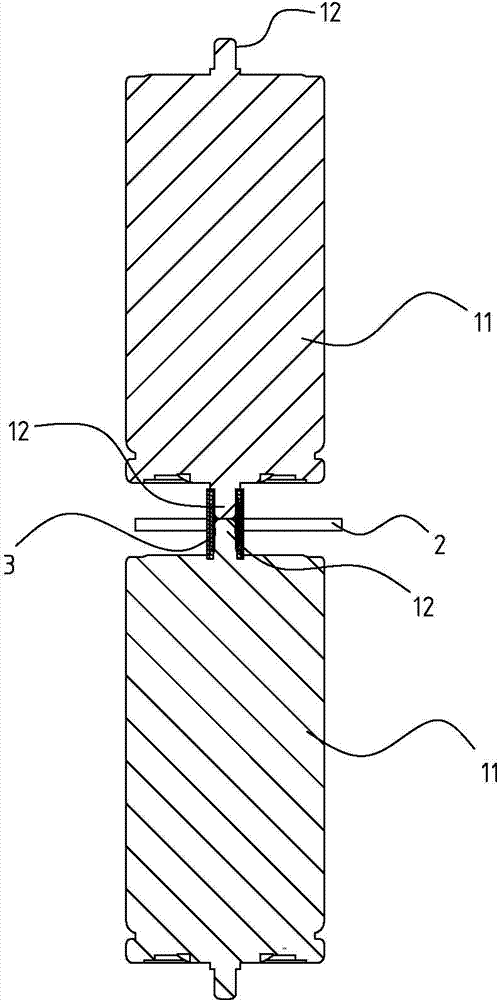

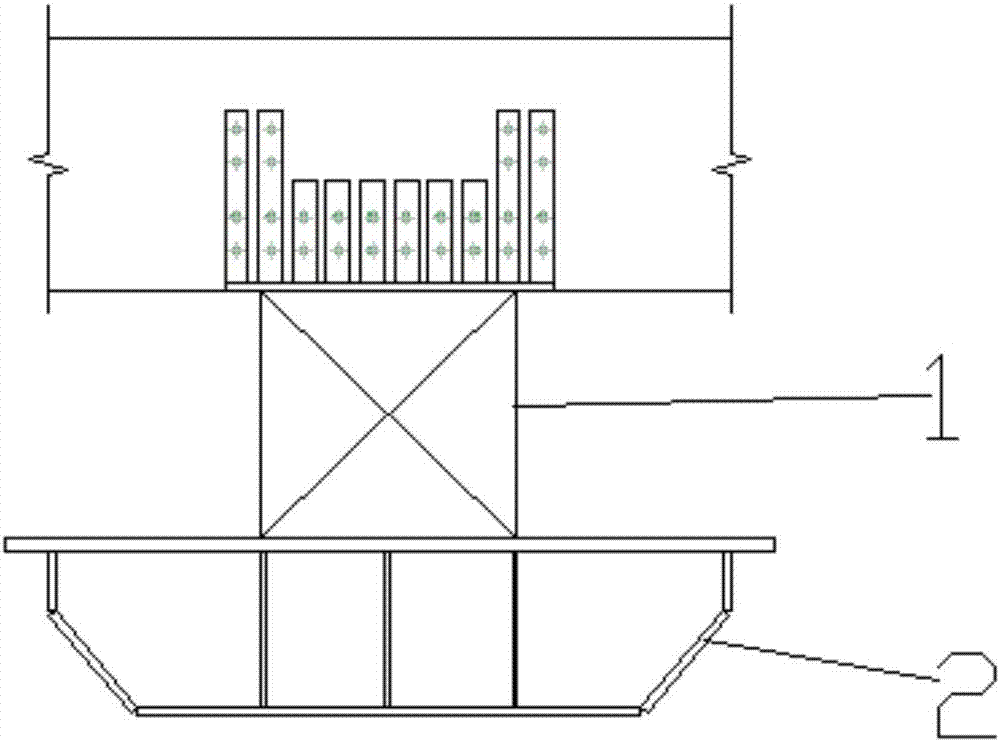

Energy-dissipation shock-absorption damper member and construction method thereof

PendingCN106894667AReliable connectionEasy to operateProtective buildings/sheltersBuilding material handlingReinforced concreteBuilding construction

The invention discloses an energy-dissipation shock-absorption damper member which comprises a main concrete frame structure and a shock absorption device. The main concrete frame structure comprises a frame beam, a frame column and a floor, the frame beam, the frame column and the floor are fixedly connected through reinforced concrete thereamong, embedded parts are arranged at the bottom of the frame column, two ends of the lower structure beam of the frame beam and the middle of the upper structure beam of the frame beam, and the shock absorption device is connected with the embedded parts; the shock absorption device comprises a damper module, a node module and a support module. The invention further provides a construction method of the above energy-dissipation shock-absorption damper member. By the above mode, the purpose of efficient energy dissipation and shock absorption can be achieved.

Owner:HEFEI CONSTR ENG GRP

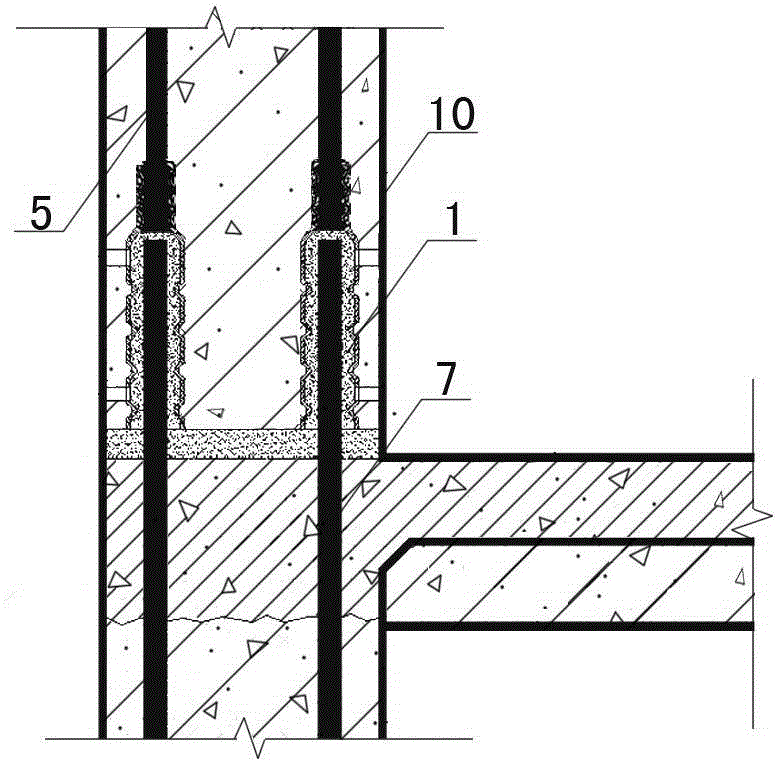

Extruded semi-grouting reinforced sleeve with built-in casing, connective structure, and construction method

InactiveCN105178516AReduce workloadImprove work efficiencyBuilding reinforcementsBuilding material handlingConcrete beamsEngineering

Disclosed are an extruded semi-grouting reinforced sleeve with a built-in casing, a connective structure, and a construction method. The sleeve is a hot-rolled seamless steel tube. The wall of the sleeve is provided with a grout inlet and a grout outlet. The sleeve is provided with circular inner projections. One end of the sleeve is an extruded end, and the rest is a grout-anchoring end. The built-in casing is arranged inside the extruded end. The inner diameter of the built-in casing is equal to the outer diameter of a rebar to be connected, and less than the inner diameter of the grout-anchoring end. All of the grout inlet, the grout outlet and the circular inner projections are located at the grout-anchoring end. By the use of the built-in casing, the deformation of the extruded end is lessened to avoid the extruded end being damaged during crimping; the sleeve is widely applicable to the rebar connection of prefabricated concrete columns in multi-storey and high-rise prefabricated assembled concrete frame structures, shear wall structures or frame shear wall structures, as well as the connection of horizontal rebars in prefabricated concrete beams, the connection of rebars in prefabricated concrete shear walls and the connection of rebars in existing reinforcement projects.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

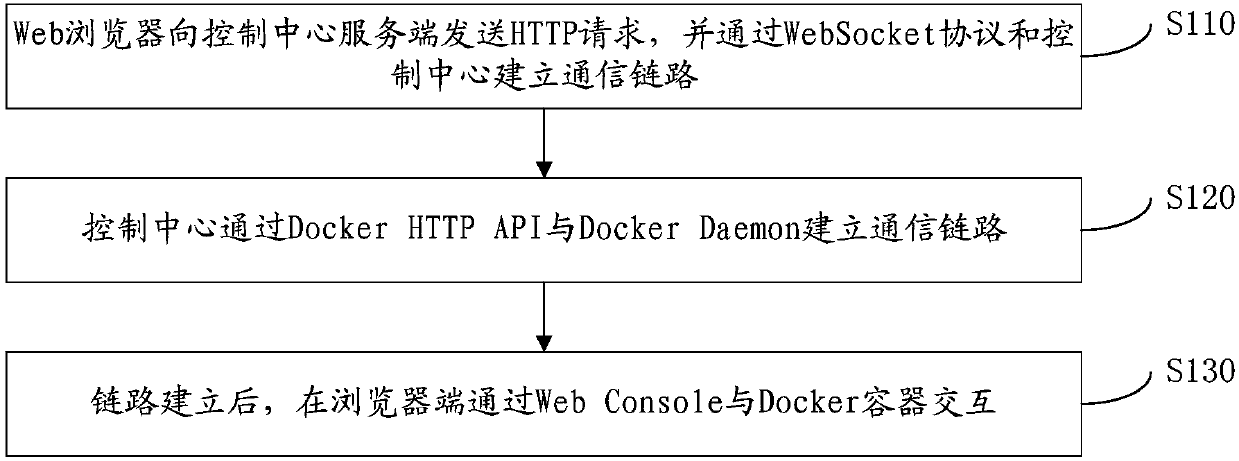

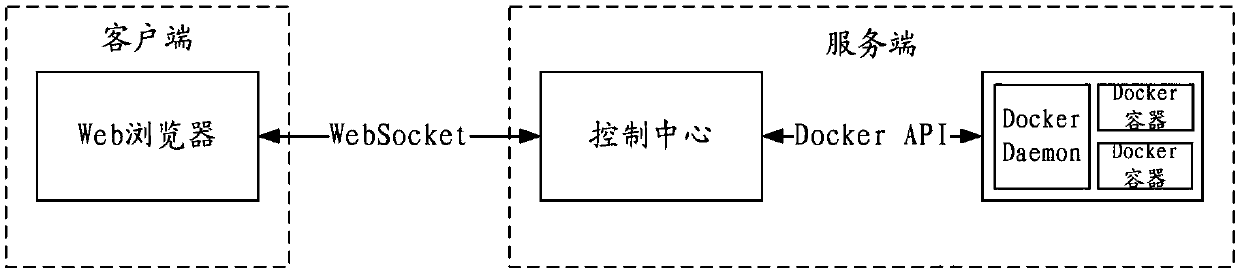

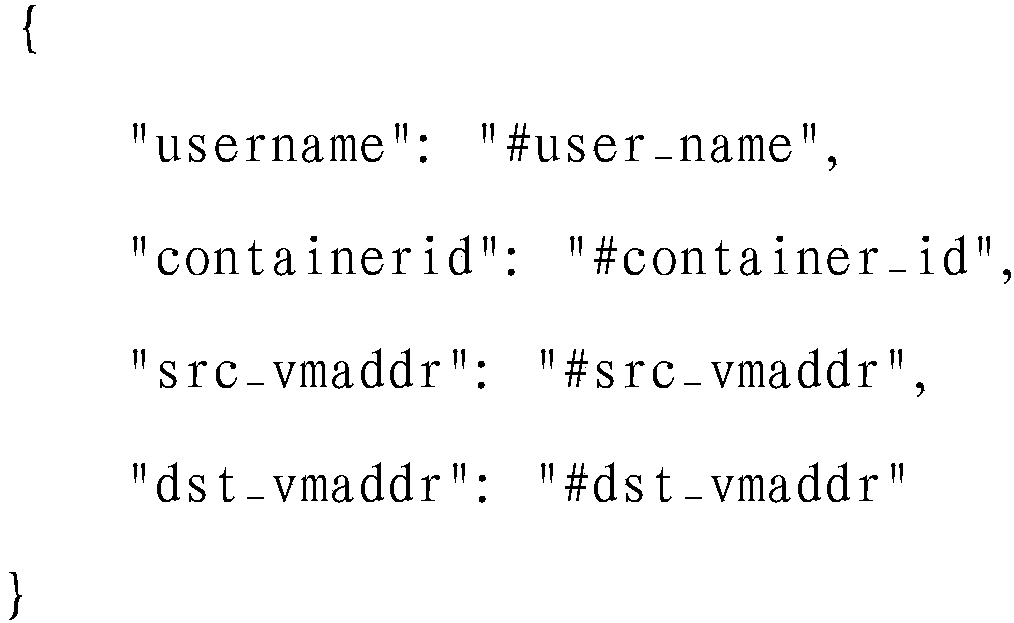

Method for entering Docker container through Web browser for operation

PendingCN107608763AEasy to operateReduce operating costsTransmissionSoftware simulation/interpretation/emulationContainerizationWeb browser

The invention relates to a method for entering a Docker container through a Web browser for operation. The method comprises the steps that the Web browser sends an HTTP request to a control center server side, and a communication link is built through a WebSocket protocol and a control center; the control center builds a communication link through a Docker HTTP API and a Docker Daemon; after the link is built, and interaction with the Docker container through the Web Console at a browser side is achieved. On a containerization service platform, operators and developers conveniently and remotely enter the container through the browser for operation, and the connection reliability is high.

Owner:ZHENGZHOU SEANET TECH CO LTD

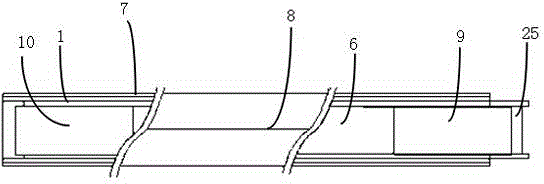

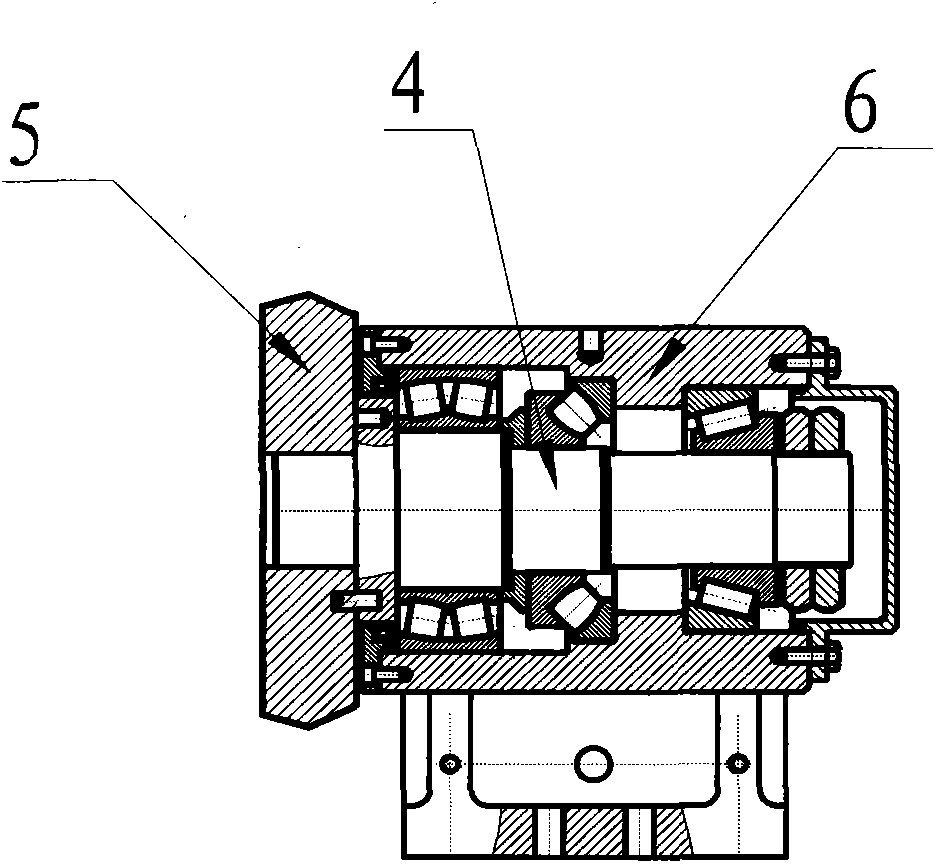

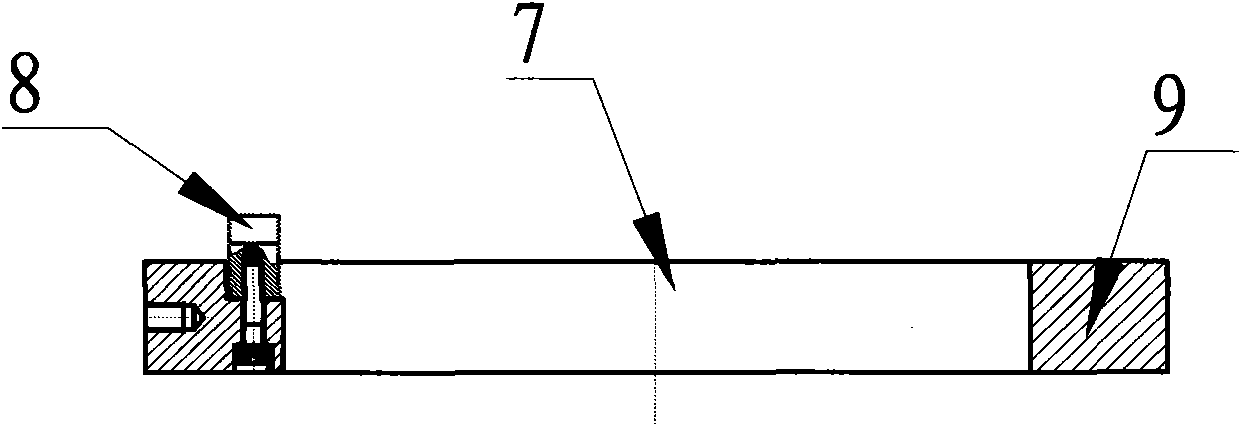

Device and method for spinning cylindrical titanium alloy part

The invention relates to a device and method for spinning a cylindrical titanium alloy part. The device comprises a spinning mould 1, a spinning wheel device 4, a fluted disc device 7 and a spinning lathe. The spinning mould 1 is mainly used for clamping the cylindrical spinning part 10 and limiting the flow of materials in the process of metal spinning. The fluted disc device 7 is used for fixing the cylindrical part in the process of metal spinning to prevent relative rotation between the cylindrical spinning part 10 and the spinning mould 1. The spinning wheel device 4 is used for applying spinning force to the cylindrical spinning part 10 in the process of metal spinning, so that plastic deformation is carried out on a titanium alloy spinning workblank, and the required shape and the required size of the cylindrical spinning part 10 are achieved. According to a method for manufacturing the cylindrical spinning part 10, before the spinning process, the spinning mould 1 and the cylindrical spinning part 10 are heated up to a certain temperature, the process of mould filling is completed, then spinning operation is carried out, after the spinning mould 1 and the cylindrical spinning part 10 are cooled, detaching is performed, and finally the high-precision high-quality cylindrical spinning part 10 is obtained.

Owner:INNER MONGOLIA AEROSPACE HONGGANG MACHINERY

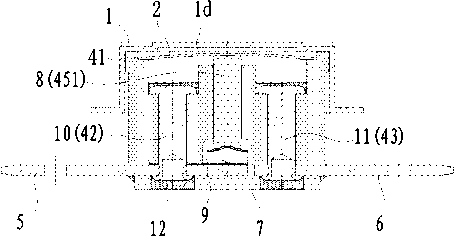

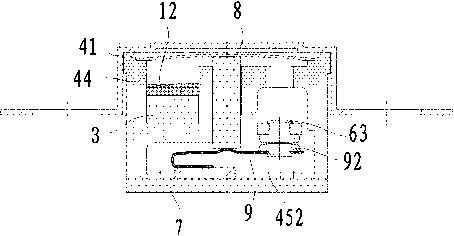

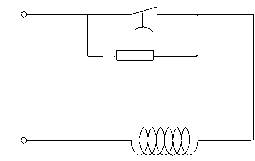

Power off reset snap action thermostat

ActiveCN103000446AReliable connectionSimple structureThermal switch detailsEngineeringPositive temperature

Owner:FOSHAN TIANPENG THERMOSTATS

Connector with quick unlocking structure

InactiveCN104037541ASimple structureReliable connectionCoupling device detailsStanding waveEngineering

The invention discloses a connector with a quick unlocking structure. The connector with the quick unlocking structure comprises a plug provided with an unlocking sleeve and a socket provided with a lock sleeve and is characterized in that sliding chutes are symmetrically arranged on a plug outer conductor in the radial direction; the unlocking sleeve is provided with an groove with an unlocking surface; sliding blocks are arc-shaped wedge blocks provided with circular grooves and are arranged on the sliding chutes of the plug outer conductor through a clamping ring in a sliding connection mode; the lock sleeve is provided with a locking face and a clamping groove; under the axial thrust, the lock sleeve of the socket pushes the sliding blocks to slide outwards in the radial direction; when the plug and the socket are in butt joint with each other in position, the sliding blocks enter the clamping groove under the elastic force of the clamping ring and are locked; in the unlocking process, the unlocking sleeve is pulled to enable the sliding blocks to be separated from the clamping groove, so that quick unlocking of the plug and the socket is achieved. Compared with the prior art, the connector with the quick unlocking structure has the advantages that the connector is simple in structure and reliable in connection, quick unlocking and passive intermodulation performance of the connector can be improved, voltage standing waves are greatly reduced, and the connector is convenient to install and especially suitable for high-power signal transmission.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

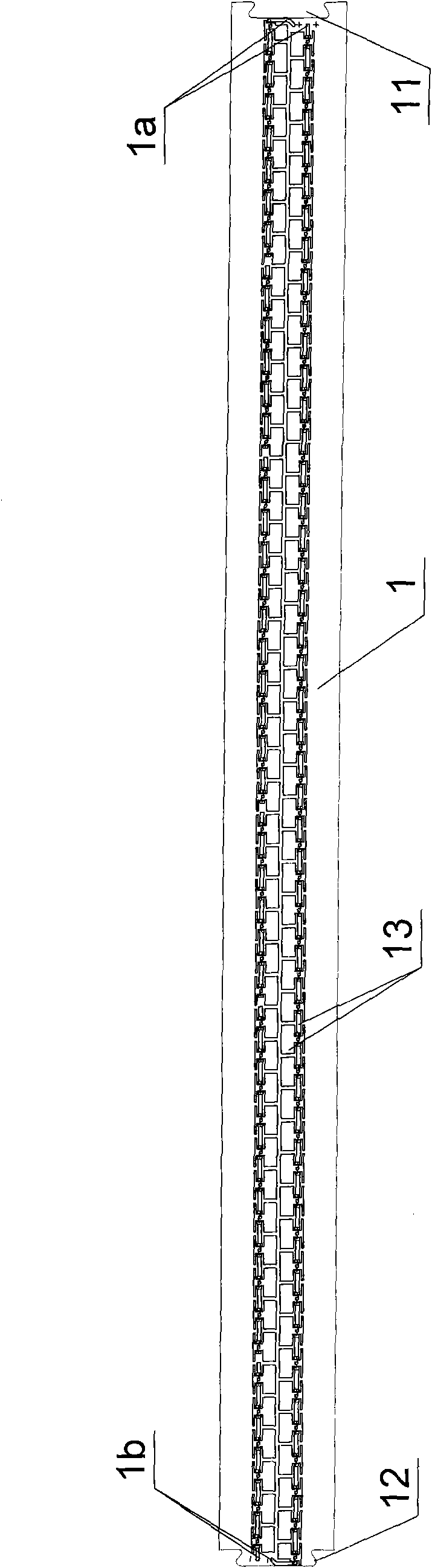

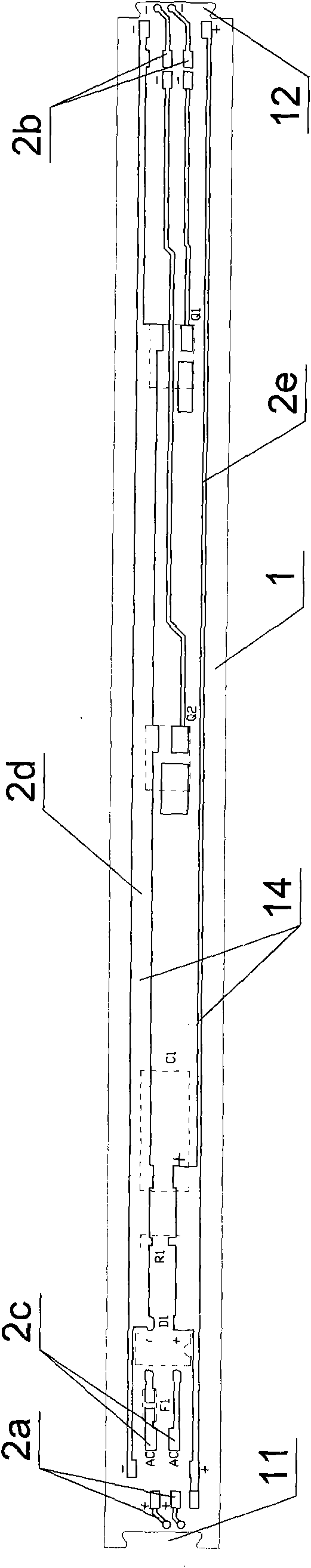

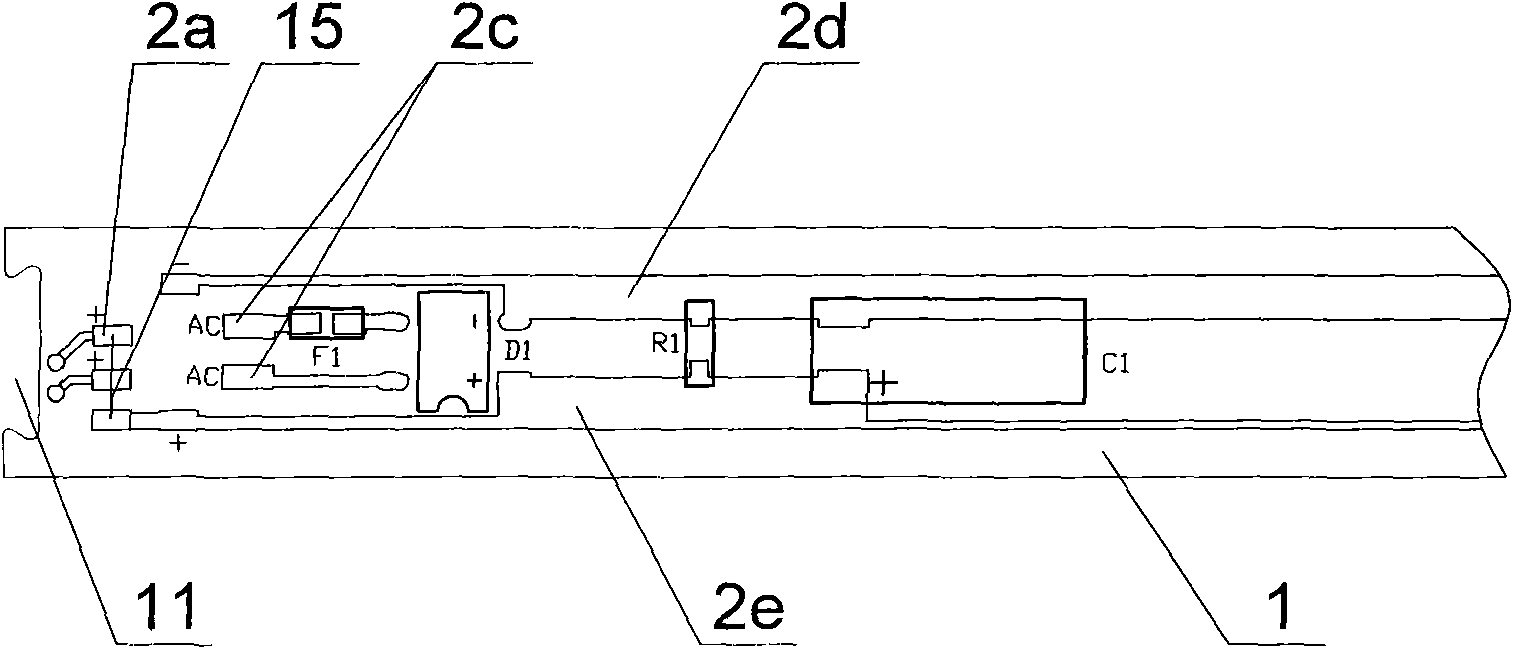

LED lamp circuit board for integrating light source and power supply and manufacture method thereof

InactiveCN101793356AAvoid excessive lengthReliable connectionPoint-like light sourceElectric circuit arrangementsElectricityPrinted circuit board

The invention discloses an LED lamp circuit board for integrating a light source and a power supply with the advantages of reliable connection, fast and simple production, high production efficiency and high product qualification ratio and a manufacture method thereof. The LED lamp circuit board comprises at least two module unit boards (1), wherein every two module unit boards (1) are fixedly connection, a metal layer (13) used for fixing LED chips (2) and forming electric connection between every two LED chips (2) is arranged on the front surface of each module unit board (1), a power line (14) which is welded with a circuit element to form a circuit is arranged on the back surface of each module unit board (1), and every two power lines (14) of two connected module unit boards (1) are electrically connected through a jumper wire phase. The manufacture method comprises the following steps of: manufacturing prefabricated circuit boards into a connected circuit board, patching the whole connected circuit board, carrying out wire bond, coating fluorescent powder and silica gel, welding the circuit element after curing, cutting each module unit board (1) into independent parts, connecting the independent parts through connecting parts and electrically connecting the power lines (14) through jumper wires. The invention can be applied to a light emitting diode illumination field.

Owner:NANKER GUANGZHOU SEMICON MFG

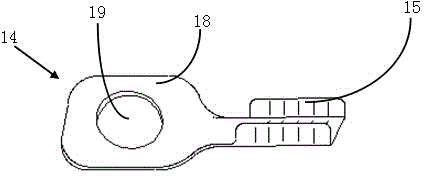

Terminal and connector

InactiveUS20060172585A1Reliable connectionImprove reliabilityCoupling contact membersUnstripped conductor connection apparatusEngineeringElectrical and Electronics engineering

A connector includes a plurality of terminals and a connector housing, receiving the terminals. Each of the terminals includes a terminal connecting portion, having a tubular shape, and receiving a mating terminal, a wire press-contacting portion including a press-contacting blade for press-contacting a wire, and the press-contacting blade having a blade width larger than a width of the terminal connecting portion, and an interconnecting portion, connecting the terminal connection portion and a wire press-contacting portion. A press-contacting direction in which the wire is press-contacted with the wire press-contacting portion is parallel to a terminal fitting direction of the terminal connecting portion. The terminal connecting portions of the terminals are received in the connector housing in parallel so that the press-contacting blades are arranged in a staggered manner. Also, a connector includes a housing and a terminal received in the housing. The terminal includes a wire connecting portion which connects a wire and an extension portion which is extended from the wire connecting portion. The extension portion has a conductive portion which is formed in a direction intersecting a direction in which the terminal is inserted into the housing. The housing has an exposure hole through which at least part of the conductive portion is exposed to an exterior.

Owner:YAZAKI CORP

Slow descending and damping device and slow descending and damping method for toilet

The invention relates to a slow descending and damping device and a slow descending and damping method for a toilet. According to the structure of the slow descending and damping device and the slow descending and damping method, a rotating shaft can perform opening rotation and covering rotation relative to an casing; when the rotating shaft performs the opening rotation relative to the casing, a damping control generation unit actions, an opening oil channel is formed between a first opening chamber and a covering chamber and a second opening chamber and a second covering chamber; when the rotating shaft performs the covering rotation relative to the casing, the damping control generation unit actions, an covering oil channel is formed between the first opening chamber and the covering chamber and the second opening chamber and the second covering chamber; the whole of the damping control generating unit is an independent body and the opening oil circuit and the covering oil circuit can be respectively formed through actions of the damping control generation unit.

Owner:赵励平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com