Biological sensor, manufacturing method and detection method thereof

A technology of biosensor and manufacturing method, which is applied in the field of flexible full-print nano-carbon material biosensor, can solve the problems of complex processing technology, difficult mass production, and large signal noise, and achieve high sensitivity, good stability, and reliable connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

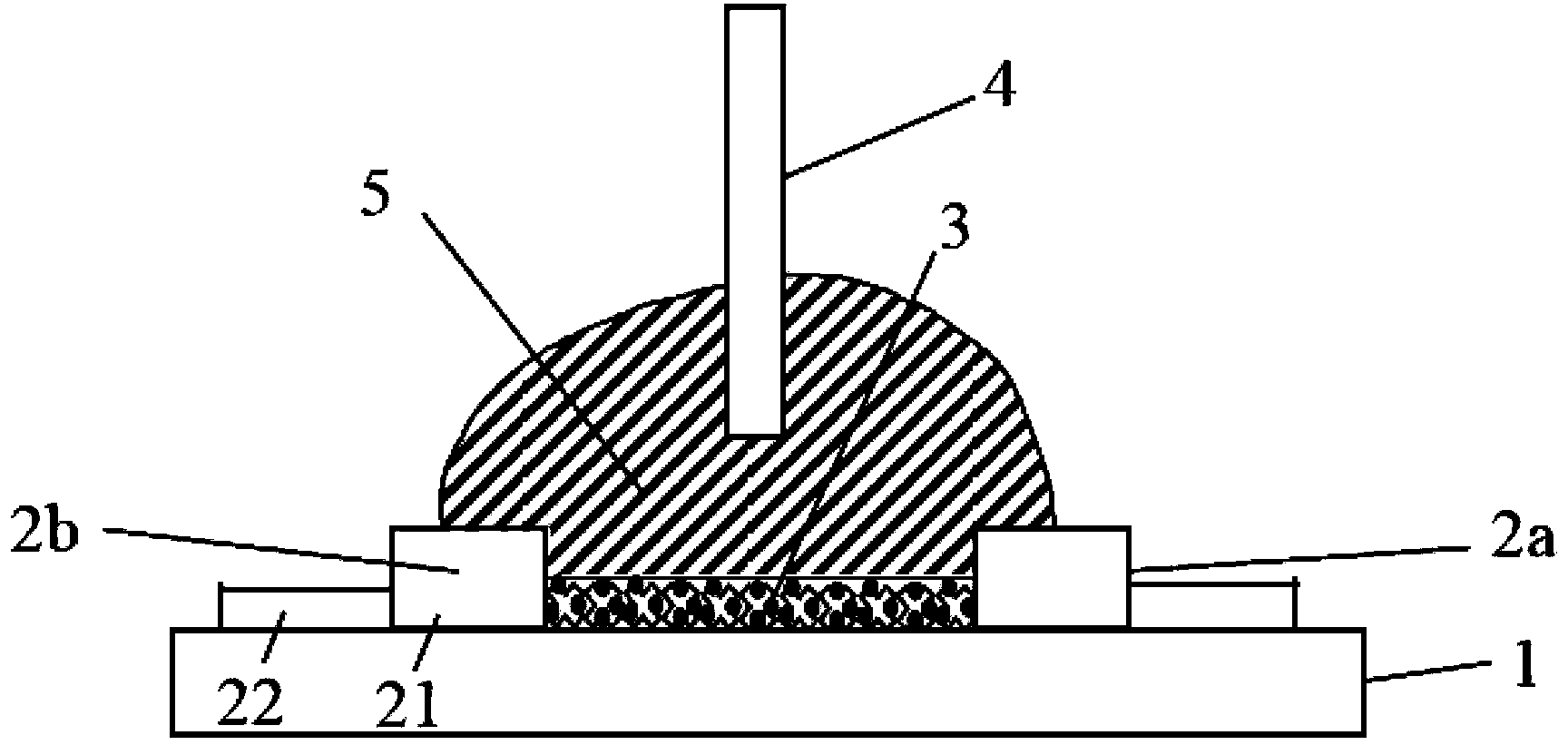

[0043] ginseng figure 1 As shown, the biosensor of this embodiment includes: a flexible substrate 1 , and a source 2 a and a drain 2 b arranged in parallel on the flexible substrate 1 .

[0044] Both the source electrode 2 a and the drain electrode 2 b include a parallel portion 21 and an extension portion 22 for electrically connecting with an external circuit (not shown in the figure).

[0045] The biosensor also includes a functionalized graphene layer 3 arranged between the source electrode 2a and the drain electrode 2b, and the functionalized graphene layer 3 is respectively connected to the parallel portion 21 of the source electrode 2a and the parallel portion 21 of the drain electrode 2b; the functionalized graphene layer The surface of layer 3 is modified with specific receptors.

[0046] The biosensor also includes a floating gate 4 , one end of which is suspended above the source 2 a and the drain 2 b without contacting the graphene layer 3 .

[0047] Below, combine...

Embodiment 2

[0062] The structure of the flexible all-printed biosensor of this embodiment is the same as that of Embodiment 1. The difference is that the flexible substrate is polyethylene terephthalate PET, the source-drain distance is 200um, the silver paste concentration is 0.08mg / mL, and the nano-carbon material used is 0.05mg / mL single-walled carbon nanotubes, called The mass of 1-pyrenebutyric acid was 120 mg, and the blocking reagent was 5% bovine serum albumin BSA.

[0063] Moreover, in this embodiment, a solution of functionalized single-walled carbon nanotubes with a concentration of 0.05 mg / mL is printed between the source electrode and the drain electrode by means of aerosol printing. Thereafter, the chip was placed in a mixed solution of 4 mM (1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride) EDC and 10 mM N-hydroxysuccinimide NHS for 1 h, and activated graphite Functionalized carboxyl groups adsorbed on alkenes.

[0064] The remaining steps can be shown in Examp...

Embodiment 3

[0066] The structure of the graphene ion-sensitive sensor of this embodiment is the same as that of Embodiment 1. The difference is polyethylene PE, the distance between source and drain is 500um, the concentration of silver paste is 0.06mg / mL, the nano-carbon material used is 0.02mg / mL single-walled carbon nanotubes, and the mass of 1-pyrene butyric acid is weighed as 100mg. The blocking reagent was 2.5% skimmed milk.

[0067] Moreover, in this embodiment, a solution of functionalized single-walled carbon nanotubes with a concentration of 0.02 mg / mL is printed between the source electrode and the drain electrode by means of aerosol printing. Thereafter, the chip was placed in a mixed solution of 2mM (1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride) EDC and 5mM N-hydroxysuccinimide NHS for 3h, and activated graphite Functionalized carboxyl groups adsorbed on alkenes.

[0068] The remaining steps can be shown in Example 1 with reference to.

[0069] In other embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com