Method of Casting Concrete Lofting Platform Using Cast Steel Lofting Platform

A platform, cast steel technology, applied in the processing of building materials, the preparation of building components on site, structural elements, etc., can solve the problems of complex process, increased production cost, self-importance, etc., to achieve a simple production process, eliminating the need for polishing , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

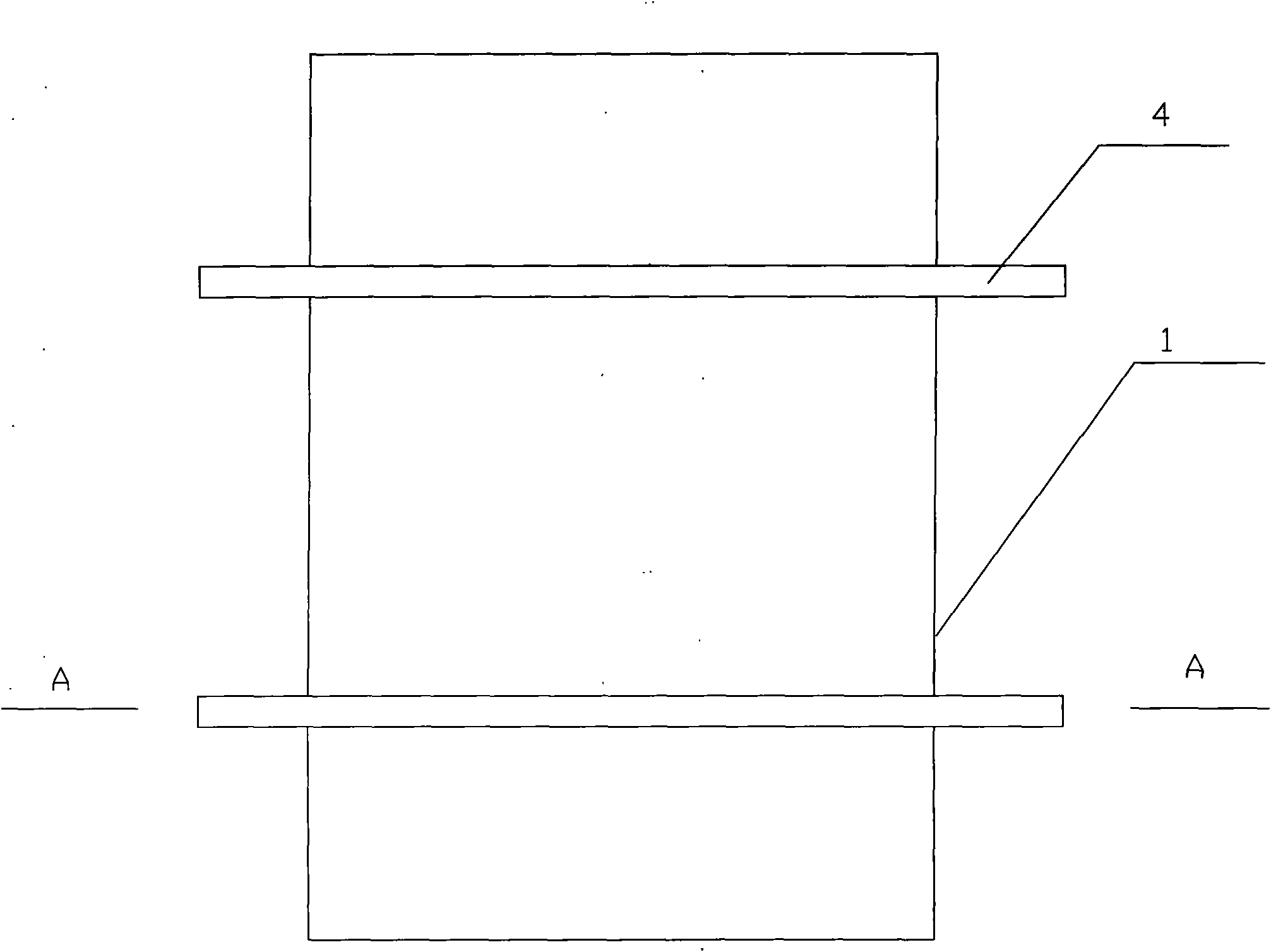

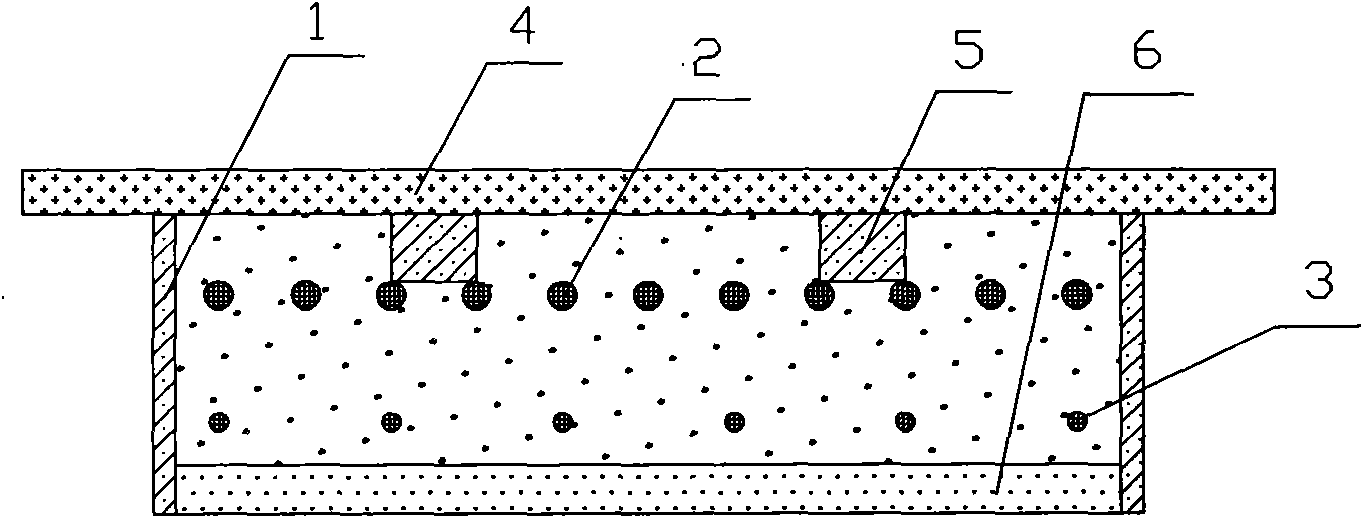

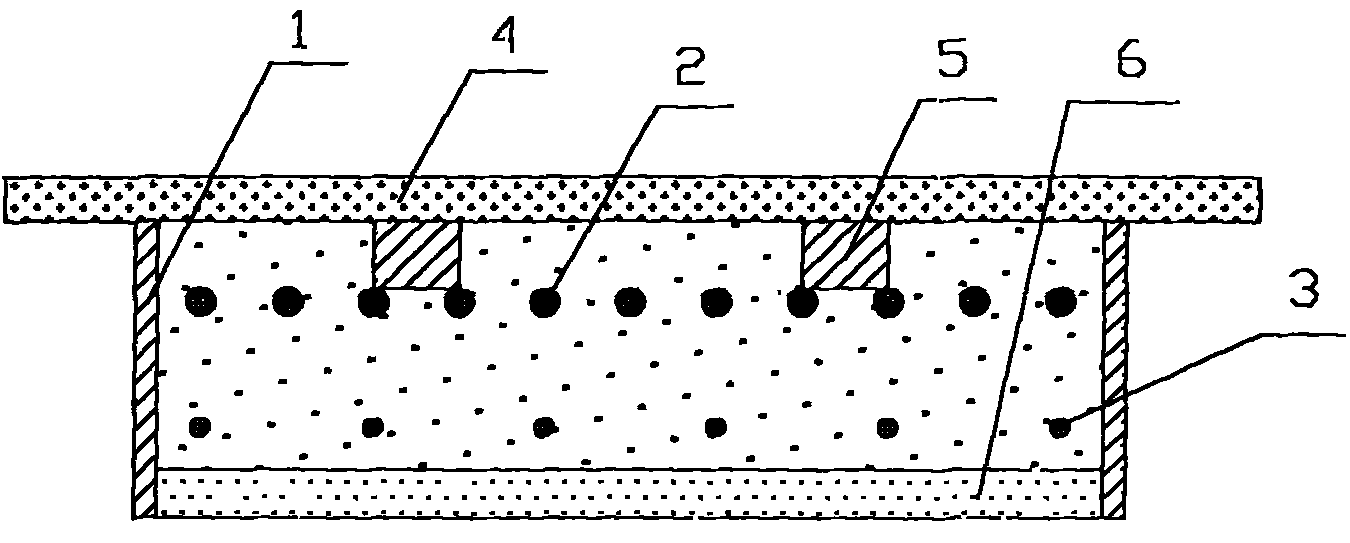

[0021] Example 1, see figure 1 , 2 , a method of utilizing a cast steel lofting platform to cast a concrete lofting platform, characterized in that it comprises the following steps:

[0022] a. Brush release agent: Mix silver powder and gasoline to make release agent with suitable consistency. Use a brush to evenly brush on the surface of the cast steel stakeout platform 6, and the thickness is controlled at 0.05-0.1mm;

[0023] B, outer mold making: the plank that height is 150-200mm surrounds and fixes along the four sides of cast steel lofting platform 6 and is outer mold 1, and cast steel lofting platform 6 is made the bottom surface of outer mold 1;

[0024] c. Reinforcing bars: two layers of reinforcing bars are placed inside the outer mold 1. The lower layer is the auxiliary reinforcing bar 3, which adopts reinforcing bars with a diameter of 10mm to 12mm and is evenly distributed on the same horizontal plane. The spacing of the auxiliary reinforcing bars 3 is 200-380mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com