Compound chemical fertilizer production process

A production process and fertilizer technology, applied in the field of producing blended compound fertilizers, can solve the problems of long fertilizer production cycle, complex process flow, high equipment cost, short production cycle, simplified process flow, occupied space and land occupation. small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

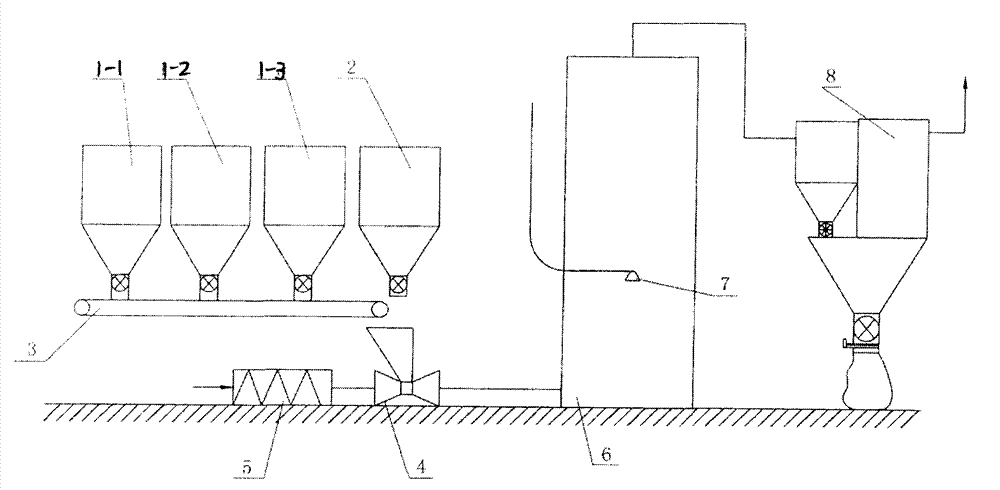

[0011] The blended compound fertilizer production process line shown in the figure consists of three fertilizer tanks 1-1, 1-2, 1-3 for holding phosphate fertilizer, potash fertilizer and trace element materials respectively and one for holding powder The ash tank 2 for coal ash is installed above the conveyor 3, a feeder 4 is installed below the outlet of the conveyor 3, the inlet of the feeder 4 is connected to a heater 5, and the outlet of the feeder 4 is connected to a drying mixer 6. The drying mixer 6 is equipped with a nozzle 7, and the liquid nitrogen fertilizer is sprayed into the drying mixer through the nozzle 7. The outlet of the drying mixer 6 is connected to the collector 8, and the collector 8 is connected with negative pressure pneumatic conveying equipment. It is also possible to press a positive pressure air supply device in front of the heater.

[0012] The production process of the present invention is as follows: the pulverized phosphate fertilizer, potash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com