Beneficiation method for producing high-quality iron ore concentrate by low-grade magnetic iron ore

A magnetite ore and ore dressing method technology, applied in the direction of chemical instruments and methods, flotation, magnetic separation, etc., can solve the problems of large consumption, increased operating costs, and difficult operation, and achieve the goal of reducing ore grinding and saving energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

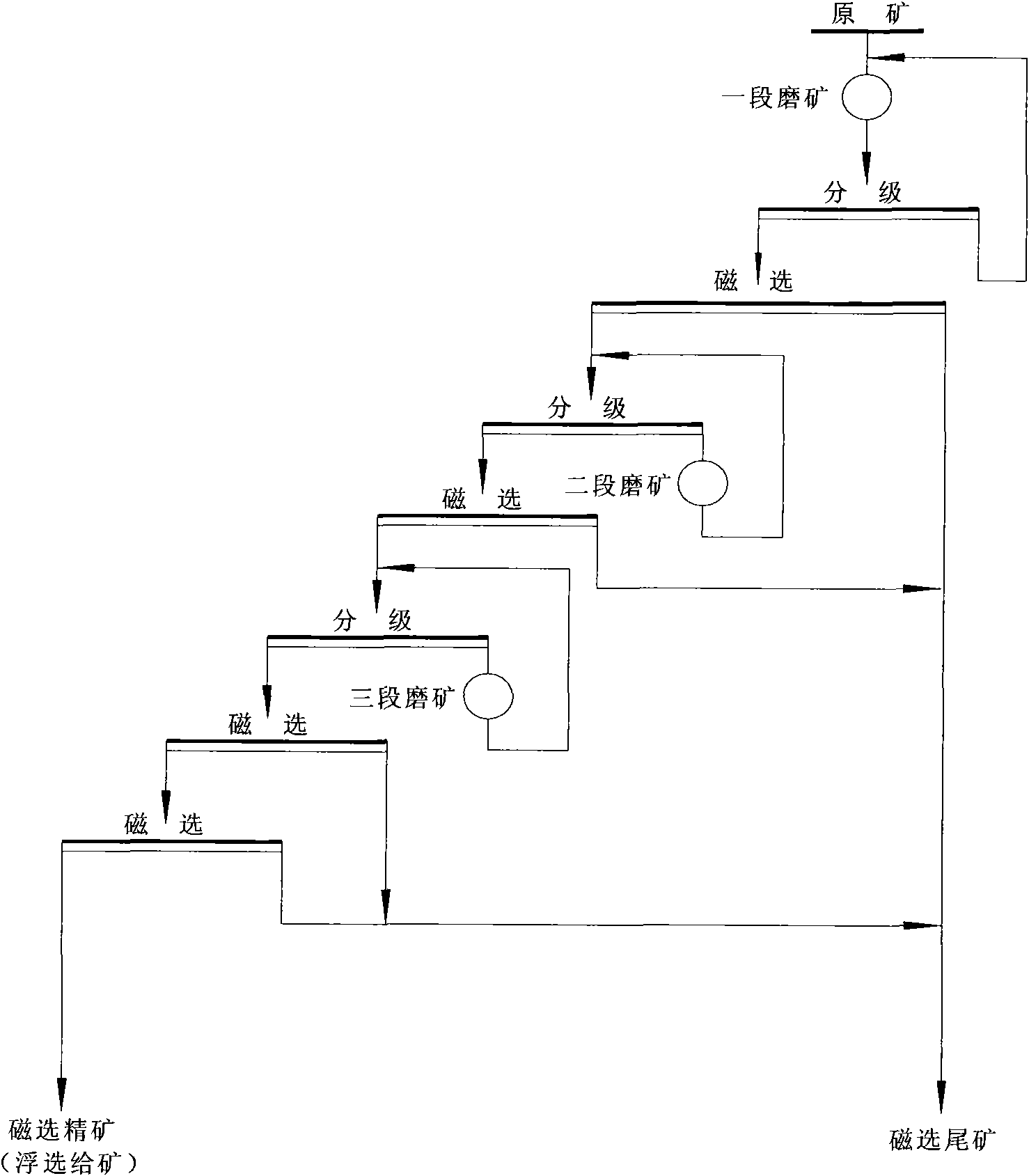

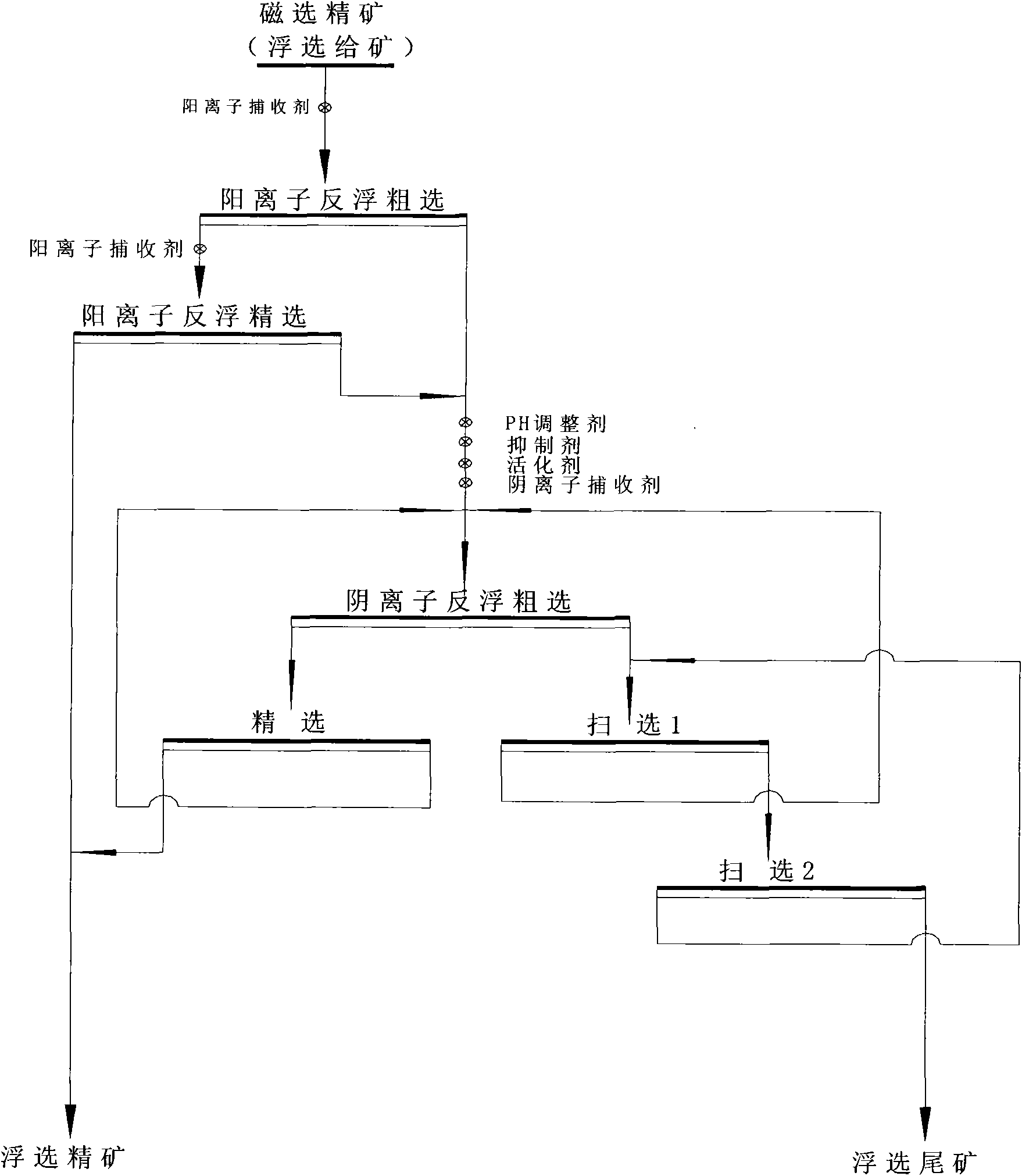

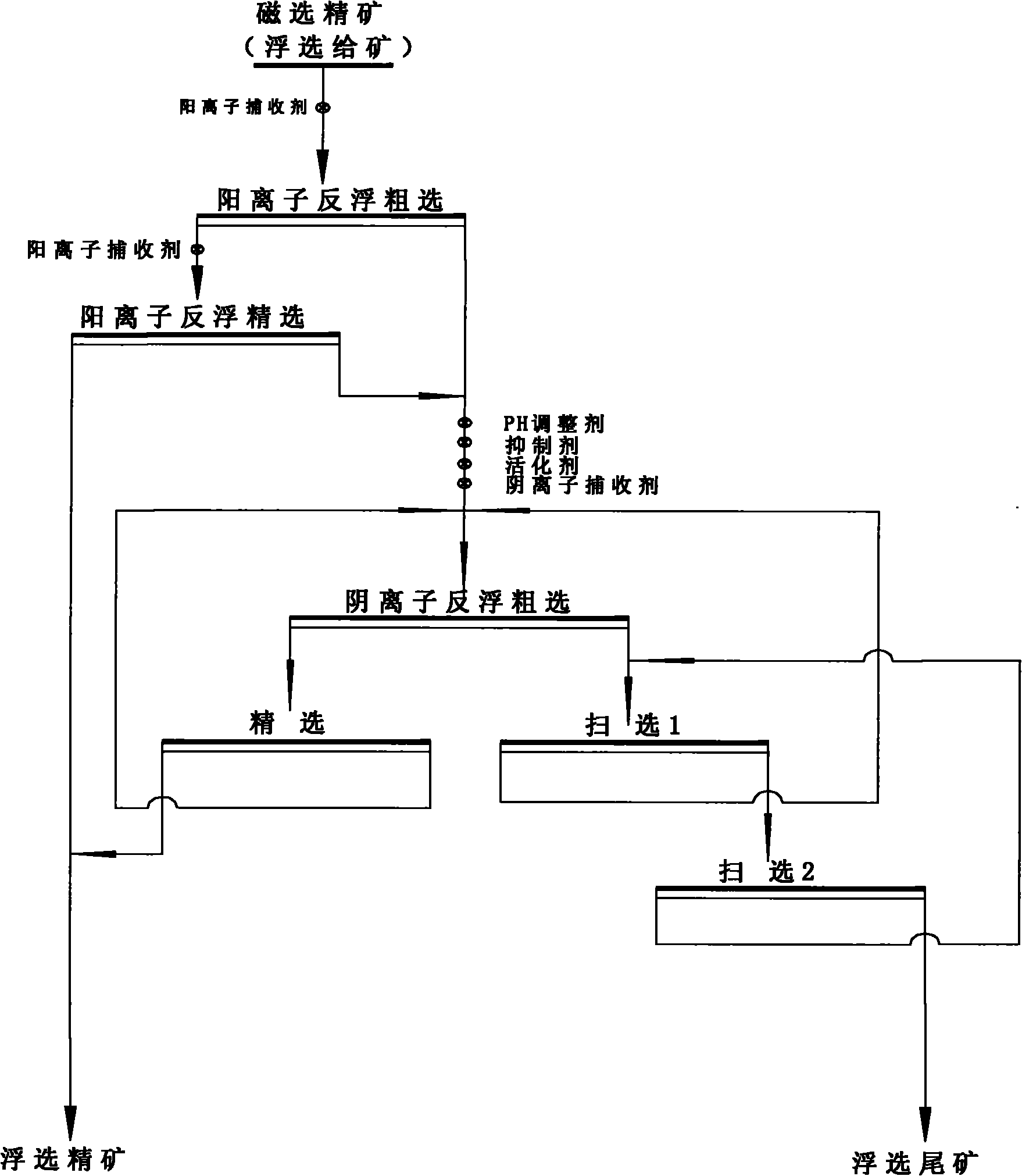

[0039] For further describing the present invention, below in conjunction with accompanying drawing, a kind of beneficiation method of producing high-quality iron ore concentrate from low-grade magnetite ore of the present invention is described in more detail.

[0040] Taking a domestic magnetite beneficiation as an example, its mineral composition is relatively simple. The metal minerals are mainly magnetite, with a content of 25-35%, followed by false hematite, a small amount of limonite, and trace amounts of pyrite and brass. mine. The gangue minerals are mainly quartz, with a content of 40-50%, followed by tremolite, actinolite, common hornblende, and a small amount of amphibole, chlorite, mica, plagioclase and calcite.

[0041] The iron silicate minerals in the ore include actinolite, tremolite and a small amount of common hornblende. Iron amphibole with high iron silicate mineral content is mostly distributed in interlayers, in side rocks in side rocks, off-surface ore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com