Manufacturing method for high-speed steel working roll at hot continuous rolling finish rolling rear section

A manufacturing method and high-speed steel technology, applied in the field of rolls and manufacturing, to avoid cracking, improve sheet grade, good accident resistance and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

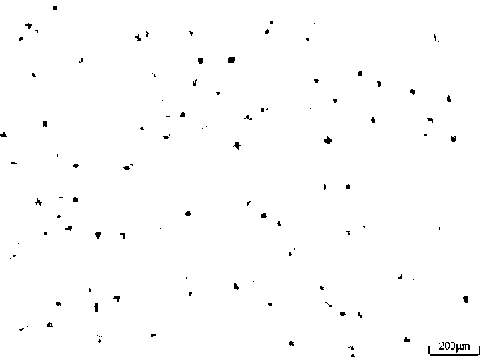

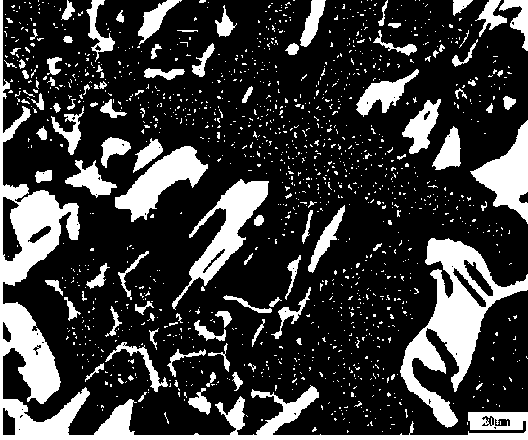

Image

Examples

Embodiment 1

[0026] a) Smelting: Use pig iron and scrap steel with appropriate alloys as raw materials, and prepare raw materials according to the set chemical composition of the working layer of the roll body and the middle value of the weight percentage of each composition, that is, C 2.75%, Si 1.7%, Mn 0.85%, Cr 3.0%, Ni 3.50%, Mo+V+W+Nb 6.0%, S≤0.05%, P≤0.10% Prepare raw materials. When smelting, put pig iron, scrap steel, and alloys into an induction furnace for smelting. The smelting temperature is 1470 ° C. Add ferrosilicon inoculants before the furnace is released, and the amount added is 1.0% of the weight of molten steel;

[0027] The material of the roll core and roll neck is ductile iron. During smelting, pig iron is used as raw material in an electric furnace. The smelting temperature is 1520°C. Before the furnace is released, an inoculant and a nodularizer are added to the molten iron. The inoculant is ferrosilicon. It is 0.6% of the weight of molten steel, and the nodulizer ...

Embodiment 2

[0035]a) Smelting: Use pig iron and scrap steel with appropriate alloys as raw materials, and prepare raw materials according to the set chemical composition of the working layer of the roll body and the middle value of the weight percentage of each composition, that is, C 2.15%, Si 0.5%, Mn 1.2%, Cr 4.5%, Ni 2.00%, Mo+V+W+Nb 2.00%, S≤0.05%, P≤0.10% Prepare raw materials. When smelting, put pig iron, scrap steel, and alloys into an induction furnace for smelting. The smelting temperature is 1450 ° C. Add ferrosilicon inoculants before the furnace is released, and the amount added is 0.8% of the weight of molten steel;

[0036] The material of the roll core and the roll neck is ductile iron. During smelting, pig iron is used as the raw material for smelting in an electric furnace. The smelting temperature is 1500°C. Before the furnace is released, an inoculant and a nodularizer are added to the molten iron. The inoculant is ferrosilicon. It is 0.5% of the weight of molten steel...

Embodiment 3

[0044] a) Smelting: Use pig iron and scrap steel with appropriate alloys as raw materials, and prepare raw materials according to the set chemical composition of the working layer of the roll body and the middle value of the weight percentage of each composition, that is, C3.50%, Si 2.00%, Mn 0.50%, Cr 1.50%, Ni 5.0%, Mo+V+W+Nb 10.0%, S≤0.05%, P≤0.10% Prepare raw materials. When smelting, put pig iron, scrap steel, and alloys into an induction furnace for smelting. The smelting temperature is 1550 ° C. Add ferrosilicon inoculants before the furnace is released, and the amount added is 0.6% of the weight of molten steel;

[0045] The material of the roll core and roll neck is ductile iron. During smelting, pig iron is used as raw material in an electric furnace. The smelting temperature is 1450°C. Before the furnace is released, an inoculant and a nodularizer are added to the molten iron. The inoculant is ferrosilicon. It is 1.0% of the weight of molten steel, and the nodulizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com