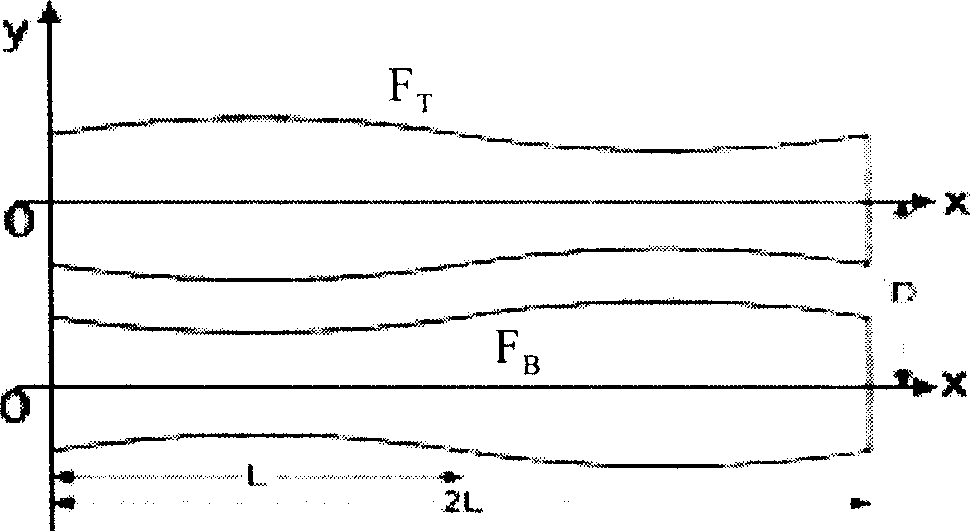

Four-high mill plate control work roll curve design method for strip rolling

A roll-shaped curve, four-high mill technology, applied in the field of steel rolling, can solve the problems of increased roll grinding cost, shortened roll service life, and no consideration of the influence of roll curve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

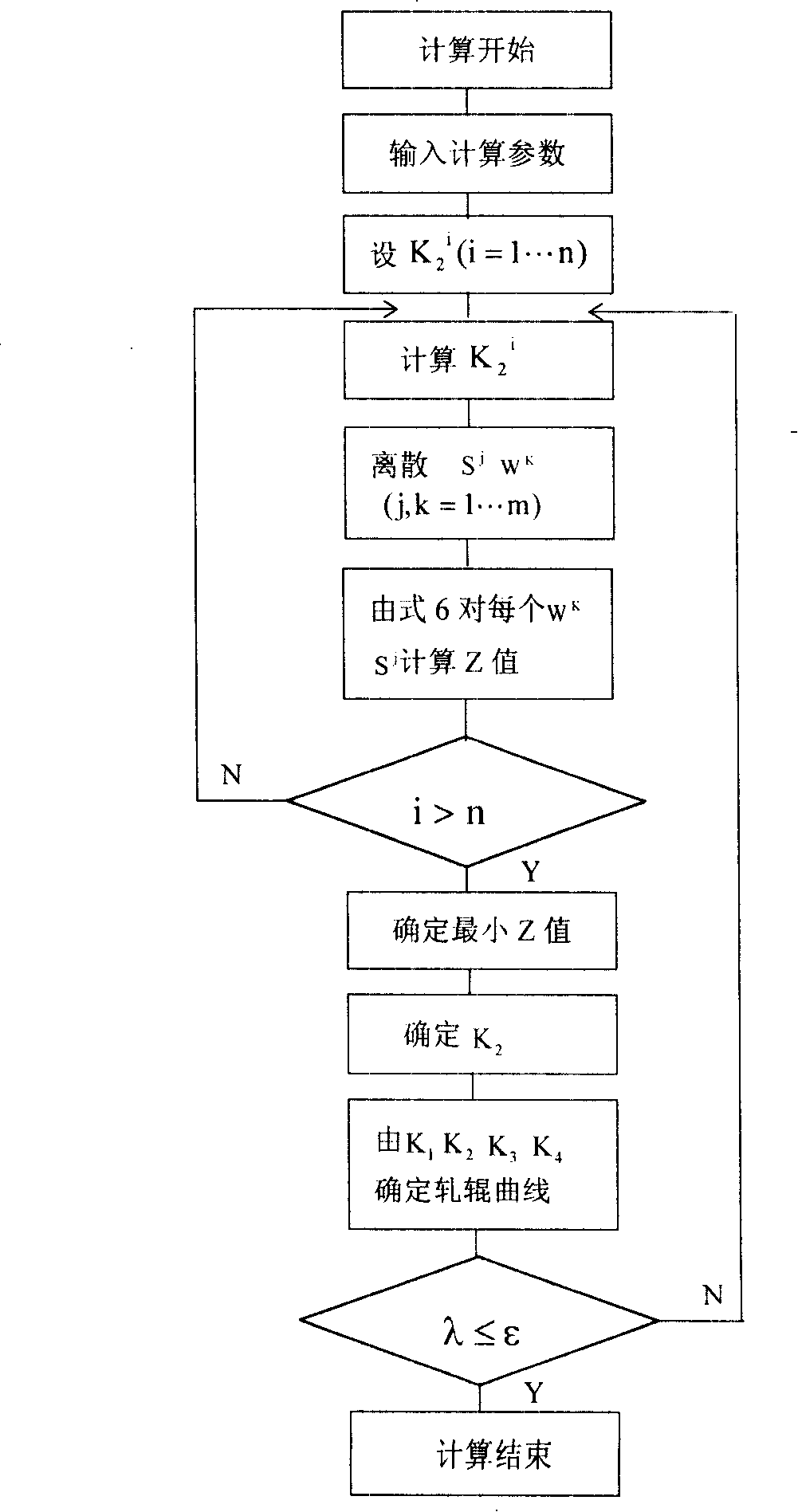

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

[0046] The present invention takes the working roll applied on the 2130mm cold rolling mill produced in the cold rolling strip industry as an example. The design parameters of the roll shape are shown in Table 1.

[0047] Table 1 Roll design parameters

[0048]

[0049] Substitute the parameters in the table into formula (6) - formula (12), and pass figure 2 The roll shape curve equation of the roll is obtained through the process calculation, see formula (13):

[0050] P T (X)=300+3.0747*e -4 X-3.1754*e -7x 2 +8.4140*e -11 x 3 (13)

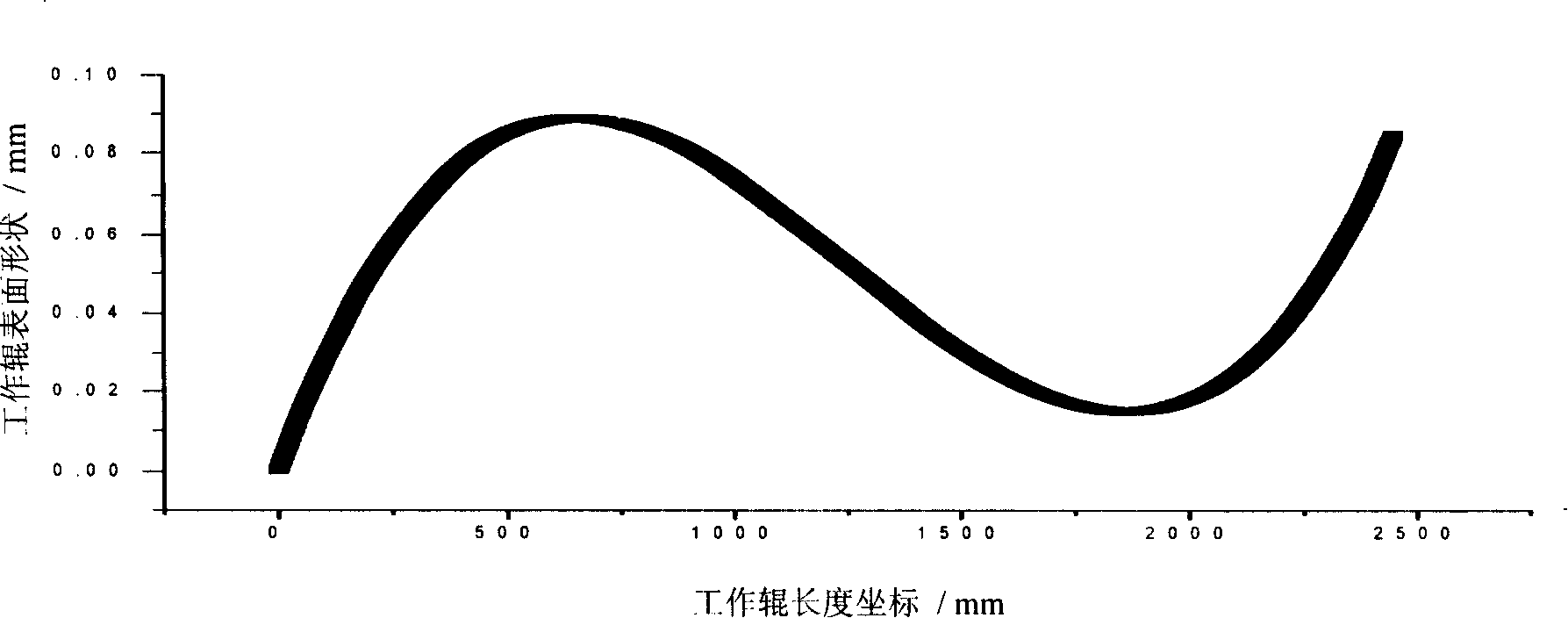

[0051] The shape of the roll surface is as image 3 As shown, the roll diameter difference between the highest point and the lowest point of the roll surface is 0.073mm. It has a linear correspondence relationship with the equivalent convexity within the range of roll traverse, such as Figure 4 . When this roll is used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com