Medical high-strength titanium alloy wire and preparation method thereof

A technology of titanium alloy and scope, applied in the field of component control and preparation of Ti-6Al-4V titanium alloy wire, can solve the problem of low plasticity, achieve high yield, reduce processing cost, and excellent plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

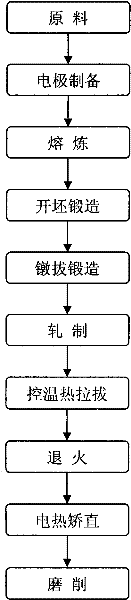

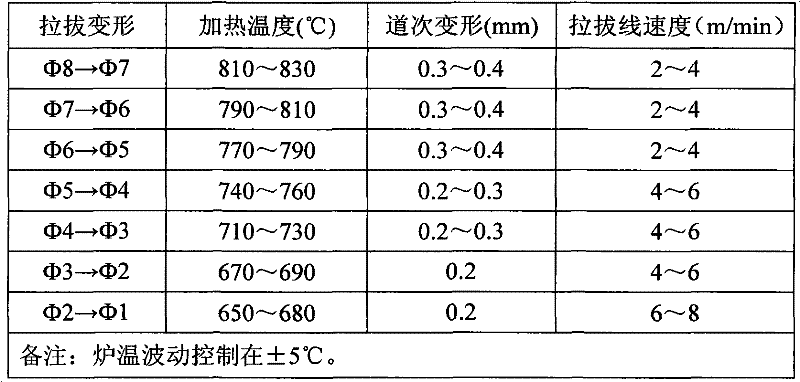

Method used

Image

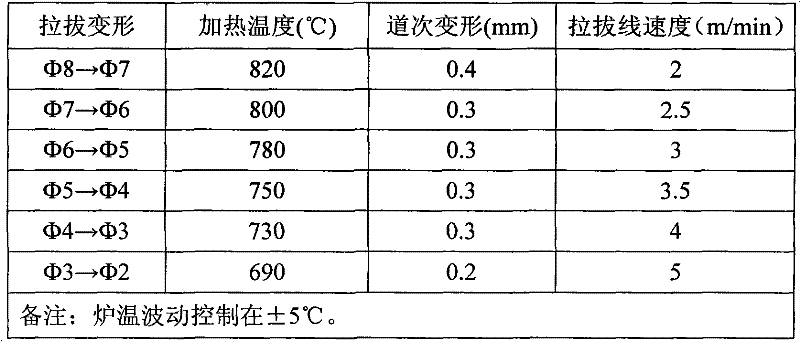

Examples

Embodiment 1

[0030] Using grade 1 sponge titanium, aluminum vanadium 85 and aluminum beans as raw materials, the Ti-6Al-4V composition (wt%) is proportioned according to Al 6.2% and V 4.1%, after mixing, it is pressed into an electrode block, and then The electrode block is welded into an electrode for smelting by plasma welding, and it is smelted three times in a vacuum consumable arc melting furnace to form an ingot. The main alloying elements, oxygen and iron of the titanium alloy three ingots are: Al 6.1%, V 4.2 %, O 0.13%, Fe 0.08%. Use a hydraulic press or an air hammer to forge the ingot at 1050-1150°C to form a □220mm upsetting and drawing forging billet, and then turn it into a Φ160mm round billet after being upset once. Diameter forging is then carried out at 950°C to form a square billet of □70mm. The billet is reheated after grinding, the heating temperature is 900°C, and the temperature-controlled rolling is carried out. During the rolling process, a cooling device is install...

Embodiment 2

[0036] Using grade 1 sponge titanium, aluminum vanadium 85 and aluminum beans as raw materials, the Ti-6Al-4V composition (wt%) is proportioned according to Al 6.2% and V 4.5%, after mixing, it is pressed into an electrode block, and then The electrode block is welded into an electrode for smelting by plasma welding, and it is smelted three times in a vacuum consumable arc melting furnace to form an ingot. The weight percentages of the main alloying elements, oxygen and iron of the titanium alloy three ingots are: Al 6.3%, V 4.5 %, O 0.15%, Fe 0.10%. Use a hydraulic press or an air hammer to forge the ingot at 1050-1150°C to form a □220mm upsetting forging billet, and then turn it into a Φ160mm round billet after two times of upsetting. Diameter forging is then carried out at 950°C to form a square billet of □70mm. The billet is reheated after grinding, the heating temperature is 890°C, and the temperature-controlled rolling is carried out. During the rolling process, a cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com