Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Effectively remove dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

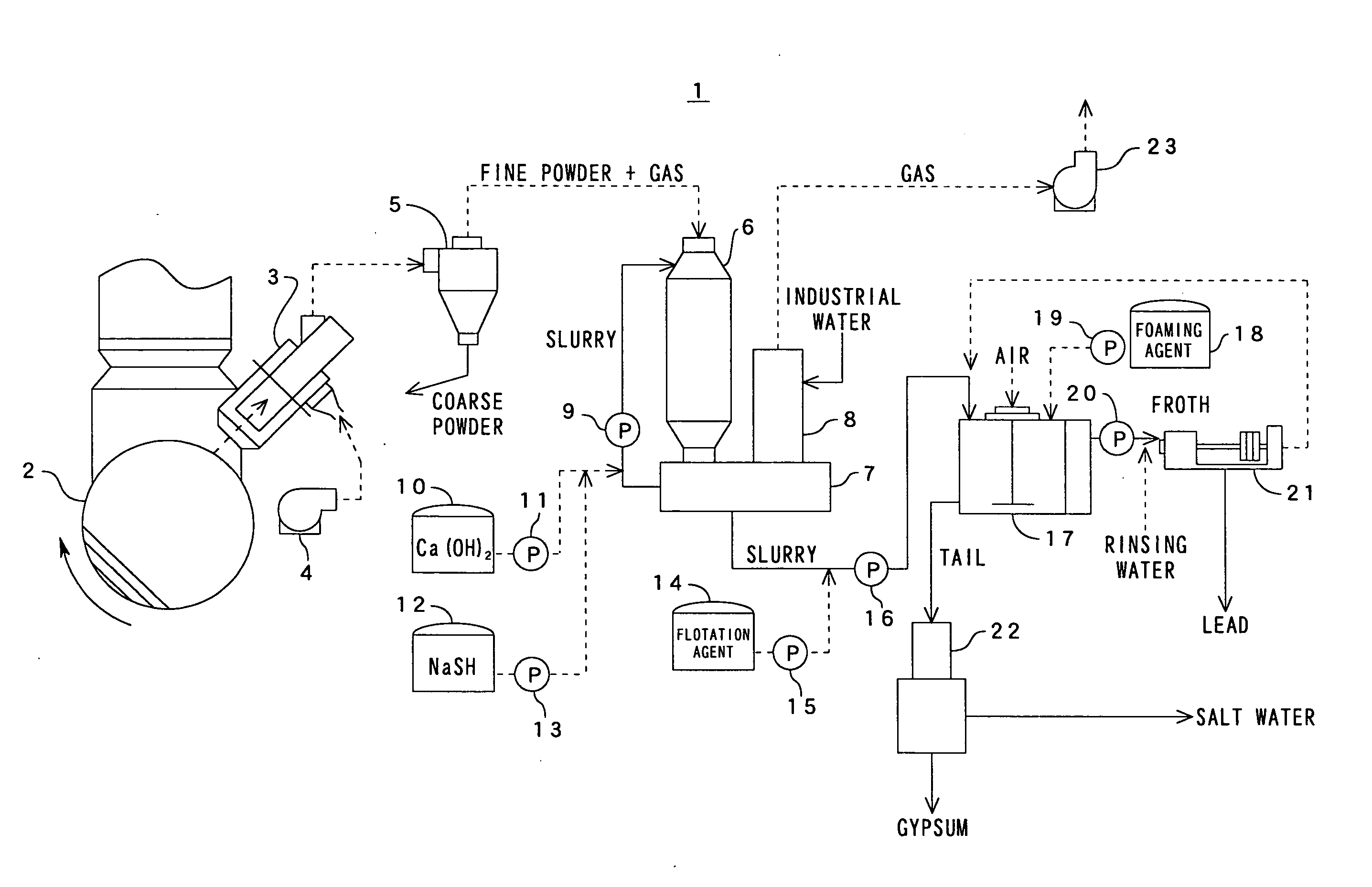

System and method for treating dust contained in extracted cement kiln combustion gas

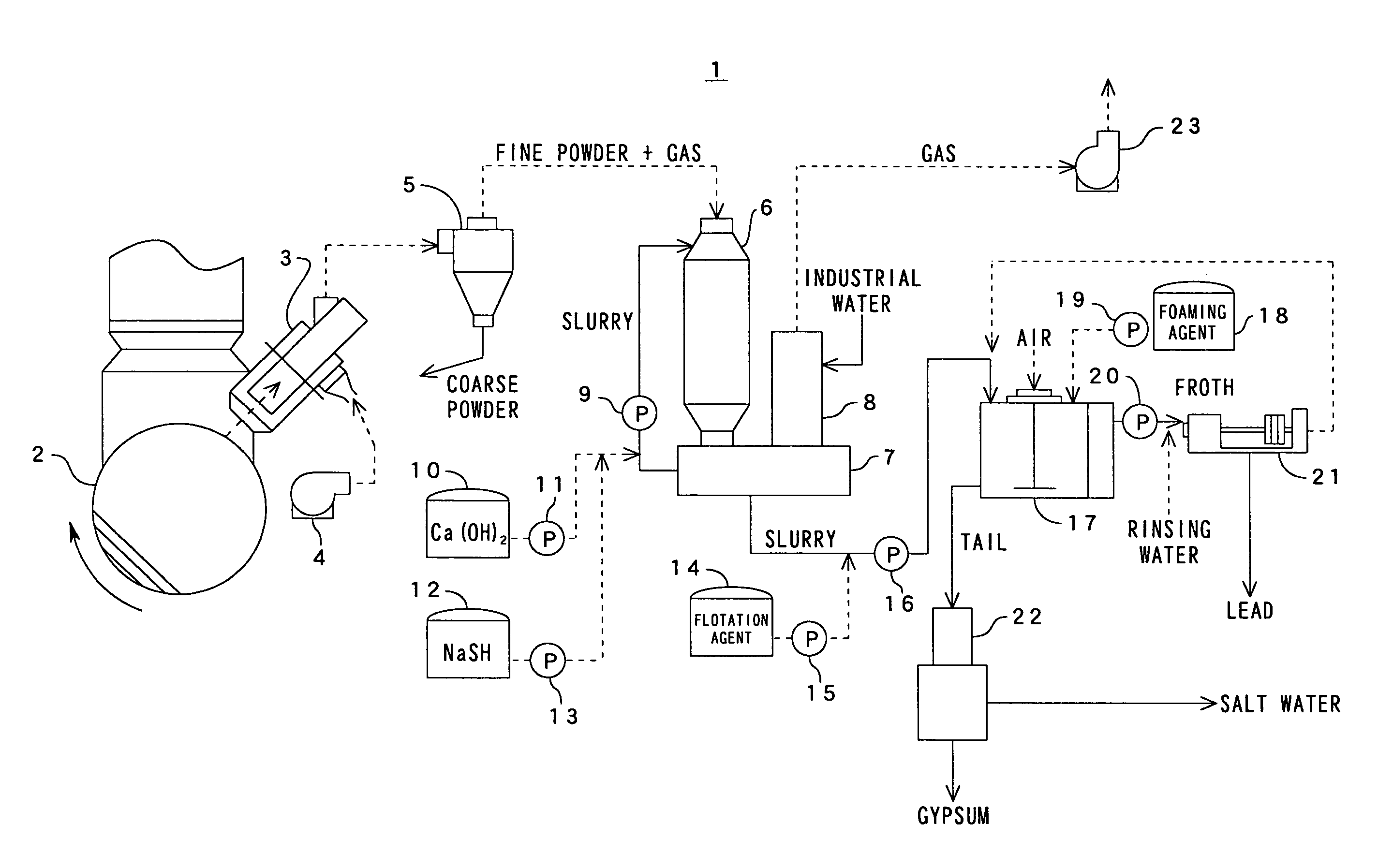

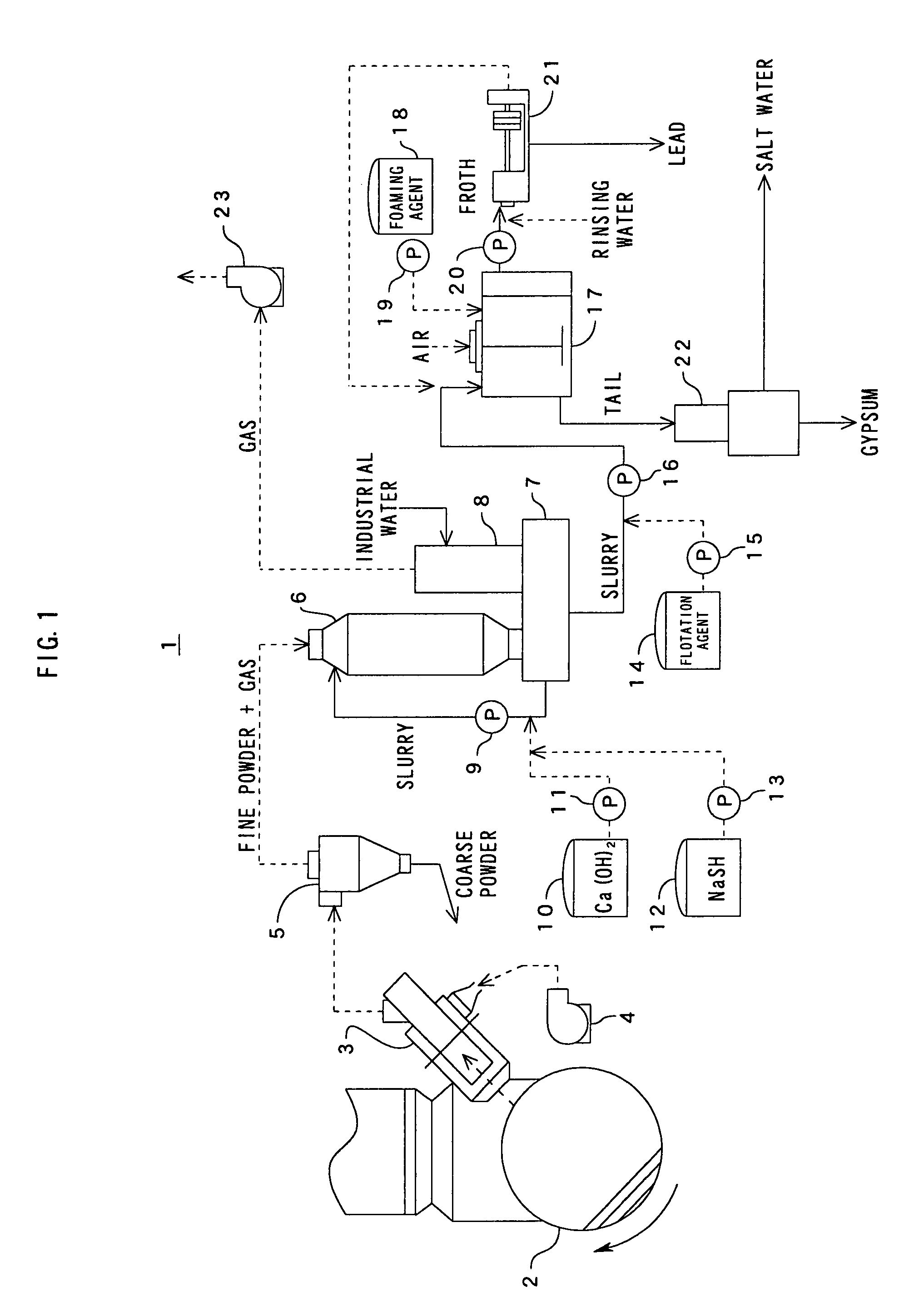

InactiveUS7789944B2Effectively remove dustLow facility requirementsCombination devicesUsing liquid separation agentCycloneSlurry

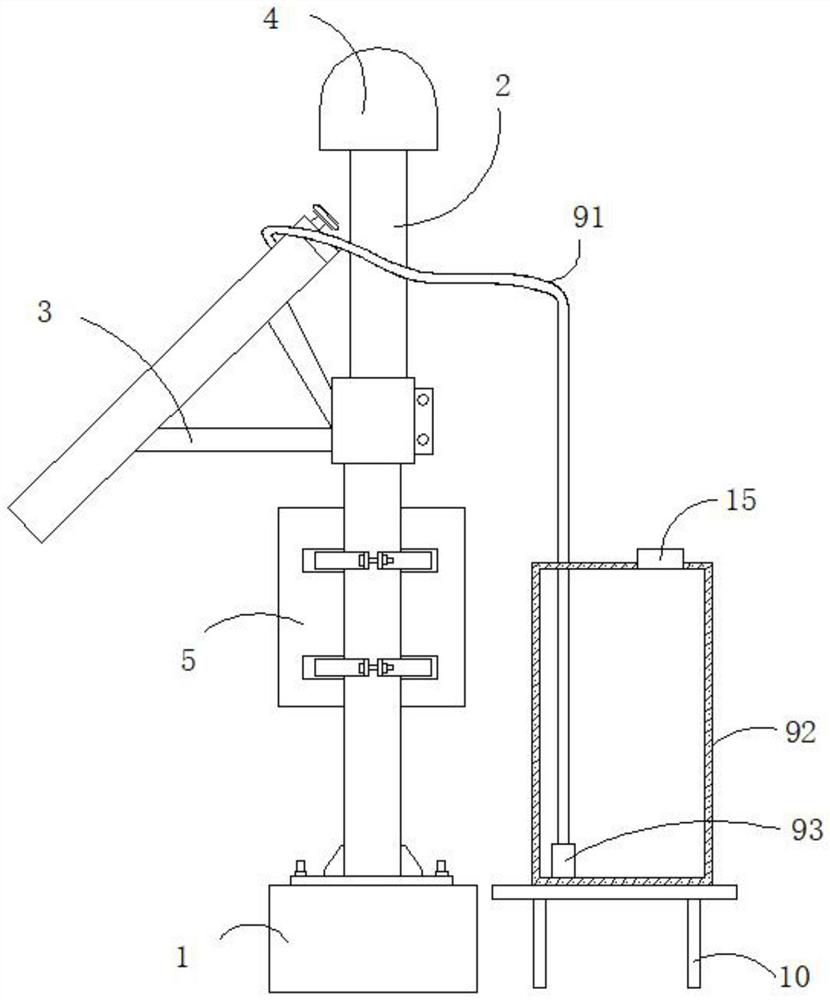

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising: a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a classifier 5 for separating coarse powder from dust contained in the combustion gas extracted by the probe 3; a wet dust collector 6 for collecting dust from the extracted gas containing fine powder discharged from the classifier 5; and devices 12, 13 for feeding sulfurizing agent for sulfurizing lead contained in the kiln exhaust gas to the wet dust collector 6, and others. From the sulfurizing-agent feeders 12, 13 are preferably added the sulfurizing agents to a circulation liquid tank 7 or a pump 9 for circulating slurry. The slurry obtained by the wet dust collector 6 is separated into froth including lead and tail side slurry including gypsum by a flotation facility 14, 17, 18.

Owner:TAIHEIYO CEMENT CORP

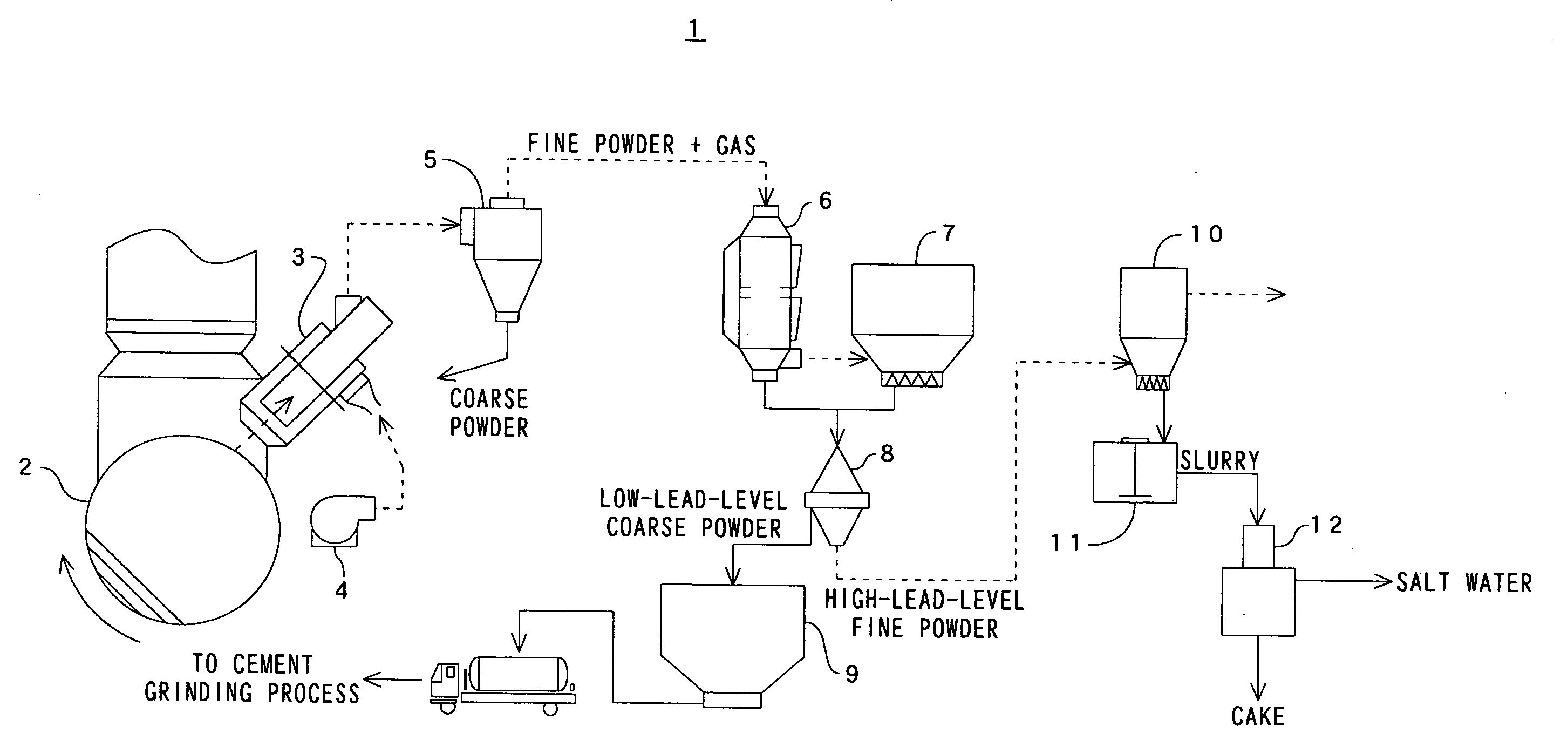

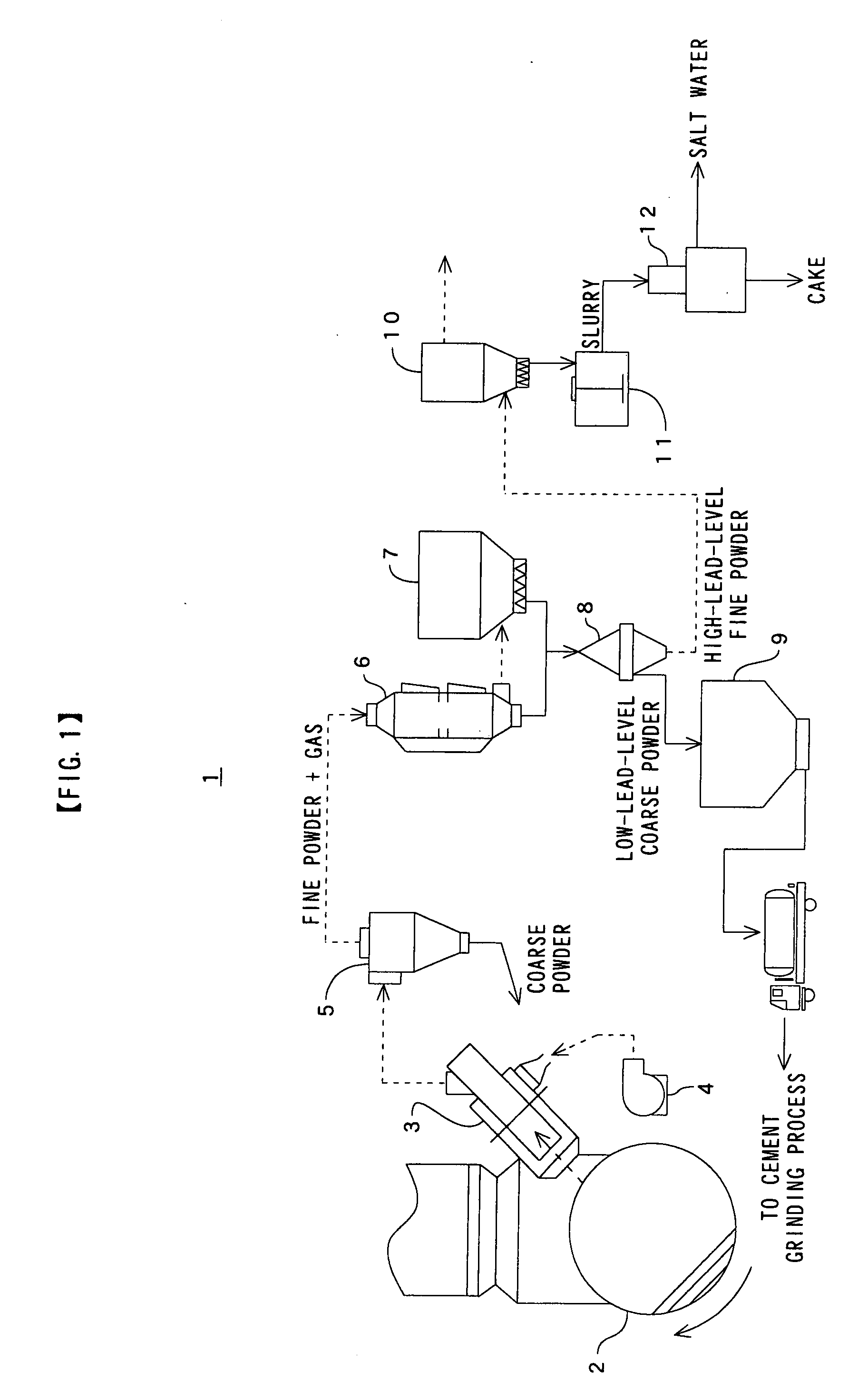

System and method for treating dust contained in extracted cement kiln combustion gas

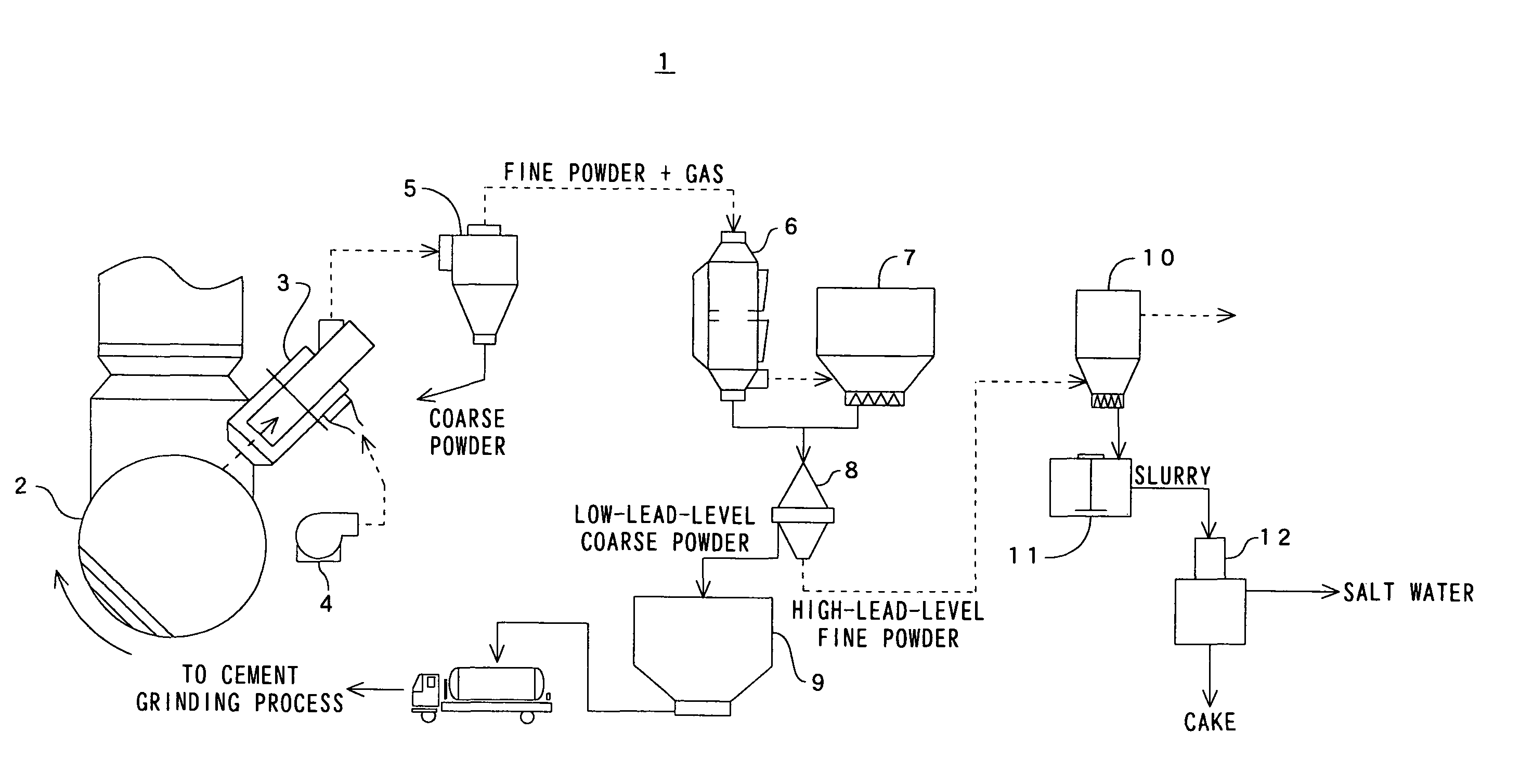

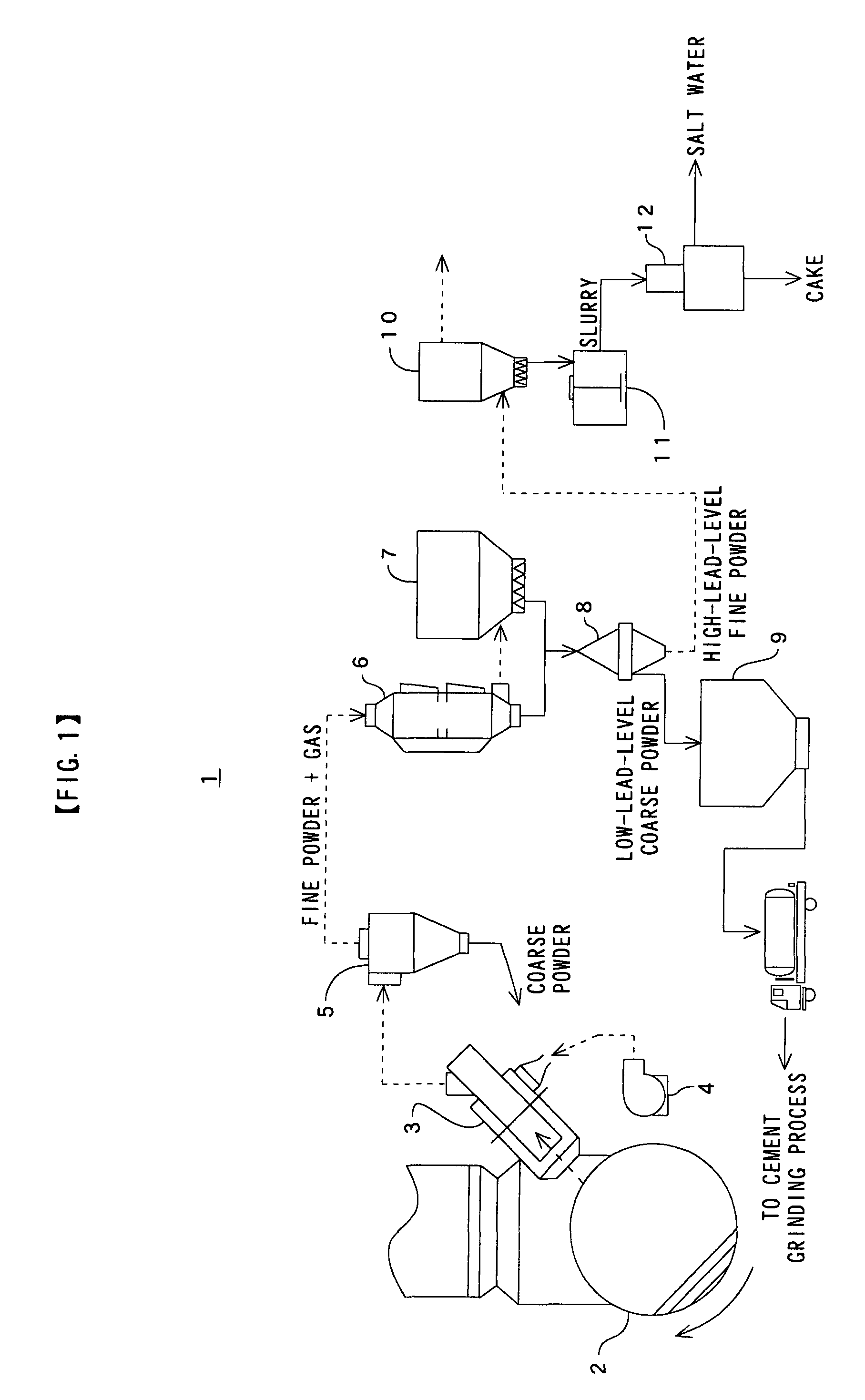

ActiveUS7749311B2Effectively remove dustLow facility requirementsCombination devicesLiquid degasificationCycloneEngineering

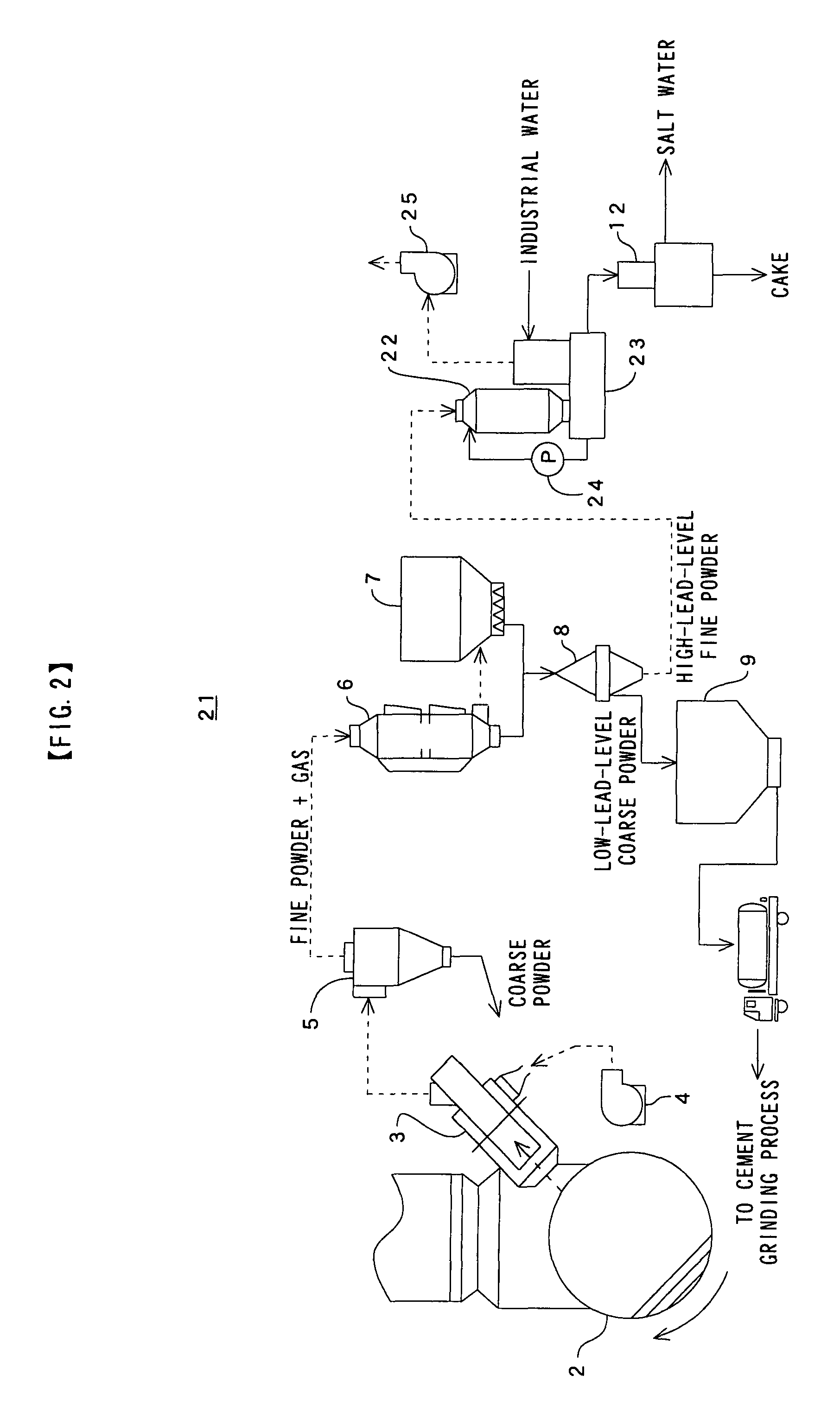

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a first classifier 5 for separating coarse powder from dust contained in the combustion gas extracted; a dust collector 7 for collecting dust from the extracted gas containing fine powder discharged from the first classifier 5; and a second classifier 8 for dividing dust discharged from the dust collector 7 into fine powder and coarse powder, and others. Since more lead is distributed on the fine powder side classified by the second classifier 8, lead can efficiently be removed without using chemicals and the like. The fine powder classified by the classifier 8 may be desalted by washing; high-lead-level cake obtained after the washing can be recycled; or salt water can be added to a cement mill. The coarse powder may be added to a cement grinding process or returned to cement material grinding process after the desaltation through washing.

Owner:TAIHEIYO CEMENT CORP

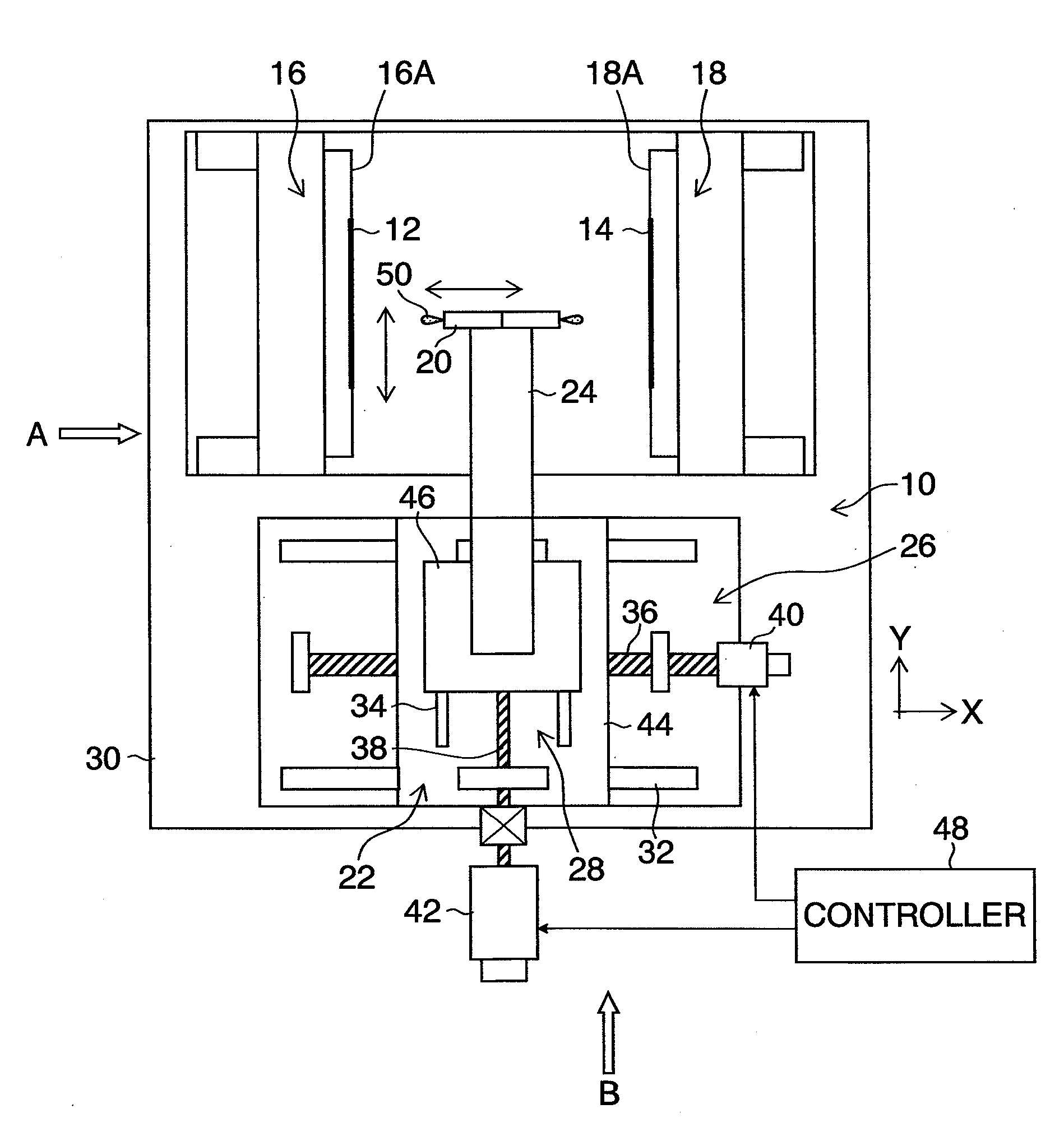

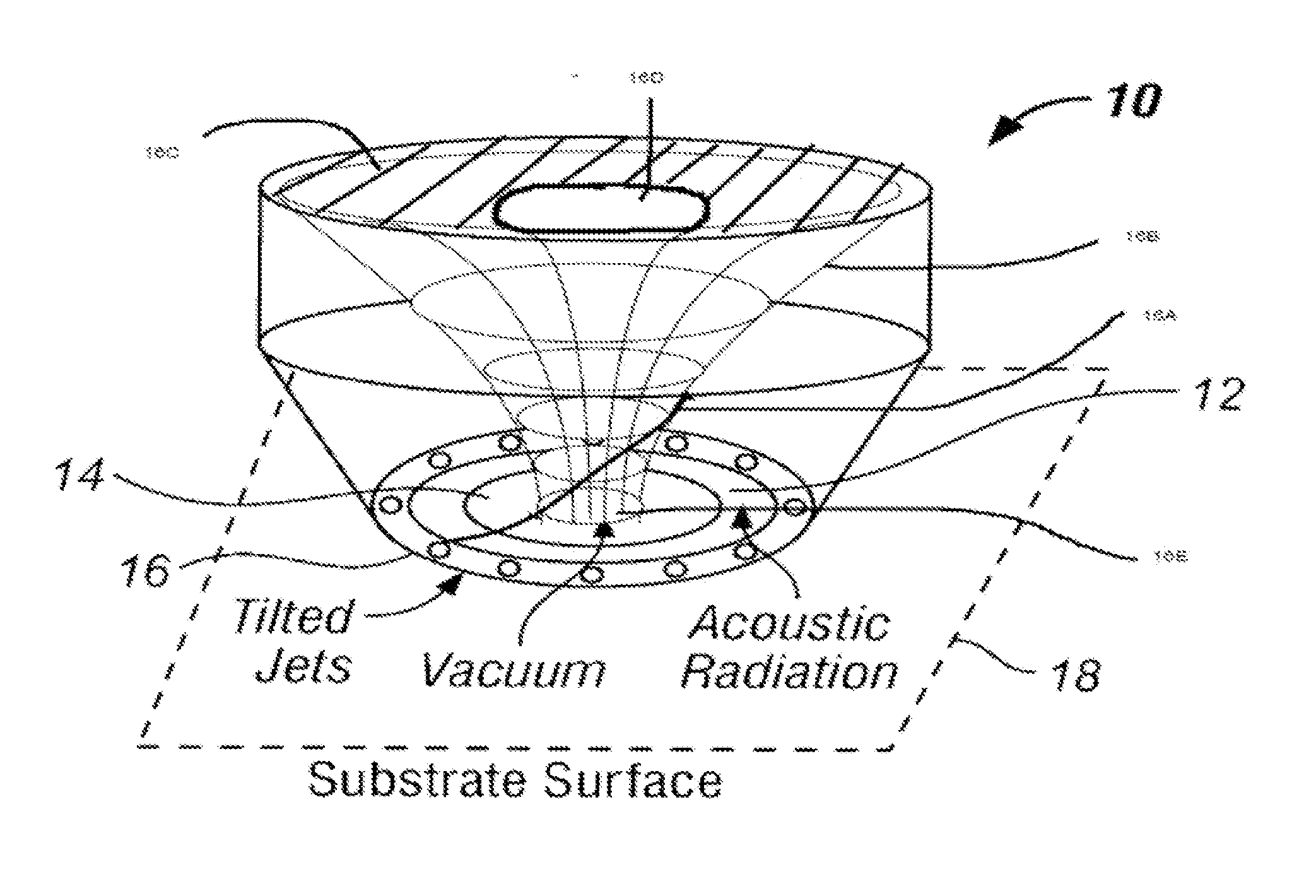

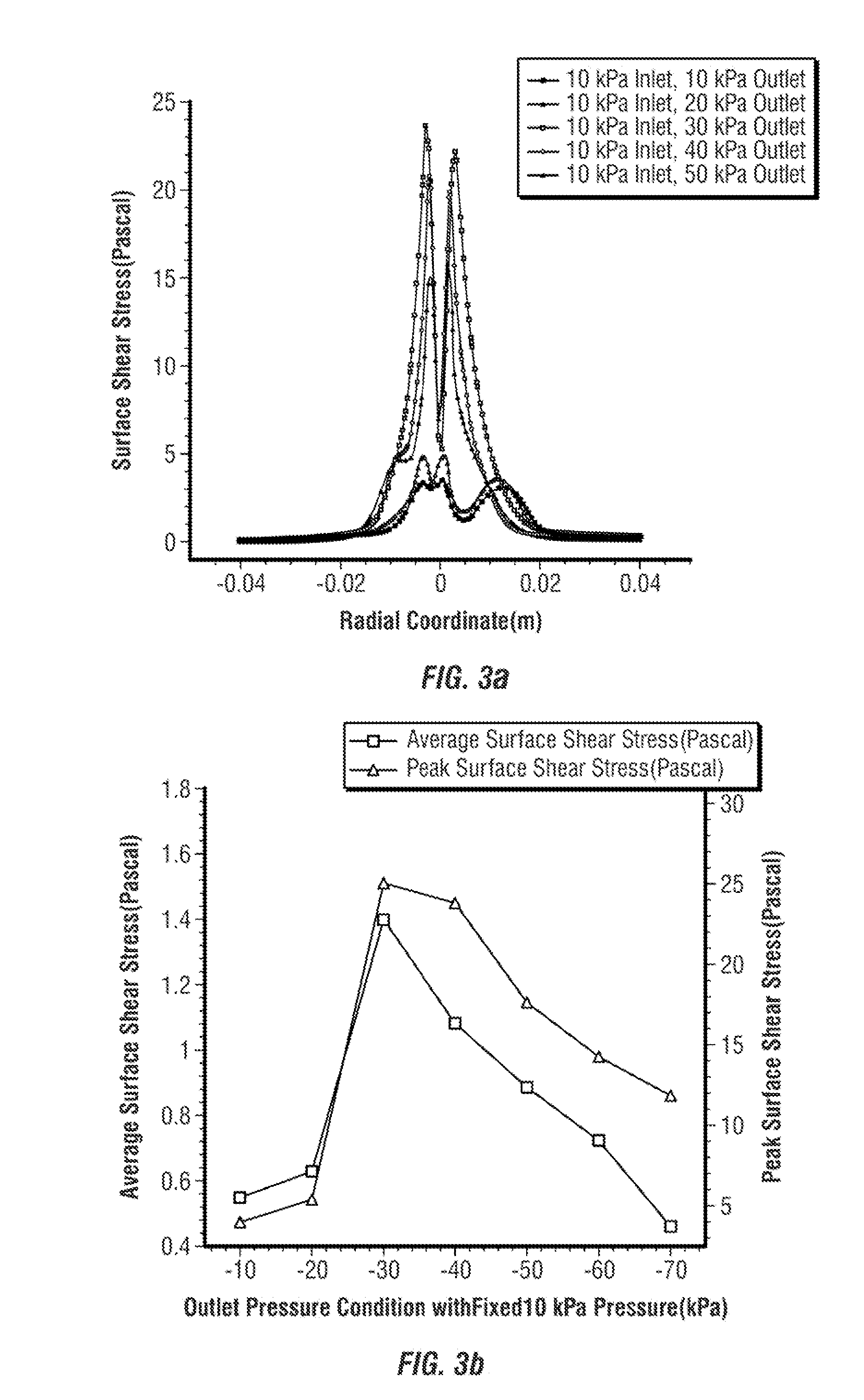

Aeroacoustic duster

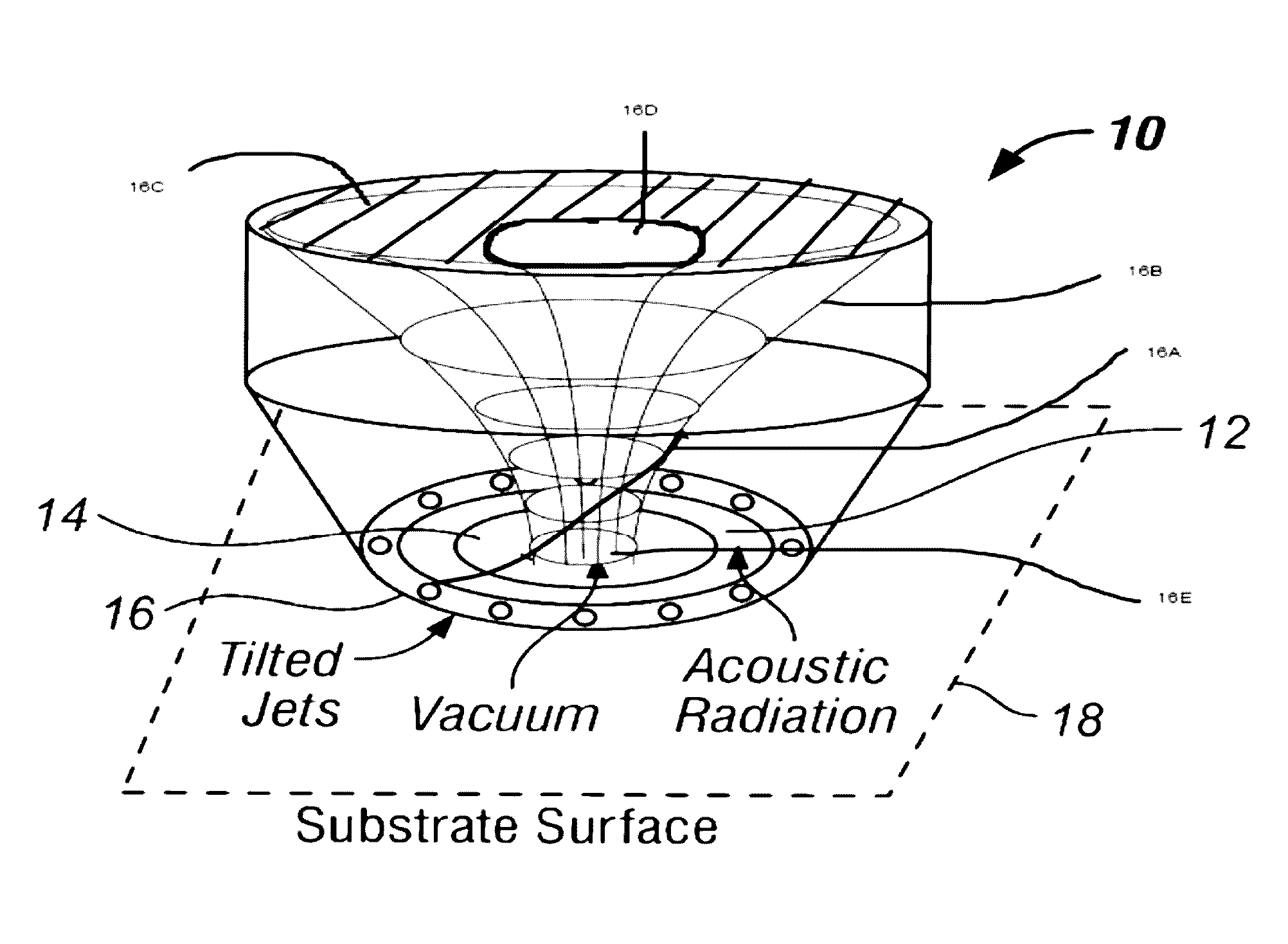

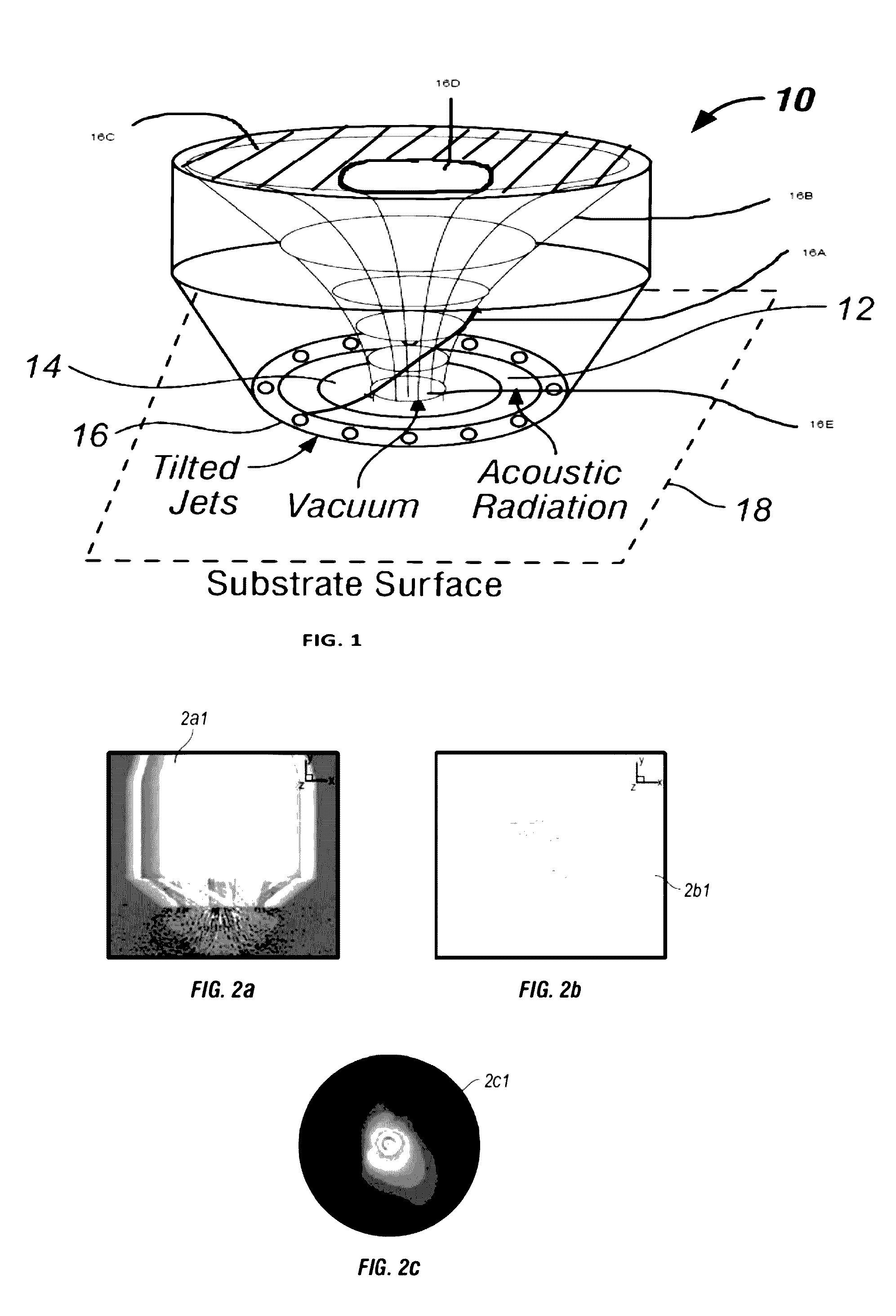

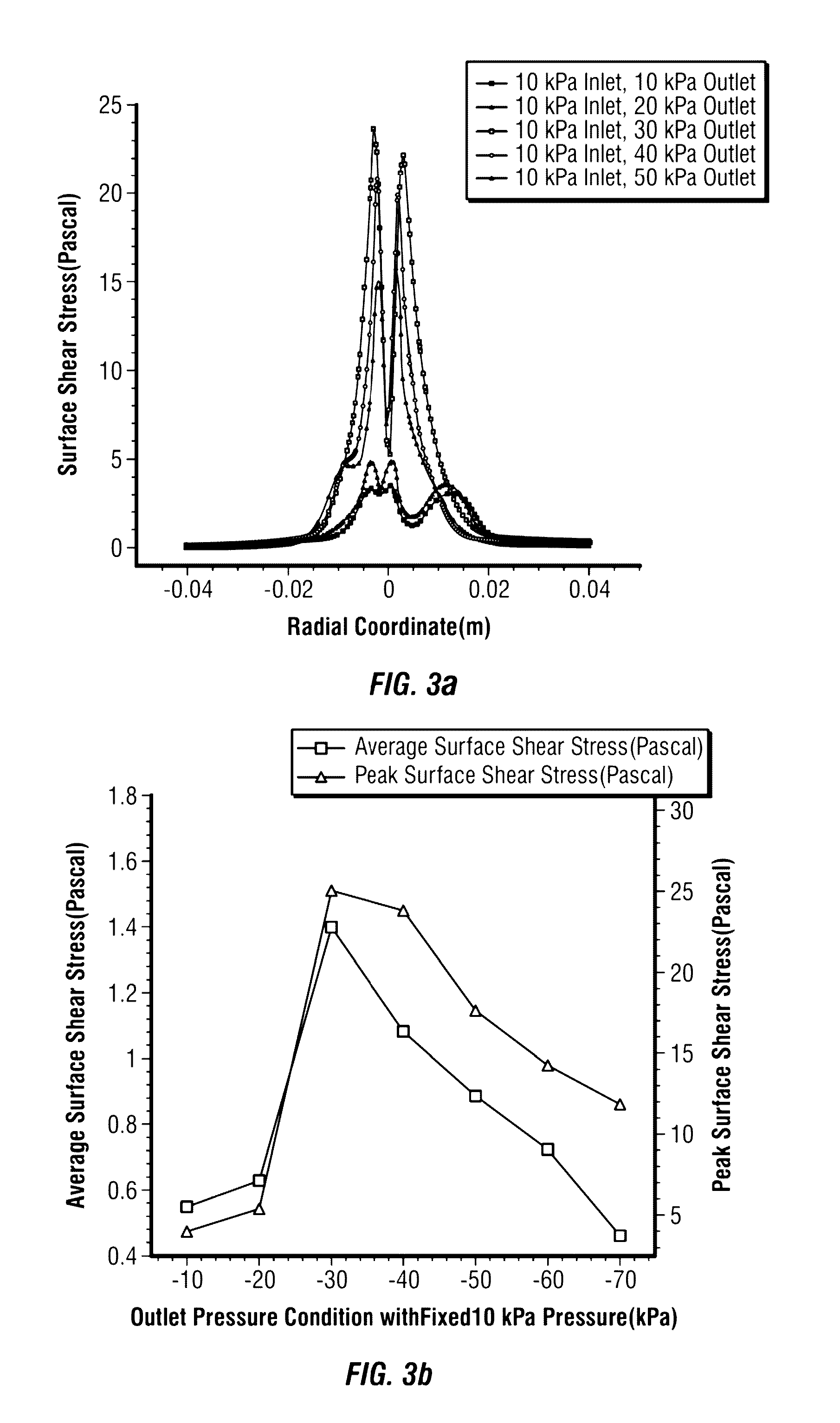

The invention disclosed herein provides for high particle removal rate and / or heat transfer from surfaces. The device removes particulate matter from a surface using a bounded vortex generated over the surface, with suction in the vortex center and jets for blowing air along the periphery. The jets are tilted in the tangential direction to induce vortex motion within the suction region. The vortex is said to be bounded because streamlines originating in the downward jets are entrained back into the central vortex.

Owner:UNIVERSITY OF VERMONT

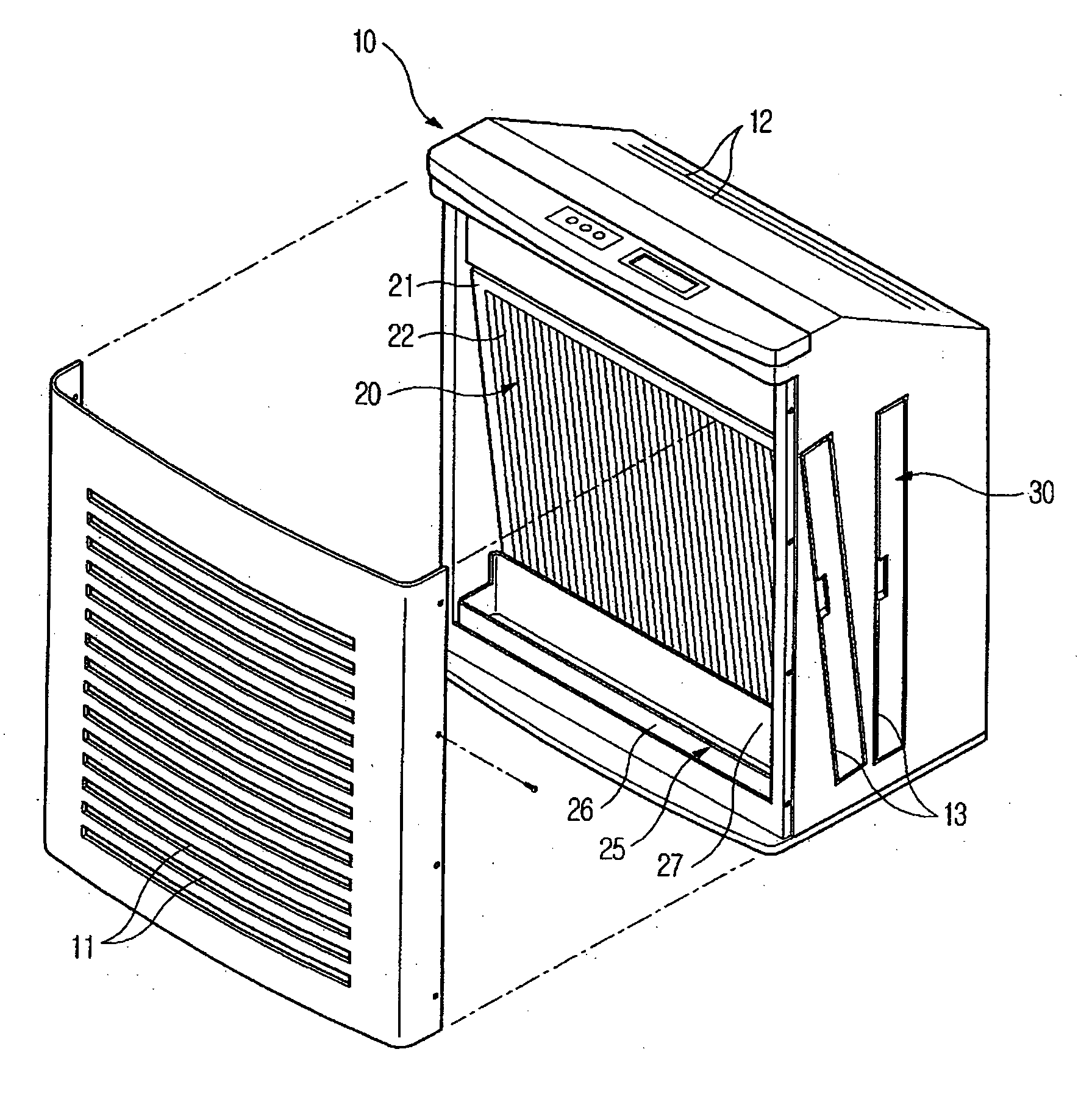

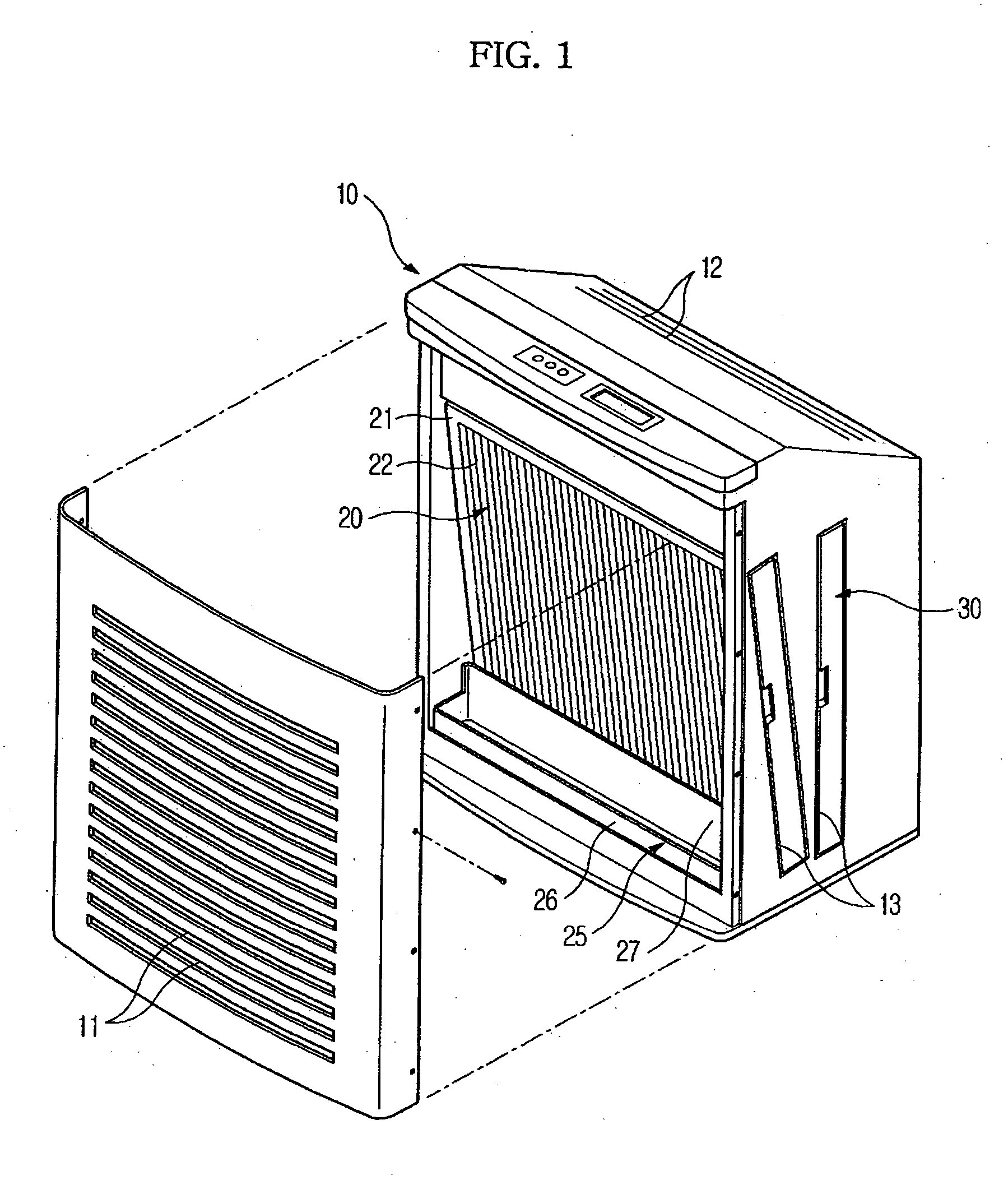

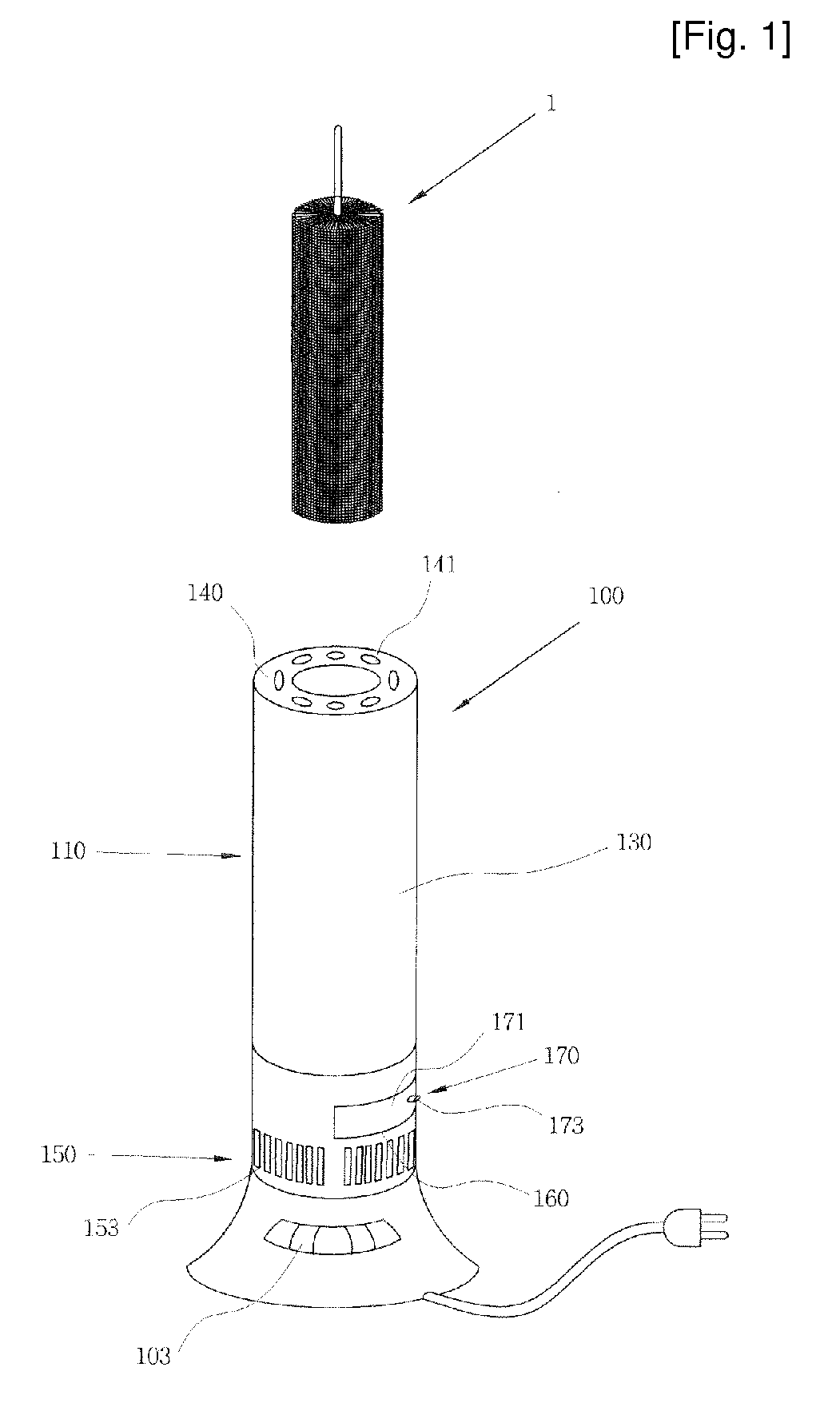

Air purifier

InactiveUS20070000219A1Conveniently and rapidly removedEasily detachedMechanical apparatusDispersed particle filtrationStatorEngineering

An air purifier includes a vibrating member disposed adjacent to a dust filter, and first and second vibration motor assemblies disposed longitudinally and transversely on the vibrating member, respectively, to cause the vibrating member to vibrate in several directions. Each of the vibration motor assemblies has a case fixed to the vibrating member, a vibrating motor disposed within the case, and a cover to close the case. The vibration motor includes a stator fitted to a sheet member within the case, a rotor rotatably disposed within the stator, and an eccentric shaft connected to the rotor to generate vibration via an eccentric rotation of the eccentric shaft.

Owner:SAMSUNG ELECTRONICS CO LTD

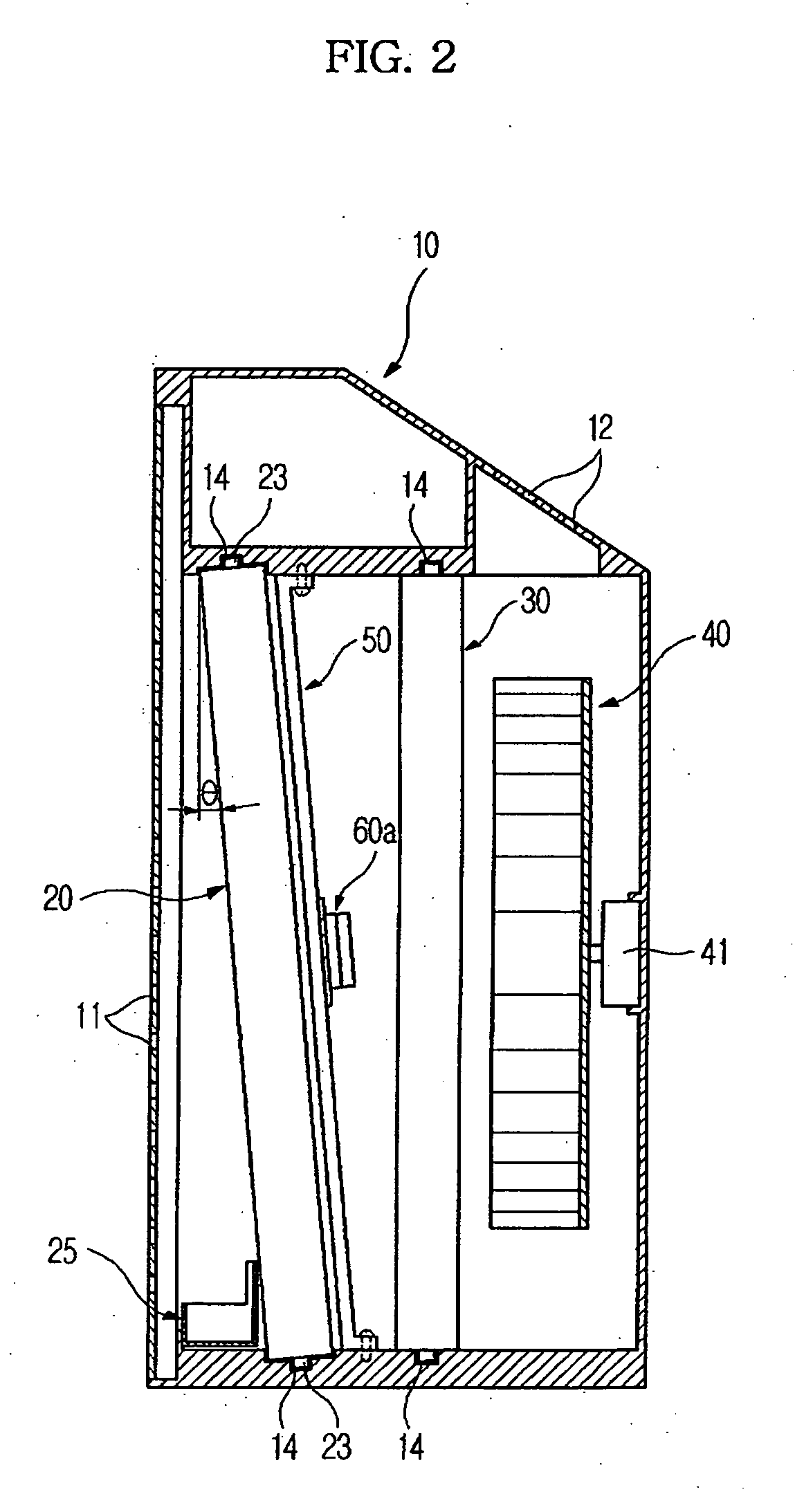

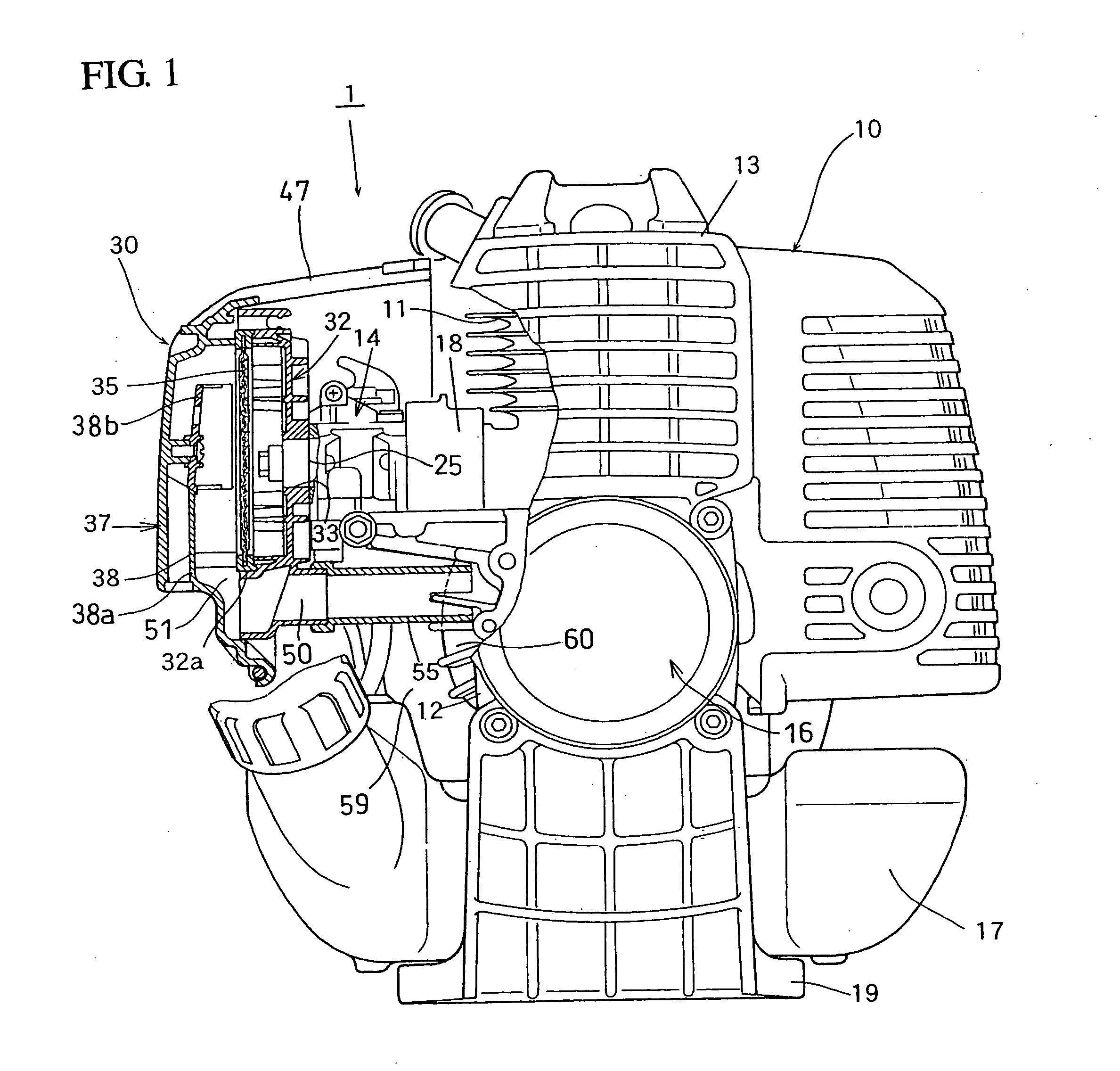

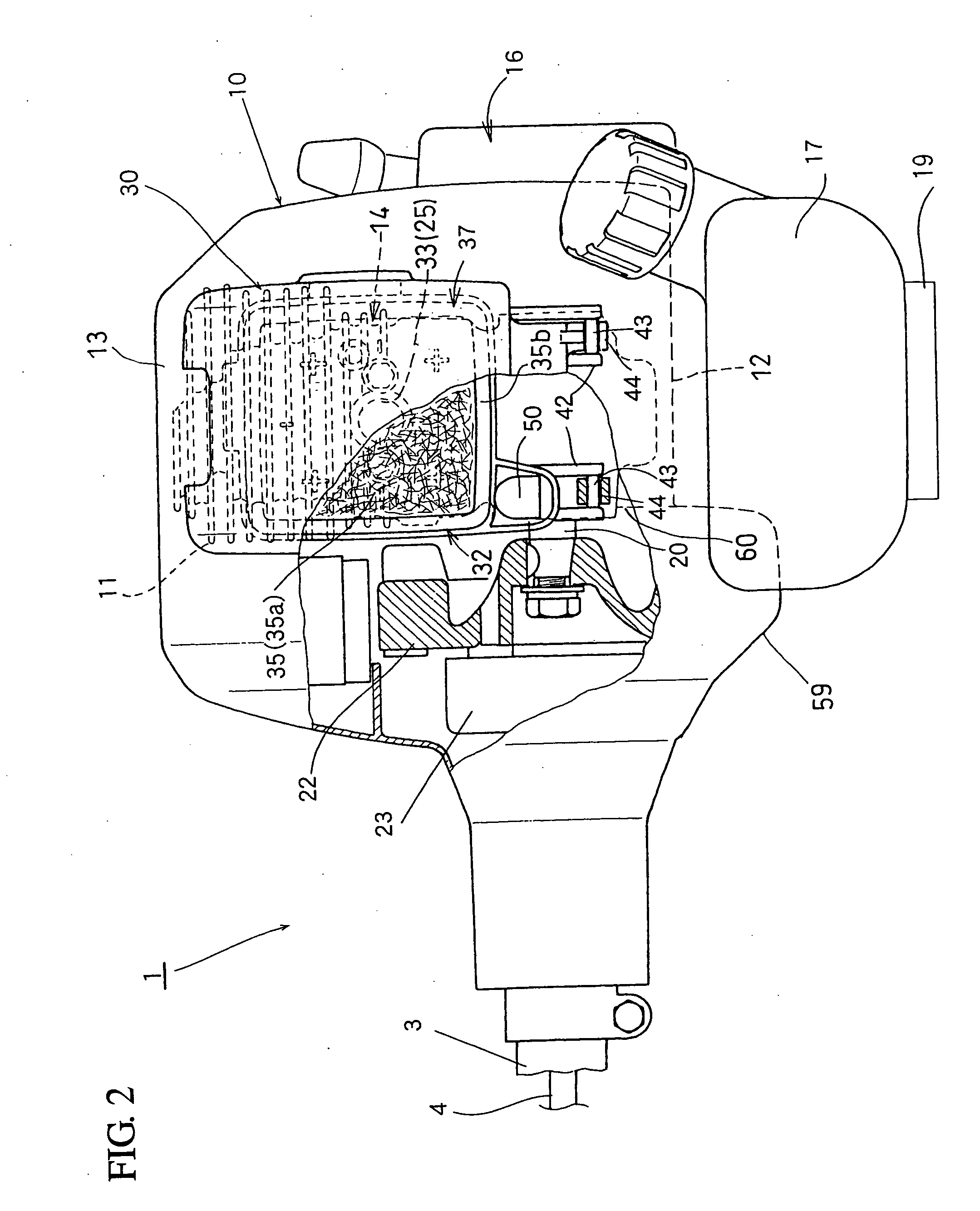

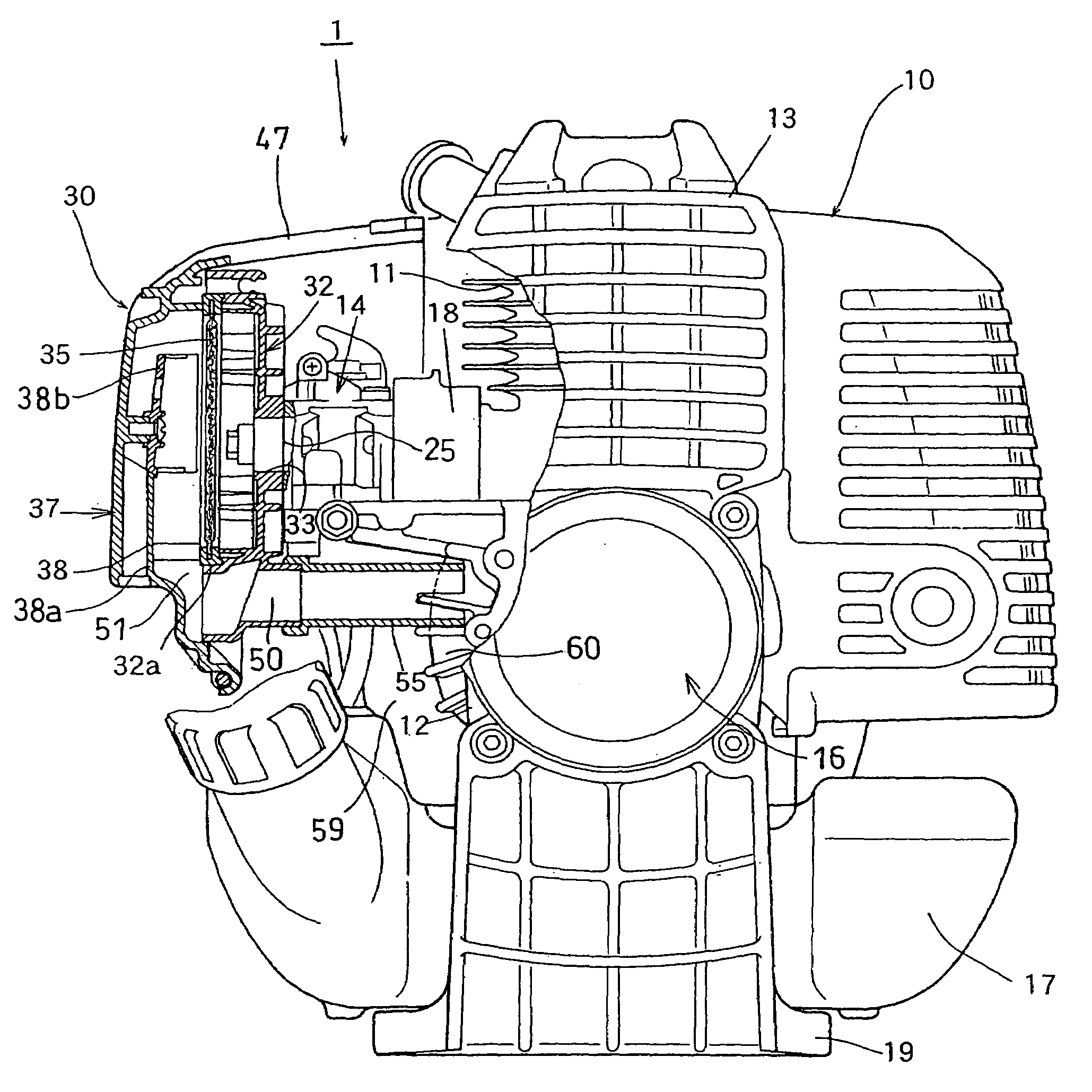

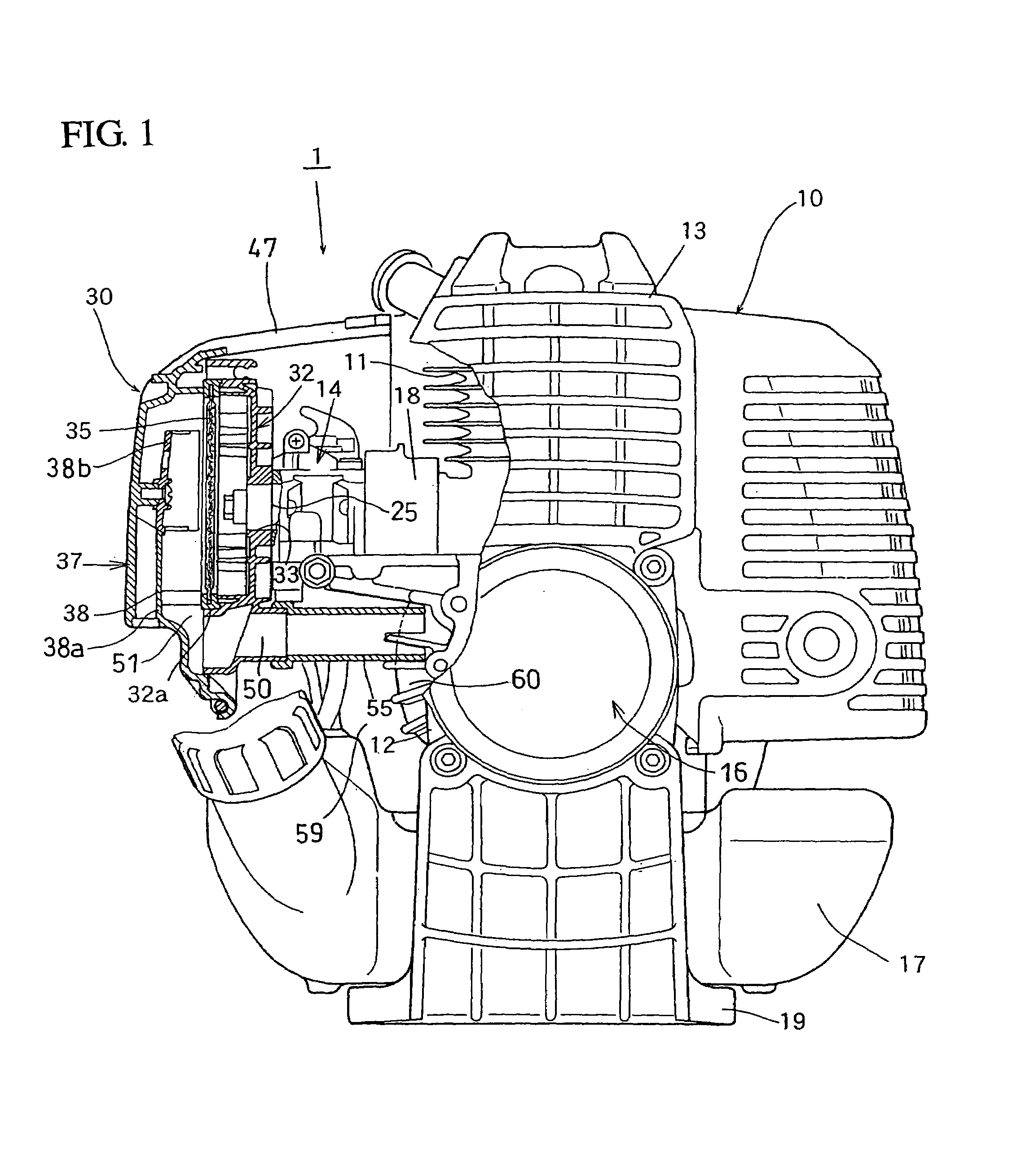

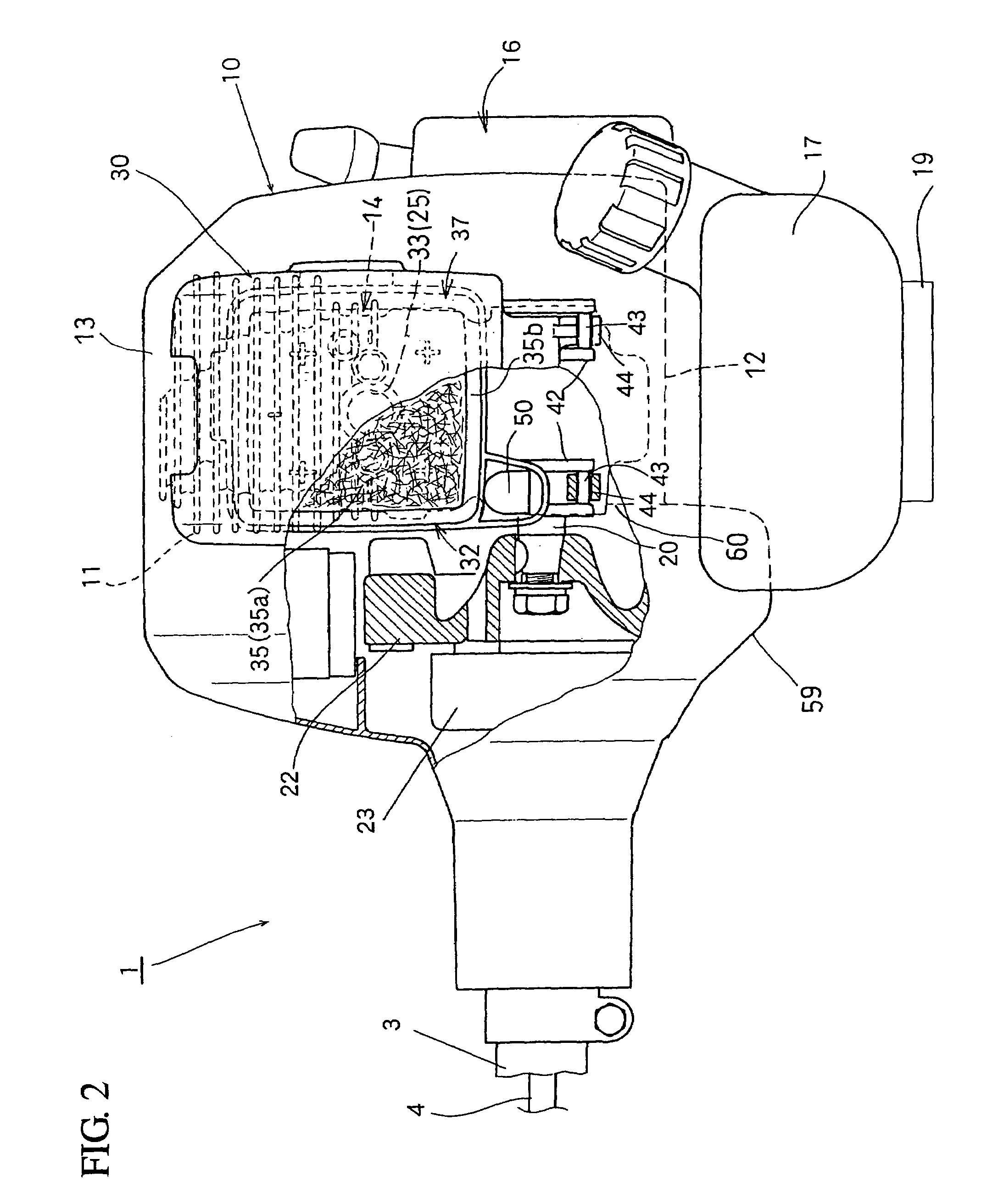

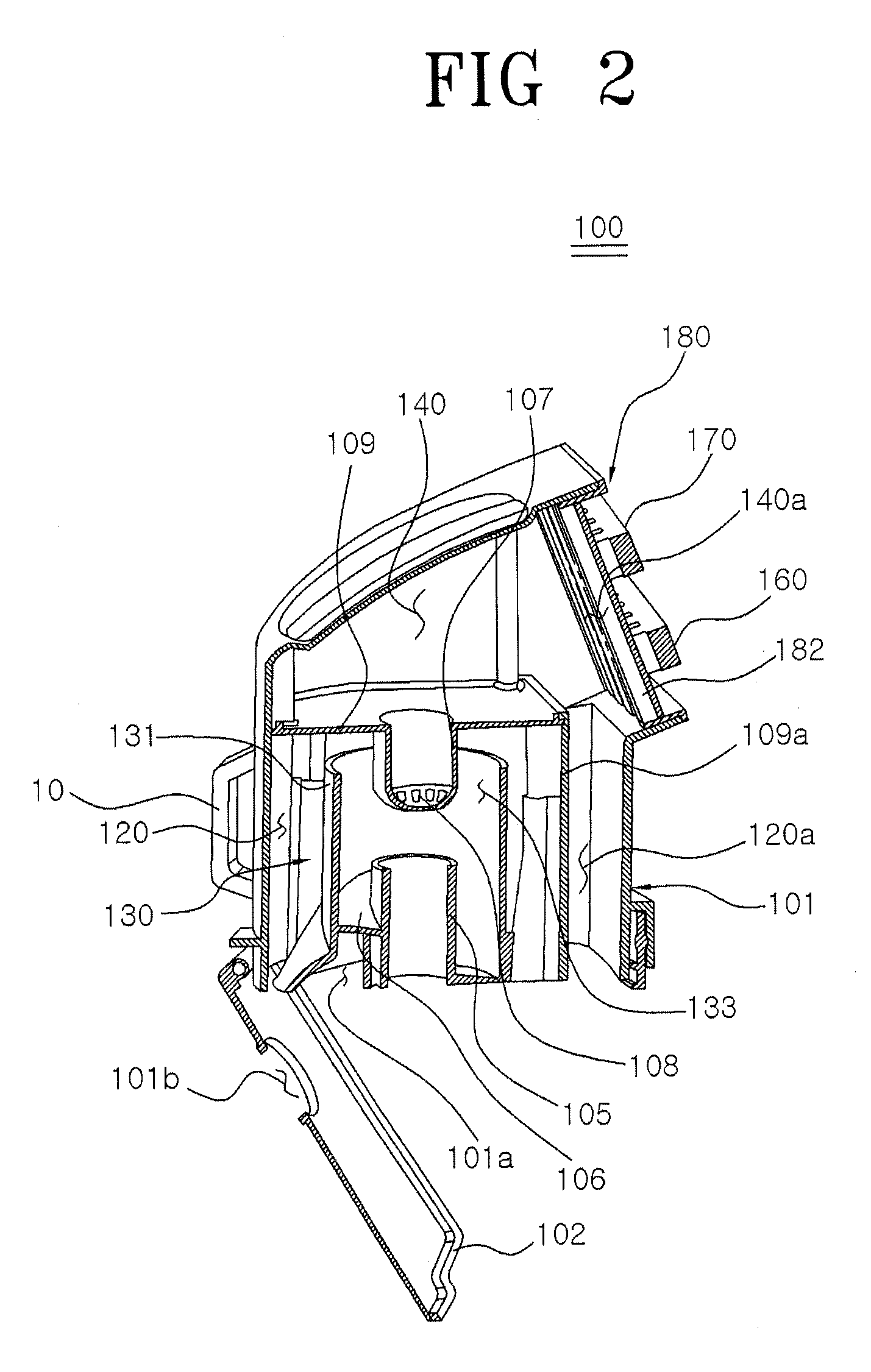

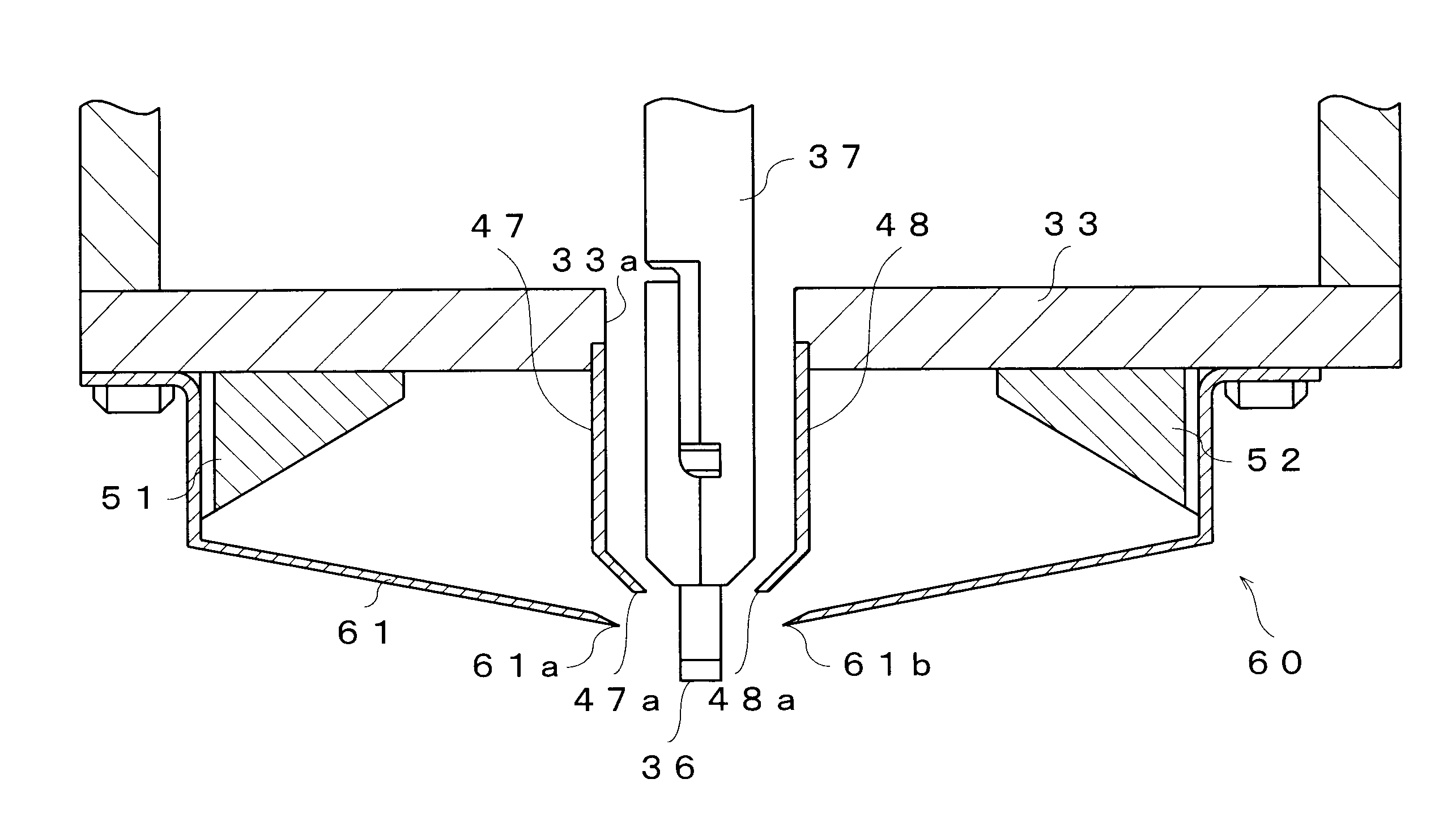

Portable power working machine

ActiveUS20050050867A1Improve system efficiencyReduce cloggingCombination devicesLiquid degasificationPortable powerEngineering

A portable power working machine is disclosed, which is capable of effectively minimizing the clogging of the air cleaner, thereby dispensing with frequent maintenance. This portable power working machine comprises an air cleaner (30) having a base body case (32) provided with a clean air discharge port (33) for introducing the air cleaned into an intake port (25) of a carburetor (14), a filter (35) which is mounted on a filter mounting opening (32a) of base body case (32) so as to seal it, and a cleaner cover (37) which is attached onto the filter (35) so as to cover the filter (35) and to guide outside air toward the filter (35), while giving a predetermined directionality to the outside air. The air cleaner (30) is also configured to include a suction port (50) and a suction guiding member (55) both designed to discharge the dust out of the air cleaner (30) through a space formed between the filter (35) and the cleaner cover (37) as the dust adhered to the outside air side of the filter (35) is sucked out by taking advantage of a negative pressure to be generated by a fan (22).

Owner:KIORITZ

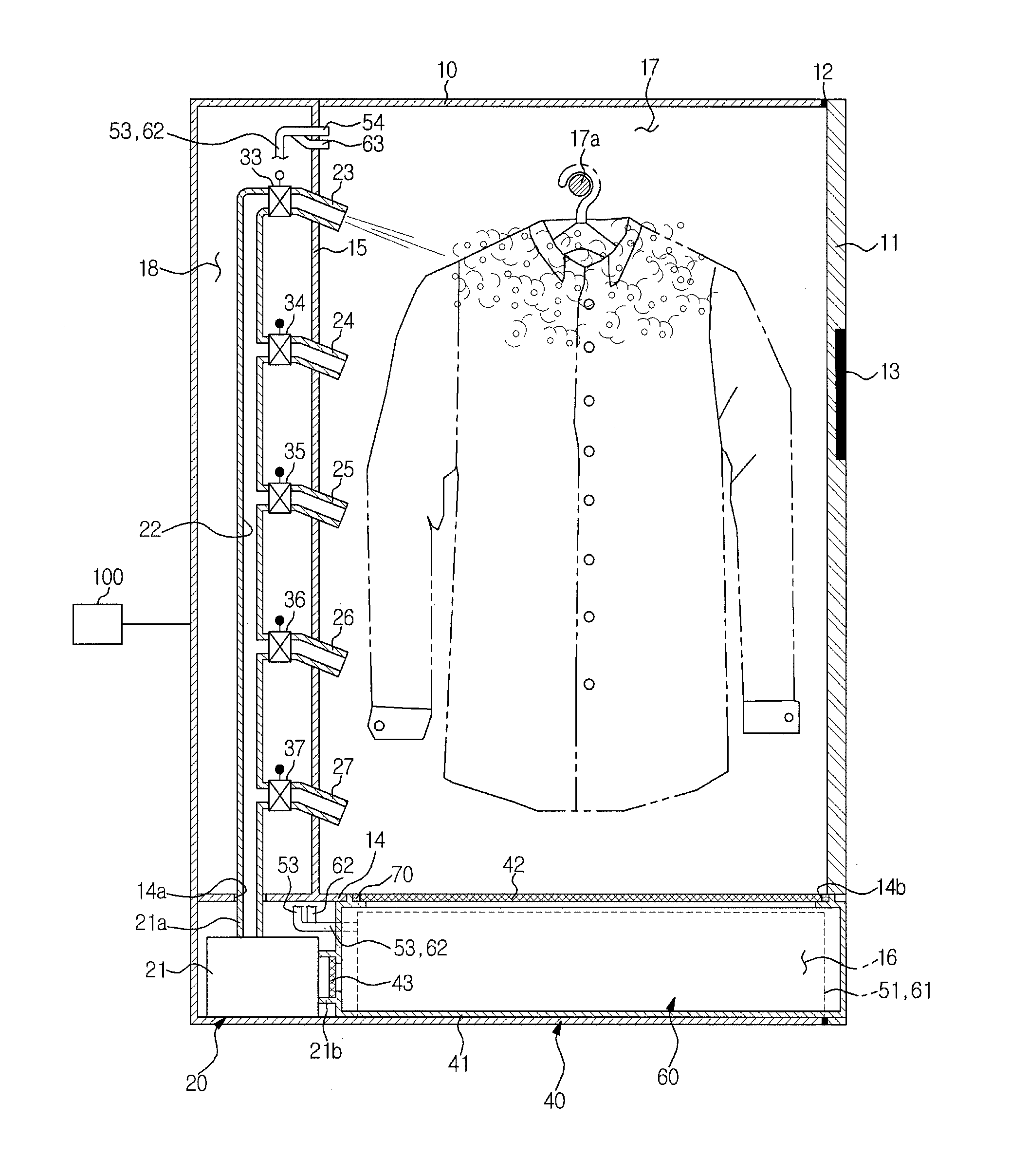

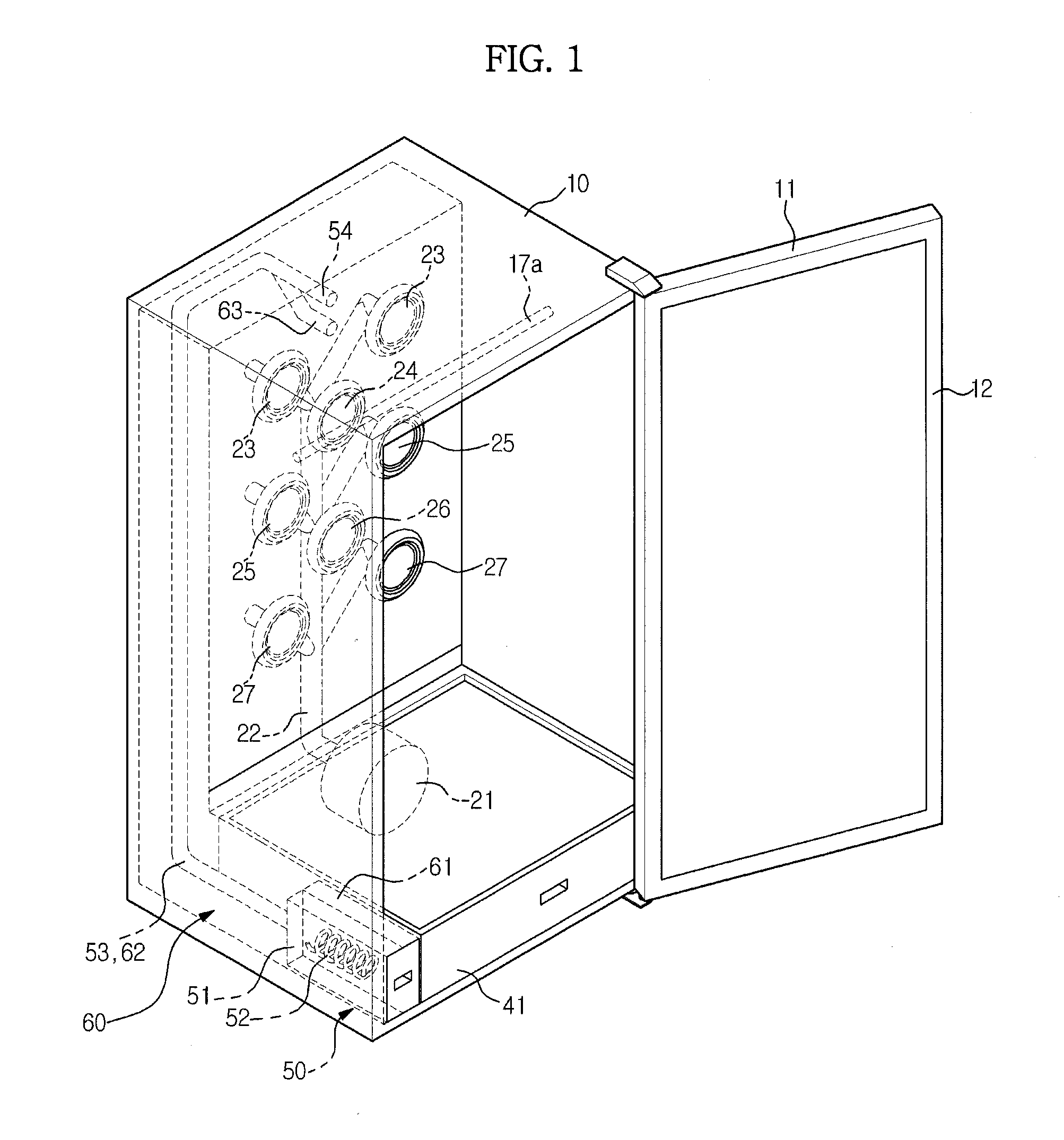

Refresh washing machine and control method thereof

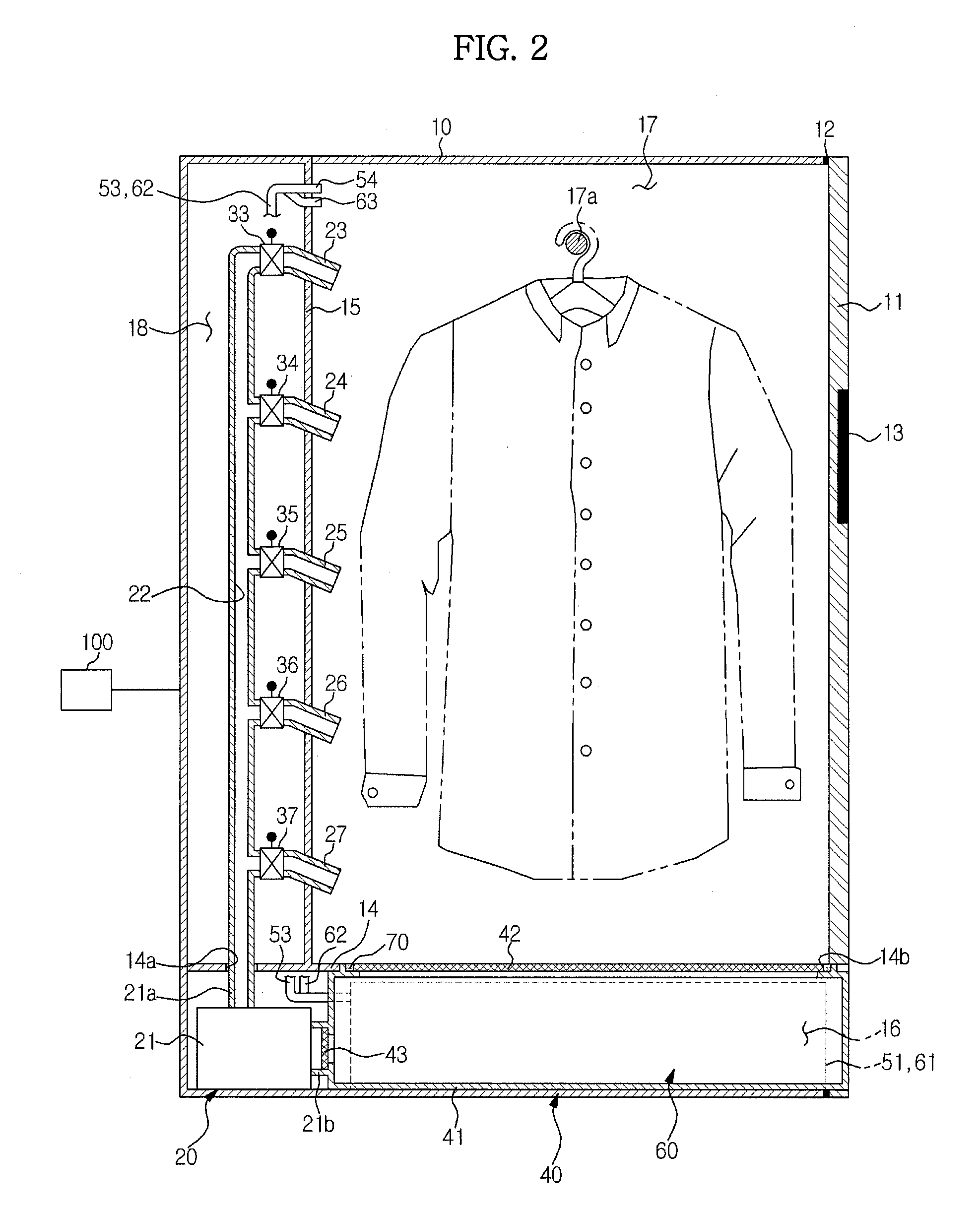

InactiveUS20120160269A1Effectively remove dustSimple structureTextile treatment machine partsHollow article cleaningSpray nozzleEngineering

A refresh washing machine including a plurality of spray nozzles to spray air into a clothes receiving compartment of a cabinet, a plurality of opening and closing valves to open and close the spray nozzles, and a controller to open at least one of the opening and closing valves and close the other opening and closing valves so that air is sequentially sprayed from the spray nozzles.

Owner:SAMSUNG ELECTRONICS CO LTD

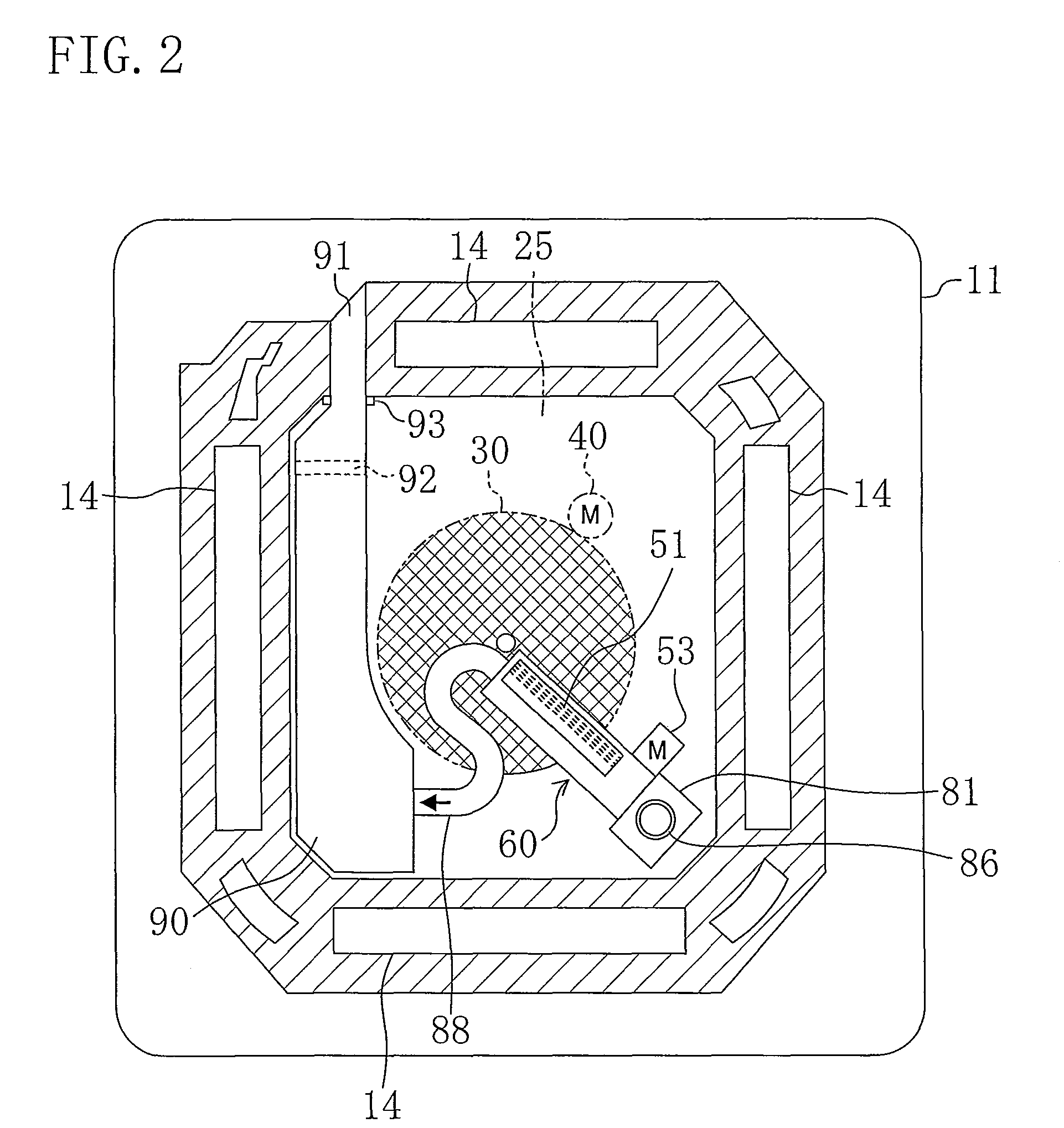

Dust collector for a vacuum cleaner having a dust removal function

ActiveUS8870988B2Volume andEffectively remove dustCleaning filter meansSuction filtersEngineeringVacuum cleaner

A dust collector includes a dust container; a centrifugal separator installed inside the dust container to separate dust from air; a filter unit installed at a discharge hole of the centrifugal separator and provided with a filter member; and a dust-removing device for dislodging dust from the filter unit. The dust-removing device includes a dust removal unit including a dust-removing member having dust-removing projections formed on an undersurface thereof, wherein the dust-removing projections move back and forth while contacting the filter unit to dislodge dust from the filter unit; and a drive unit for providing driving power to the dust removal unit.

Owner:SAMSUNG ELECTRONICS CO LTD

System and Method for Treating Dust Contained in Extracted Cement Kiln Combustion Gas

InactiveUS20080092739A1Low facility and run costEfficiently removeCombination devicesUsing liquid separation agentLiquid tankCyclone

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising: a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a classifier 5 for separating coarse powder from dust contained in the combustion gas extracted by the probe 3; a wet dust collector 6 for collecting dust from the extracted gas containing fine powder discharged from the classifier 5; and devices 12, 13 for feeding sulfurizing agent for sulfurizing lead contained in the kiln exhaust gas to the wet dust collector 6, and others. From the sulfurizing-agent feeders 12, 13 are preferably added the sulfurizing agents to a circulation liquid tank 7 or a pump 9 for circulating slurry. The slurry obtained by the wet dust collector 6 is separated into froth including lead and tail side slurry including gypsum by a flotation facility 14, 17, 18.

Owner:TAIHEIYO CEMENT CORP

Portable power working machine

ActiveUS7007660B2Frequent maintenanceConvenience to workCombination devicesLiquid degasificationPortable powerEngineering

A portable power working machine is disclosed, which is capable of effectively minimizing the clogging of the air cleaner, thereby dispensing with frequent maintenance. This portable power working machine comprises an air cleaner (30) having a base body case (32) provided with a clean air discharge port (33) for introducing the air cleaned into an intake port (25) of a carburetor (14), a filter (35) which is mounted on a filter mounting opening (32a) of base body case (32) so as to seal it, and a cleaner cover (37) which is attached onto the filter (35) so as to cover the filter (35) and to guide outside air toward the filter (35), while giving a predetermined directionality to the outside air. The air cleaner (30) is also configured to include a suction port (50) and a suction guiding member (55) both designed to discharge the dust out of the air cleaner (30) through a space formed between the filter (35) and the cleaner cover (37) as the dust adhered to the outside air side of the filter (35) is sucked out by taking advantage of a negative pressure to be generated by a fan (22).

Owner:KIORITZ

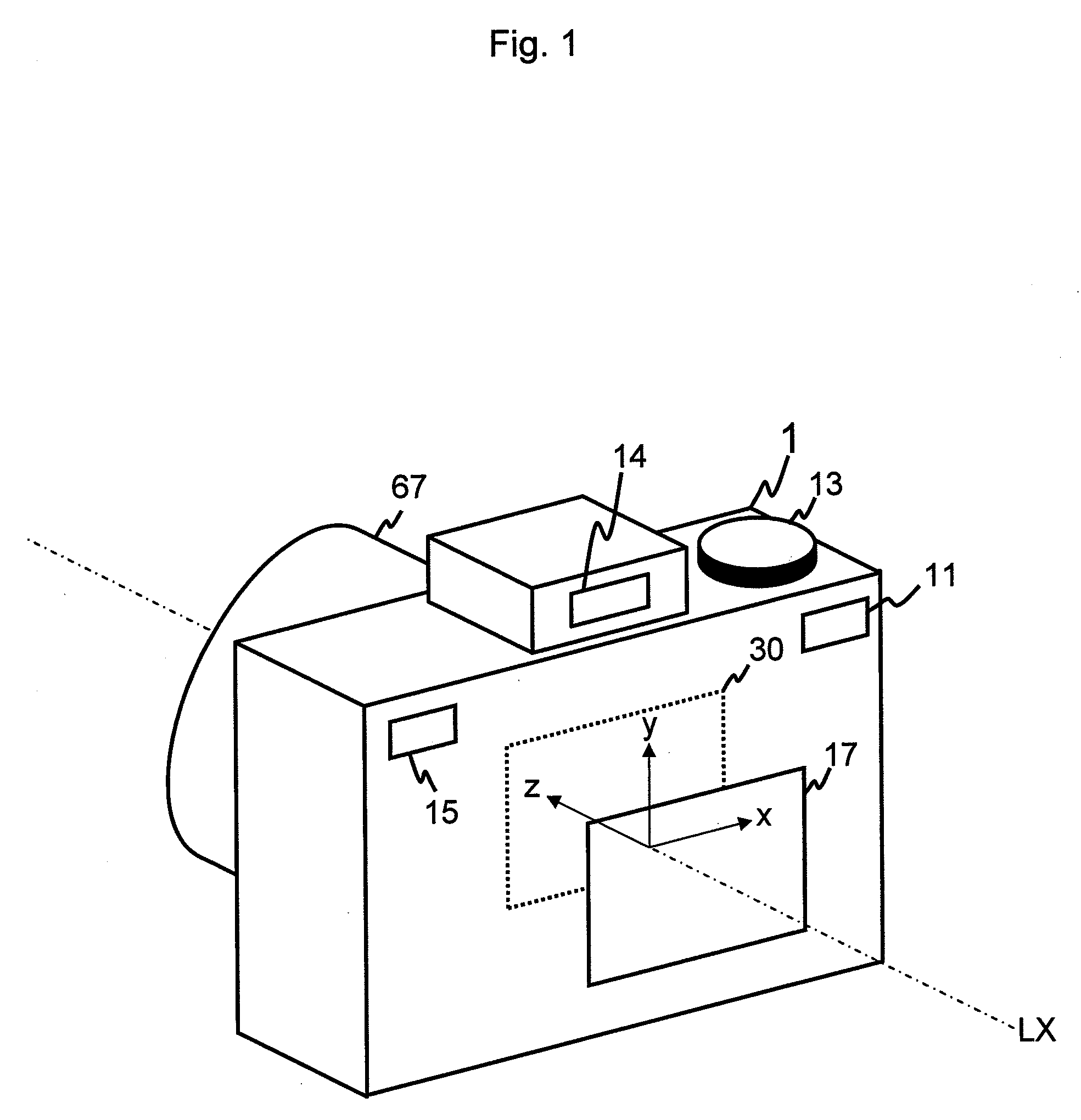

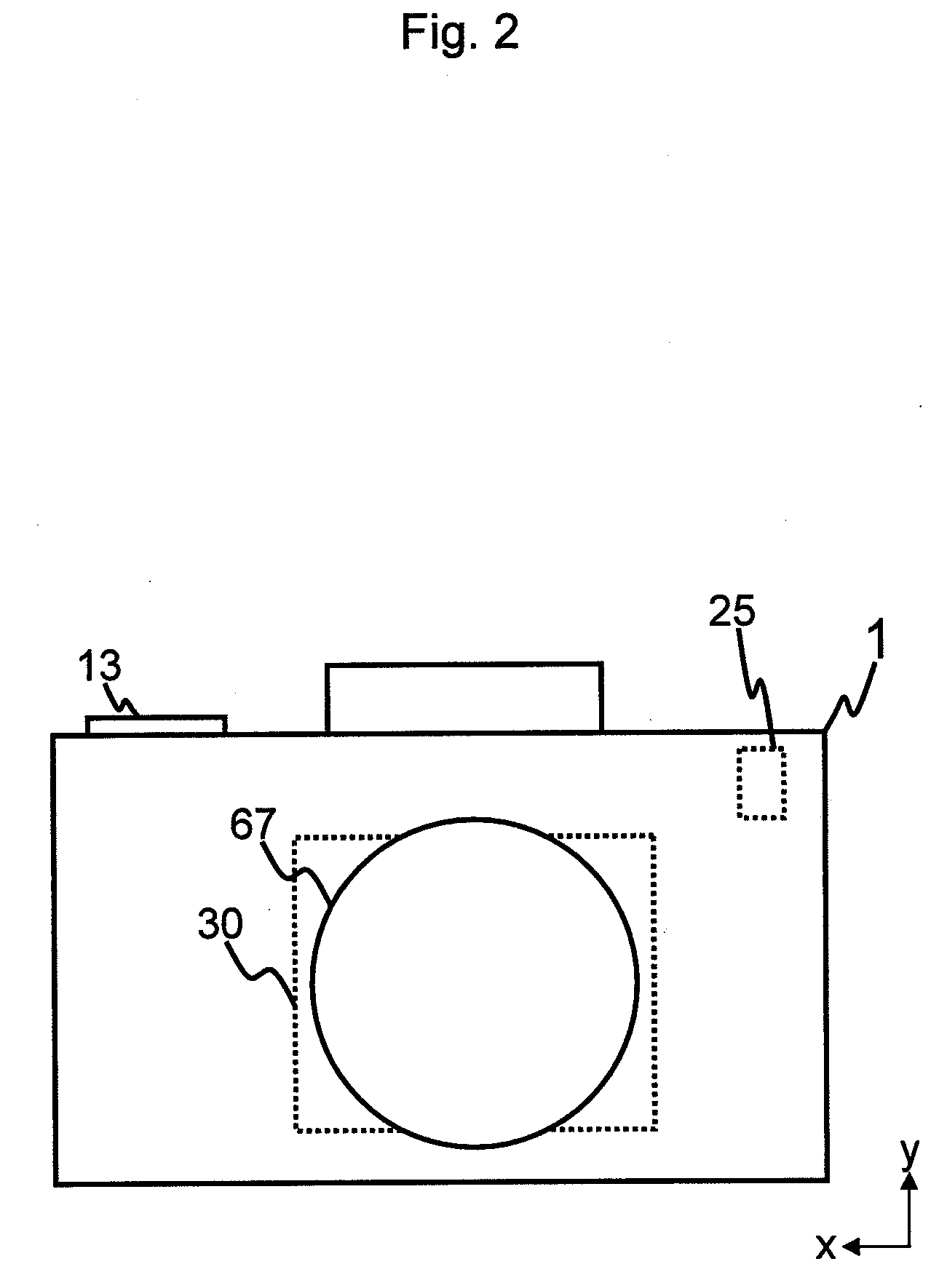

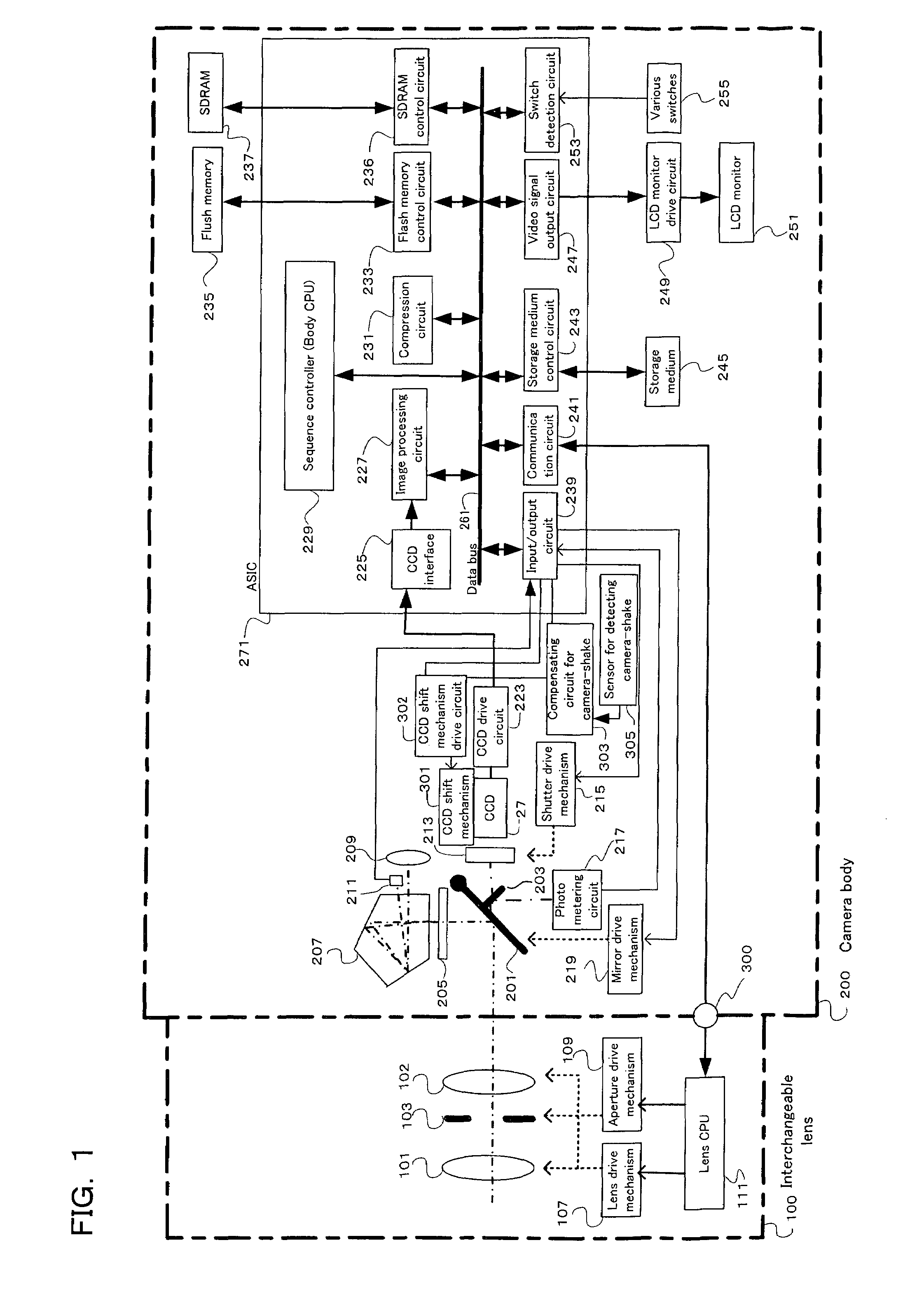

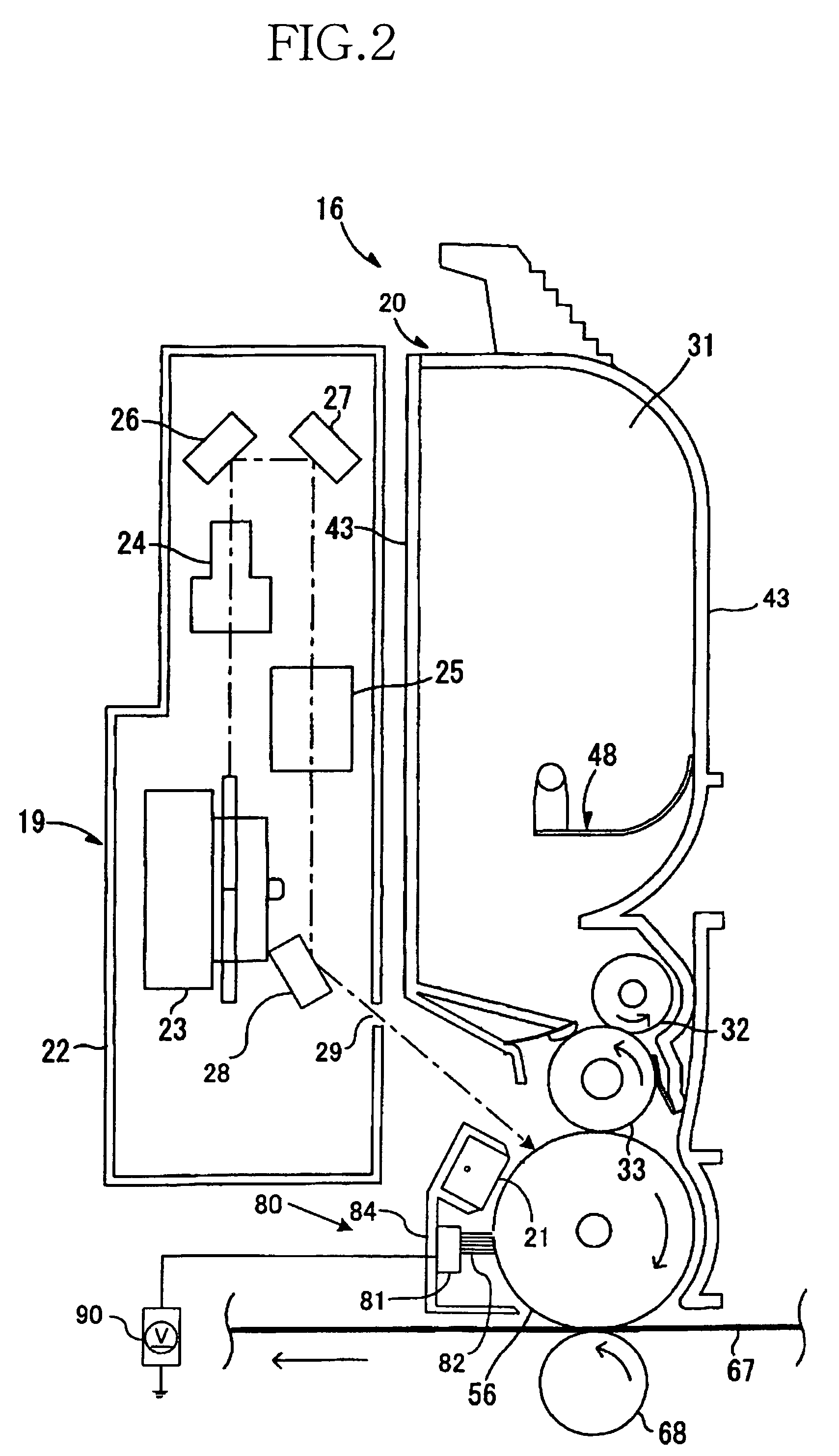

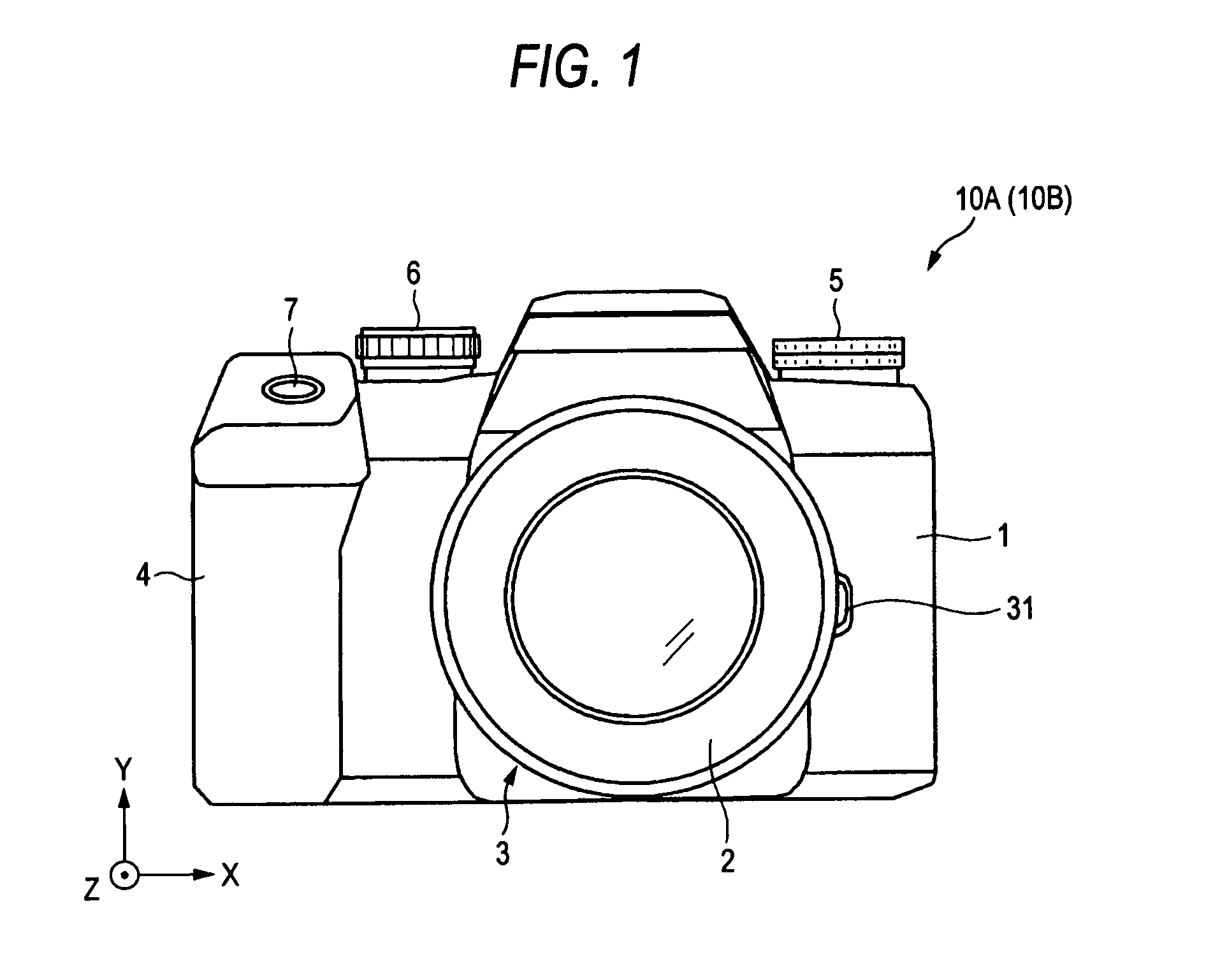

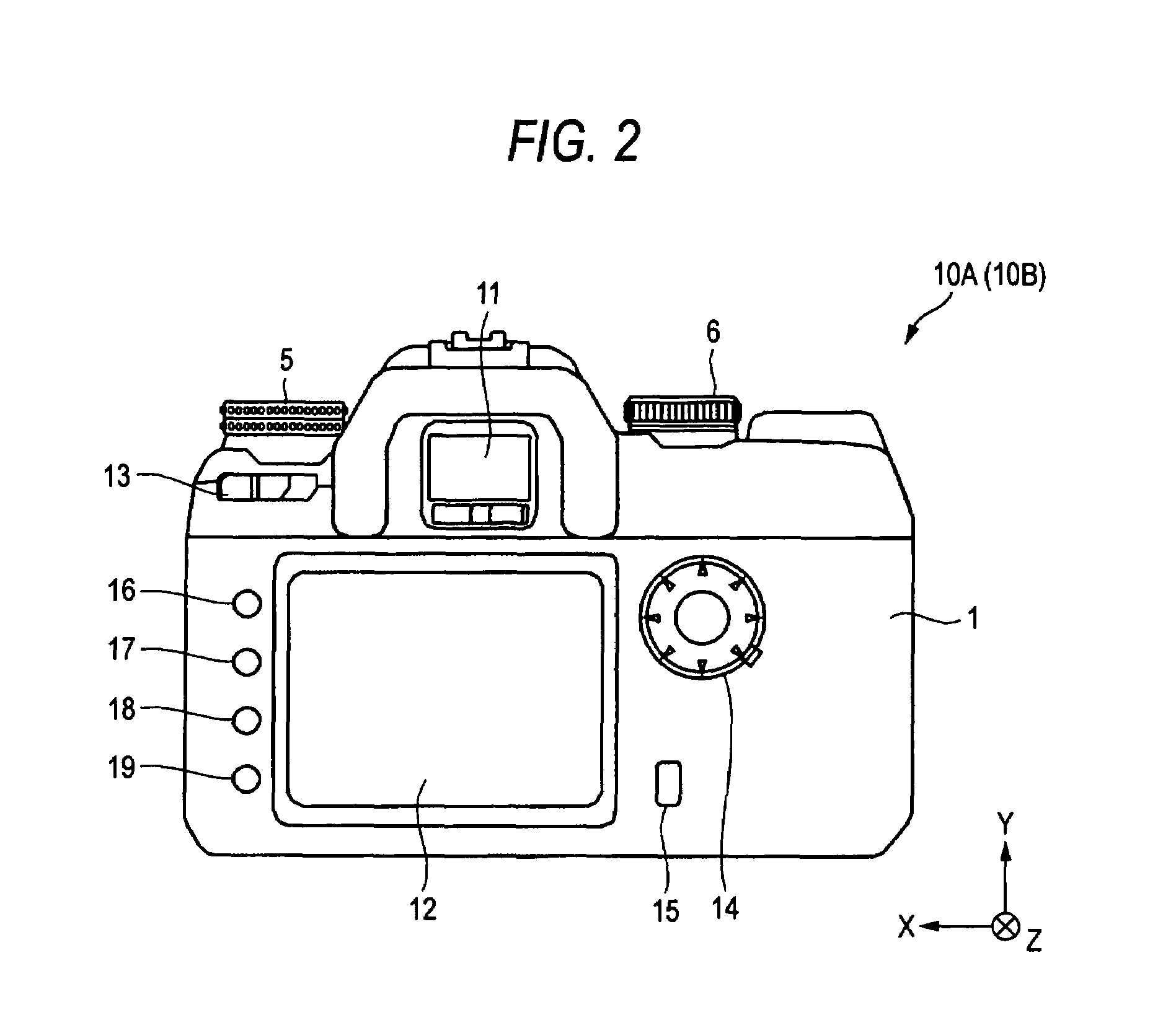

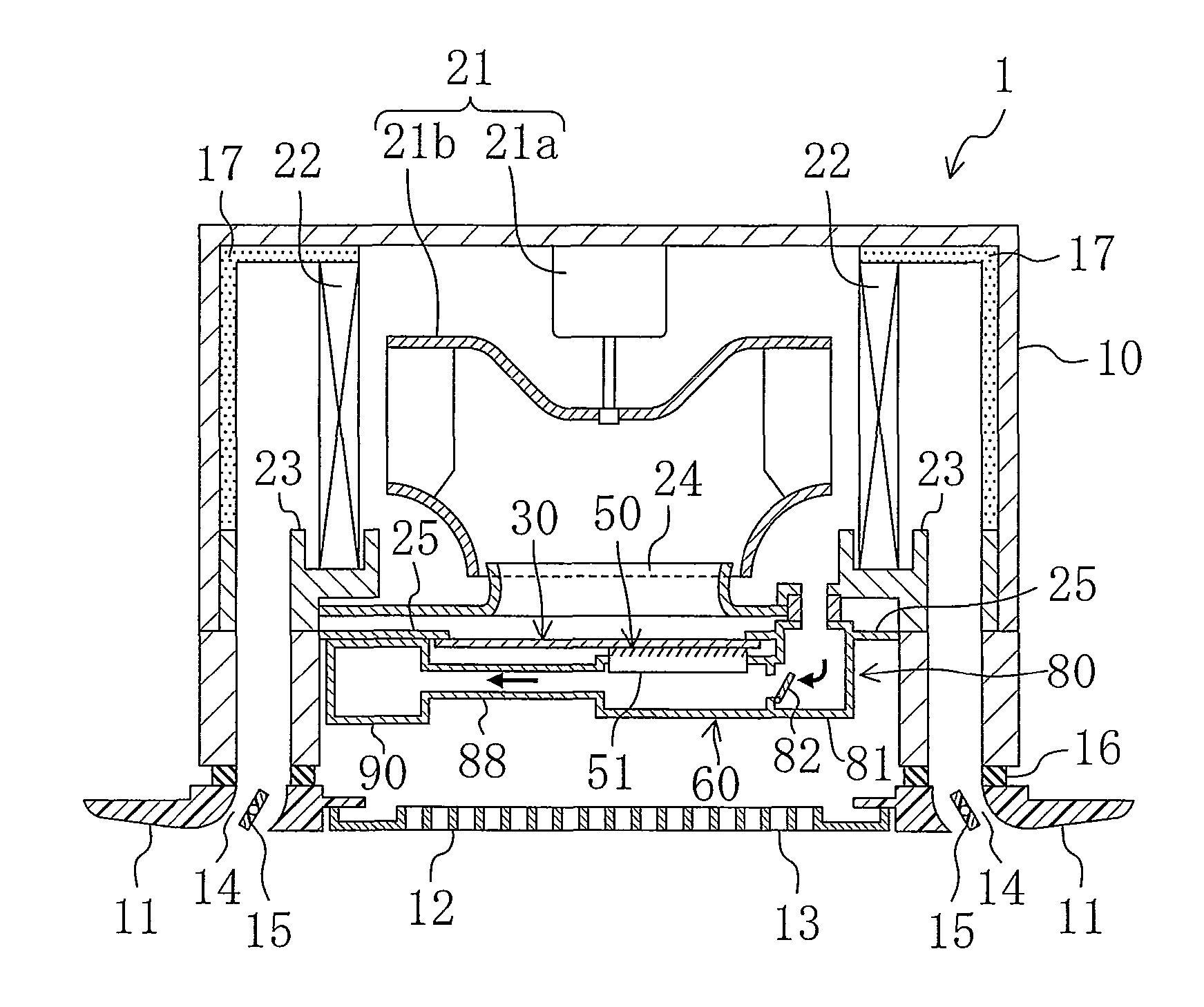

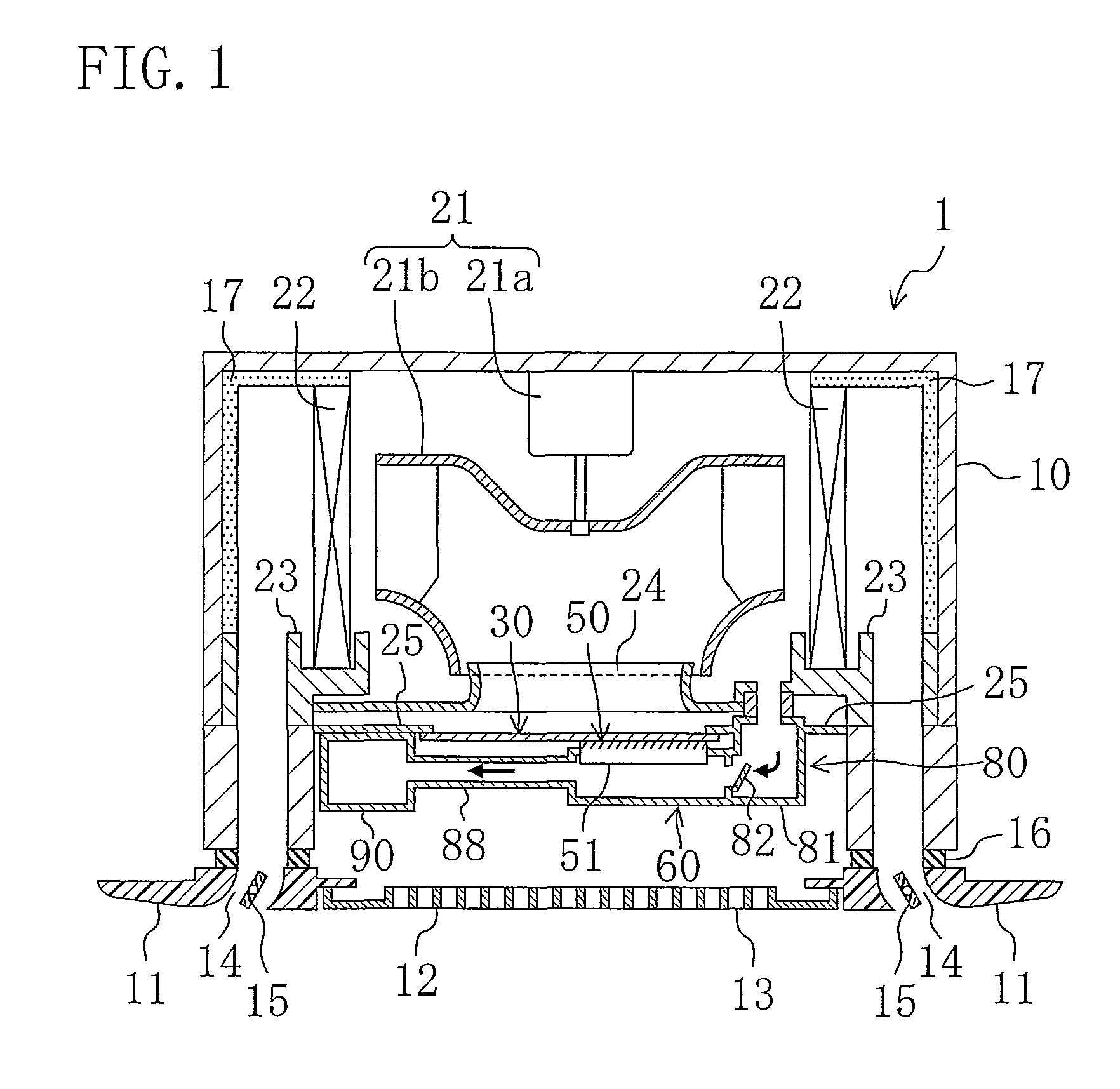

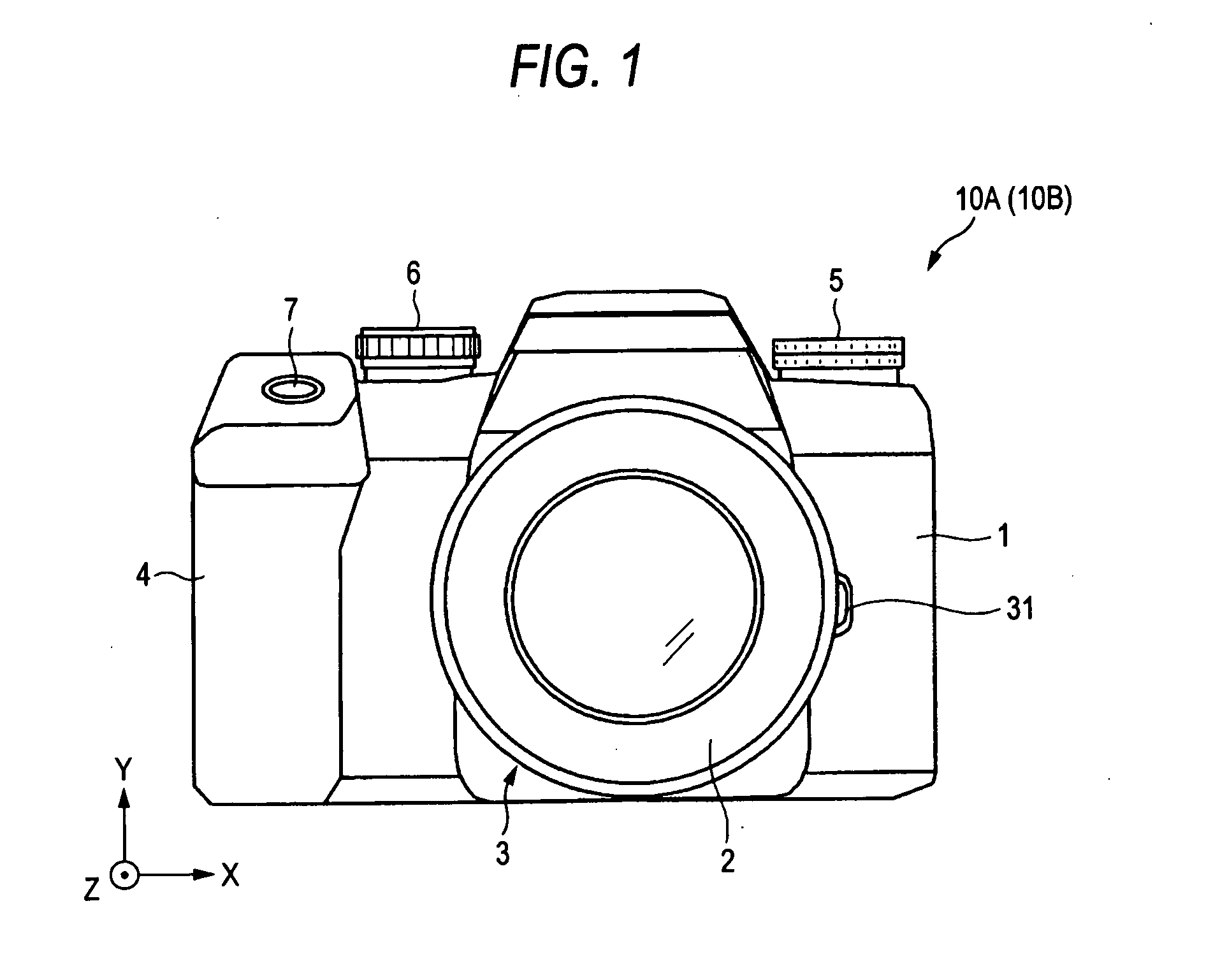

Dust removal apparatus of photographing apparatus

InactiveUS20080084492A1Reduce damageEffectively remove dustTelevision system detailsColor television detailsDust controlMechanics

A dust removal apparatus of a photographing apparatus comprises a movable unit and a controller. The movable unit has an imaging device and is movable. The controller strikes the movable unit against a boundary of a range of movement of the movable unit as a dust removal operation. The controller counts the number of times of the dust removal operation, measures an elapsed time from the point when counting the number of times of the dust removal operation commences. When the elapsed time is less than or equal to a time period and the number of times of the dust removal operation is equal to or greater than a predetermined number of times, the controller halts the dust removal operation until a predetermined time period has elapsed.

Owner:PENTAX RICOH IMAGING CO LTD

Dust collector for a vacuum cleaner having a dust removal function

ActiveUS20120117927A1Minimizing functionEasy to assembleCleaning filter meansCombination devicesAir separationVacuum cleaner

A dust collector includes a dust container; a centrifugal separator installed inside the dust container to separate dust from air; a filter unit installed at a discharge hole of the centrifugal separator and provided with a filter member; and a dust-removing device for dislodging dust from the filter unit. The dust-removing device includes a dust removal unit including a dust-removing member having dust-removing projections formed on an undersurface thereof, wherein the dust-removing projections move back and forth while contacting the filter unit to dislodge dust from the filter unit; and a drive unit for providing driving power to the dust removal unit.

Owner:SAMSUNG ELECTRONICS CO LTD

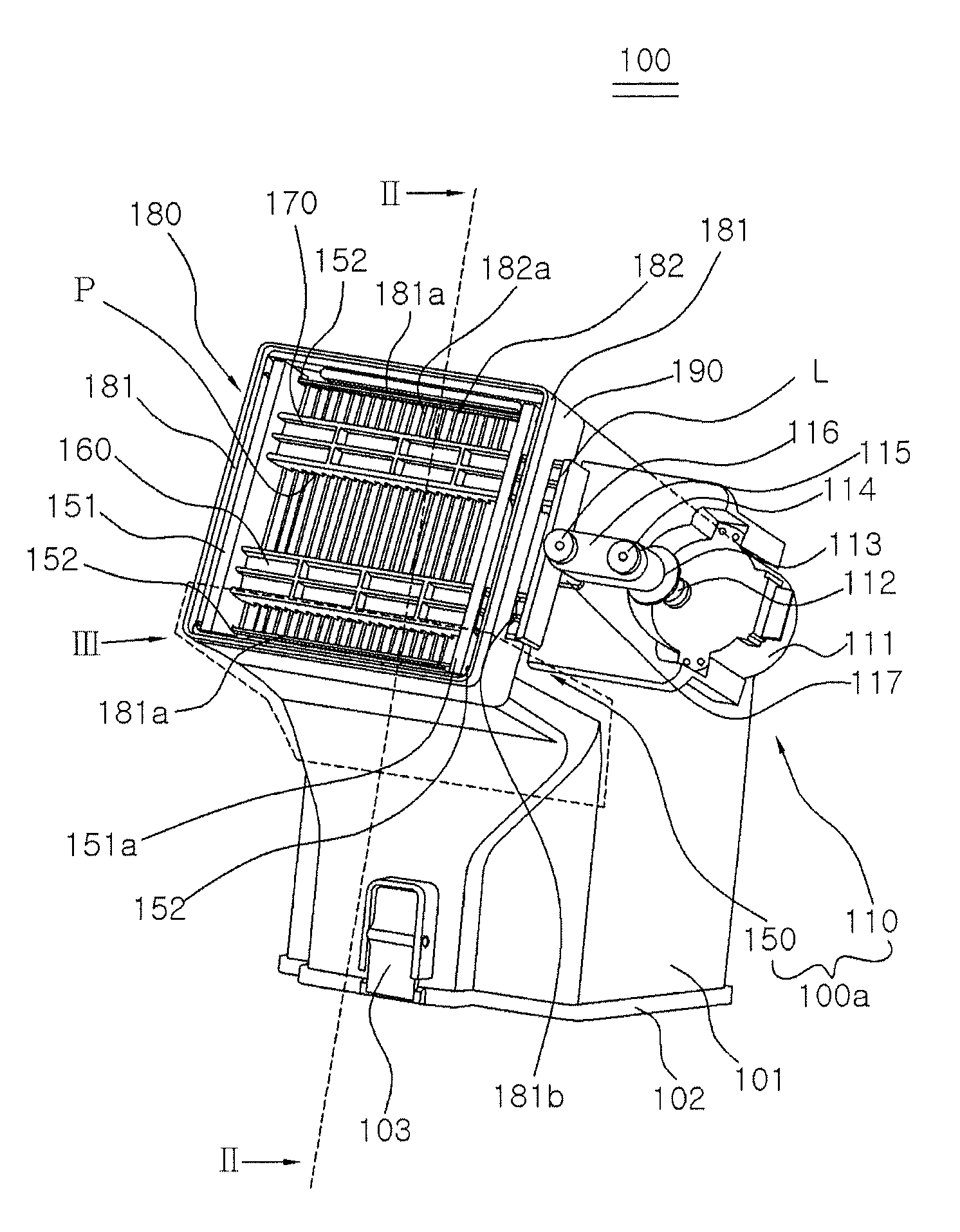

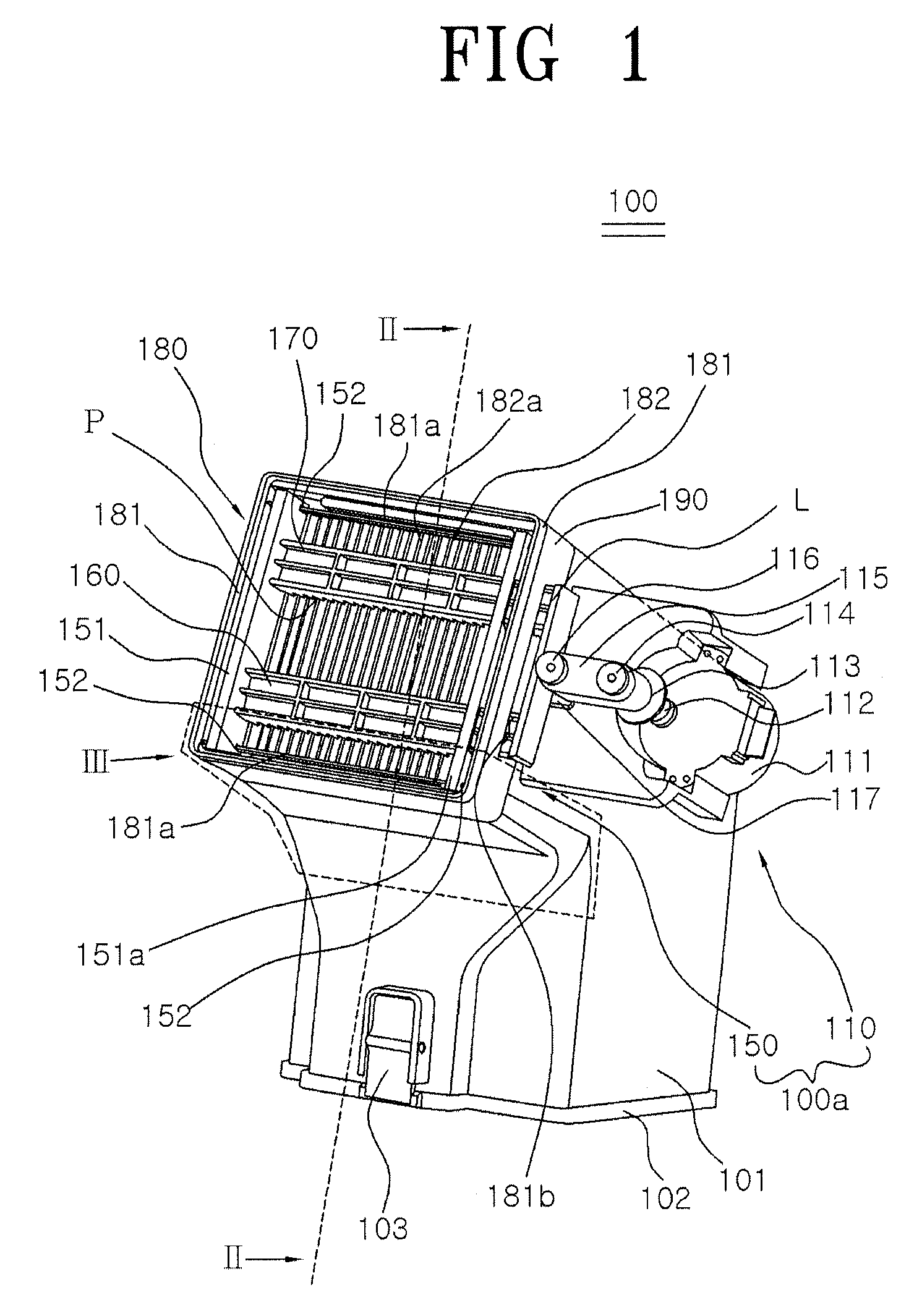

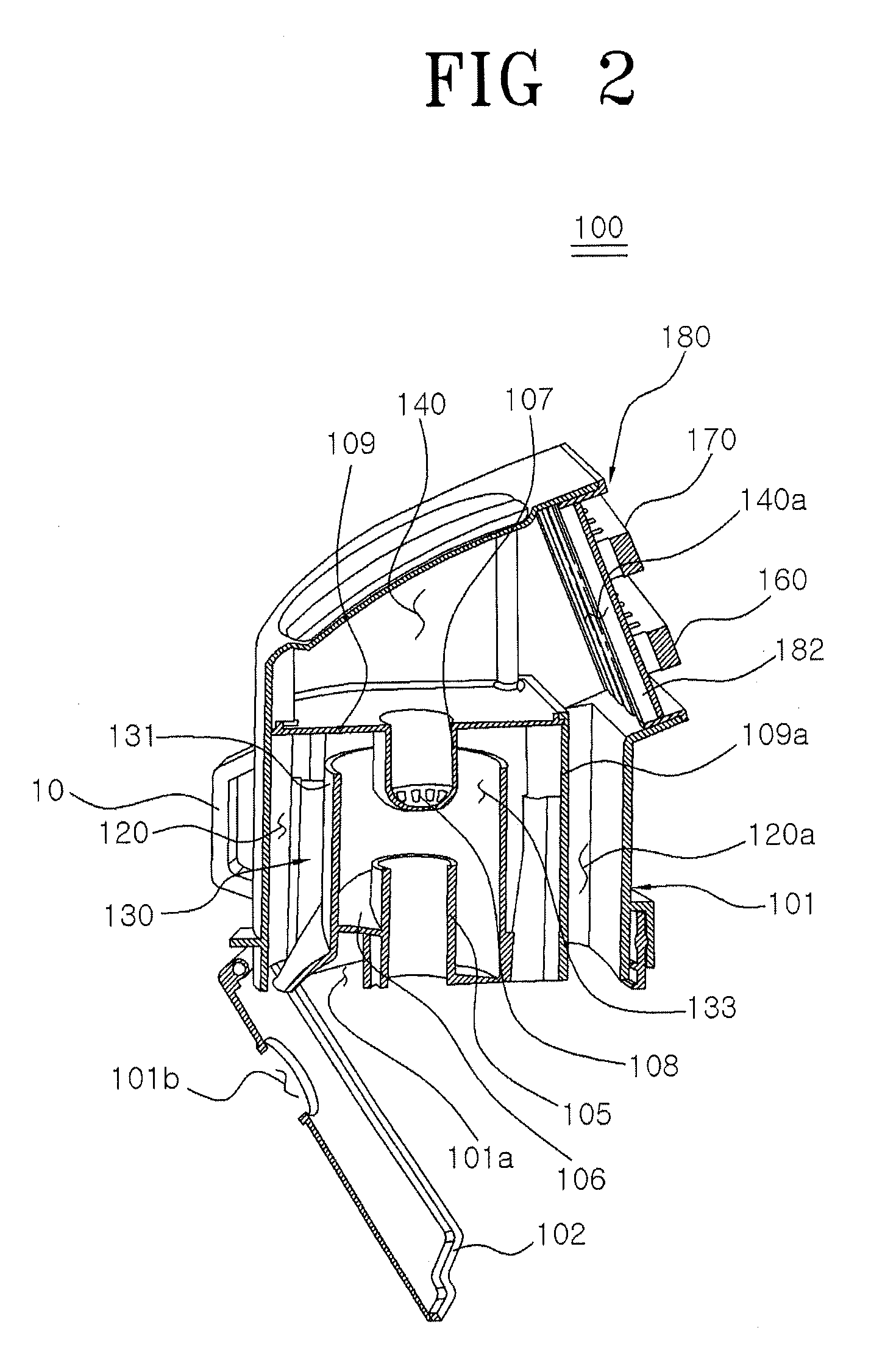

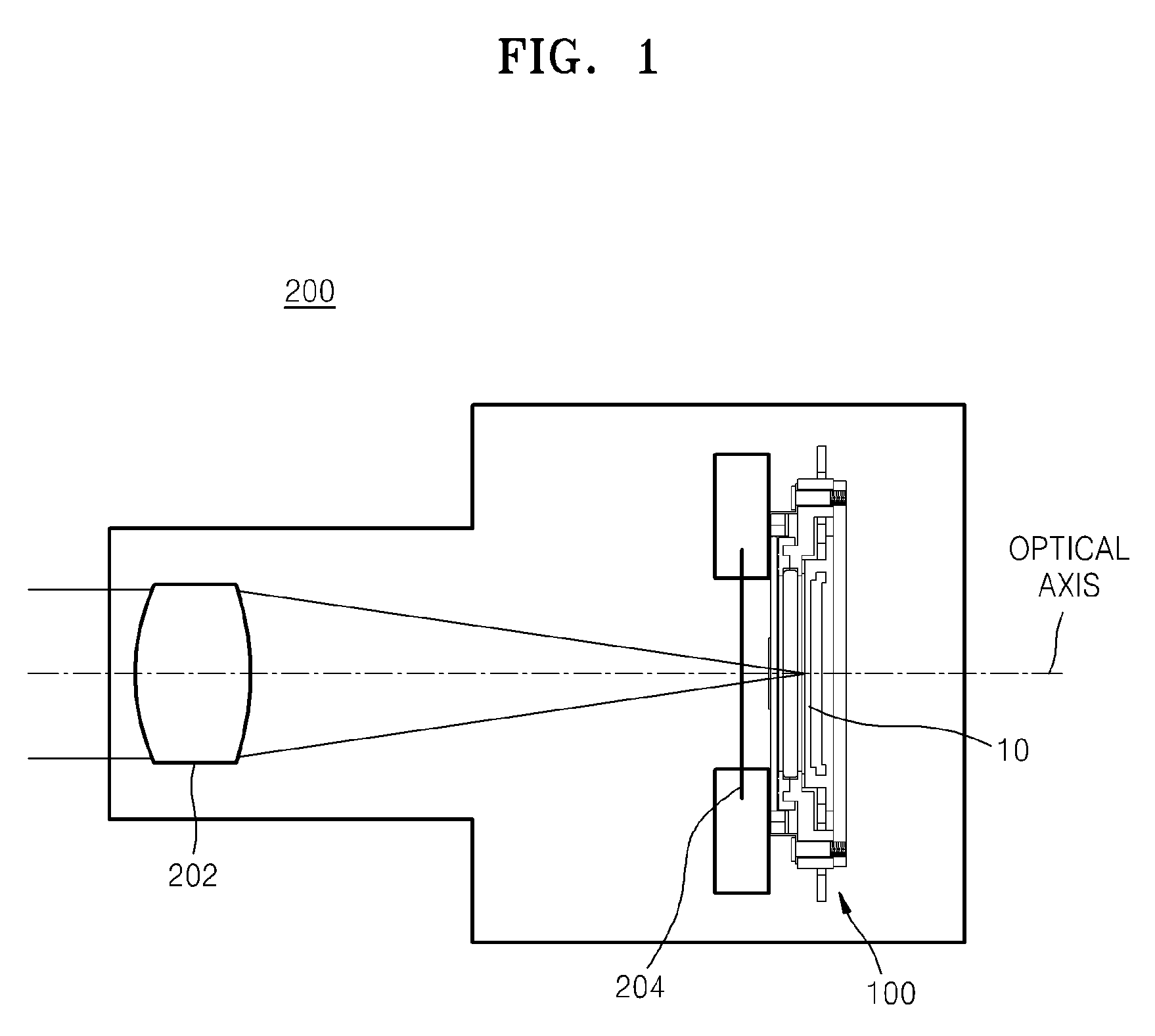

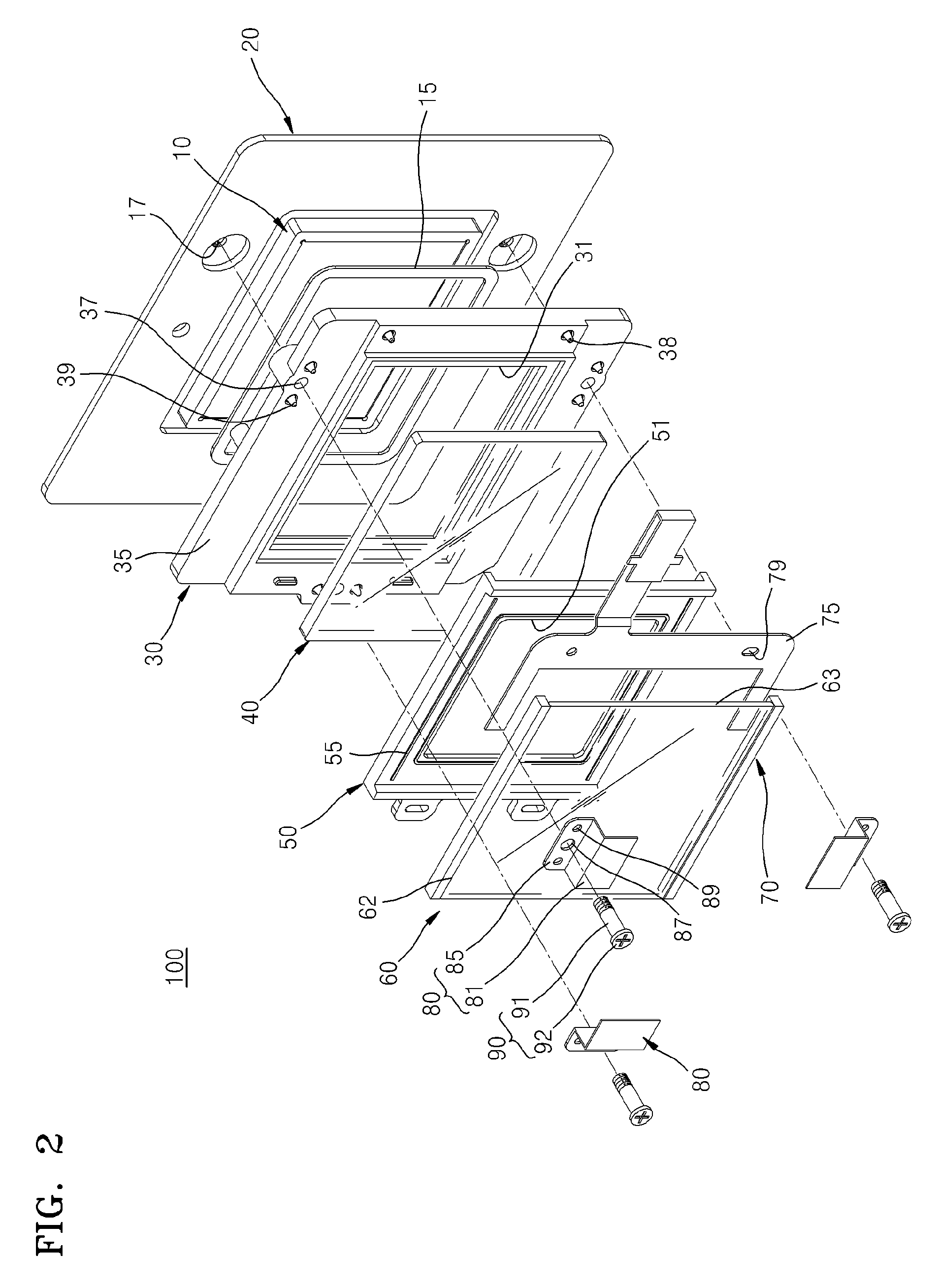

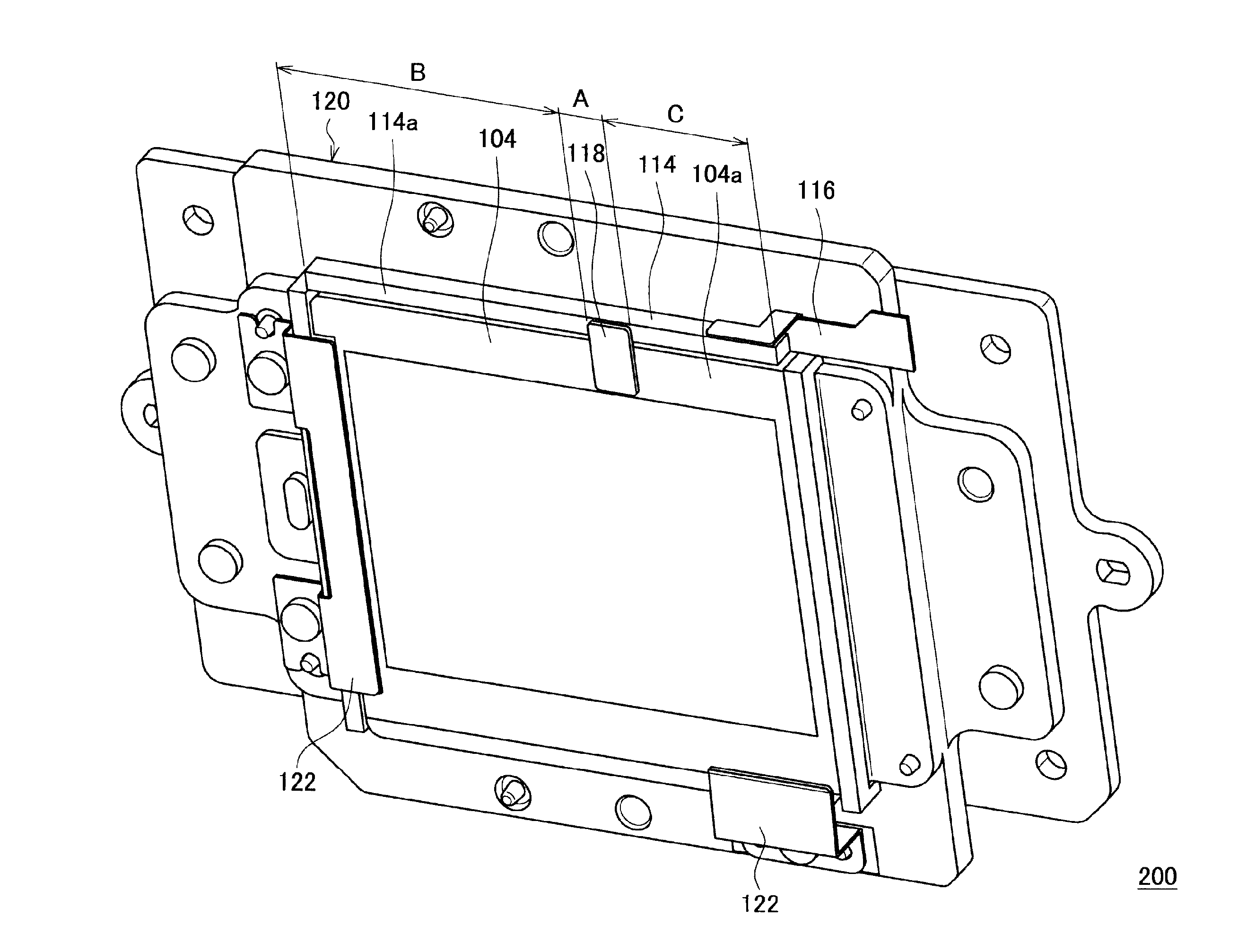

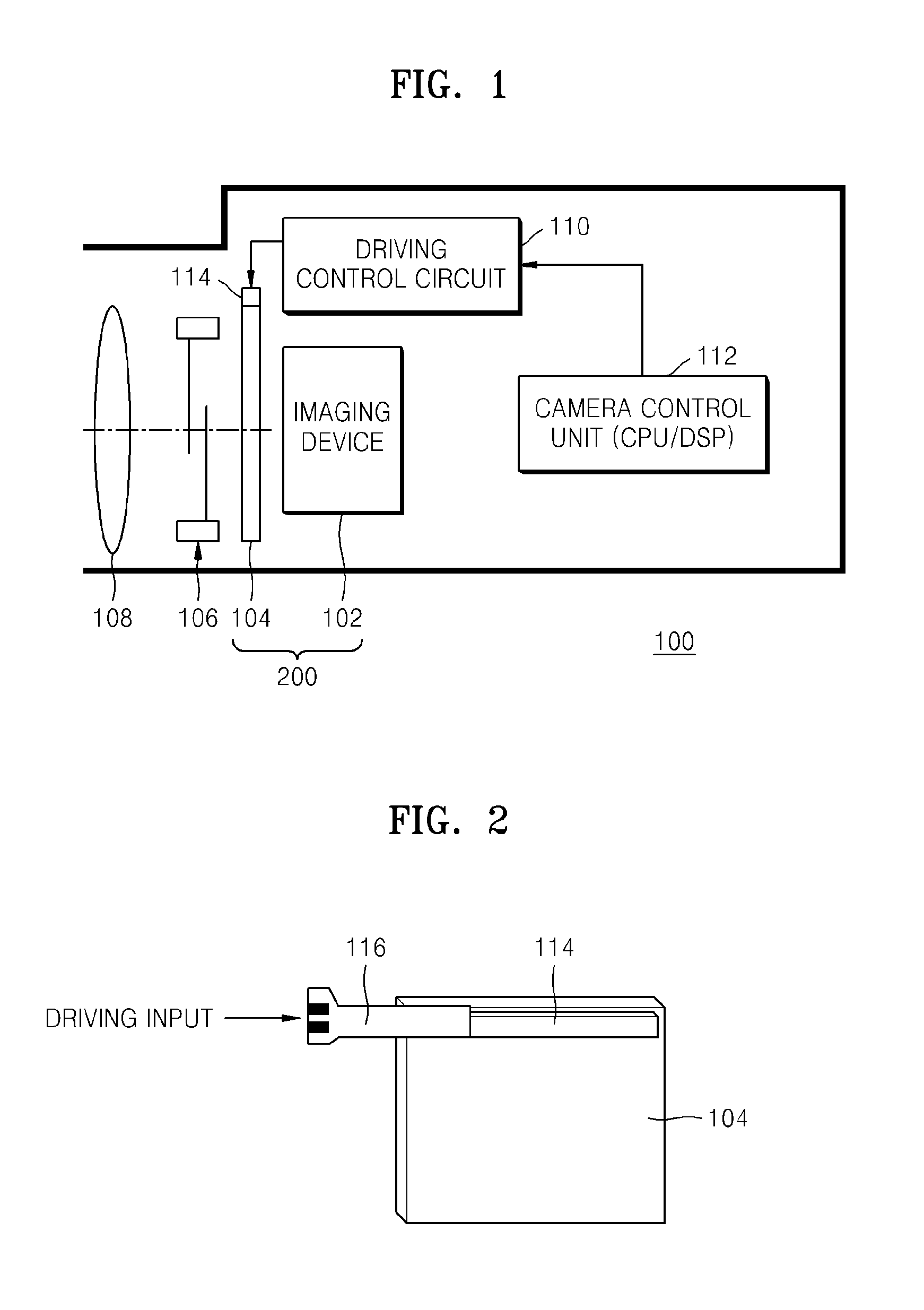

Imaging apparatus and camera including the same

ActiveUS20140160346A1Effectively remove dustTelevision system detailsColor television detailsLight fluxEngineering

An imaging apparatus includes an imaging element unit having an imaging element and an optical element which is integrally formed with the imaging element and through which a luminous flux of light for imaging passes, a first piezoelectric element, and a displacement increment mechanism connected to the first piezoelectric element and the imaging element unit. The displacement increment mechanism displaces the imaging element unit by expanding or contracting the first piezoelectric element, where a portion of the first piezoelectric element in a lengthwise direction thereof is attached to the optical element.

Owner:SAMSUNG ELECTRONICS CO LTD

Image pickup apparatus controlling shake sensing and/or shake compensation during dust removal

ActiveUS7680403B2Effectively remove dustTelevision system detailsColor television detailsCamera lensOptical axis

Owner:OM DIGITAL SOLUTIONS CORP

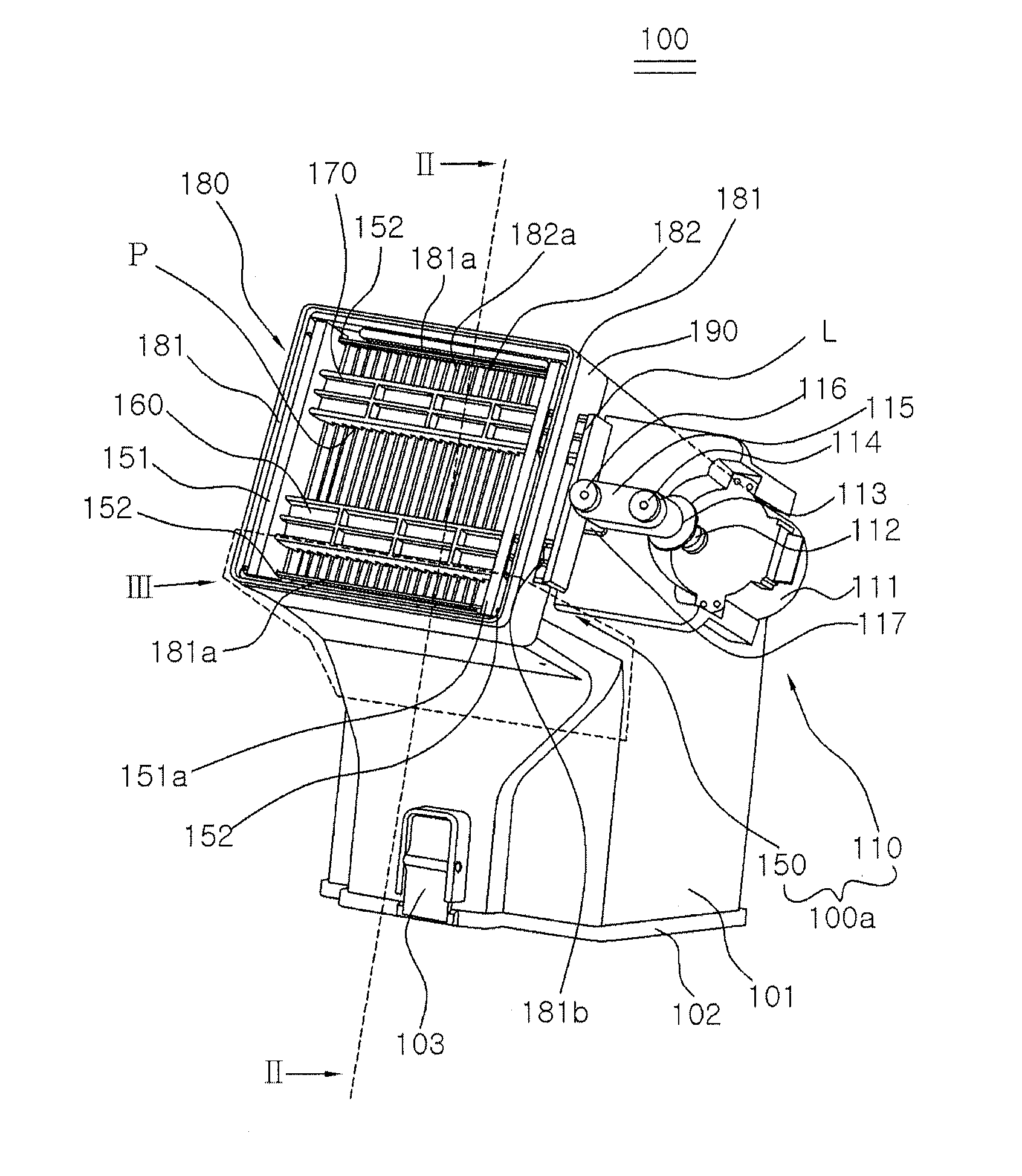

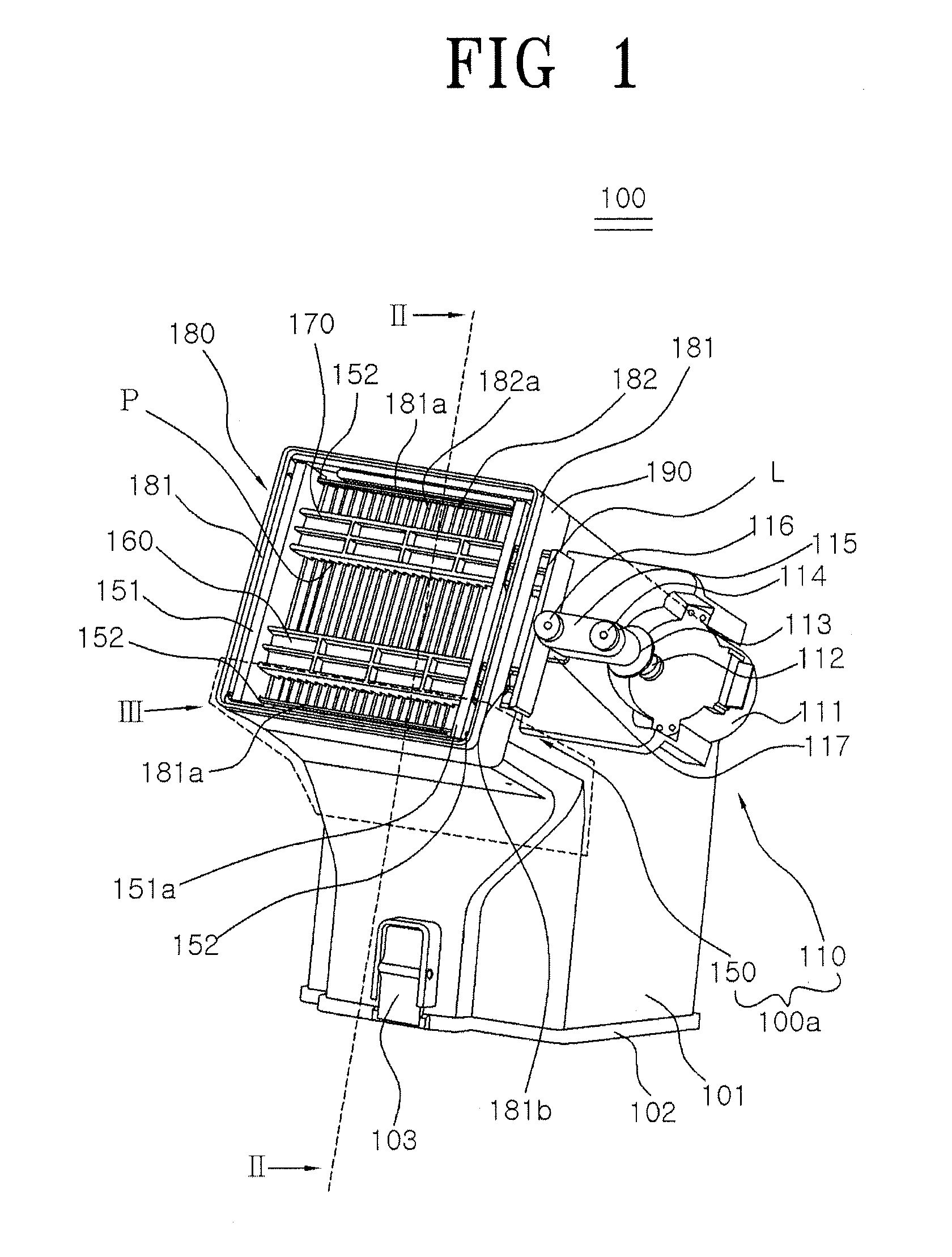

Dust collector for duster

InactiveUS20100101043A1Easy and efficient removalEasy to disassembleCleaning filter meansSuction filtersBristleDust collector

The invention concerns a dust collector for a duster, and provides a dust collector for a duster for sucking and removing dust on the bristle of a duster. The dust collector for a duster in order to achieve the aforementioned object of the invention is characterized in that it comprises: a case having one side of a dual pipe type of an inner pipe and an outer pipe and the other side provided with exhaust holes, and also having a structure of transferring dust taken off the duster placed inside of the inner pipe through openings provided on the inner pipe to a filter with air and then discharging only the air; a fan provided in the case for forcibly transferring the sucked air through the openings to the exhaust holes to discharge it; and a filter provided in an air transfer path in the case and for collecting the dust transferred with the air.

Owner:KIM HAI KWANG +1

Method and apparatus for cleaning master disk

InactiveUS20090020143A1Dust removal effect be improveEffectively remove dustLiquid processingReconditioning/cleaning record carriersEngineeringSelf adhesive

In a method of cleaning a master disk according to the present invention, a self-adhesive surface sticking / peeling operation is performed on dust on the master disk by reciprocatingly oscillating the self-adhesive member while applying external forces in a plurality of directions. Dust on the master disk can be effectively removed by moving the self-adhesive member in this way and by using the adhesion of the self-adhesive member. Since the cleaning method according to the present invention is a removal method using a physical force, it has both the effect of removing organic materials and the effect of removing inorganic materials. Further, according to the present invention, the master disk to be cleaned can be cleaned in a state of being mounted on a disk holding member such as a holder. Therefore an apparatus of a comparatively simple construction can be applied in on-line form according to the cleaning method.

Owner:FUJIFILM CORP

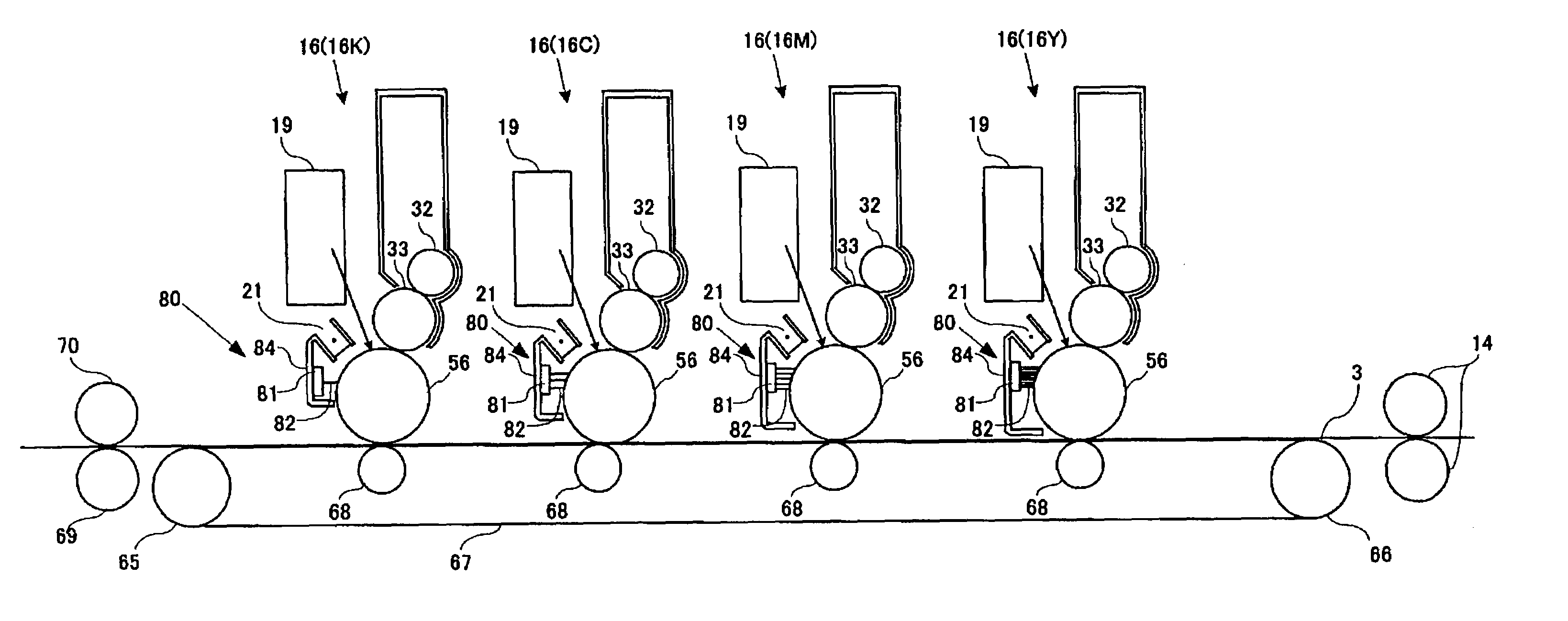

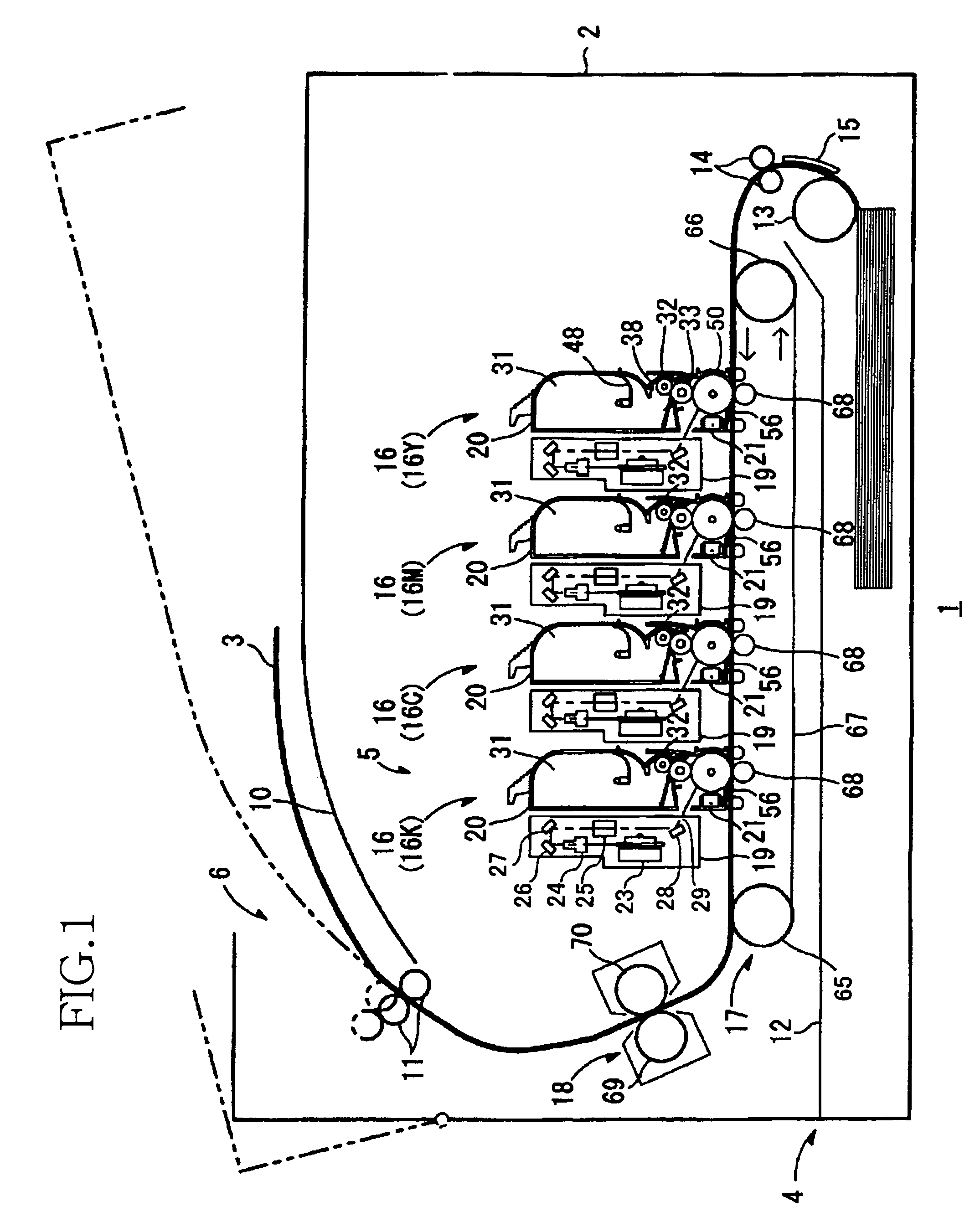

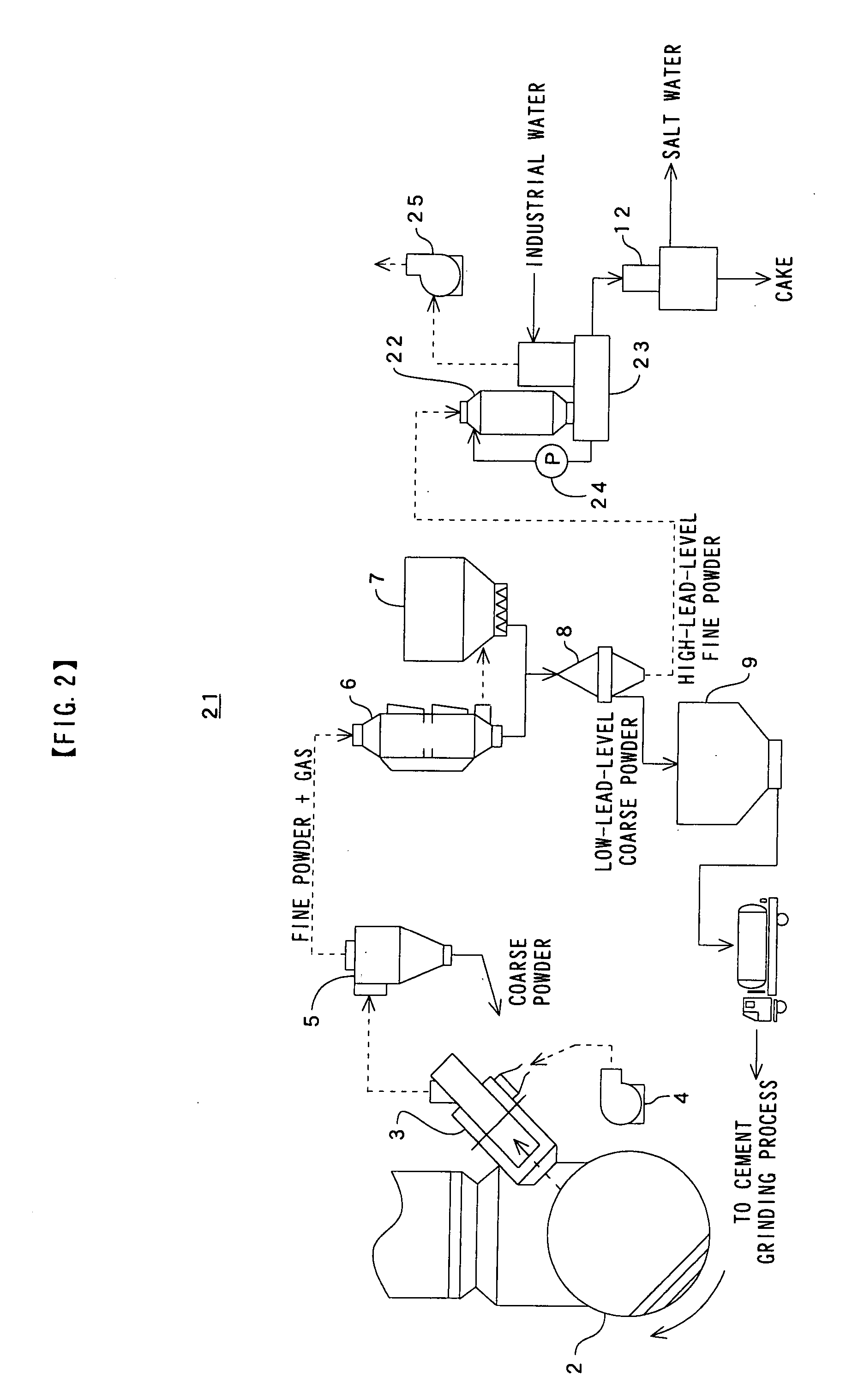

Image forming apparatus

An apparatus having image forming units to form respective toner images of different colors on a toner-image receiving medium, each unit including an image carrier, a static-latent-image forming portion to form a static latent image on the image carrier, a developing portion to apply a toner of the corresponding color to the image carrier, for forming the toner image on the image carrier, and a toner transferring portion to transfer the toner image from the image carrier to the medium, wherein the image forming units are disposed so as to be opposed to the medium and operable to sequentially transfer the toner images from the image carriers to the medium, and the developing portion of each unit is operable to adsorb the toner remaining on the image carrier after the toner image is transferred to the medium, and wherein at least the image forming unit located at the most upstream position of the apparatus is provided with a dust removing portion to remove, from the image carrier, a dust which has been transferred to the image carrier during a transfer of the toner image from the image carrier to the medium.

Owner:BROTHER KOGYO KK

System and Method for Treating Dust Contained in Extracted Cement Kiln Combustion Gas

ActiveUS20080092735A1Effectively remove dustLow facility requirementsCombination devicesLiquid degasificationCycloneEngineering

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a first classifier 5 for separating coarse powder from dust contained in the combustion gas extracted; a dust collector 7 for collecting dust from the extracted gas containing fine powder discharged from the first classifier 5; and a second classifier 8 for dividing dust discharged from the dust collector 7 into fine powder and coarse powder, and others. Since more lead is distributed on the fine powder side classified by the second classifier 8, lead can efficiently be removed without using chemicals and the like. The fine powder classified by the classifier 8 may be desalted by washing; high-lead-level cake obtained after the washing can be recycled; or salt water can be added to a cement mill. The coarse powder may be added to a cement grinding process or returned to cement material grinding process after the desaltation through washing.

Owner:TAIHEIYO CEMENT CORP

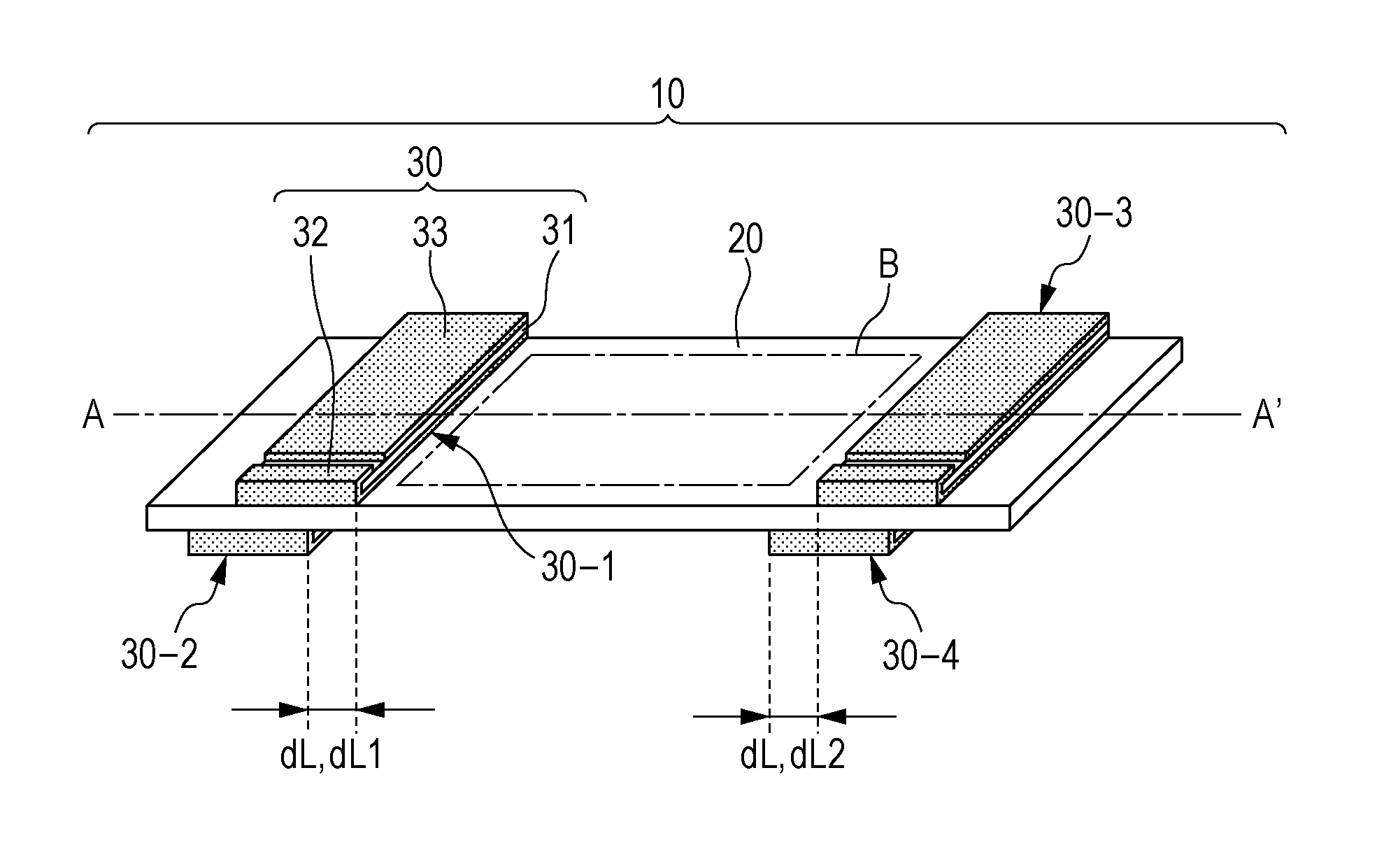

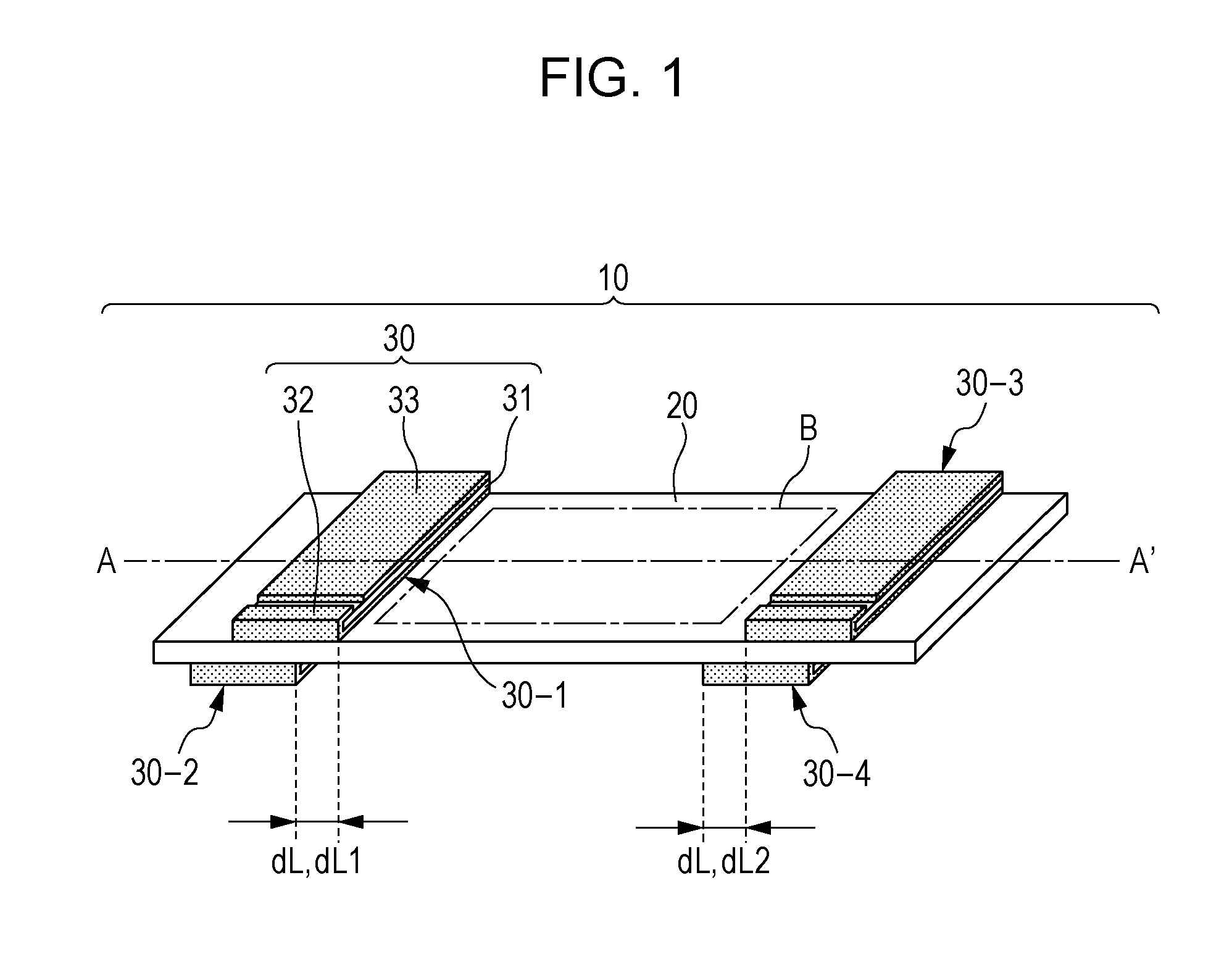

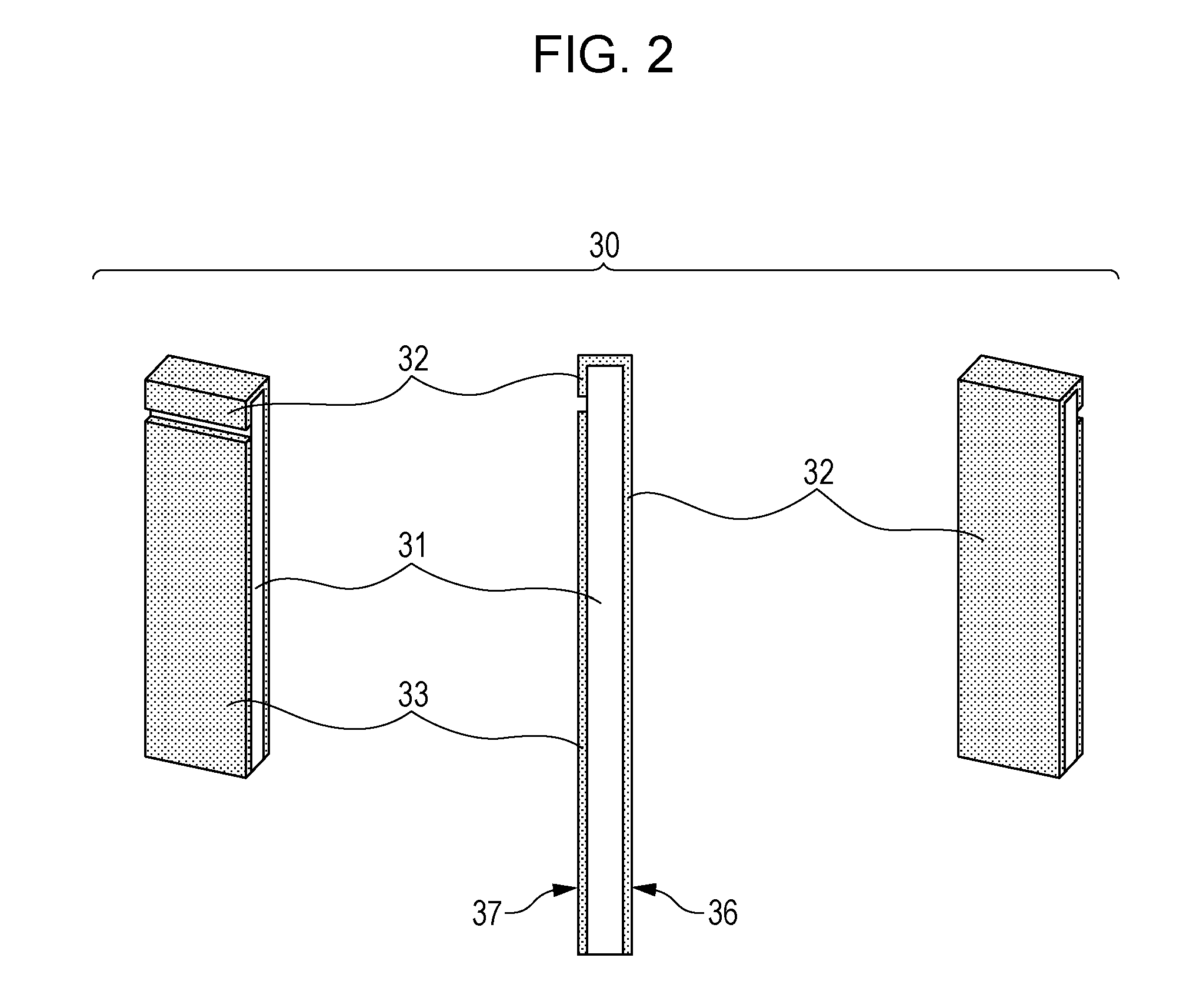

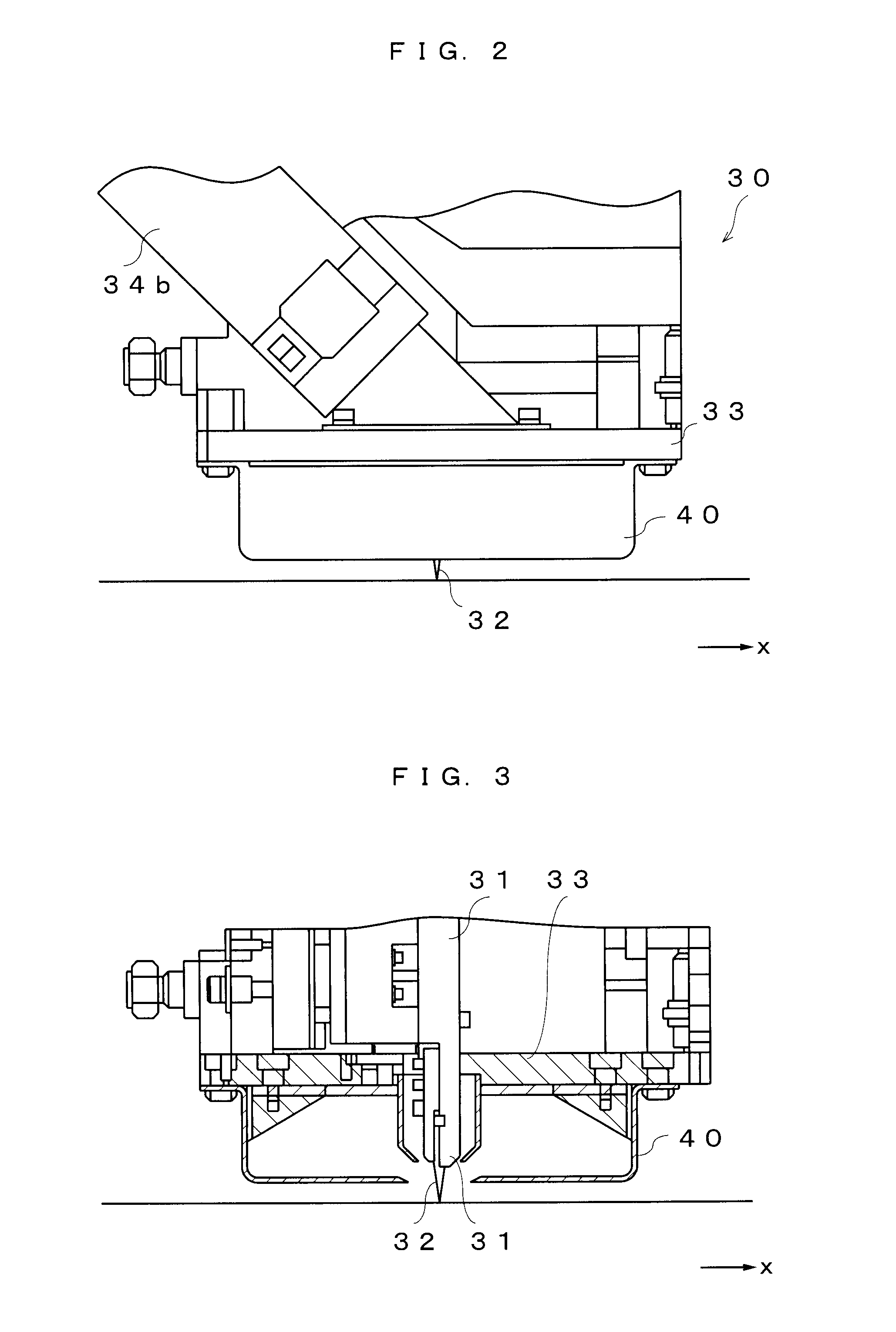

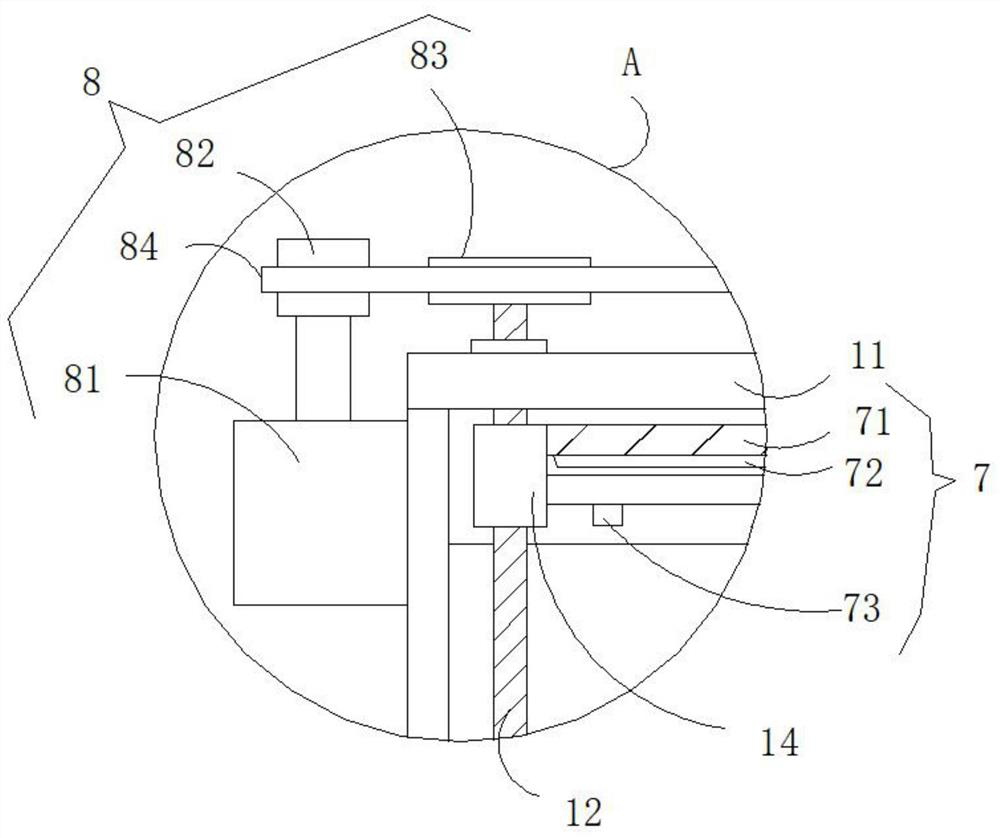

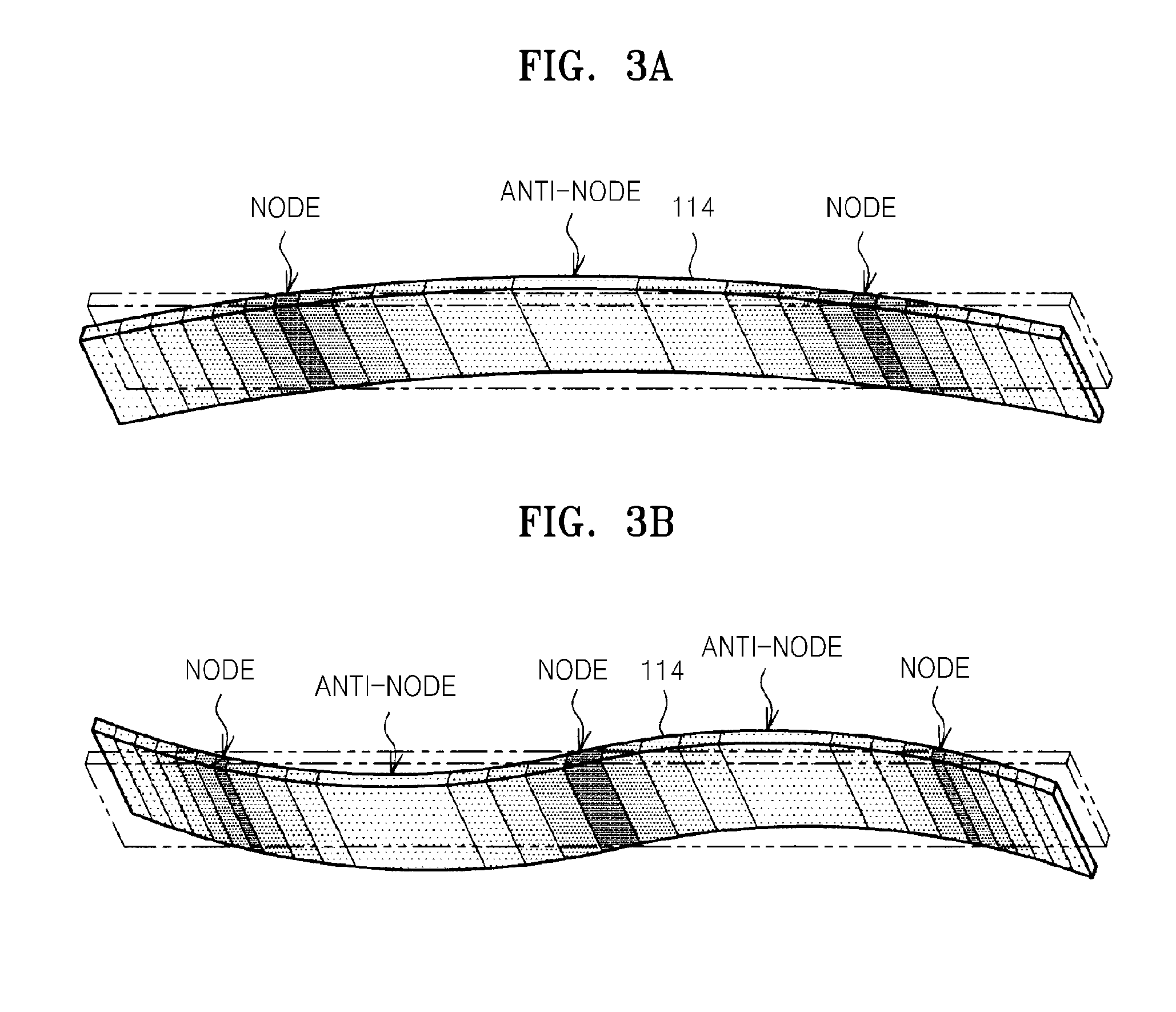

Dust removing device and image pickup apparatus

InactiveUS8866952B2Effectively remove dustTelevision system detailsCarpet cleanersElectricityTarget surface

A dust removing device generates vibrations at least at a wavelength λ in a vibrating member by applying alternating voltages to a first piezoelectric element and a second piezoelectric element, respectively. The first piezoelectric element is provided on a first surface of the vibrating member that is on a side having a target surface. The second piezoelectric element is provided on a second surface of the vibrating member that is opposite the first surface. When the first piezoelectric element and the second piezoelectric element are projected in a direction that is normal to the target surface, a distance dL1 between a vibration generating end of the first piezoelectric element and a vibration generating end of the second piezoelectric element is expressed in the form dL1>0, where dL1≠nλ / 2 and n is a positive integer.

Owner:CANON KK

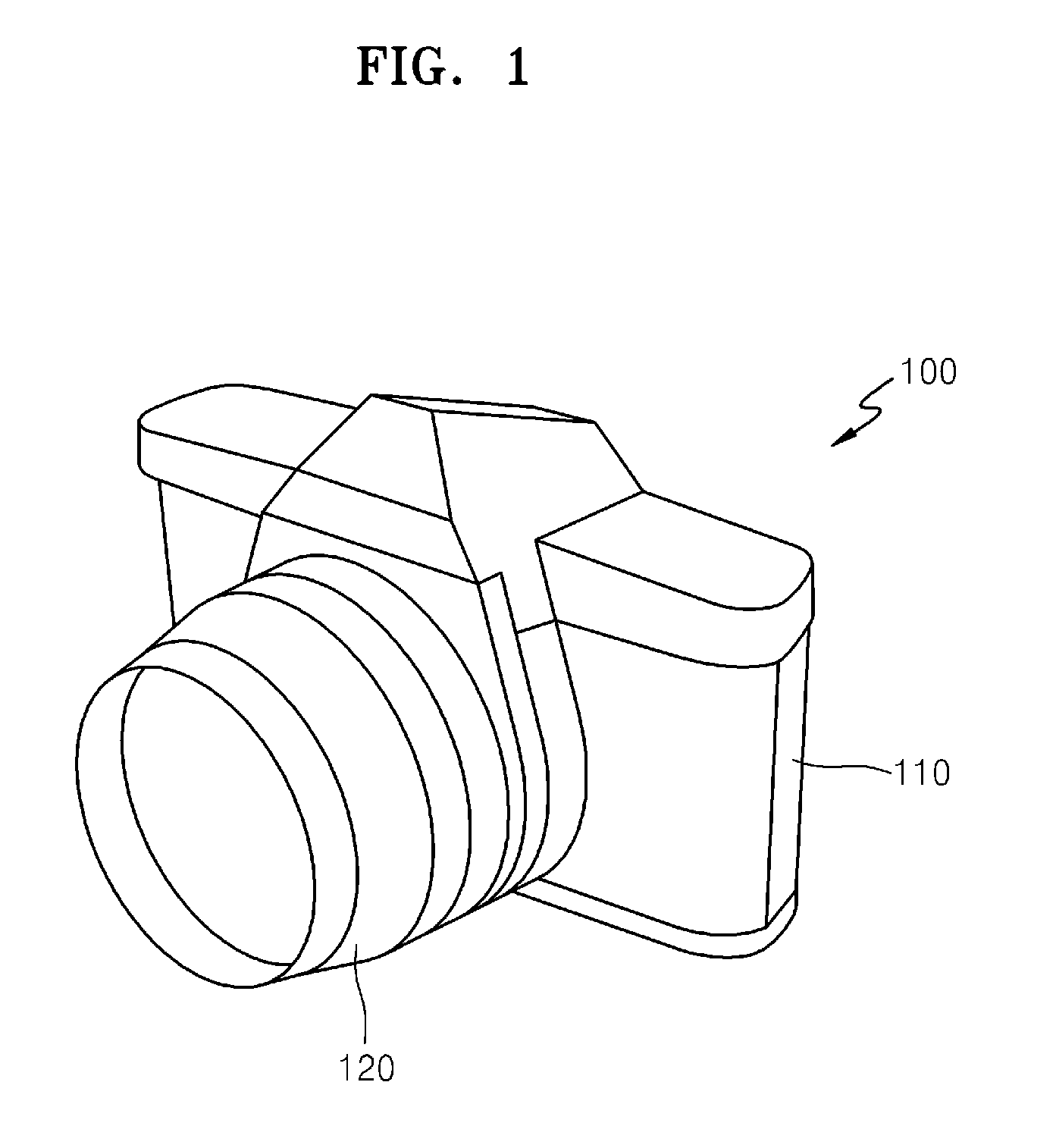

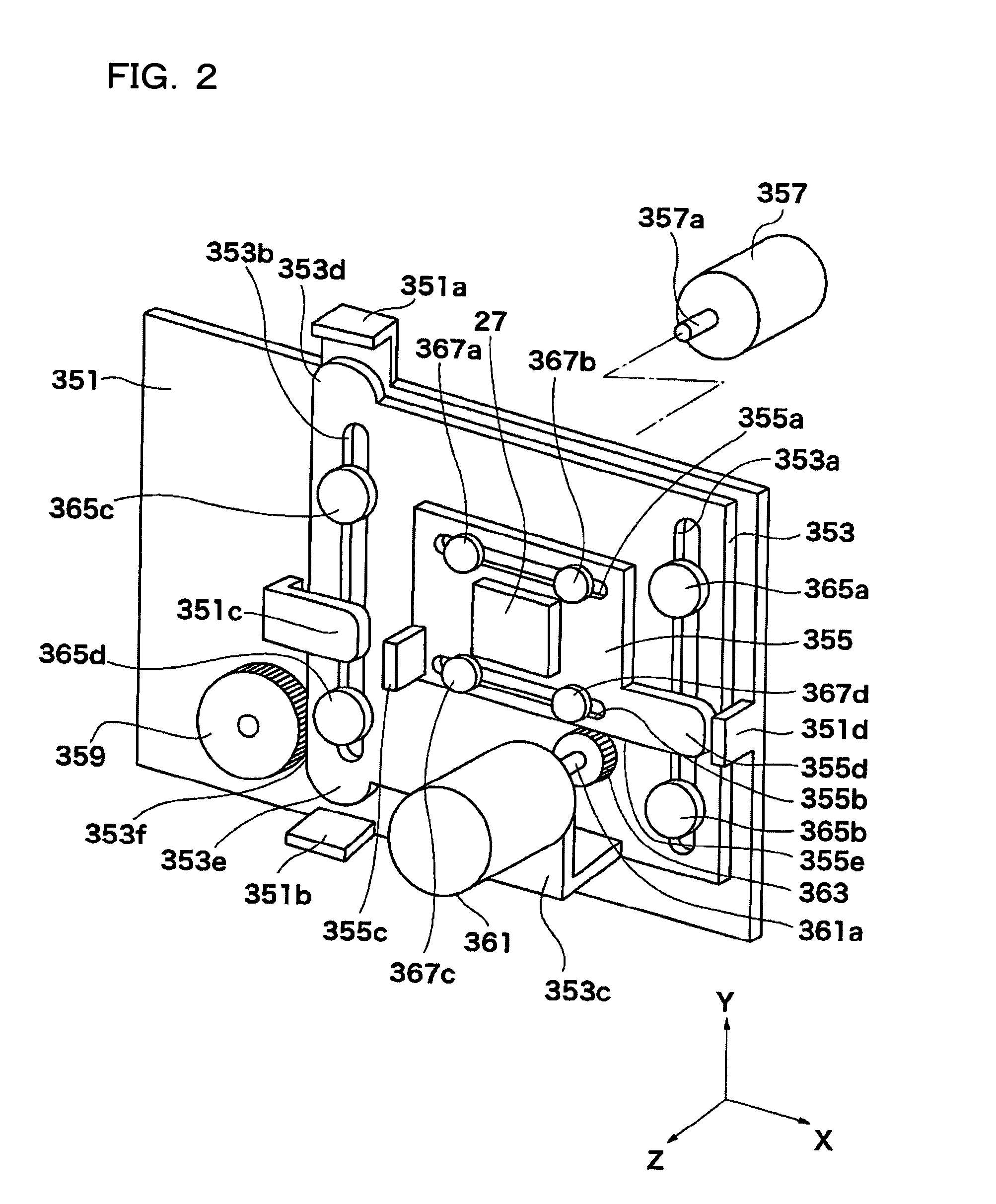

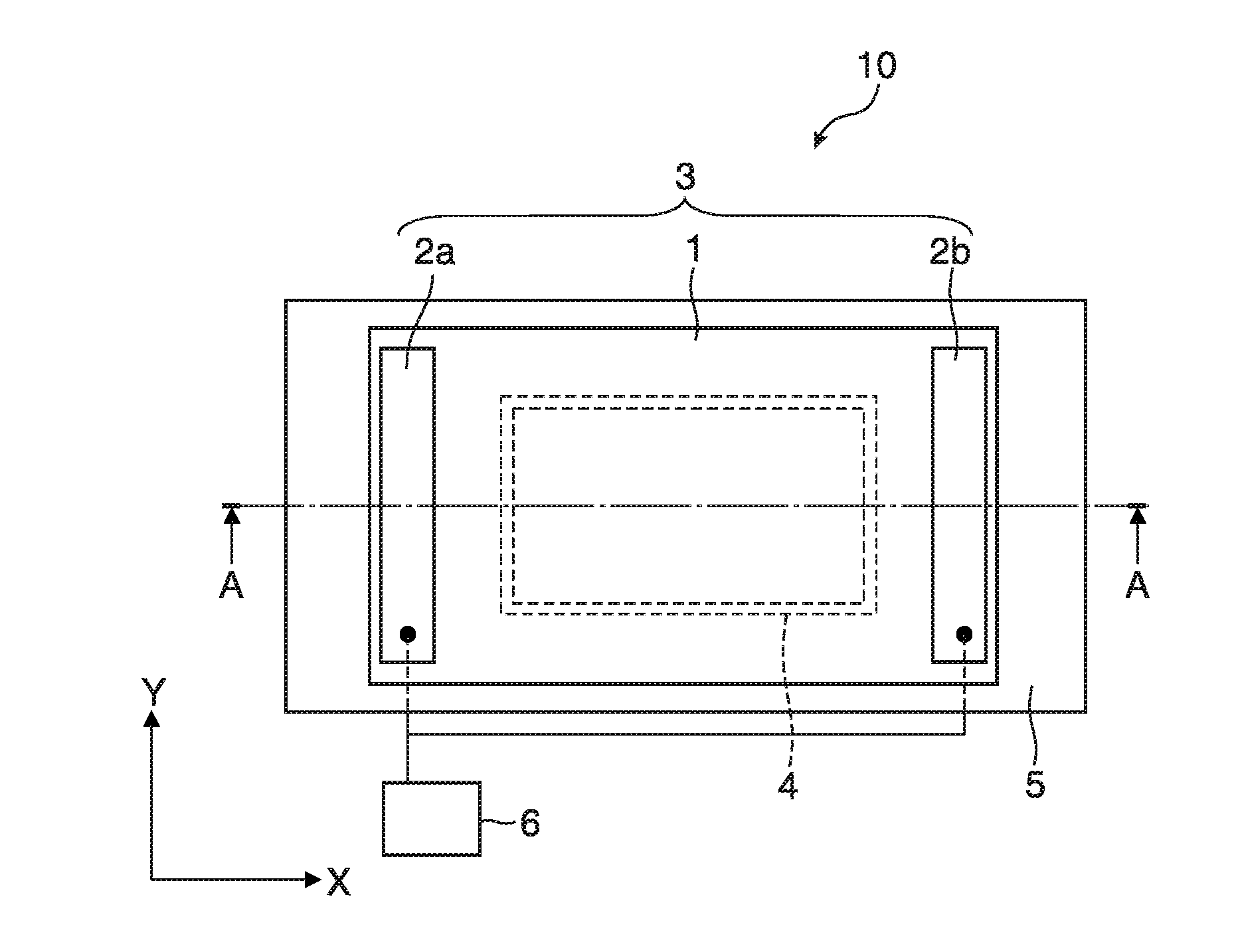

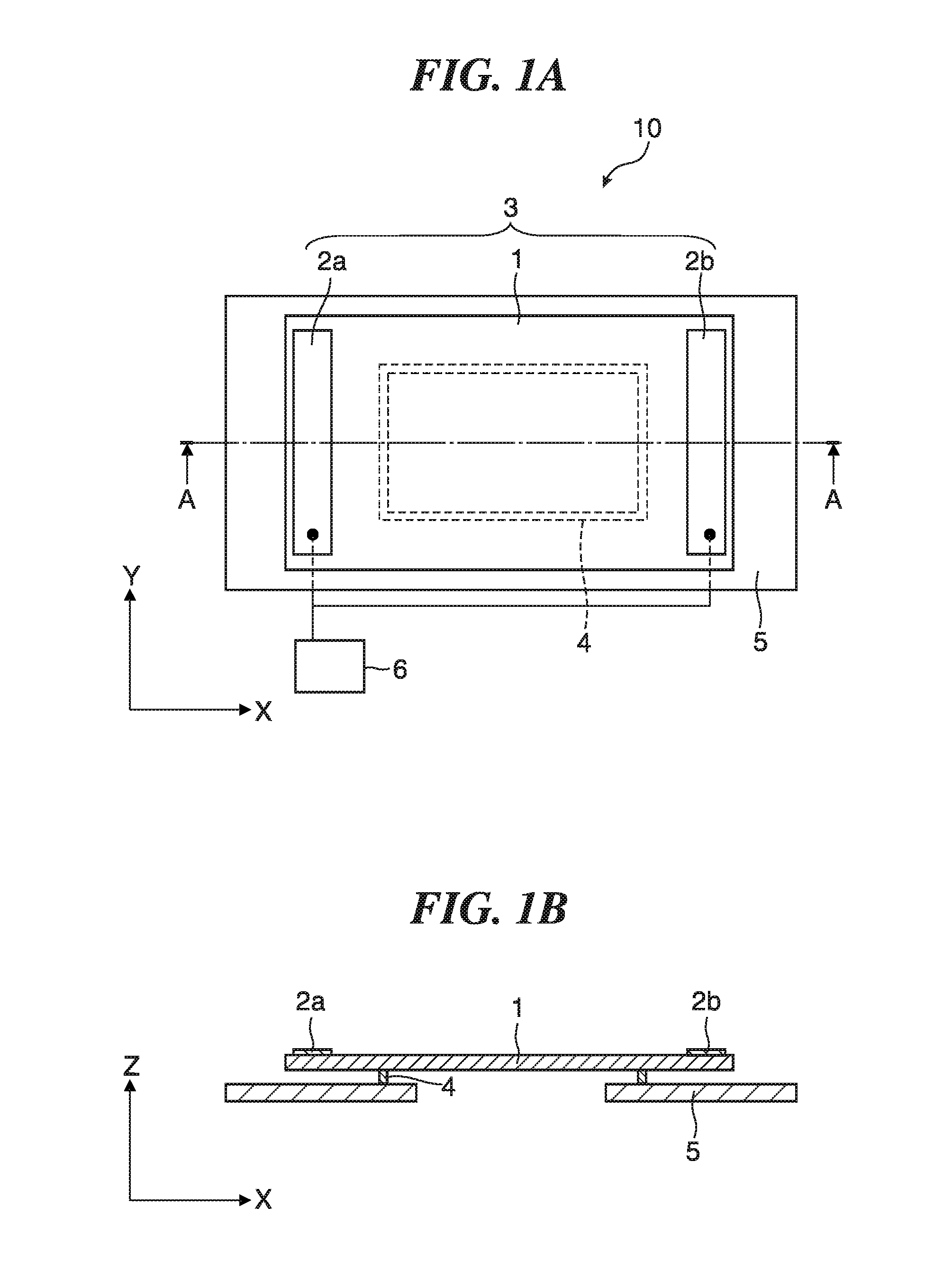

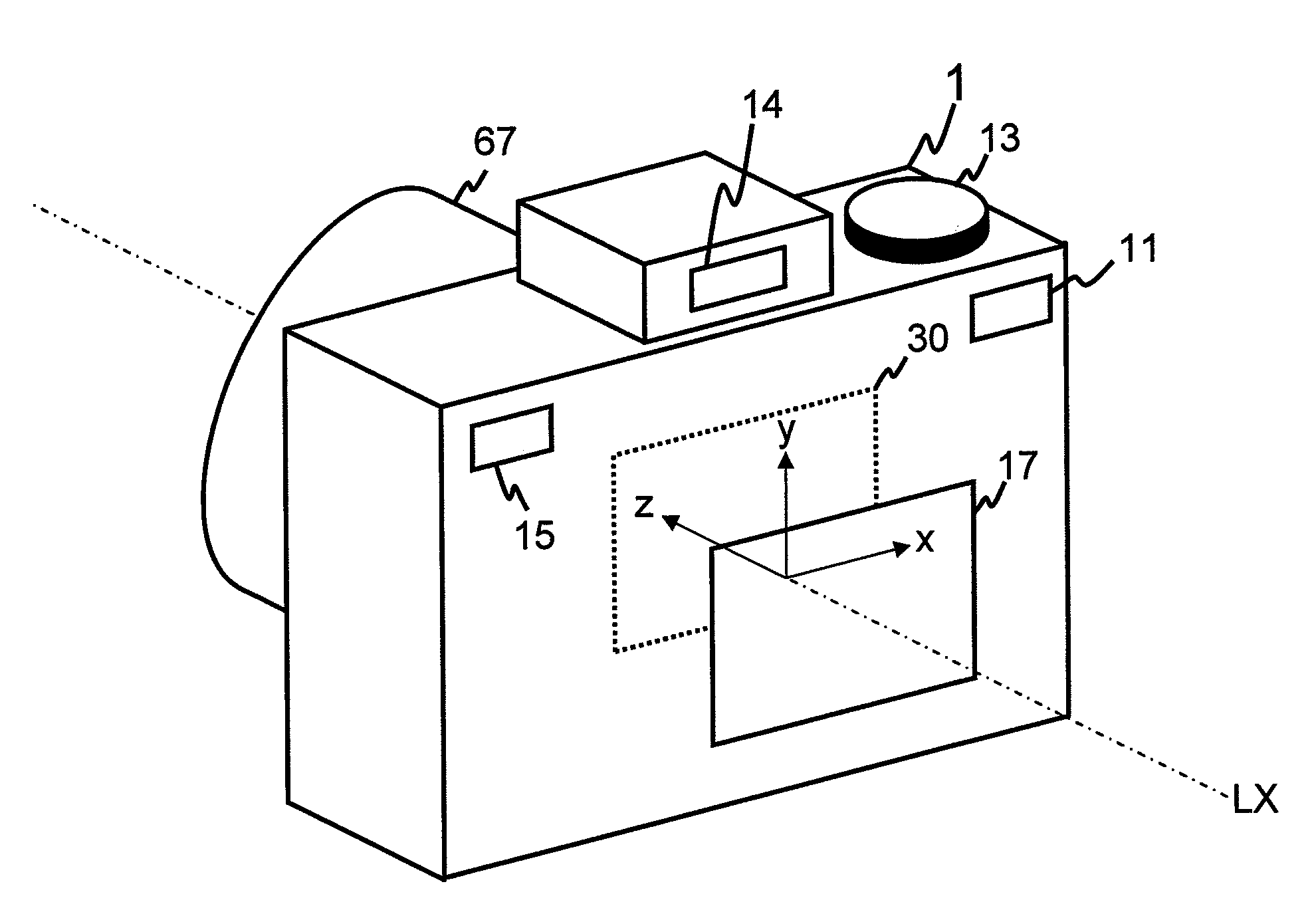

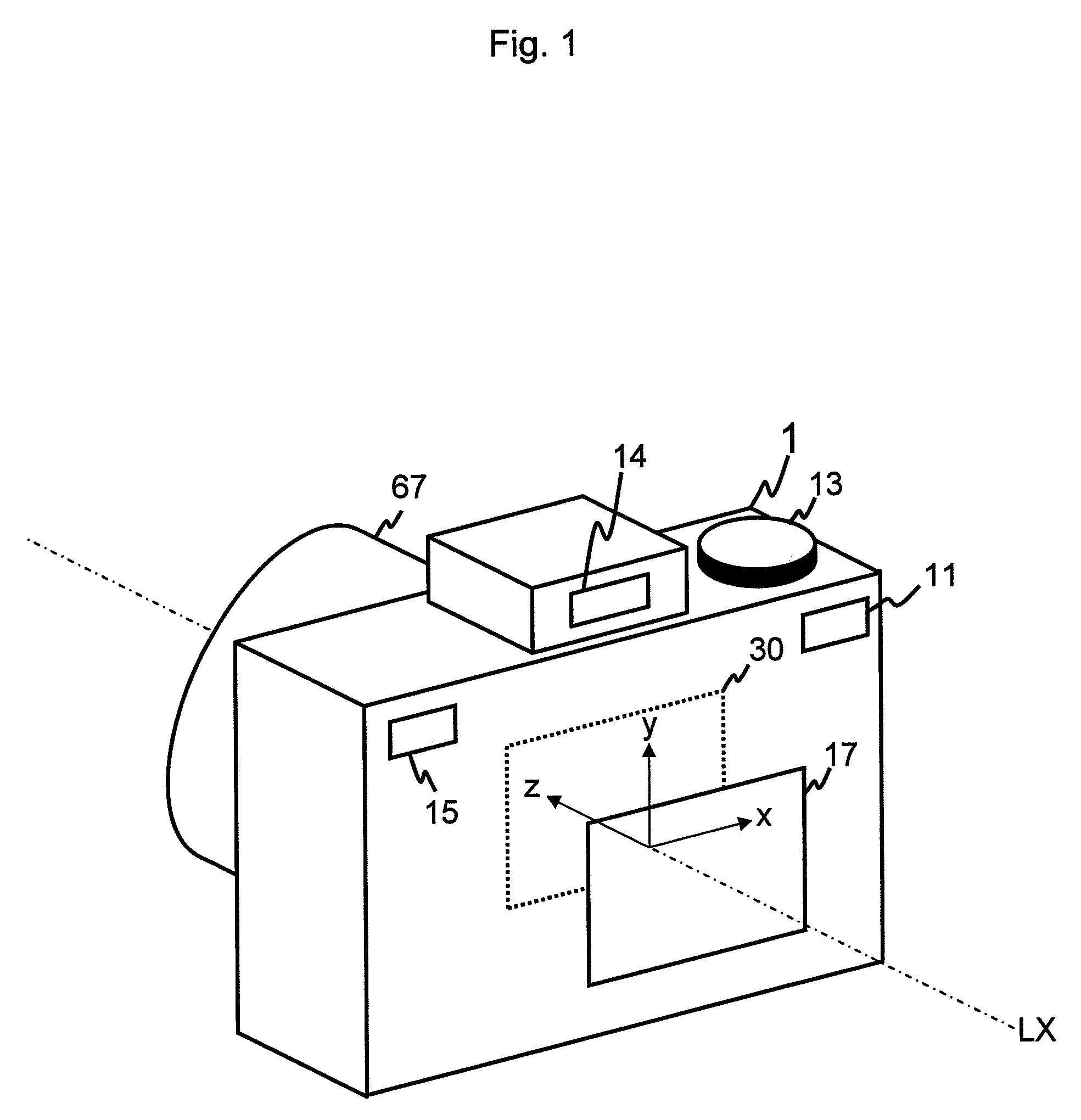

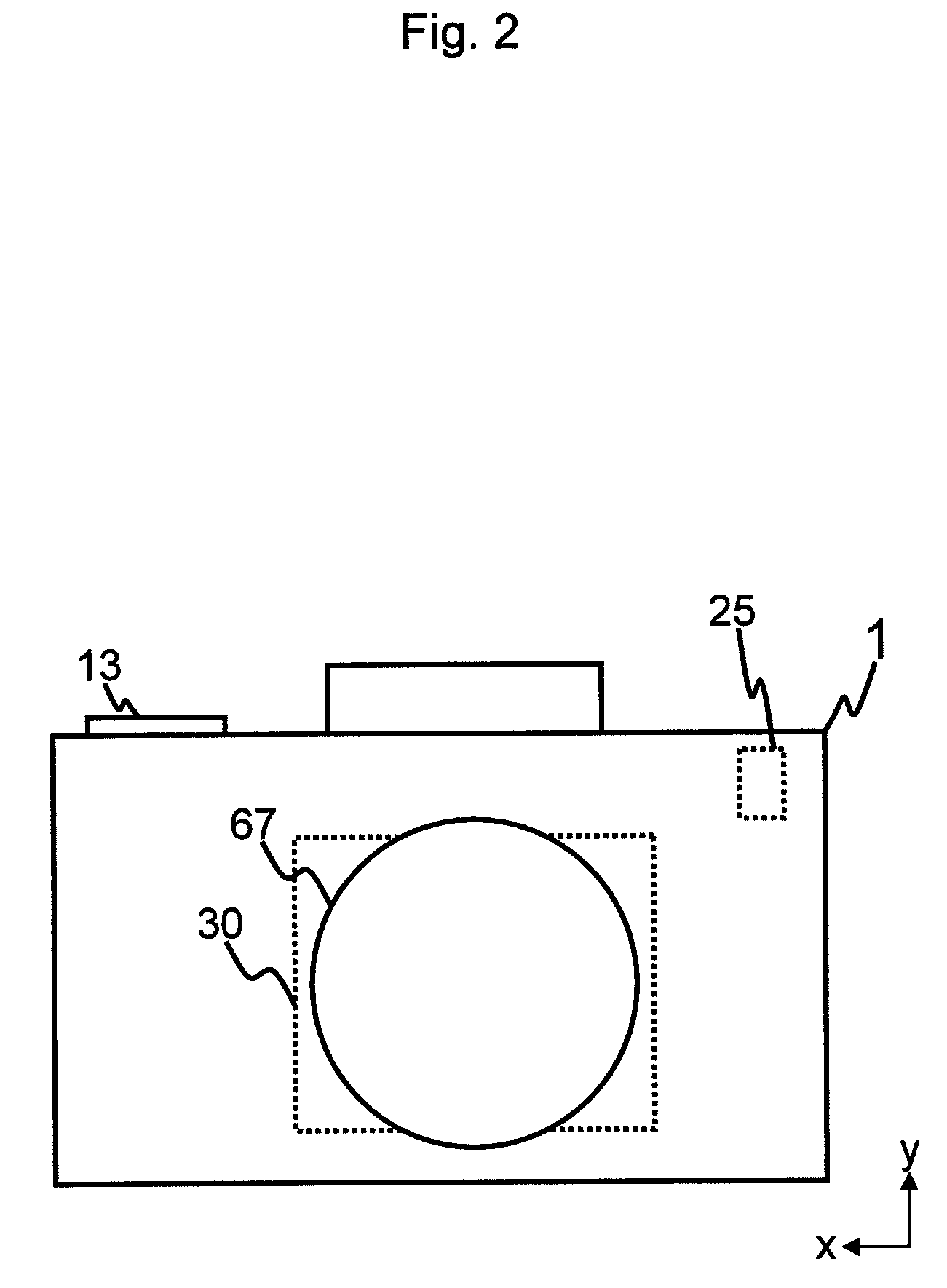

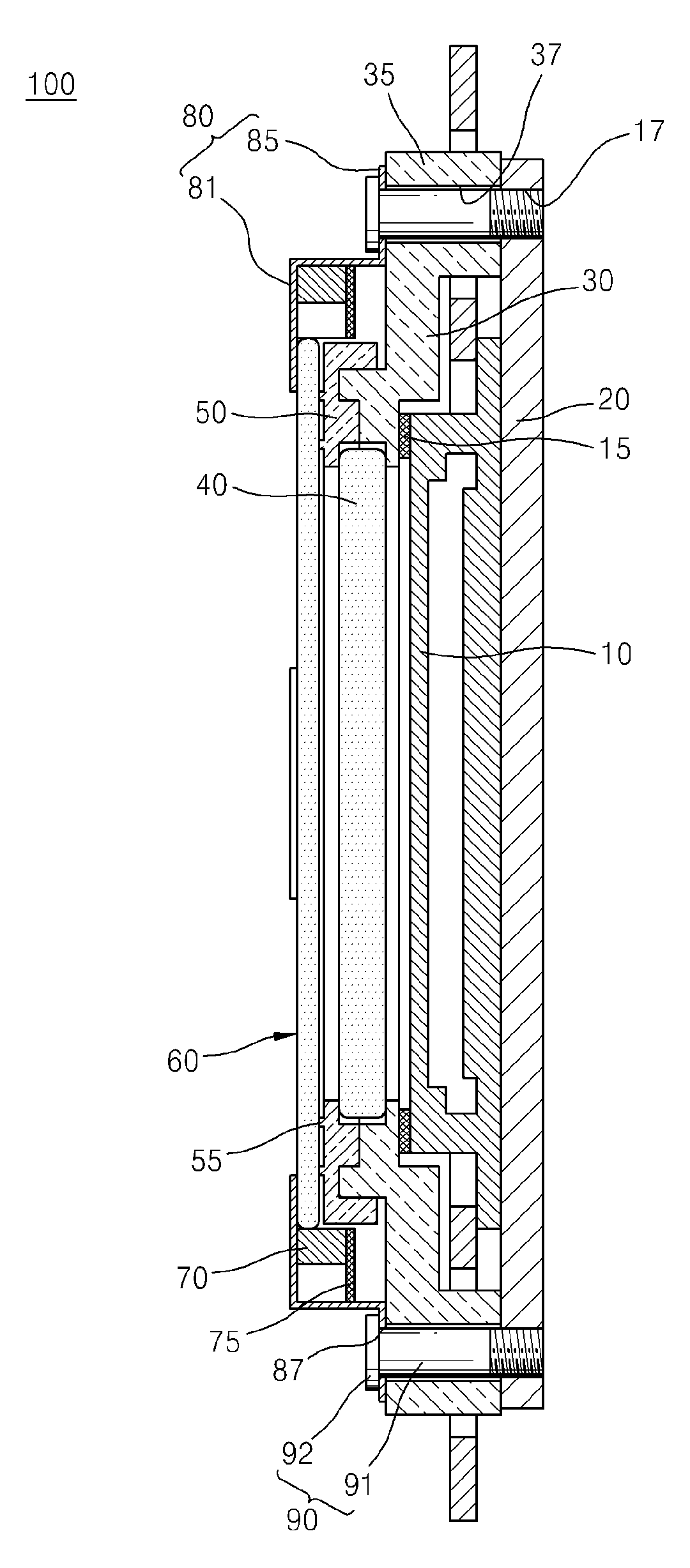

Imaging apparatus

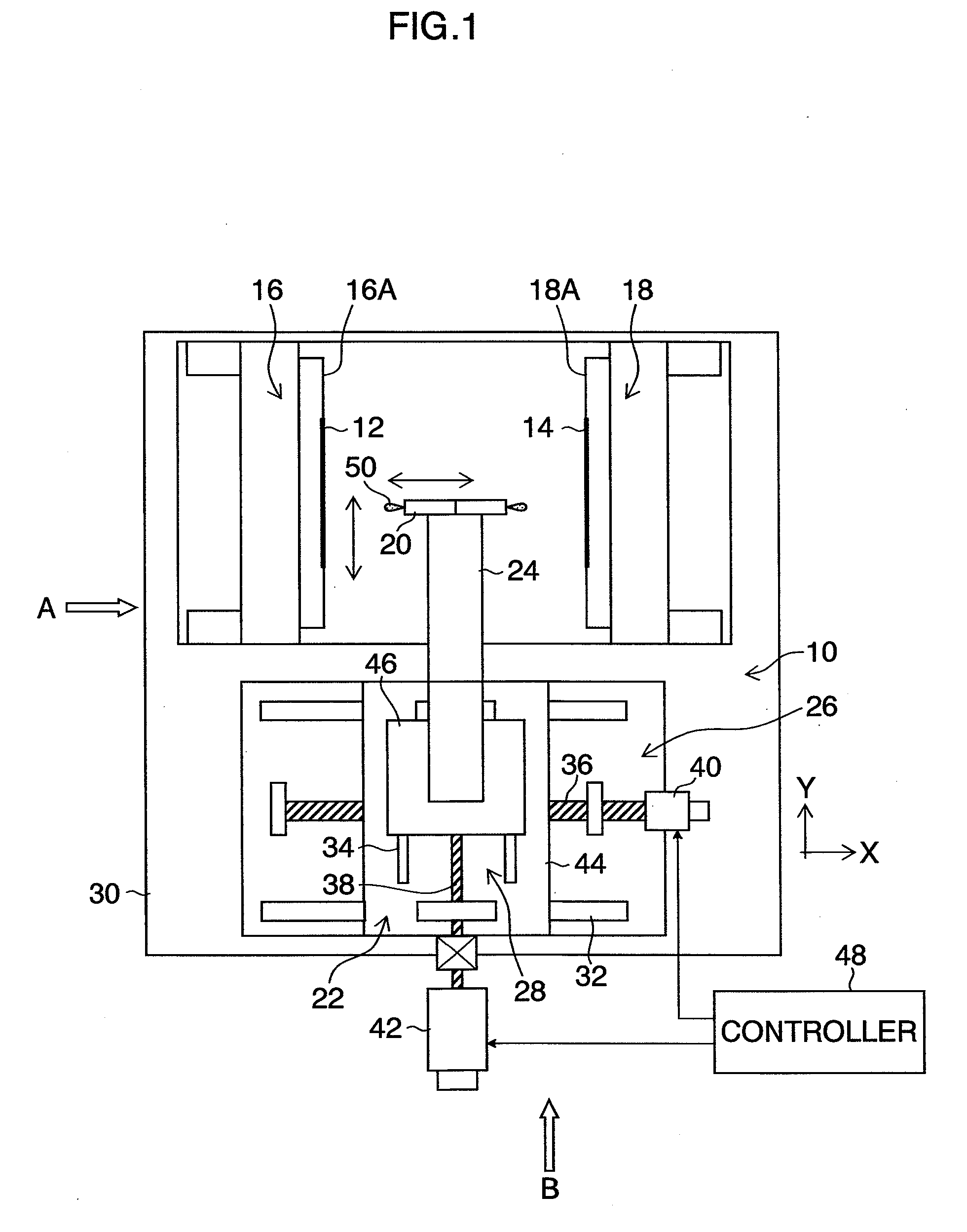

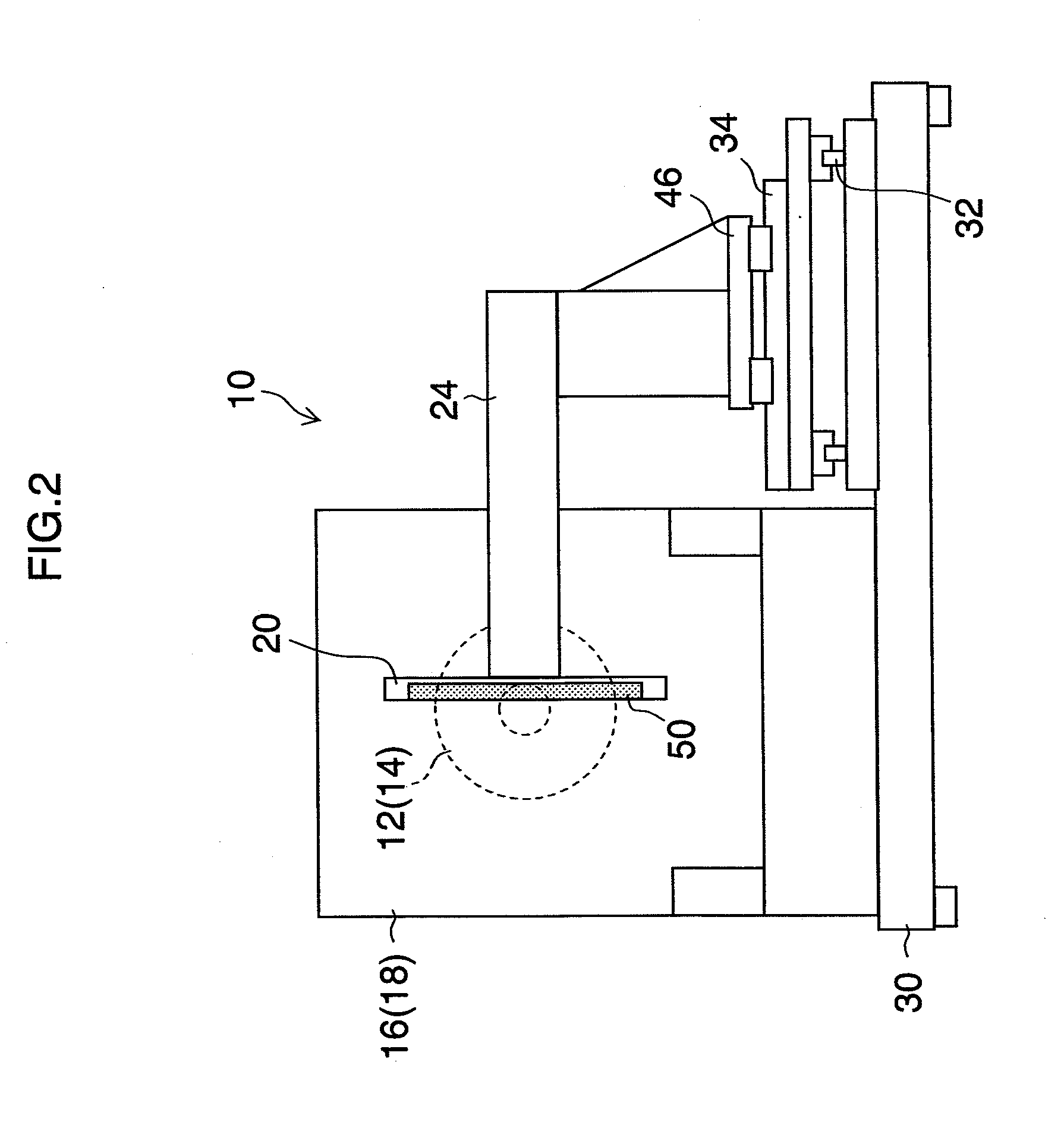

InactiveUS7554075B2Effectively remove dustEffective imagingTelevision system detailsPrintersEngineeringActuator

There is disclosed an imaging apparatus having: (a) a drive mechanism for moving an imaging device subunit having an imaging device in mutually perpendicular first and second directions; (b) a first actuator for moving the imaging device subunit in the first direction; (c) a second actuator for moving the imaging device subunit in the second direction; (d) a sensing device for detecting the direction of gravity; and (e) a dust-removing device for shaking off dust adhering to the imaging device subunit by moving the subunit using at least one of the two actuators. The dust-removing device has: a setting unit for setting a direction of motion in which the imaging device subunit is moved, based on the direction of gravity detected by the sensing device; and a selecting unit for selecting an actuator used to drive the imaging device subunit in the direction of motion set by the setting unit from the first and second actuators.

Owner:SONY CORP

Indoor unit of air conditioner

ActiveUS8523969B2Preventing degradation of dust removing performanceIncrease volumeCombination devicesMechanical apparatusBristleAir filter

An air filter (30) intermittently rotates by a predetermined rotation angle at each time, while being in contact with a bristle portion (51b) of a rotating brush (51). Accordingly, dust on the air filter (30) is scraped by the bristle portion (51b). The brush member (51) rotates about an axial center of a shaft (51a) at each stop of the intermittent rotation of the air filter (30), to come into contact with a cleaning brush member (52). According, dust on the brush member (51) is removed by the cleaning brush member (52).

Owner:DAIKIN IND LTD

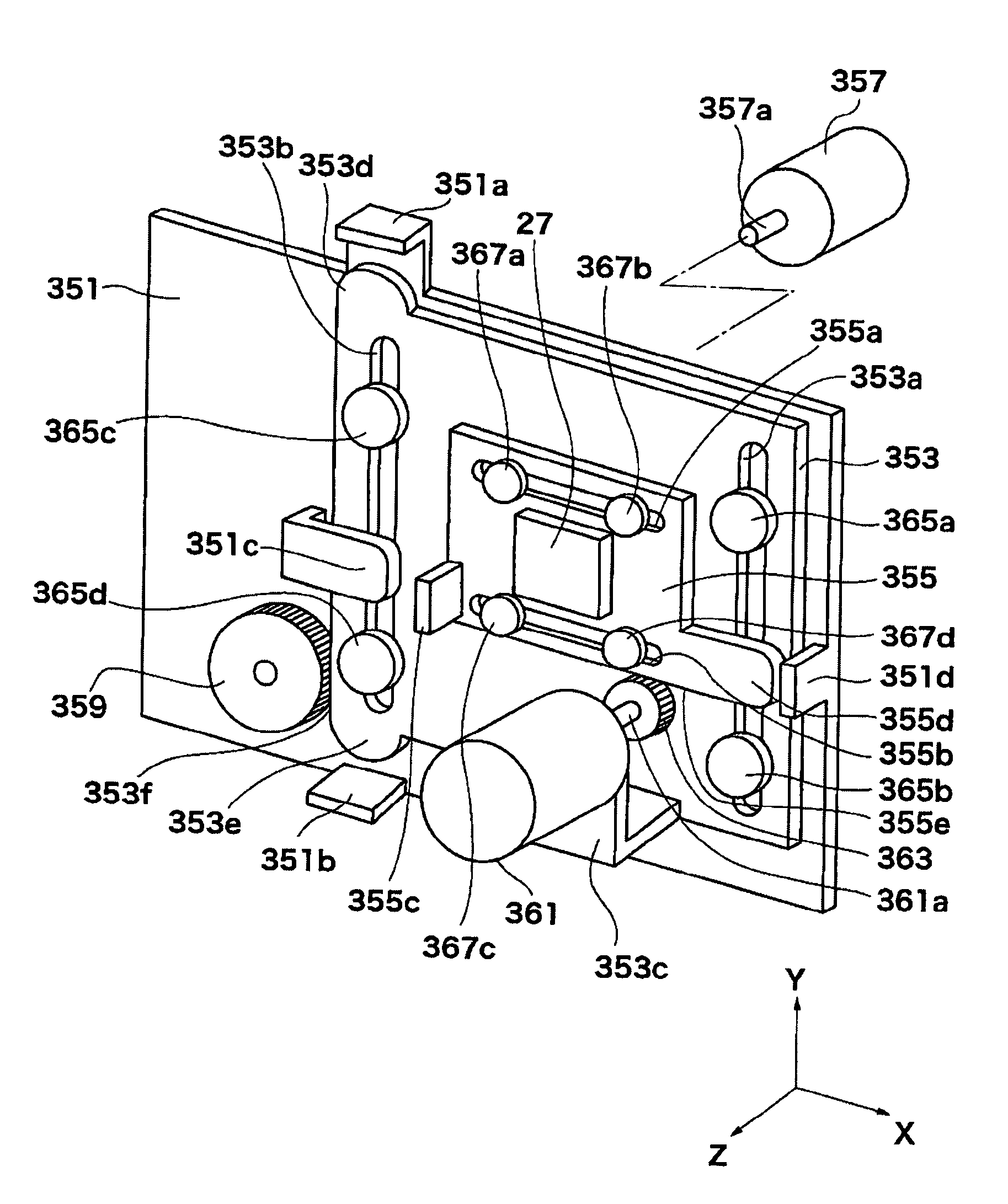

Driving method for vibration body, vibration driving device, and image pickup apparatus

ActiveUS20160246052A1MiniaturizationReduce impactTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElastomerVibration amplitude

A vibration driving device that is capable of exciting a vibration of desired amplitude with a low voltage. A vibration body has a plate-like elastic body and an electro-mechanical energy conversion element that is joined to the elastic body. A control unit excites a vibration in a first vibration mode and a vibration in a second vibration mode in the vibration body by applying alternation voltages to the electro-mechanical energy conversion element. Orders or numbers of nodes of the vibrations in the first and second modes in a first direction that intersects perpendicularly with a thickness direction of the elastic body are mutually different by one. And orders or numbers of nodes of the vibrations in the first and second modes in a second direction that intersects perpendicularly with the thickness direction of the elastic body and the first direction are mutually different by one.

Owner:CANON KK

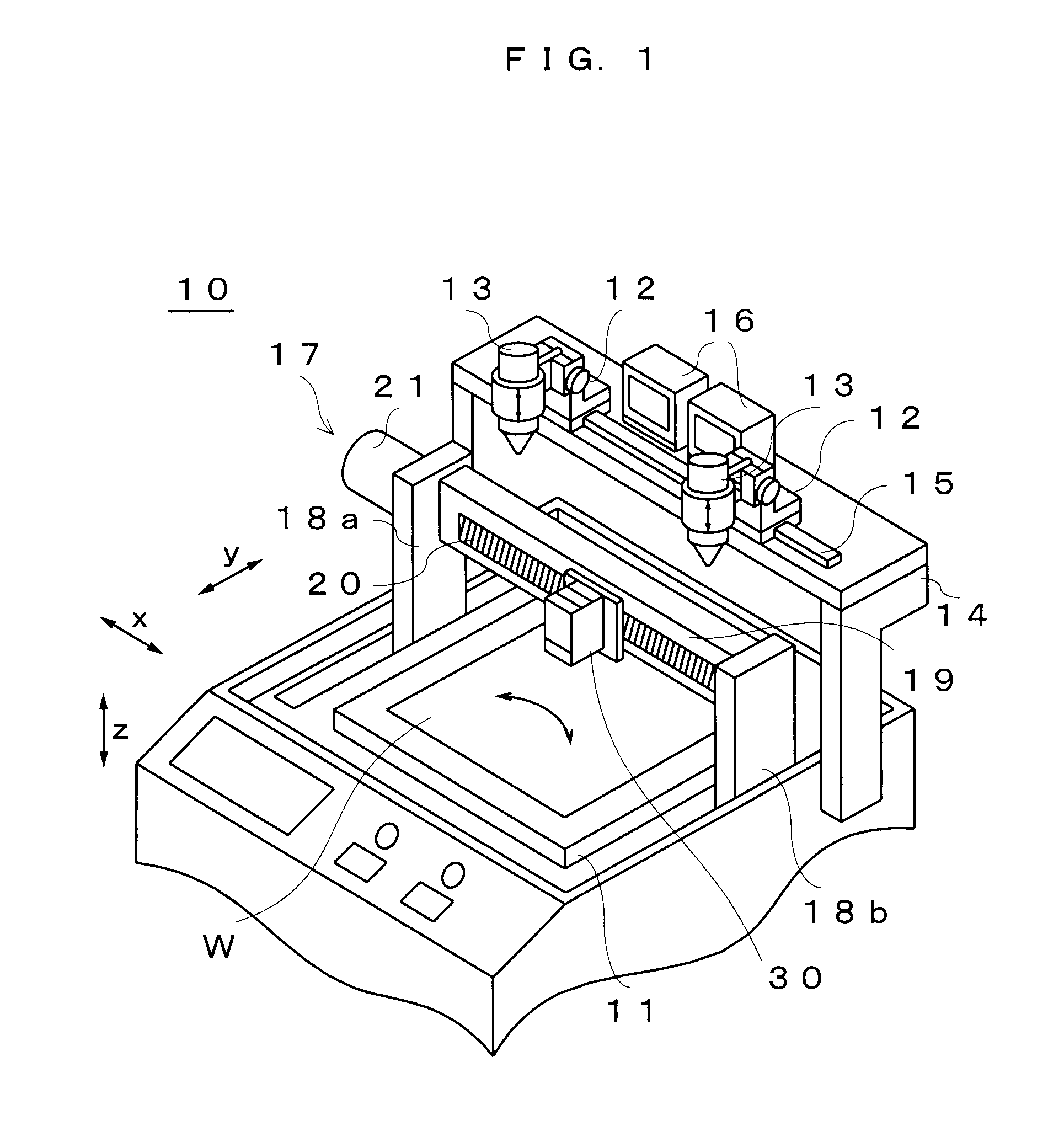

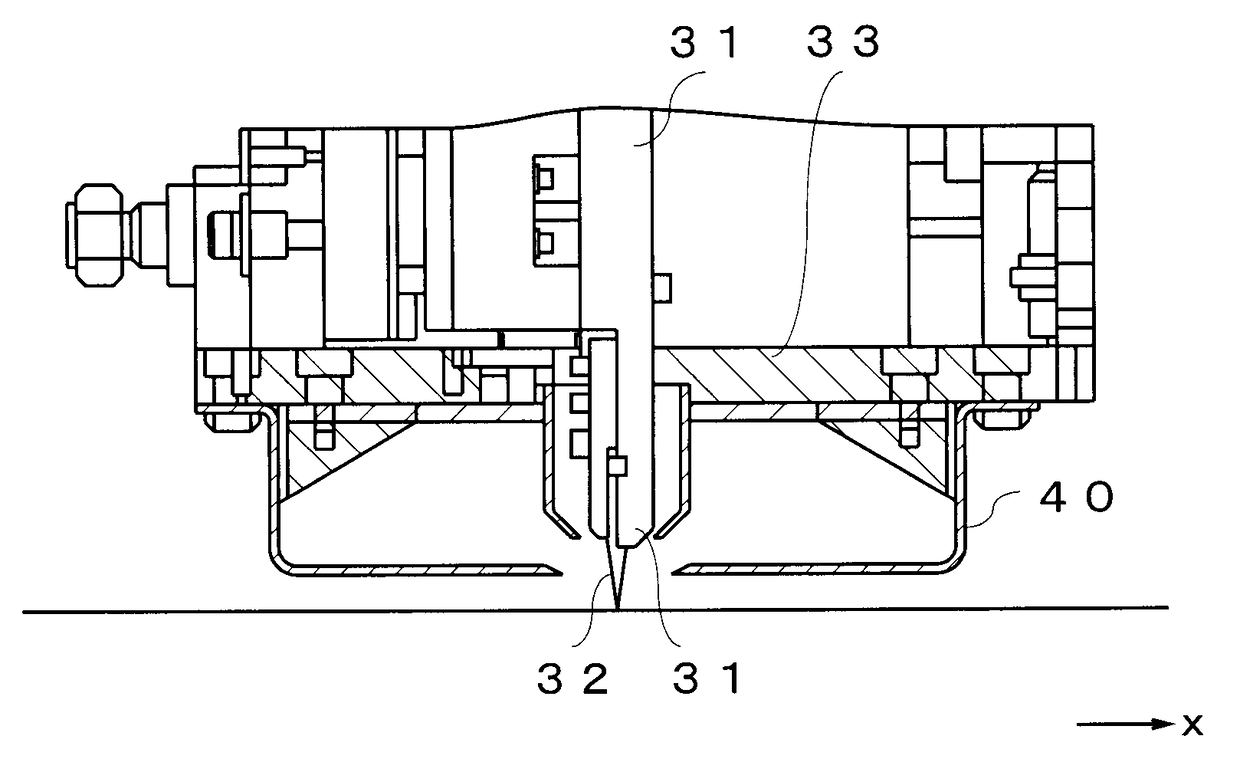

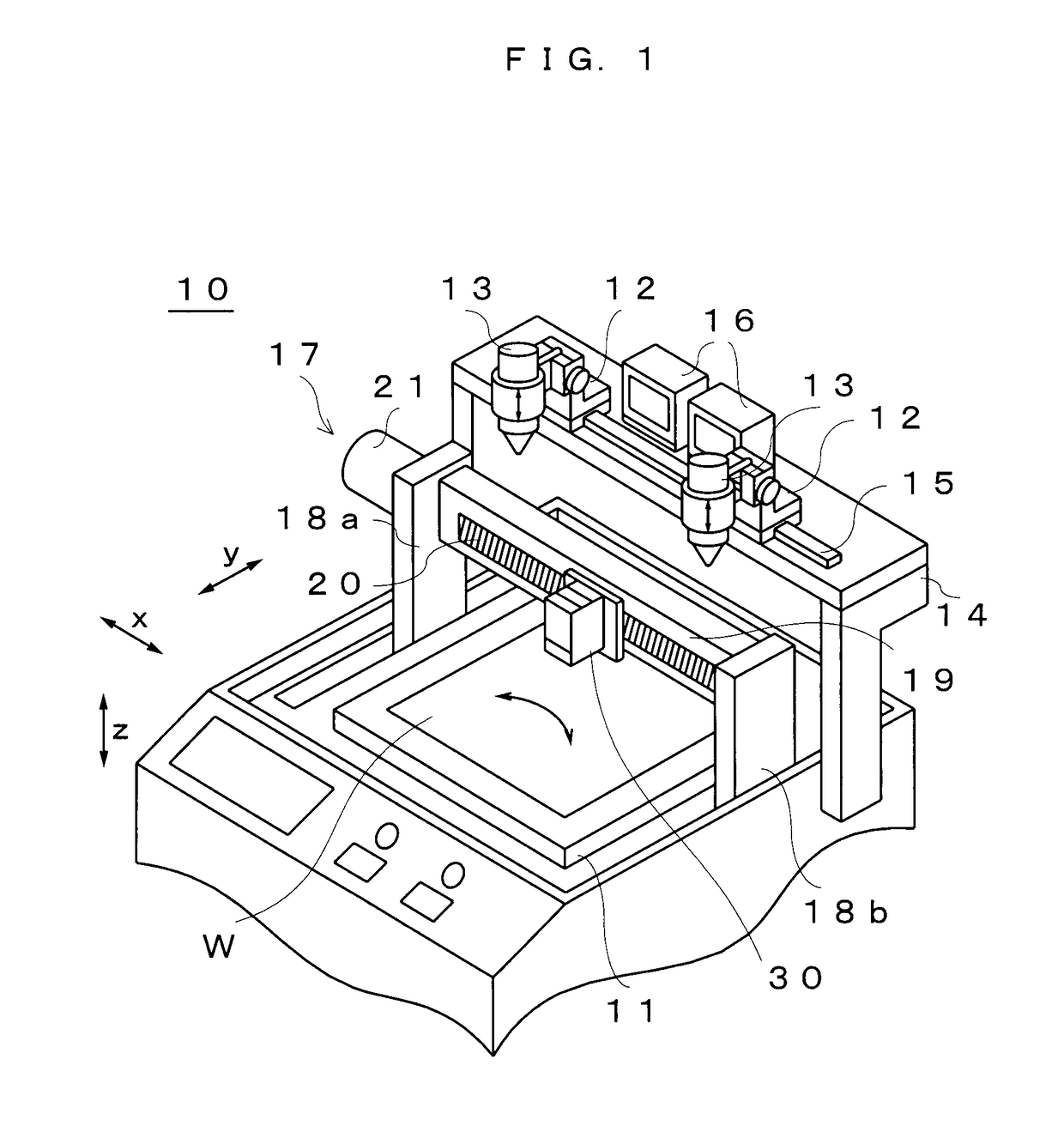

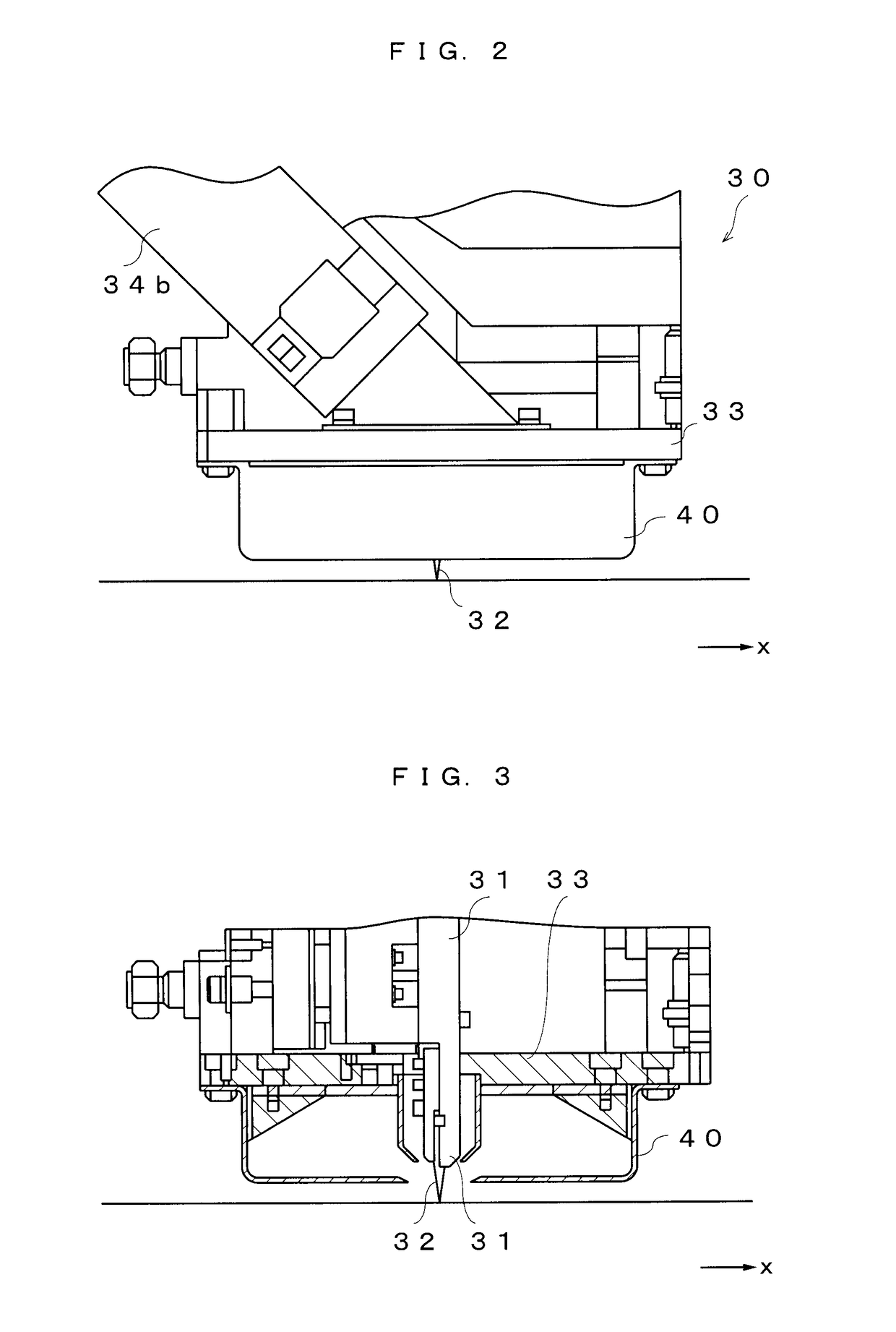

Dust collecting mechanism for groove machining head and groove machining apparatus

InactiveUS20150348808A1Eliminate riskEffectively remove dustSemiconductor/solid-state device manufacturingWorking accessoriesEngineeringMechanical engineering

A groove machining head has a dust collecting hood 40 having a suction port in the vicinity where tools 32 protrude from a bottom plate 33 of the groove machining head. When performing groove machining on a substrate W using the groove machining head 30, a blower 35 sucks air inside the dust collecting hood 40 through ducts 34. Doing so can suck dust produced by the groove machining through the suction port of the dust collecting hood 40 before attachment of the dust on the substrate W.

Owner:MITSUBOSHI DIAMOND IND CO LTD

Imaging apparatus

InactiveUS20080310022A1Effective imagingEfficient removalTelevision system detailsPrintersEngineeringActuator

There is disclosed an imaging apparatus having: (a) a drive mechanism for moving an imaging device subunit having an imaging device in mutually perpendicular first and second directions; (b) a first actuator for moving the imaging device subunit in the first direction; (c) a second actuator for moving the imaging device subunit in the second direction; (d) a sensing device for detecting the direction of gravity; and (e) a dust-removing device for shaking off dust adhering to the imaging device subunit by moving the subunit using at least one of the two actuators. The dust-removing device has: a setting unit for setting a direction of motion in which the imaging device subunit is moved, based on the direction of gravity detected by the sensing device; and a selecting unit for selecting an actuator used to drive the imaging device subunit in the direction of motion set by the setting unit from the first and second actuators.

Owner:SONY CORP

Displacement monitoring station

InactiveCN111981969AEffectively remove dustGuarantee the efficiency of converting electric energyBatteries circuit arrangementsPhotovoltaicsElectrical batteryEngineering

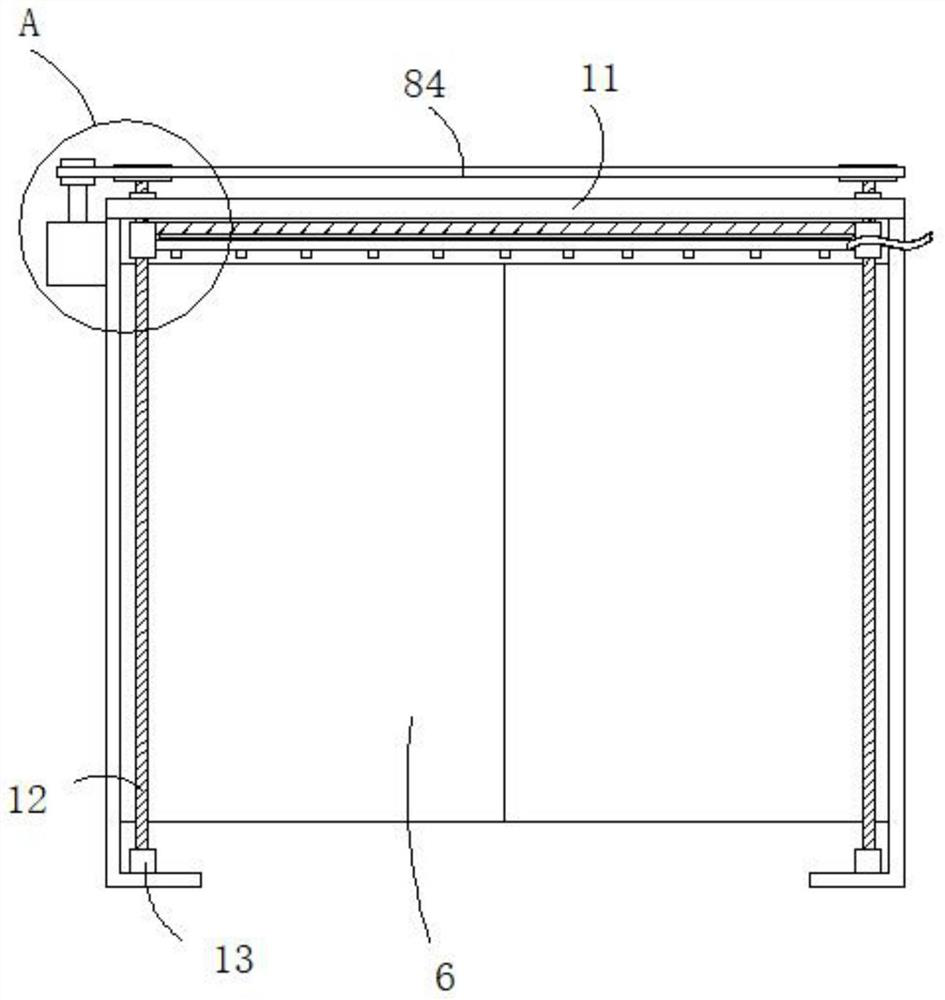

The invention discloses a displacement monitoring station. The station comprises a monitoring stand column, a photovoltaic panel, a monitoring element, an antenna, a battery and a cleaning device, thebattery is charged and energy is stored through the photovoltaic panel; power is supplied to the monitoring element, the antenna and the cleaning device; displacement monitoring of the side slope isachieved through cooperation of the antenna and the monitoring element, the photovoltaic panel is provided with the cleaning device, the cleaning device comprises the nozzle and the cleaning piece, the nozzle sprays and washes the photovoltaic panel and then scrapes and cleans the photovoltaic panel through the cleaning piece, accumulated dust on the photovoltaic panel is effectively removed, andthe efficiency of converting solar energy into electric energy by the photovoltaic panel is guaranteed.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

Dust removal apparatus of photographing apparatus

InactiveUS7903167B2Reduce harmEffectively remove dustTelevision system detailsColor television detailsEngineeringRange of movement

A dust removal apparatus of a photographing apparatus comprises a movable unit and a controller. The movable unit has an imaging device and is movable. The controller strikes the movable unit against a boundary of a range of movement of the movable unit as a dust removal operation. The controller counts the number of times of the dust removal operation, measures an elapsed time from the point when counting the number of times of the dust removal operation commences. When the elapsed time is less than or equal to a time period and the number of times of the dust removal operation is equal to or greater than a predetermined number of times, the controller halts the dust removal operation until a predetermined time period has elapsed.

Owner:RICOH IMAGING COMPANY

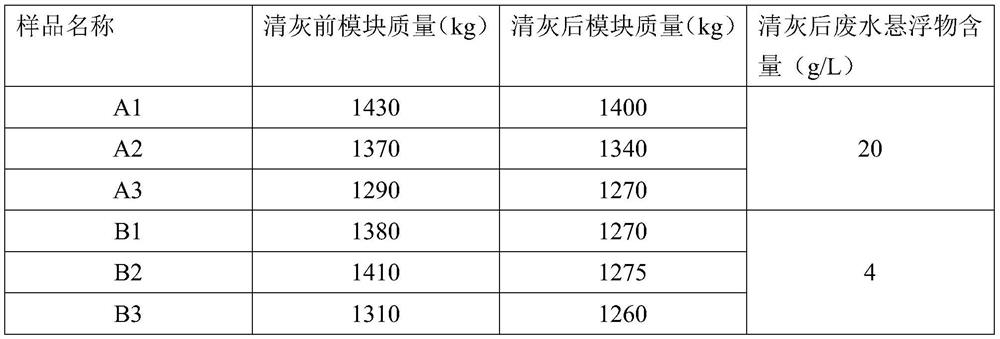

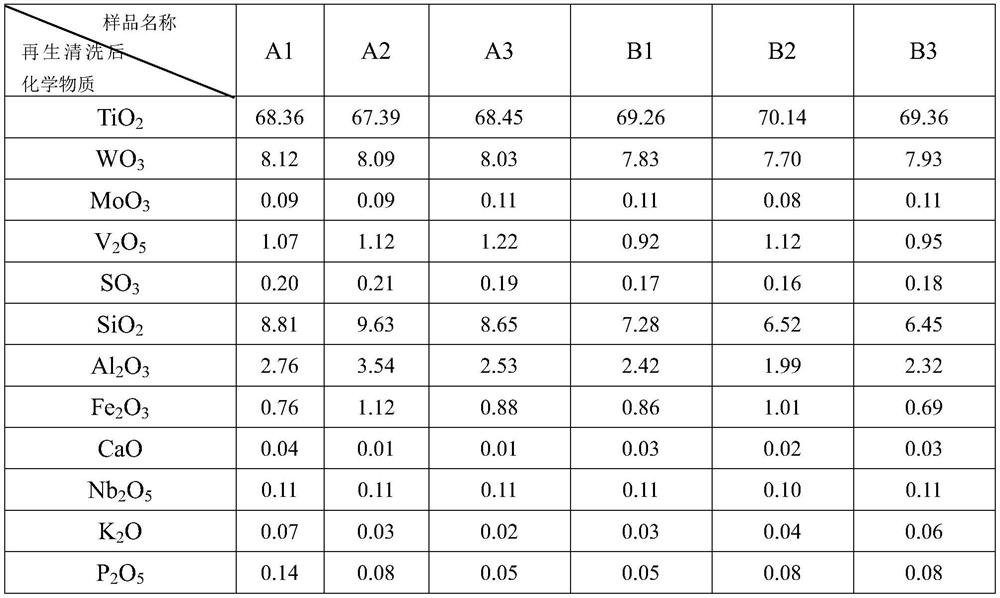

Ash removal method for regeneration pretreatment of plate-type denitration catalyst

PendingCN113441190ARealize purging one by oneReduce difficultyDispersed particle separationCatalyst regeneration/reactivationPtru catalystEnvironmental engineering

The invention discloses an ash removal method for regeneration pretreatment of a plate-type denitration catalyst. The ash removal method comprises the following steps: (1) dry-process ash removal via compressed-air purging: disassembling a catalyst module, removing accumulated ash on the surface of a catalyst unit body, putting the catalyst unit body into an automatic ash blowing equipment room, conducting blowing with compressed air in the windward side and the leeward side of the catalyst unit body separately, and placing the catalyst unit body having been subjected to ash removal in a module box again; (2) wet-process ash removal via automatic spraying: starting an automatic spraying and washing line to spray and wash the catalyst module; (3) ash removal via high-pressure water gun flushing: flushing the windward side of the catalyst module via a high-pressure water gun under the condition that the high-pressure water gun and the windward side of the catalyst module forms an angle of 90 degrees, then flushing a module box shell, hoisting the catalyst module, and conducting flushing from the leeward side of the catalyst module by using the high-pressure water gun. The method can be used for comprehensively and thoroughly removing accumulated ash on the outer surface of the catalyst and the pore channels of the catalyst, and follow-up catalyst regeneration difficulty is reduced.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD +1

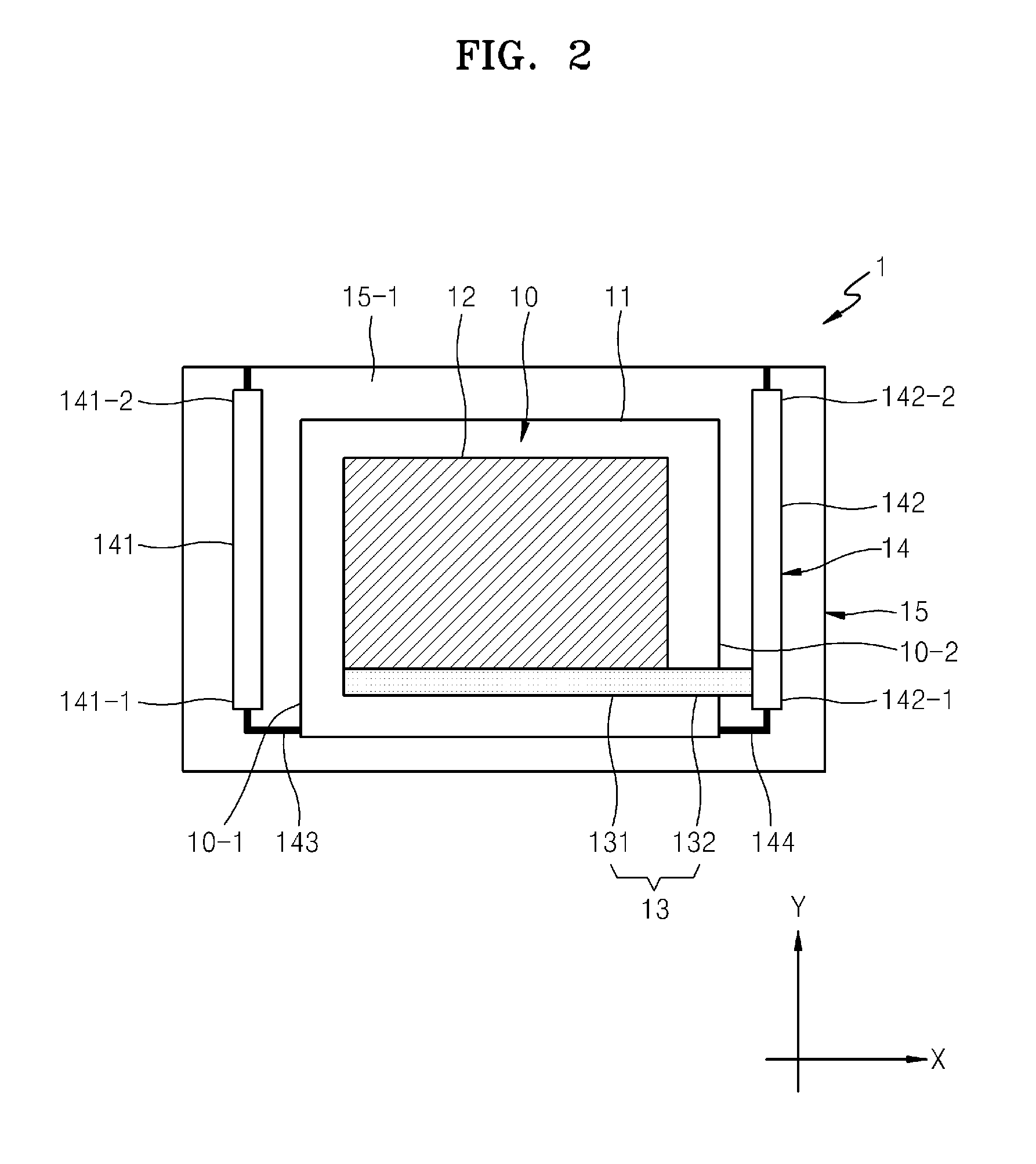

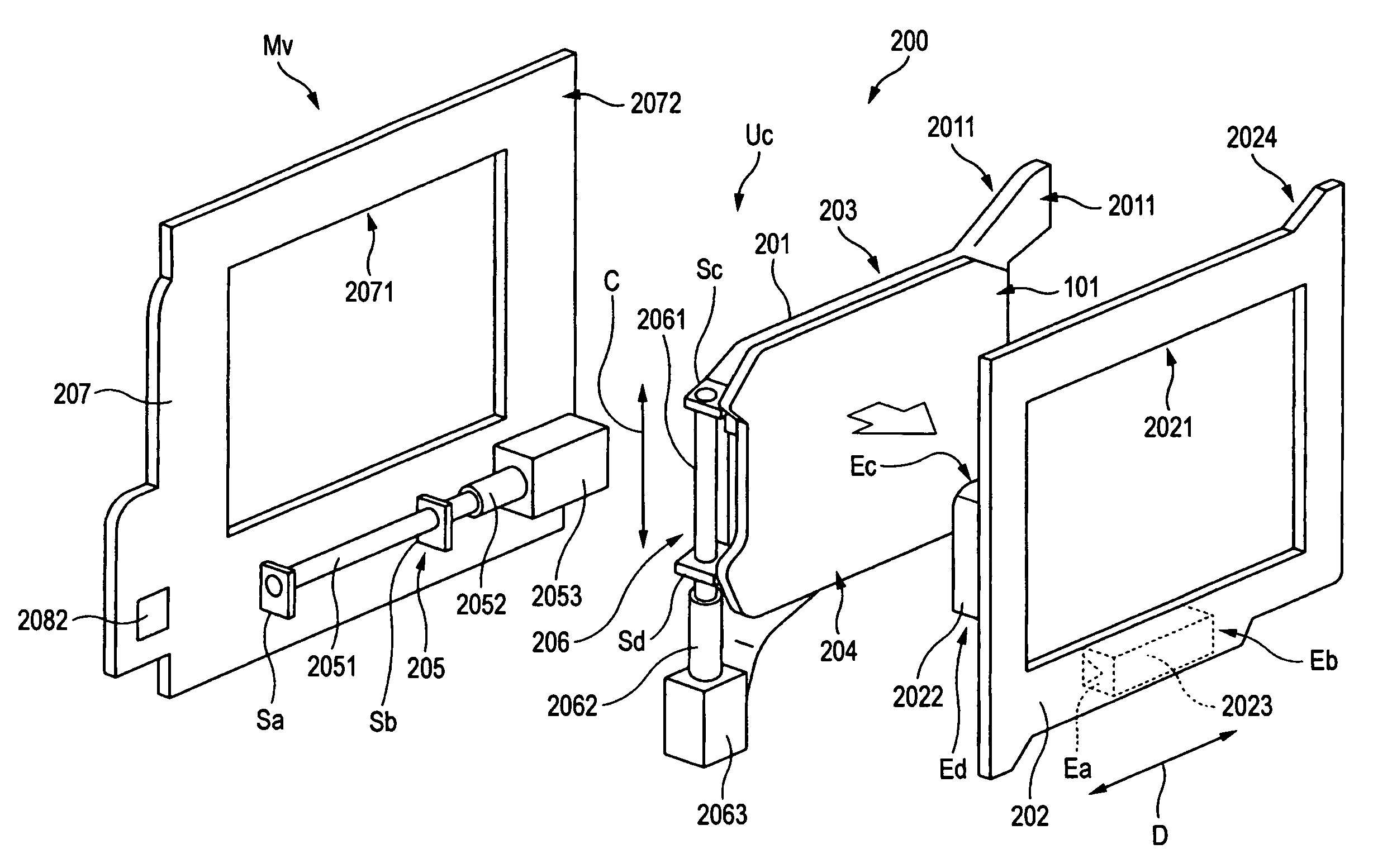

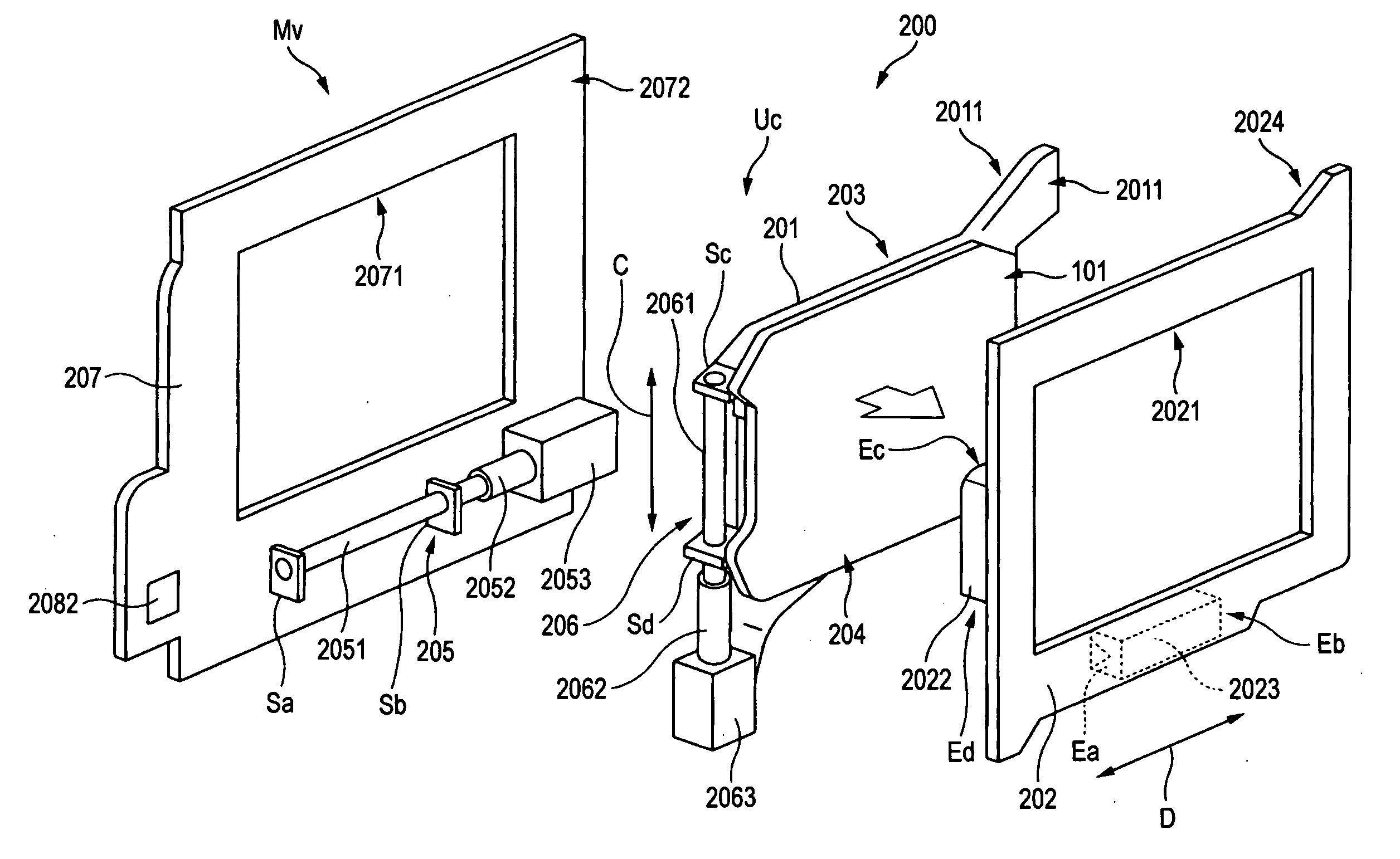

Image sensor assembly for removing dust from a surface of an image sensor

InactiveUS9041859B2Removal from surfaceStably maintain combination state of componentTelevision system detailsColor television detailsComputer scienceOptical filter

An image sensor assembly includes: an image sensor; a support plate disposed on a back surface of the image sensor; a first frame which includes a first hole which is open allowing incident light onto the image sensor and is disposed on a front surface of the support plate to enclose at least a side edge of the image sensor; an optical filter disposed in the first hole to block a part of the incident light; a second frame which includes a second hole which is open to allow light to be incident onto the optical filter and is disposed in front of the first frame; a front plate which is disposed in front of the second hole to contact a front surface of at least a side edge of the second frame; and a vibrator which is combined with at least a side edge of the front plate.

Owner:SAMSUNG ELECTRONICS CO LTD

Dust collecting mechanism for groove machining head and groove machining apparatus

InactiveUS9673070B2Effectively remove dustEliminate riskSemiconductor/solid-state device manufacturingWorking accessoriesMechanical engineering

Owner:MITSUBOSHI DIAMOND IND CO LTD

Image-capturing apparatus with asymmetric vibration element

InactiveUS8964049B2Effectively remove dustIncrease dust removal functionTelevision system detailsColor television detailsNon symmetricAcoustics

An image-capturing apparatus including an imaging device to convert light into an electrical signal; a vibration plate disposed in front of the imaging device to transmit the light to the imaging device; a vibration generating unit mounted on the vibration plate and to generate a vibration when a driving signal is input to the vibration generating unit; and a vibration partitioning unit mounted on at least one of the vibration plate or the vibration generating unit to asymmetrically deliver the generated vibration to the vibration plate.

Owner:SAMSUNG ELECTRONICS CO LTD

Aeroacoustic Duster

ActiveUS20140289997A1Efficiently removeEfficiently remove dustFluid dynamicsSuction nozzlesEngineeringNozzle

The invention disclosed herein provides for high particle removal rate and / or heat transfer from surfaces. The device removes particulate matter from a surface using a bounded vortex generated over the surface, with suction in the vortex center and jets for blowing air along the periphery. The jets are tilted in the tangential direction to induce vortex motion within the suction region. The vortex is said to be bounded because streamlines originating in the downward jets are entrained back into the central vortex.

Owner:UNIVERSITY OF VERMONT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com