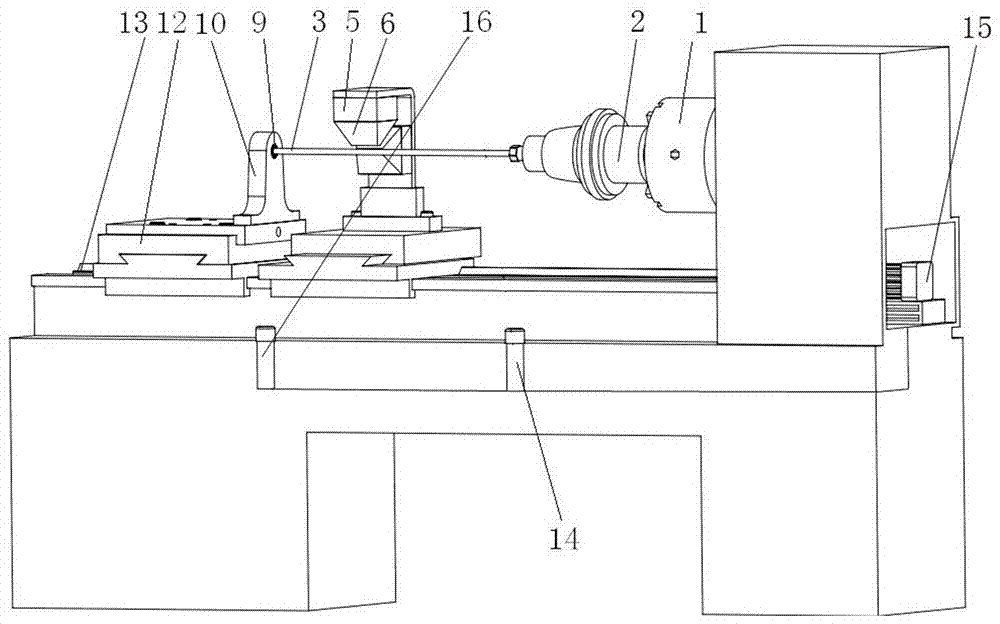

Inner surface polishing device of large-length-diameter-ratio slender pipe and method thereof

A polishing device and a technology with a large length-to-diameter ratio, which is applied in the direction of grinding the workpiece support, can solve the problems of heat generation and low grinding efficiency, and achieve the effect of increasing the magnetic induction intensity and improving the grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

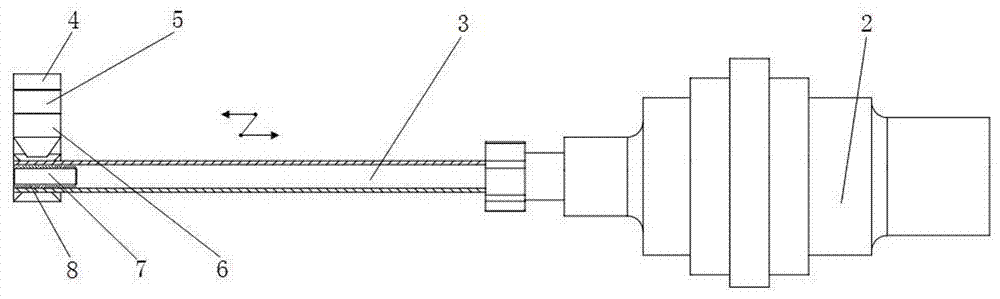

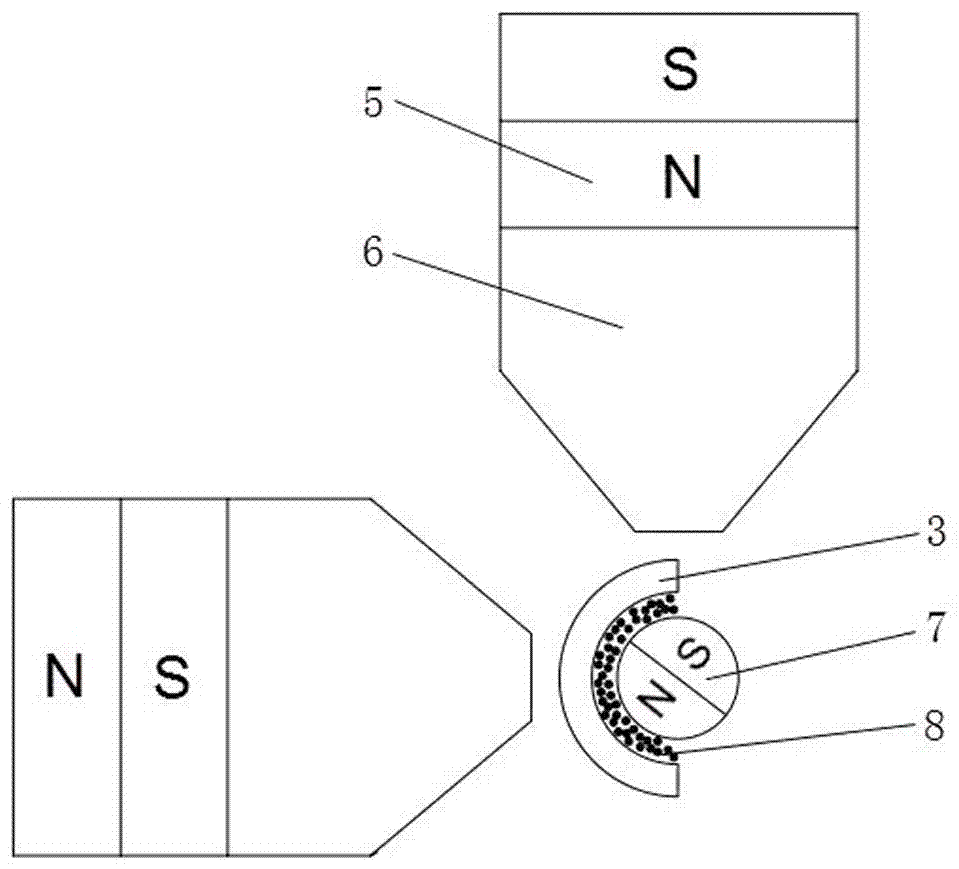

Method used

Image

Examples

Embodiment 1

[0041] Example 1, the elongated tube 3 with a surface roughness value of about 2.2 μm is ground with the device and method of the present invention. Before grinding, the inner surface of the elongated tube 3 has obvious pits, protrusions and obvious Machining textures with large peaks and troughs in the surface roughness profile (e.g. Figure 5In a), during the grinding process, the magnetic abrasive particles 8 will scratch the inner surface of the cutting workpiece, and will impact the inner surface of the workpiece with high-frequency vibration. This process is similar to mechanical shot peening, and the addition of vibration makes the magnetic abrasive particles The tumbling and renewal functions of 8 are enhanced, and the magnetic abrasive particles 8 fully participate in the grinding, and the surface morphology of the processed workpiece is more fine and uniform, and the surface roughness value at this time can reach 0.15 μm (such as Figure 5 shown in middle b); the ori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com