Method for preparing compound element processed non-oriented silicon steel for high-efficiency motor

A high-efficiency technology for oriented silicon steel, which is applied in the field of preparation of non-oriented silicon steel for high-efficiency motors, can solve the problems of reduced magnetic induction intensity, and achieve the effects of stable magnetic performance, high magnetic induction intensity, and low iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

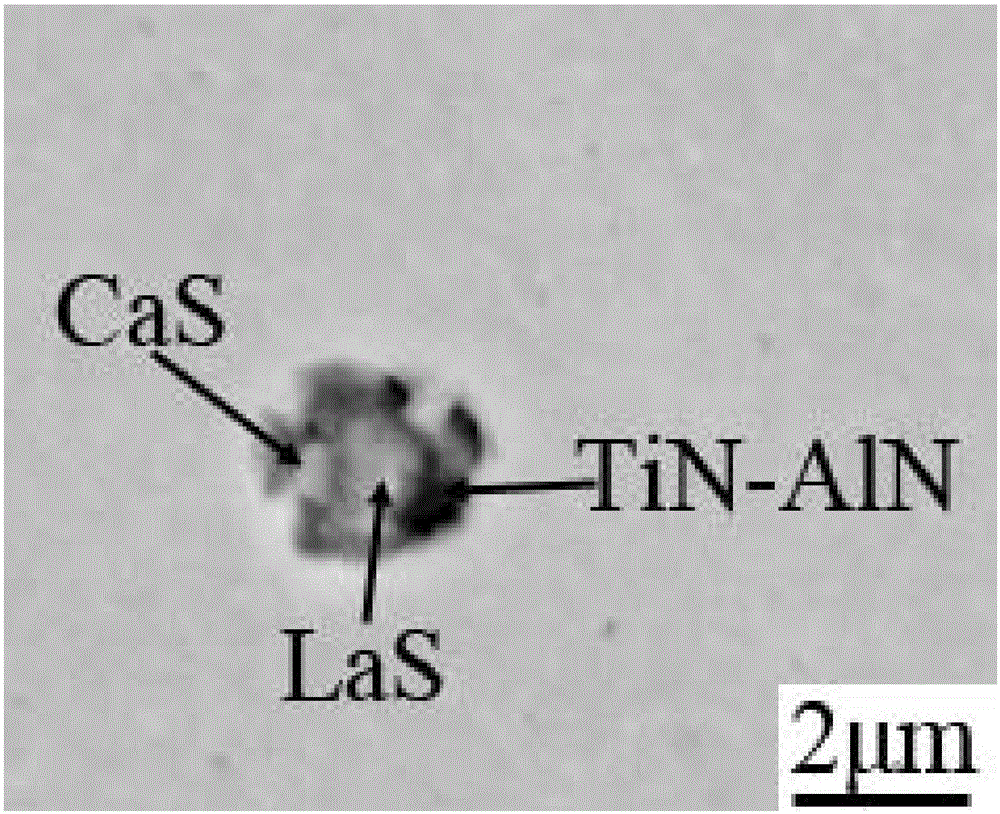

Image

Examples

Embodiment Construction

[0029] In order to further understand the contents of the present invention, the present invention will be further described below in conjunction with the examples.

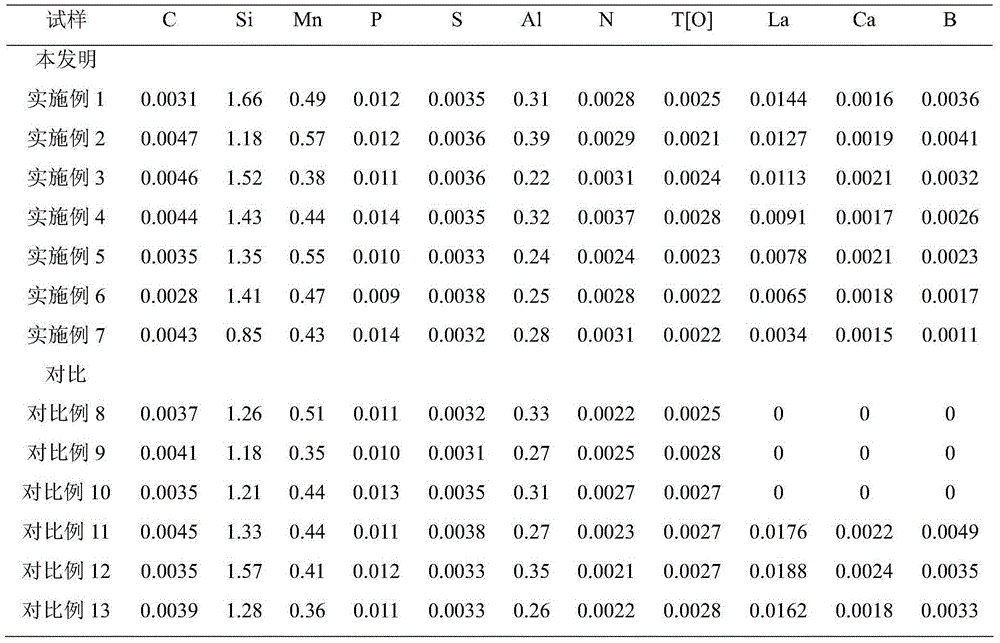

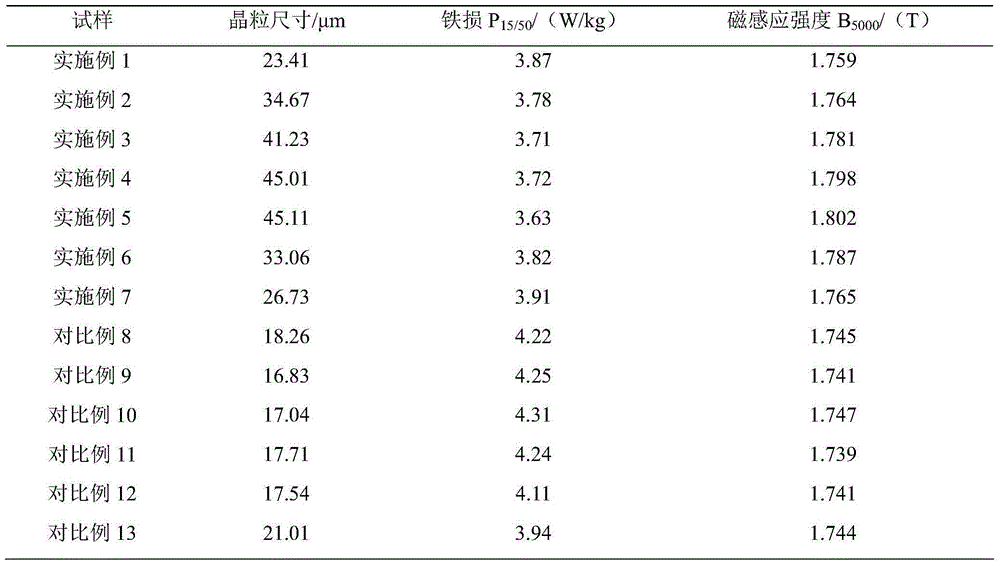

[0030] The chemical composition (by weight percentage) of the non-oriented silicon steel for high-efficiency motors treated with compound elements of the present invention is: C≤0.005%, Si: 0.8%-1.7%, Mn: 0.3%-0.6%, Al: 0.2 %~0.4%, P≤0.015%, S≤0.004%, N≤0.004%, T[O]≤0.003%, La: 0.003%~0.015%, Ca: 0.0015%~0.0025%, B: 0.001%~0.004 %, the rest is Fe and unavoidable impurities.

[0031] The embodiment of the present invention and the comparative example are prepared according to the following process steps and technical parameters: (1) adopt vacuum induction furnace smelting according to the above-mentioned composition and cast into 6.5kg steel ingot; (2) ingot is heated in the muffle furnace of 1150 ℃ and Heat preservation for 1h, then forge into a billet of 80mm×70mm×L; (3) After the billet is soaked at 1180°C, it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com