Brake-by-wire system of automobile

A braking system and automobile line technology, applied in the direction of brakes, brake transmission devices, vehicle components, etc., can solve the problems of total braking force, adverse effects of feedback braking force, inconvenient installation and layout, safety hazards, etc., and achieve structural improvement Small size, high pressure control precision, and the effect of reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

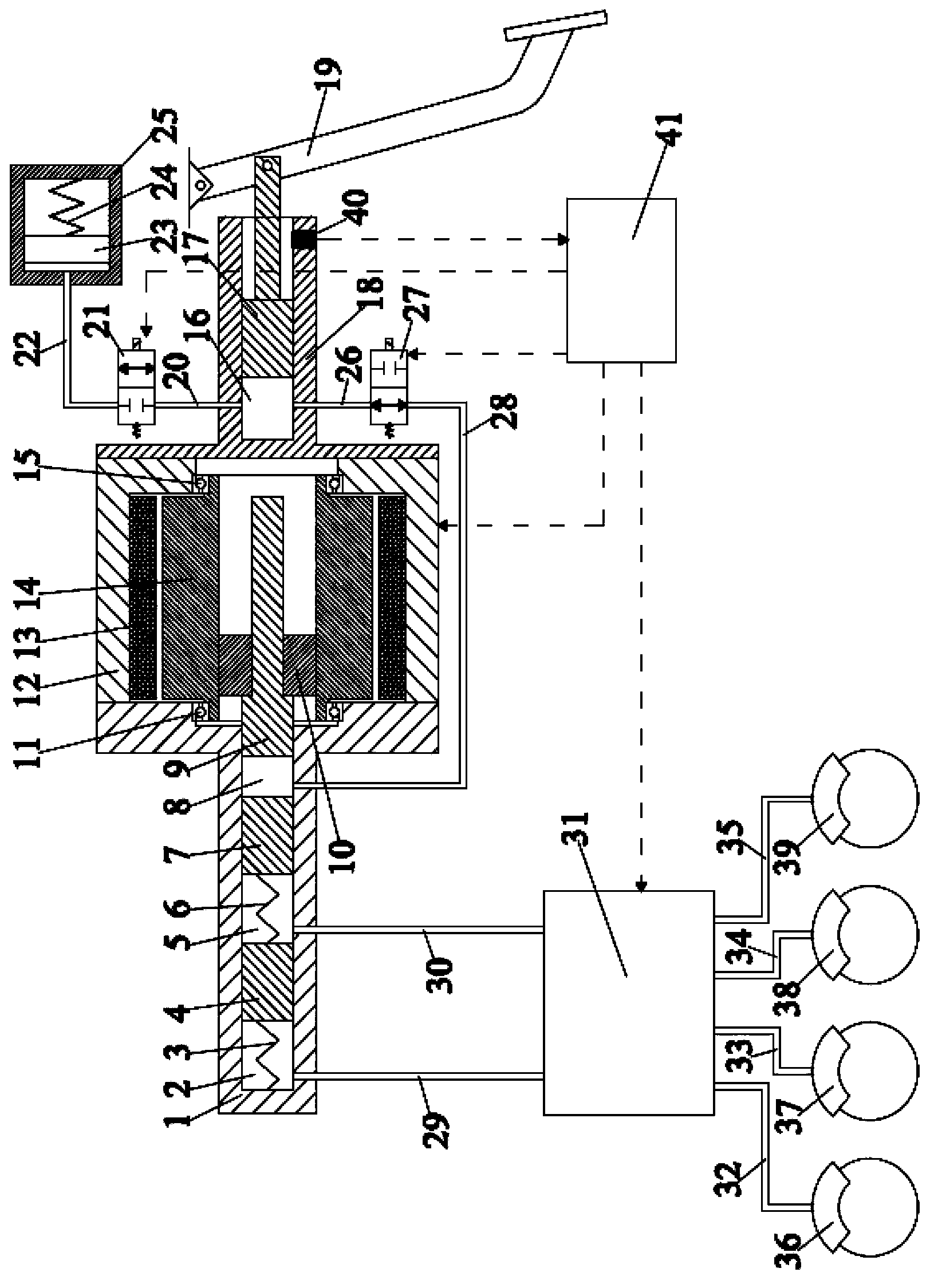

[0016] The automobile brake-by-wire system proposed by the present invention has a structure such as figure 1 As shown, it includes master cylinder shell 1, master cylinder first cavity piston 7, master cylinder first cavity spring 6, master cylinder second cavity piston 4, master cylinder second cavity spring 3, motor, nut 10, Screw rod 9, first bearing 11, second bearing 15, push rod housing 18, push rod 17, brake pedal 19, simulator valve 21, isolation valve 27, simulator, hydraulic control unit 31, left front brake 36, Right front brake 37, left rear brake 38, right rear brake 39.

[0017] The first inner chamber piston 7 of the master cylinder and the second inner chamber piston 4 of the master cylinder use the central valve piston used in the prior art; the first inner chamber piston 7 of the master cylinder and the second inner chamber piston 4 of the master cylinder are placed in the main cylinder In the cylinder shell 1; the first cavity piston 7 of the master cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com