Swirler and pre-mixing combustor adopting same

A premixed combustion and swirler technology, applied in the combustion chamber, combustion method, combustion equipment, etc., can solve the problems of boundary layer tempering, increase local high temperature area, increase the gas flow rate of premixing channel, etc., to achieve convenient power adjustment , to avoid tempering and hanging fire, the effect of stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

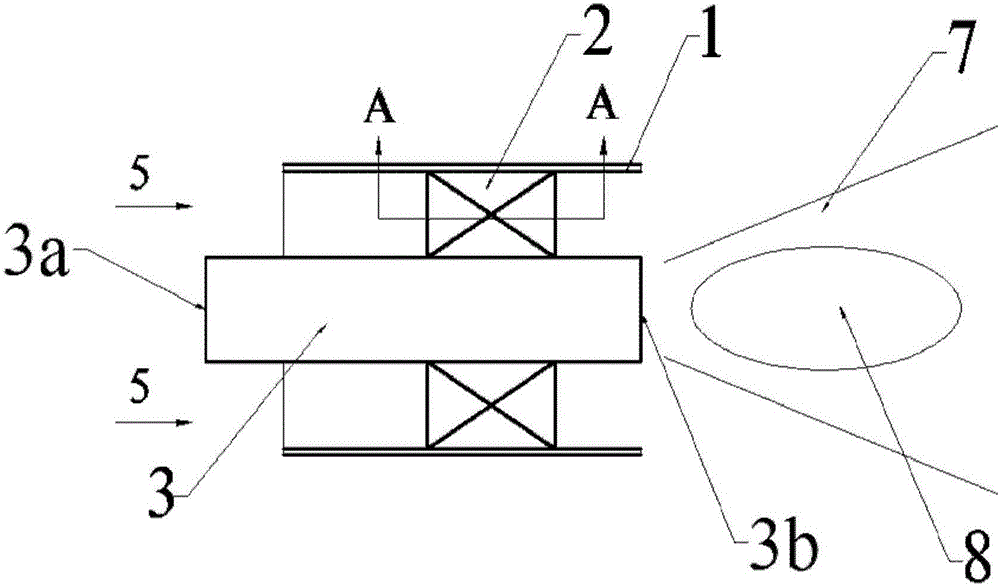

Method used

Image

Examples

Embodiment 1

[0039] This embodiment describes the application of the present invention in combination with the working process of the gas turbine, see Figure 6 . A gas turbine generally includes a compressor 31 , a combustion chamber 32 , a turbine 33 , and a load 35 (such as a generator) and the like. The air 30 is compressed by the compressor 31 to form a high-pressure gas 37, and then enters the combustion chamber 32 to be mixed with fuel to form a high-temperature and high-pressure flue gas 38. The flue gas 38 drives the turbine 33 to rotate to do work and drives the compressor 31 and the load 35 to rotate, and is output to the outside power or electricity.

[0040] The fuel supply pipeline 36 of the combustion chamber 32 of the gas turbine should be provided with corresponding valves and branches according to the needs of the burner. The fuel pipeline applying the burner of the present invention must include at least two types of branches: the diffusion fuel pipeline 36a and the pr...

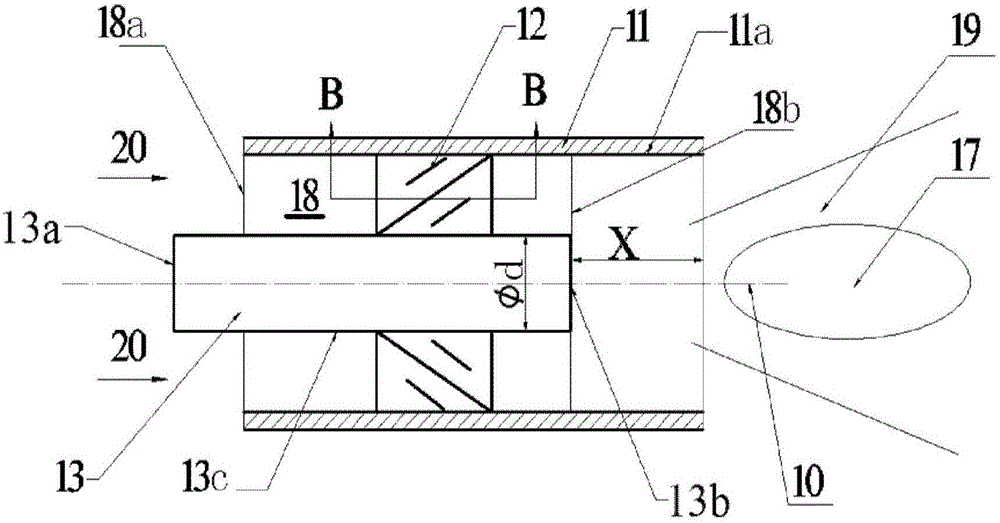

Embodiment 2

[0044] The novel burner of the present invention can also be applied to gas or oil-fired boilers, see Figure 7 . In the case of using fuel oil, there needs to be a heating device that heats the fuel oil to evaporate it into vapor. After the fuel oil is evaporated into a gaseous state, its application is similar to that of gaseous fuel, so the application for gas described later is the same Can be used for fuel. The gas boiler includes a boiler body 44, a blower 41, a burner 43, a fuel pipeline 46, and the like. After the air 30 is pressurized by the blower 41, it enters the burner and mixes with the premixed fuel 46b. After passing through the swirler 12, it burns stably. discharge. The start-up process and fuel adjustment involved in this burner are similar to the application in the combustion chamber of a gas turbine, and will not be repeated here.

[0045] described in Example 1 Figure 8 The hollow swirl vane structure shown can also be applied in gas boiler burners....

Embodiment 3

[0047] A deformation structure of the present invention such as Figure 9 As shown, this deformation relates to the large vane 21 or the small vane 22 of the novel swirler of the present invention. There may be several through holes 25 on the swirl blade, with a diameter of 0.5 to 6mm, which penetrate the windward side and the leeward side of the swirl blade, and guide the high-pressure airflow on the windward side to the leeward side, which can further eliminate the low-speed area on the leeward side .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com