Liquid-liquid reaction experimental apparatus based on hydraulic rotary spraying

A technology of liquid-liquid reaction and hydraulic rotation, which is applied in chemical/physical/physicochemical fixed reactors, etc., can solve the problems of incomplete mixing of reactants, difficulty in controlling the liquid rate, hidden safety hazards of manual feeding, etc., to achieve beneficial Experimental observation and experimental research, complete response, and effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

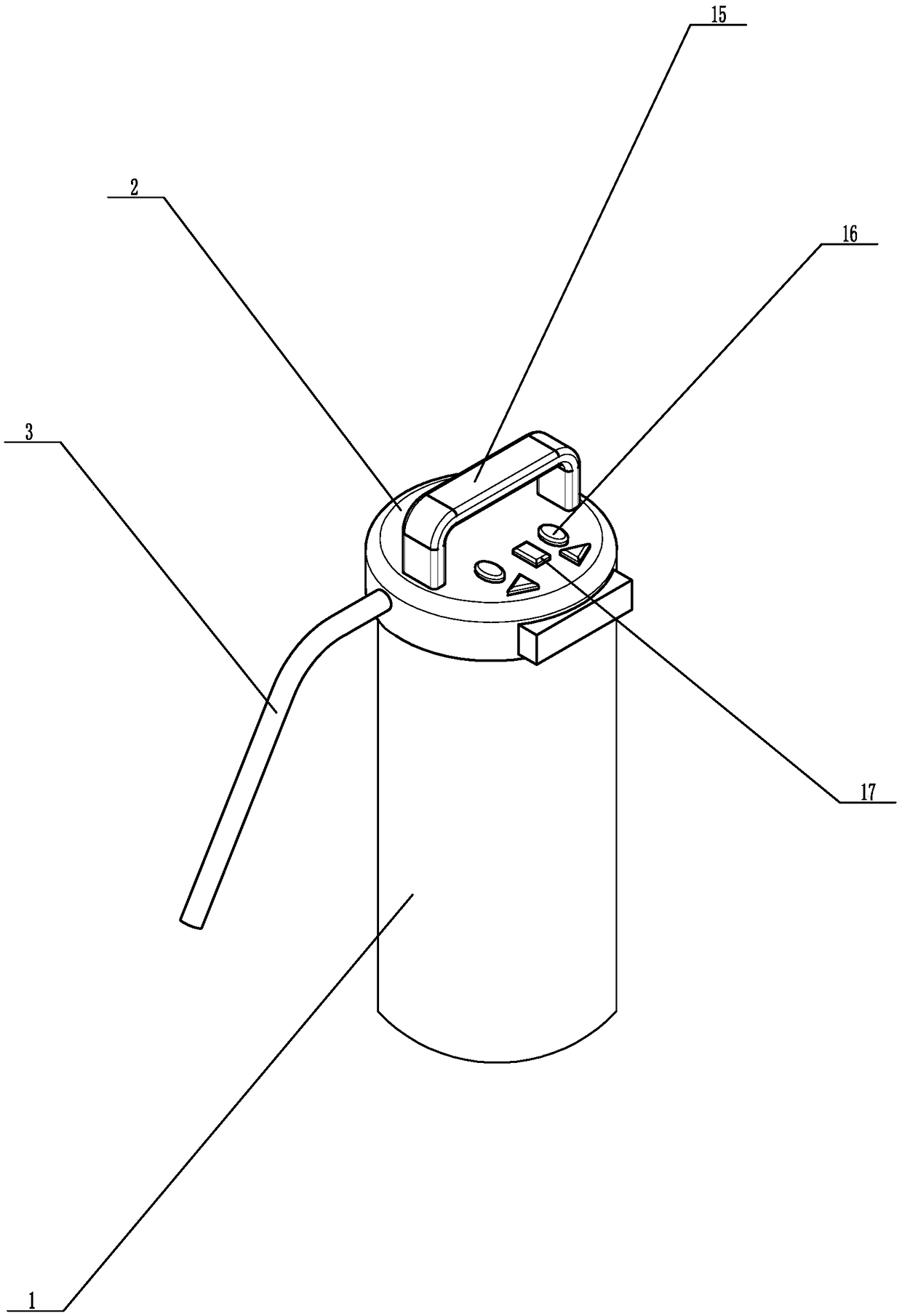

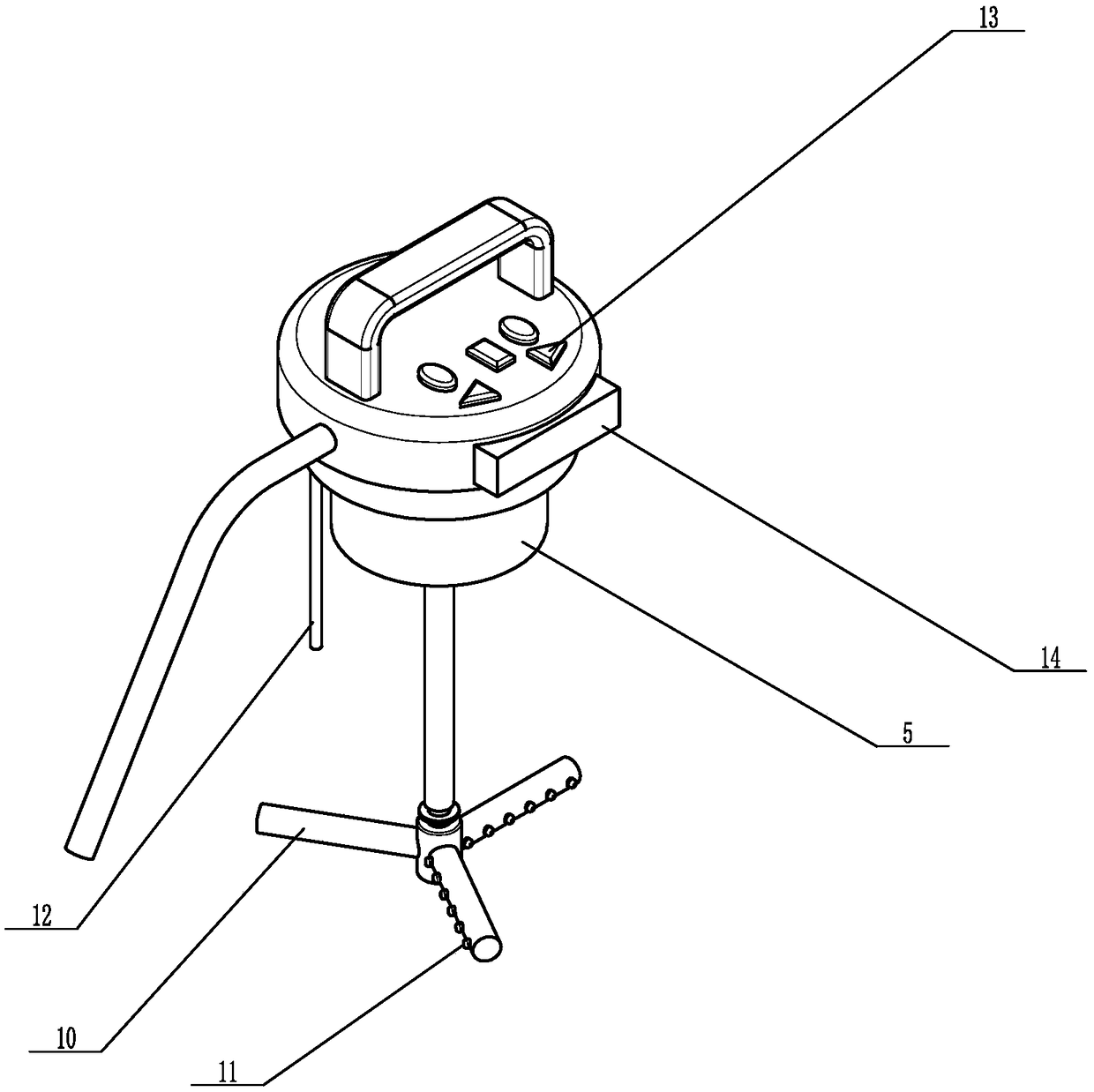

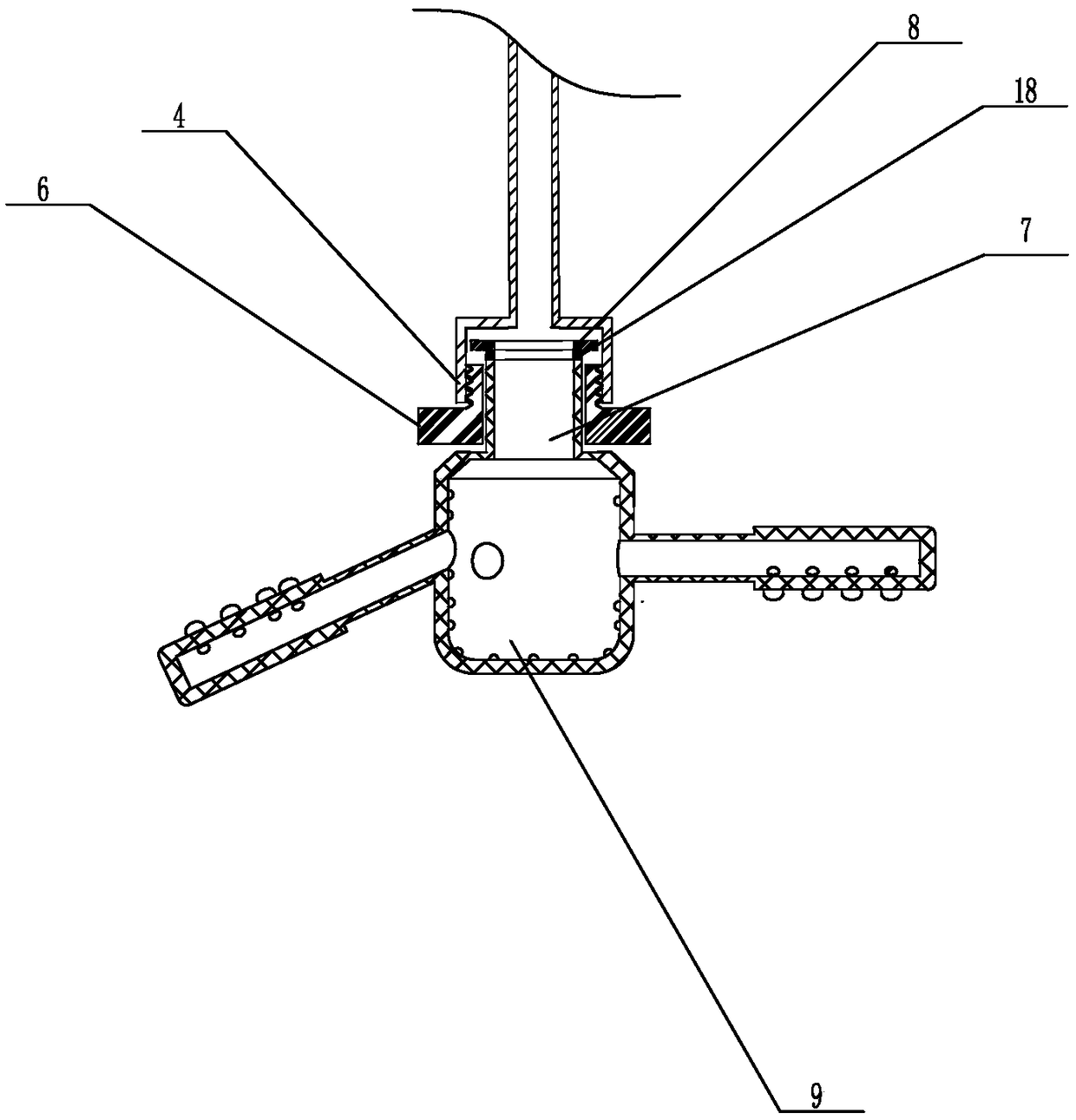

[0018] Such as figure 1 Propose a kind of specific embodiment of the present invention as shown, comprise the reaction tank 1 that is cylindrical, the top of described reaction tank 1 is provided with the tank lid 2 that cooperates with it to be connected detachably, in order to make this experimental device be applicable to under different reaction conditions liquid-liquid reaction, and at the same time ensure that the tank cover 2 and the reaction tank 1 are tightly connected. In this implementation, an internal thread is provided at the bottom of the tank cover 2, and an external thread is provided at the top of the reaction tank 1. The reaction tank 1 and the tank cover 2 Realize fast detachable tight connection by threaded connection, be convenient to unscrew or install tank cover 2, be convenient to take and place this experimental device simultaneously, present embodiment is also provided with a frame-shaped rotating handle 15 on the top of tank cover 2, for This experi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com