Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Reduce chemical reaction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antiwear antifriction composite additive for lubricating oil (grease)

InactiveCN104046407AIncrease surface areaIncrease the speed of diffusionAdditivesMetallurgyReaction rate

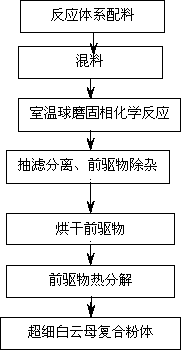

The invention discloses an antiwear antifriction composite powder for lubricating oil (grease) and a preparation method thereof and relates to a nano-rare earth oxide-cladding ultrafine muscovite composite powder for the fields of lubricating oil, lubricating grease and the like. the invention is characterized in that a muscovite powder, rare-earth salt and its ligand are used as raw materials; a solid-phase reaction system is crushed by shear force and impact force generated during the ball-milling process, specific surface area of reactants is increased, and reaction rate is raised so as to raise ratio of nucleation rate to growth rate; a fine and uniform precursor is prepared, and then washing, drying and control of thermal decomposition temperature and time are carried out so as to obtain the nano-rare earth oxide-cladding ultrafine muscovite composite powder with different particle sizes and cladding systems; and after undergoing surface modification, the nano-rare earth oxide-cladding ultrafine muscovite composite powder is added into base oil or lubricating grease at different proportions of (0.5%-3%). In four-ball friction, friction coefficient can be reduced, and friction-pair wear scar diameter is minimized.

Owner:SICHUAN UNIV

Neutral blockage removing agent composition used for oil recovery formation in oilfield and preparation method thereof

ActiveCN104194758ALow corrosion rateUnblocking safetyDrilling compositionButanedioic acidSuccinic acid

The invention relates to a neutral blockage removing agent composition used for an oil recovery formation in an oilfield. The neutral blockage removing agent composition is prepared from the following raw materials in parts by weight: 10-14 parts of polyepoxysuccinic acid amine, 35-40 parts of diethylenetriaminepentaacetic acid amine, 33-37 parts of hydroxyl succinic acid amine, 20-25 parts of polyacrylamide, 7-10 parts of sodium polyaspartate, 10-14 parts of sodium gluconate, 10-15 parts of activated clay, 20-25 parts of potassium peroxodisulfate, 9-11 parts of hydroxyl butanedioic acid amine, 4-7 parts of sodium salicylate, 5-9 parts of hexamethylene tetramine, 0.2-0.3 part of vanadium pentoxide, 2-5 parts of starch, 5-8 parts of alpha-sulphonated fatty acid methyl ester and derivative thereof (MES) and 0.1-0.3 part ofdiethyl ethanolamine. The neutral blockage removing agent composition is used for the blockage removal of an oil pumping well and a screw pump well in the oilfield, can effectively solve the problems of cleaning blockage removal of the oil pumping well and the screw pump well in the oilfield and the corrosion of oil recovery equipment, has high blockage removing speed, is neutral and is free of corrosion; waste liquid for blockage removal can be degraded and does not need to be discharged onto the ground to be subjected to sewage treatment, no corrosion, dead angle, precipitation or secondary well blockage are generated, and more safety and more reliability are realized as compared with traditional pickling blockage removing, biological blockage removing and solvent blockage removing.

Owner:兰州熙瑞化工科技有限公司

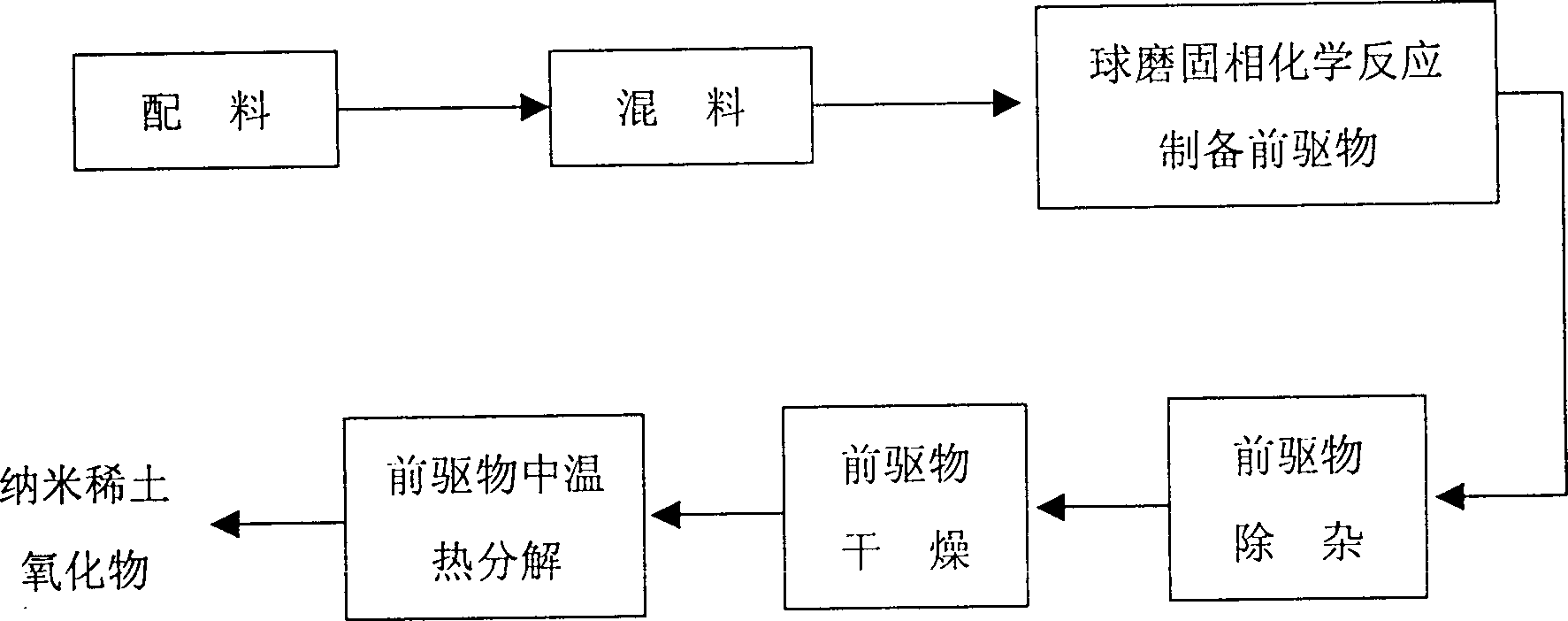

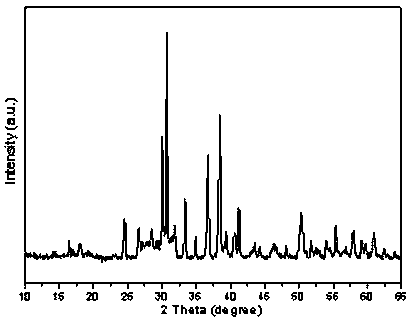

Preparation method of room-temperature ball-milling solid phase chemical reaction of rare earth mixing with nano stannic oxide

InactiveCN101746812ALarge specific surface areaIncrease the speed of diffusionTin oxidesChemical reactionReaction rate

The invention discloses a preparation method of room-temperature ball-milling solid phase chemical reaction of rare earth mixing with nano stannic oxide, relates to a preparation technology of the rare earth mixing with the nano stannic oxide, which can be applied for antistatic coating, plastics, fibre and other fields. Inorganic salts containing stannum and rare earth are taken as reactants, oxalic acid, ammonium carbonate, ammonium bicarbonate, sodium oxalate or sodium carbonate is taken as a ligand, the processing steps are sequentially dosing, mixing and preparing precursors of the room-temperature ball-milling solid phase chemical reaction, and the targeted product can be obtained after impurity removing, drying and thermal decomposition. The preparation method is characterized in that the reaction process does not use water, the stannum ion can be prevented from hydrolysis, uniform mixing can be realized, a solid phase reaction system is broken by utilizing the shearing force and the impact force generated during the ball milling process, the specific surface area of the reactant is increased, the reaction rate is increased, micro-fine and uniform precursors can be prepared, then the processes of cleaning, drying and controlling the thermolysis temperature and time are carried out, and thereby the rare earth mixing with nano stannic oxide powder, the particle size distribution of which is 30 to 80nm and has controllable morphology, can be obtained.

Owner:SICHUAN UNIV

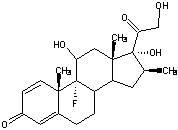

Fluorous synthesis method of betamethasone

InactiveCN102304163AReasonable designReduce chemical reaction timeSteroidsChemical reactionDrugs synthesis

The invention relates to a fluorous synthesis method of betamethasone, belonging to the technical field of steride medicament synthesis methods in pharmaceutical chemistry. The method comprises the following process steps: fluorinating and refining betamethasone epoxide which is used as a raw material so as to obtain betamethasone. According to the invention, the fluorous synthesis method of betamethasone is reasonable in design, thus chemical reaction time is greatly reduced, production period is shortened, a whole technical level of a product is greatly improved, cost is reduced by 15% as compared with the conventional process, and the fluorous yield of betamethasone reaches 85-90%.

Owner:ZHEJIANG XIANJU XIANLE PHARMA

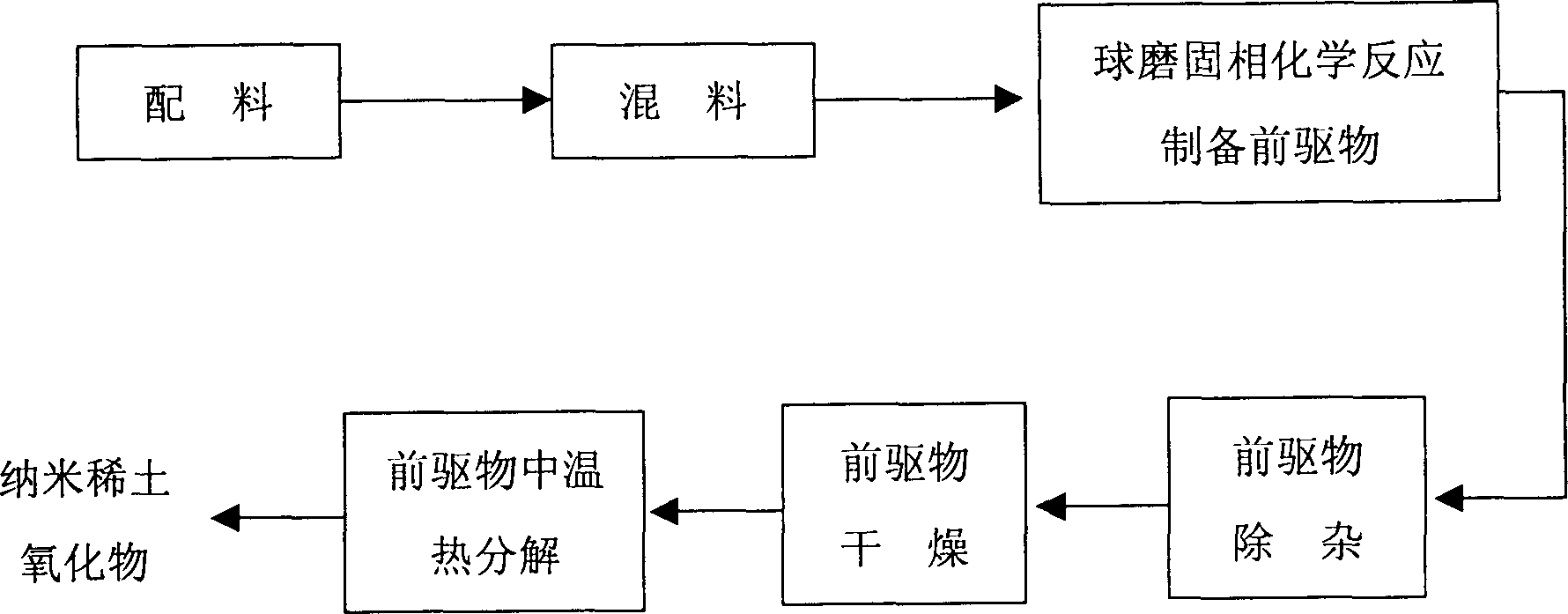

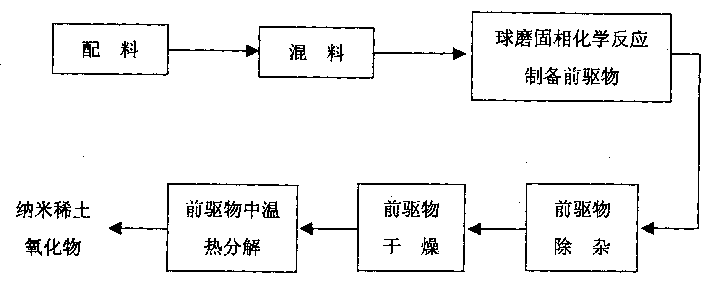

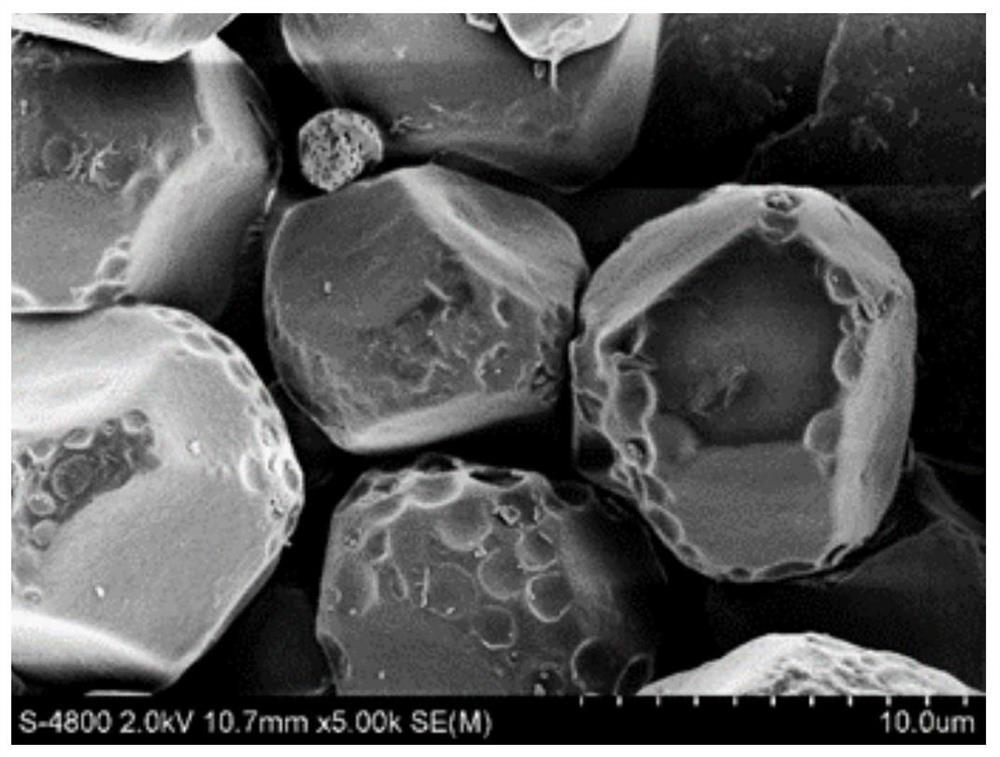

Process for preparing rare-earth nano oxide by ball grinding and solid-phase chemical reaction

InactiveCN1386706AQuick smashIncrease surface areaRare earth metal compoundsSodium acetrizoateRare-earth element

A nano rare-earth oxide is prepared from the inorganic salt of rare-earth element (Ce, La, Pr, Nd, or Tb) and ligand (oxalic acid, sodium oxalate, dicarbonate, 8-hydroxyquinoline, complexon, etc) through proportioning, mixing, and ball grinding while solid-phase chemical reaction to obtain precursor, removing impurities, drying, and medium-temp thermal decomposition. Its advantages are simple process, low cost, saving energy, high purity (more than 99%) and narrow size distribution (10-30 nm).

Owner:SICHUAN UNIV

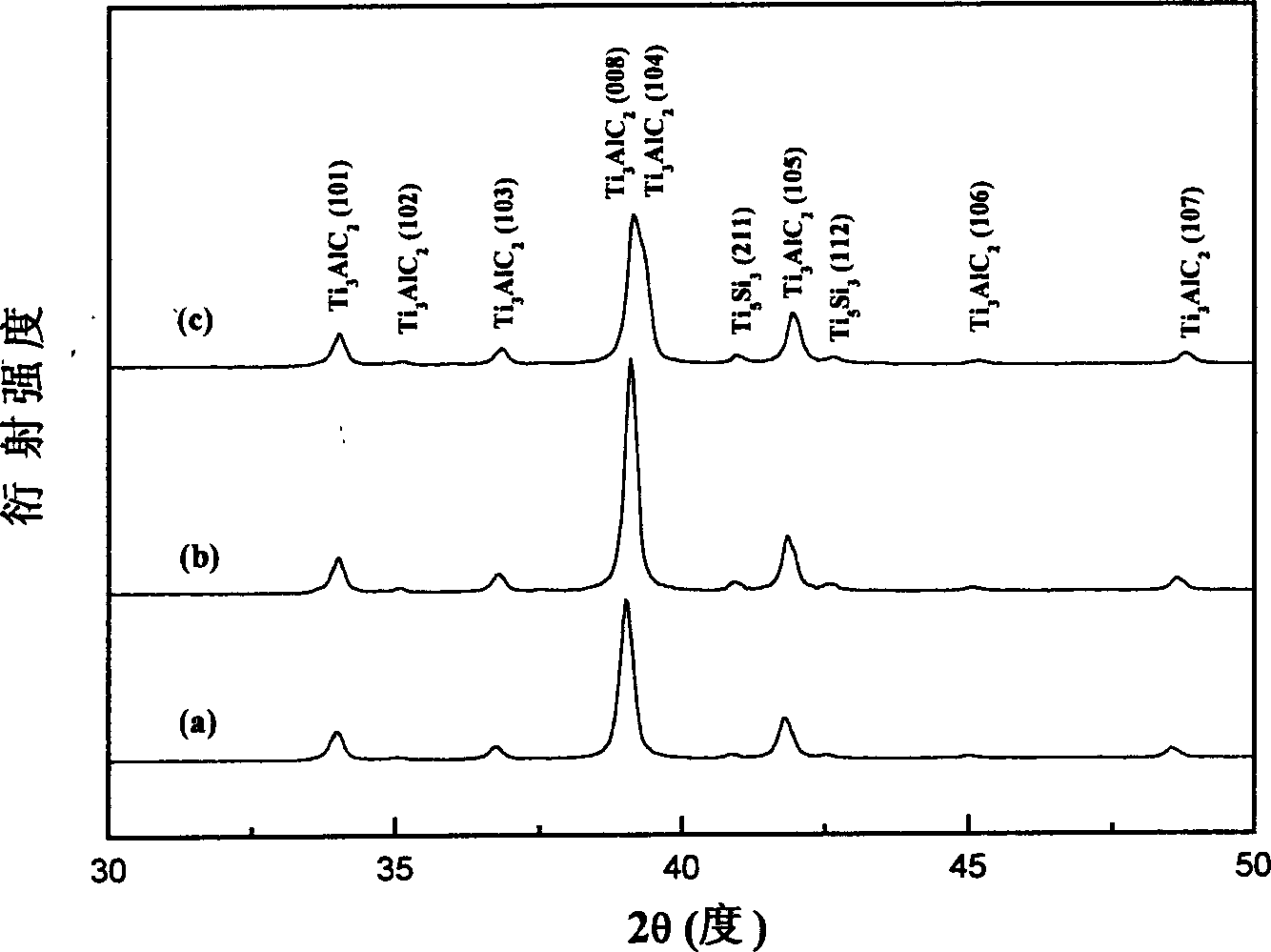

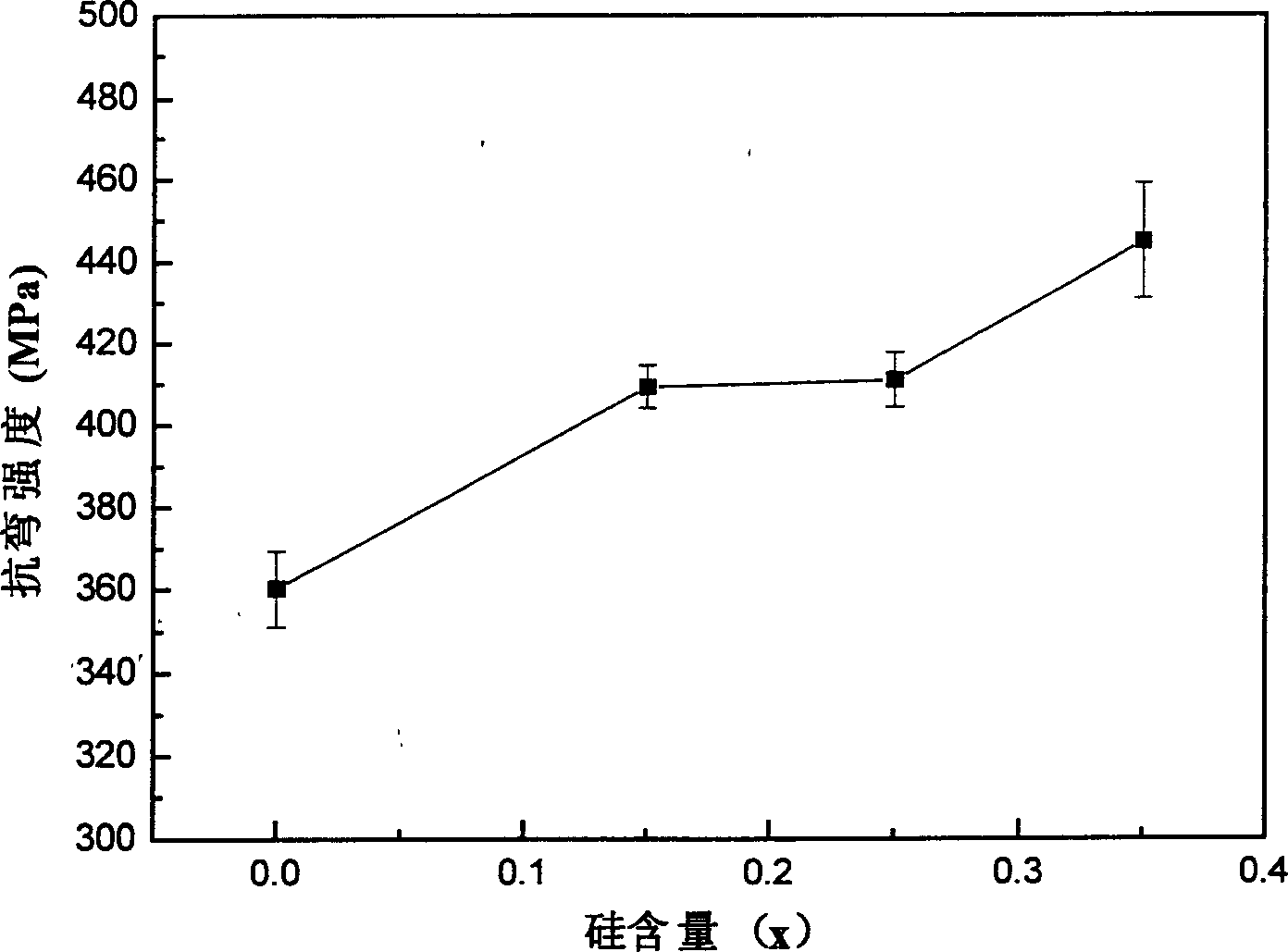

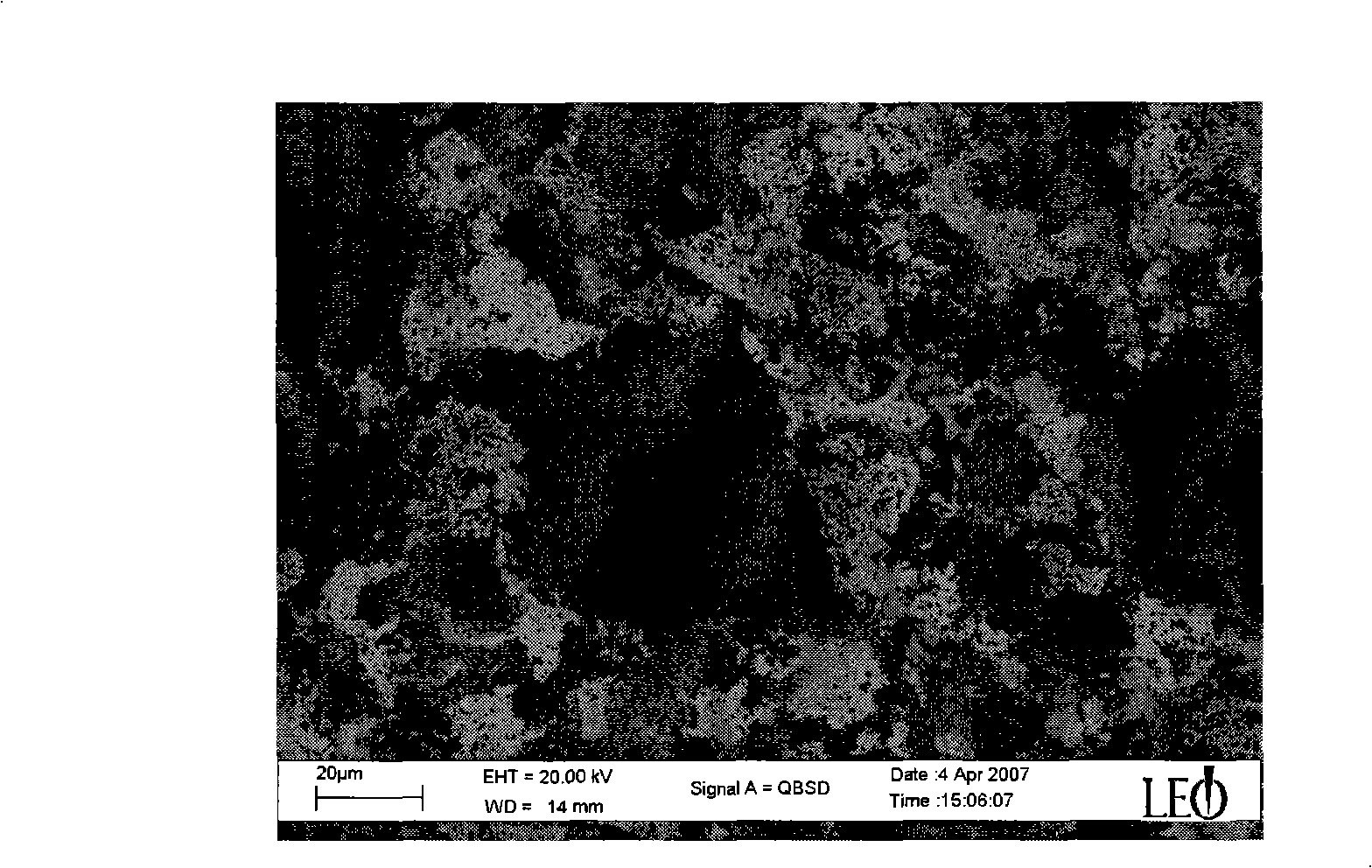

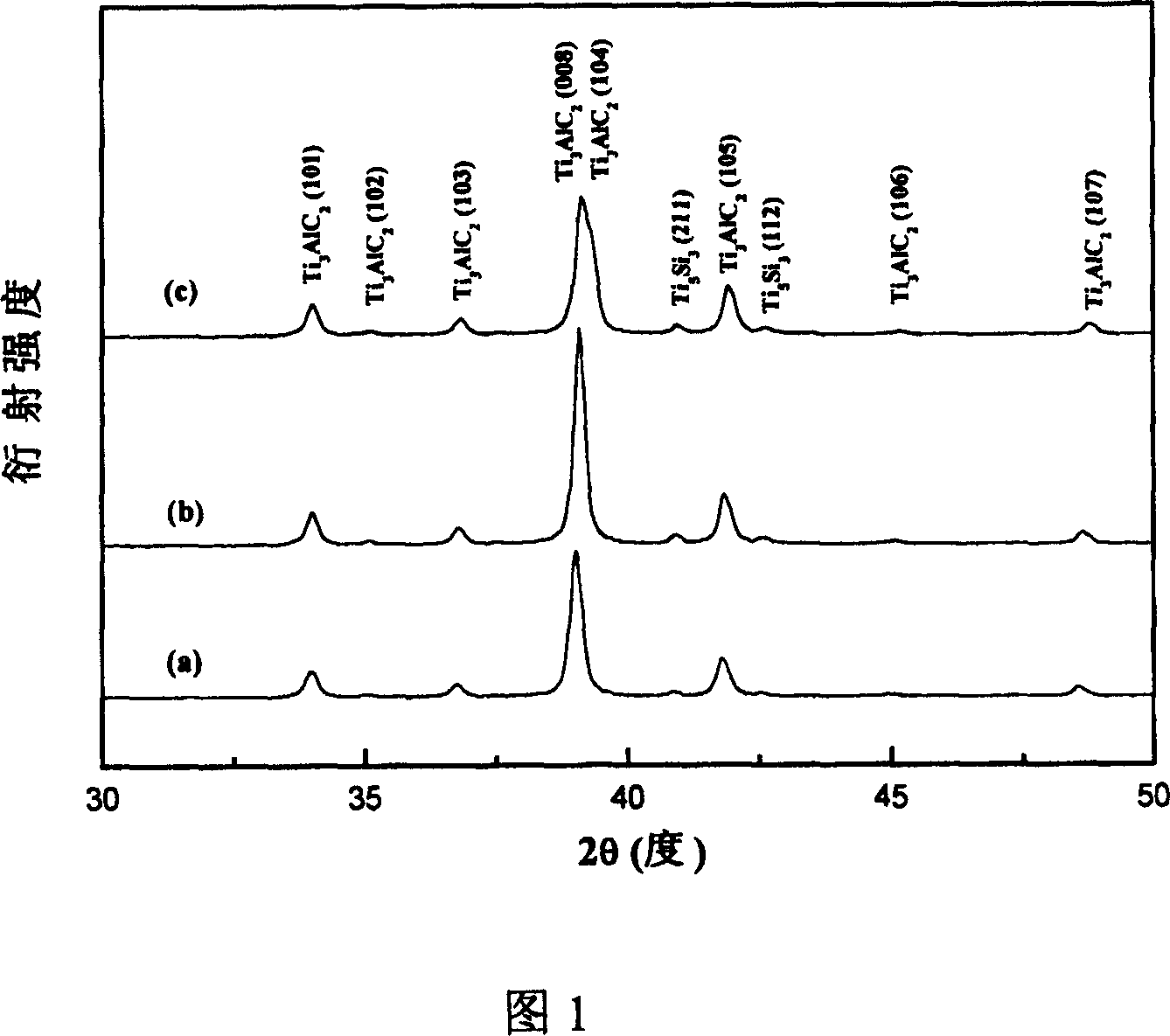

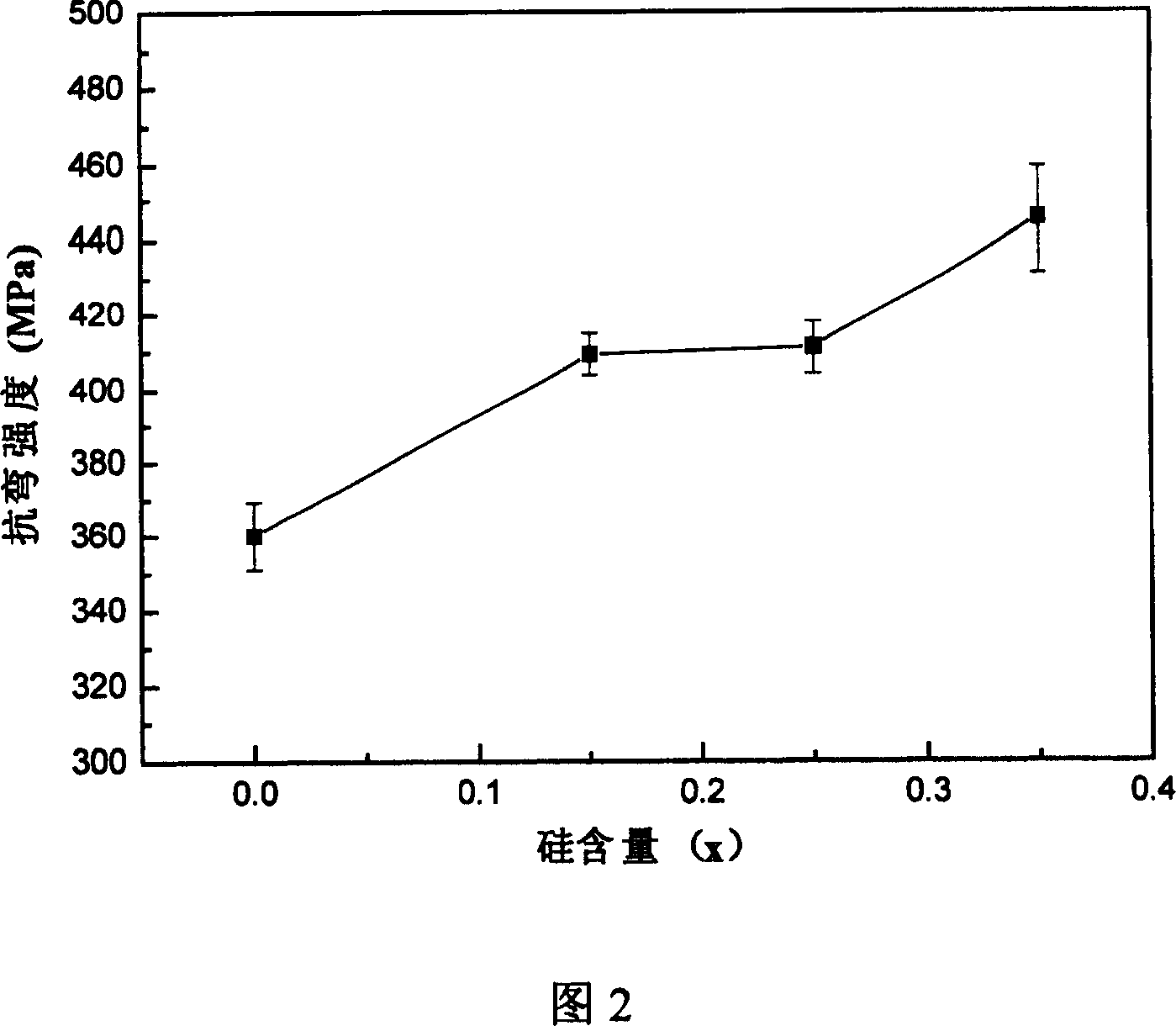

Ti3AlC2/Ti5Si3 compound material and its preparation method

The invention relates to a method for synthesizing titanium silicide (Ti5Si3) granule in original position to intensify the composite material based on titanium carbide aluminum (Ti3AlC2). Adding a certain amount of silicon, to prepare the Ti3AlC2 / Ti5Si3 composite material of different volume ratio, the volume percentage of the titanium silicide granule is 10-40%. The specific preparing method comprises: employing titanium powder, aluminium powder, silicon powder and graphite powder as raw material, the mole ratio of Tií†Alí†Sií†C is 3: (1.1-x): (1.8~2.0), and x is 0.1-0.5, mixing the raw material powder with physical-mechanical means for 8-24 hours, loading into the graphite mould, the forced pressure is 10-20 Mpa, calcinating in the heating furnace under protective atmosphere, the heating-up speed is 10-50 Deg C / min, the calcining temperature is 1400-1600 Deg C and lasting for 0.5-2 hours, the calcinating pressure is 20-40 Mpa. The titanium carbide aluminium / titanium silicide of high purity and high intensity can be produced under lower temperature and in shorter time by applying this invention.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Zirconium titanium carbide particle reinforced silicon aluminum titanium carbide zirconium based composite material and preparation thereof

InactiveCN101343183AImprove mechanical propertiesTake full advantage of strengtheningTitanium zirconiumTitanium carbide

The invention relates to a ceramic-matrix composite material as well as a preparation method thereof, in particular to a titanium zirconium carbide particle reinforced silica-alumina titanium zirconium carbide matrix composite material and a preparation method thereof. A zirconium titanium carbide particle reinforced silica-alumina titanium zirconium carbide solid solution adopting the in-situ synthesis has a zirconium titanium carbide particle reinforced phase with the volume percentage of 5 to 30 percent; and the preparation method comprises: firstly, taking a titanium powder, a zirconium powder, a silicon powder, an aluminum powder and a graphite powder as raw materials, mixing the materials by a physical mechanical method for 10 to 25 hours, putting the materials in a graphite mould for cold briquetting, with the exerted pressure of 5 to 20MPa, and sintering the materials in a hot pressing furnace input with a protective atmosphere, with a rate of rise of temperature of 5 to 50DEG C / min, a sintering temperature of between 1400 and 1650 DEG C, the sintering time of 0.5 to 2 hours, and a sintering pressure of 20 to 40MPa. The composite material and the method can prepare the titanium zirconium carbide particle reinforced silica-alumina titanium zirconium carbide matrix composite material with excellent combination properties such as high purity, high density, high hardness, high toughness and high-temperature mechanical property under rather low temperature and in a short period of time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Aluminum oxide granule reinforced aluminum titanium carbide base composite material and its preparation method

InactiveCN1769240AImprove mechanical propertiesAntioxidant will not decreaseTitanium matrix compositesAl powder

The invention relates to a method for preparation of Ti2Al2 / Al2O3 composite by an in-situ hot pressing / solid- liquid phase reaction. The pottery can be prepared by using Al2O3 particles strengthening Ti3AlC2 ternary layer, alumina particle strengthening phase being 5-30% by volume ratio; and the specific method for preparation is as following: using titanium powder, aluminum powder, graphite powder, and alumina powder as the raw material with the molar ration of Ti: Al: C being 3: (0.9-1.1): (1.8-2.0), adding the alumina powder by predetermined volume ratio; mixing the material powders for 8-24 hours by physics machine means, adding into graphite die for cold press with pressure of 10-20MPa, and sintering in a hot-pressing stove in a protective atmosphere, with the heating-up speed of 5-50Deg. C / min, sintering temperature of 1400-1600Deg. C, sintering time of 0.5-2 hours, and sintering pressure of 20-40MPa. In the invention, aluminum-titanium carbide composite reinforced by alumina particle with high purity, high strength and thermostability can be prepared in lower temperature, shorter time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

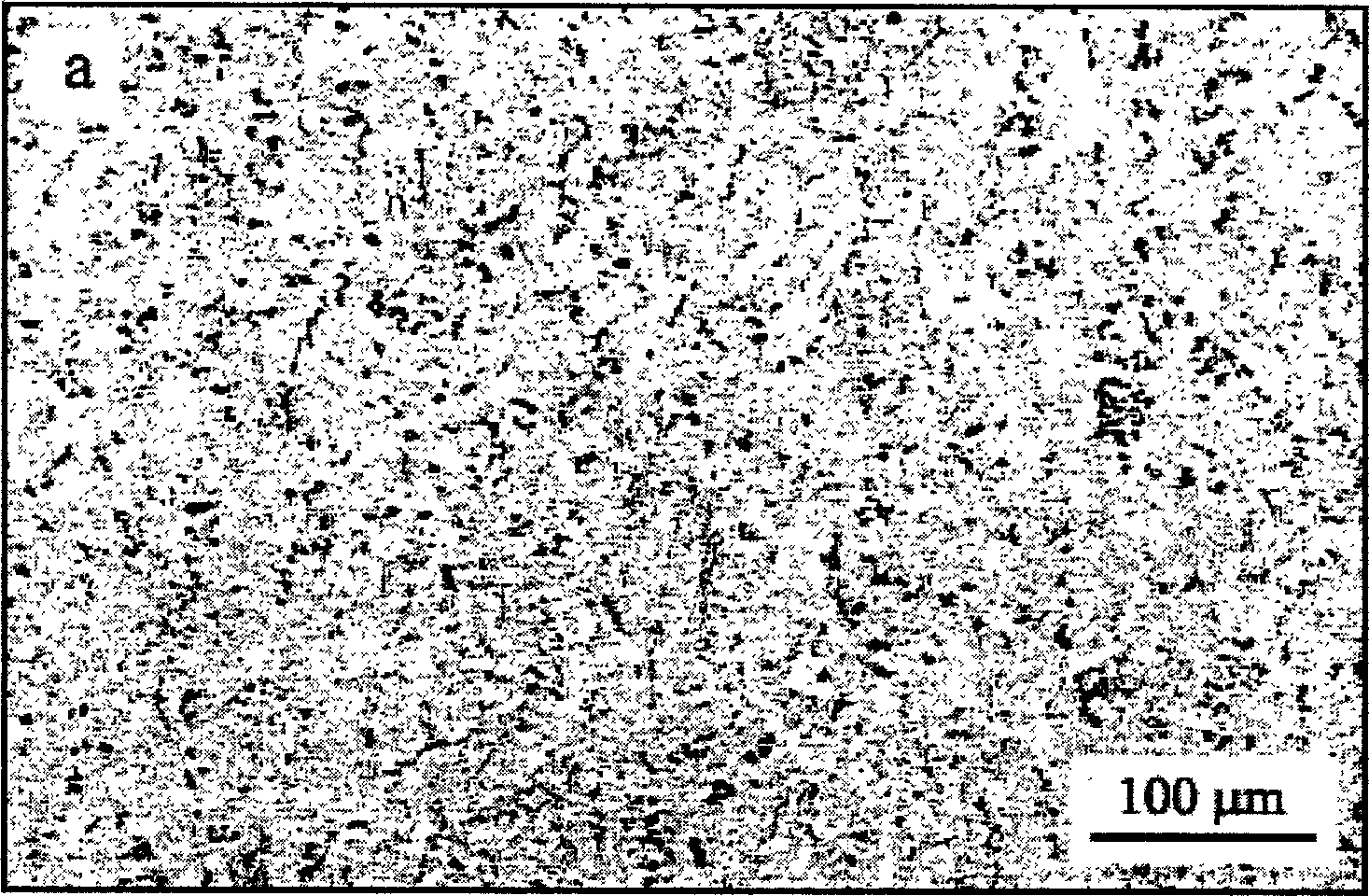

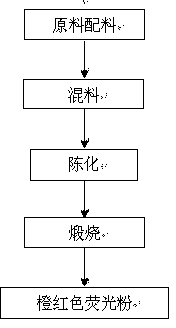

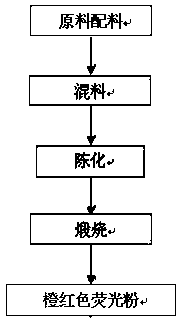

Synthetic method of silicate orange red fluorescent powder for white light light-emitting diode (LED)

ActiveCN102936495ALarge specific surface areaIncrease the speed of diffusionLuminescent compositionsLuminous intensityRare earth

A synthetic method of silicate orange red fluorescent powder for a white-light light-emitting diode (LED) belongs to a preparation technique of rare earth phosphor. The chemical formula of the rare earth phosphor is Sr3-x-yMySiO5:Xeu2+(M=Mg, Ca and Ba), wherein 0<x<0.1, and 0<y<0.2. The synthetic method particularly comprises steps of weighting corresponding alkali metal salt, ethyl orthosilicate and europium nitrate according to stoichiometric ratio of each element; then weighting a surface active agent and a fluxing agent which are 0.1-2wt% of a total mass of a drug; sufficiently hydrolyzing the ethyl orthosilicate, mixing the alkali metal salt, the europium nitrate, the surface active agent and the chelating agent in an aqueous solution, and enabling the molar ratio of the reactant and the chelating agent to be 1:2-6; and then mixing the two solutions, sufficiently stirring to form a transparent and clear solution, ageing under constant temperature, drying to obtain predecessor powder, evenly mixing the predecessor powder and a cosolvent, burning for 3-6 hours in a reducing atmosphere, enabling the burning temperature to be 1100 DEG C-1400 DEG C, and then obtaining the needed fluorescent powder. The fluorescent powder prepared by the synthetic method is wide in excitation wavelength, high in light intensity, good in crystallinity and narrow in size distribution and can be used for red fluorescent powder for the white-light LED.

Owner:重庆美地路艺建筑科技有限公司

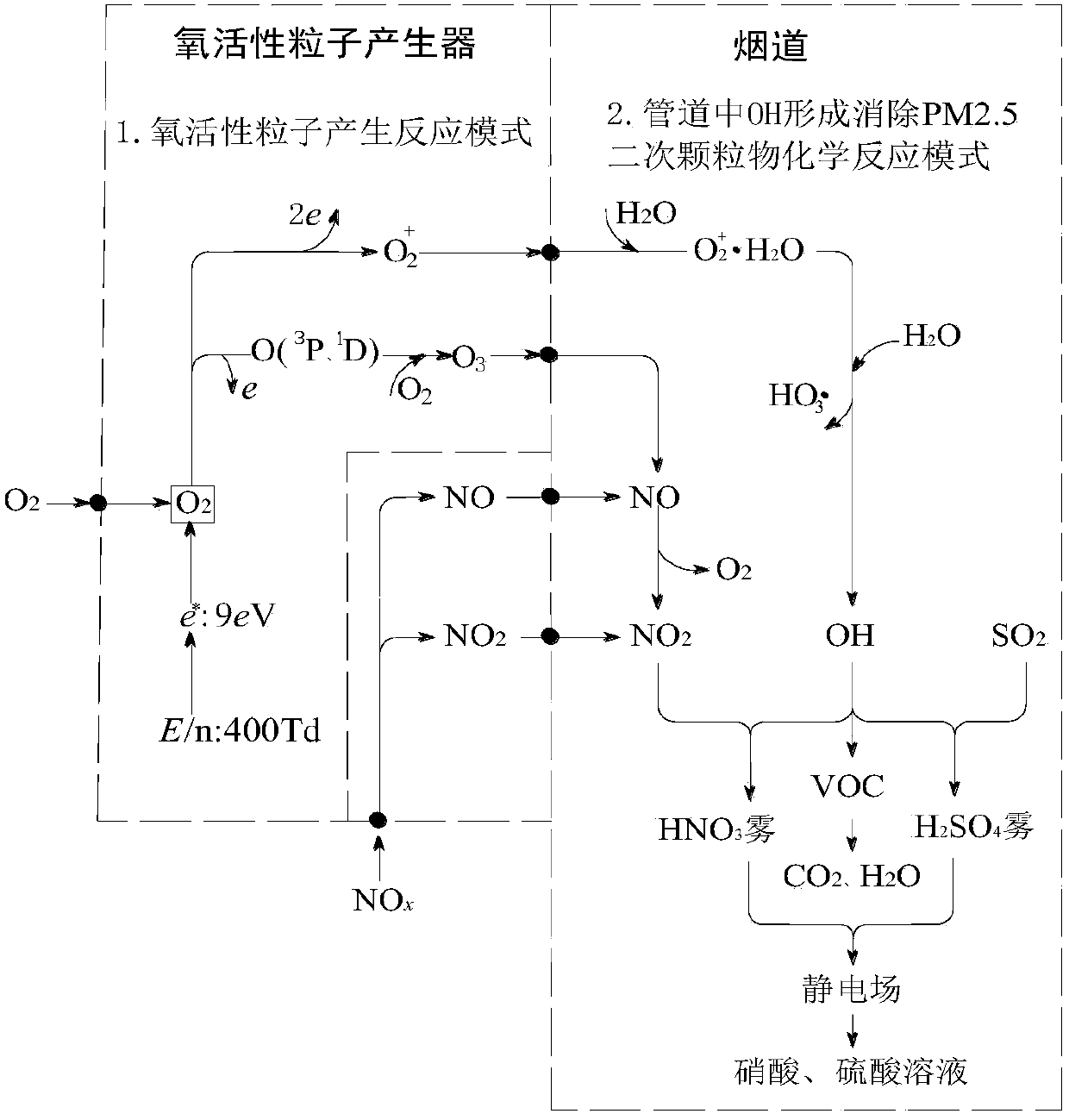

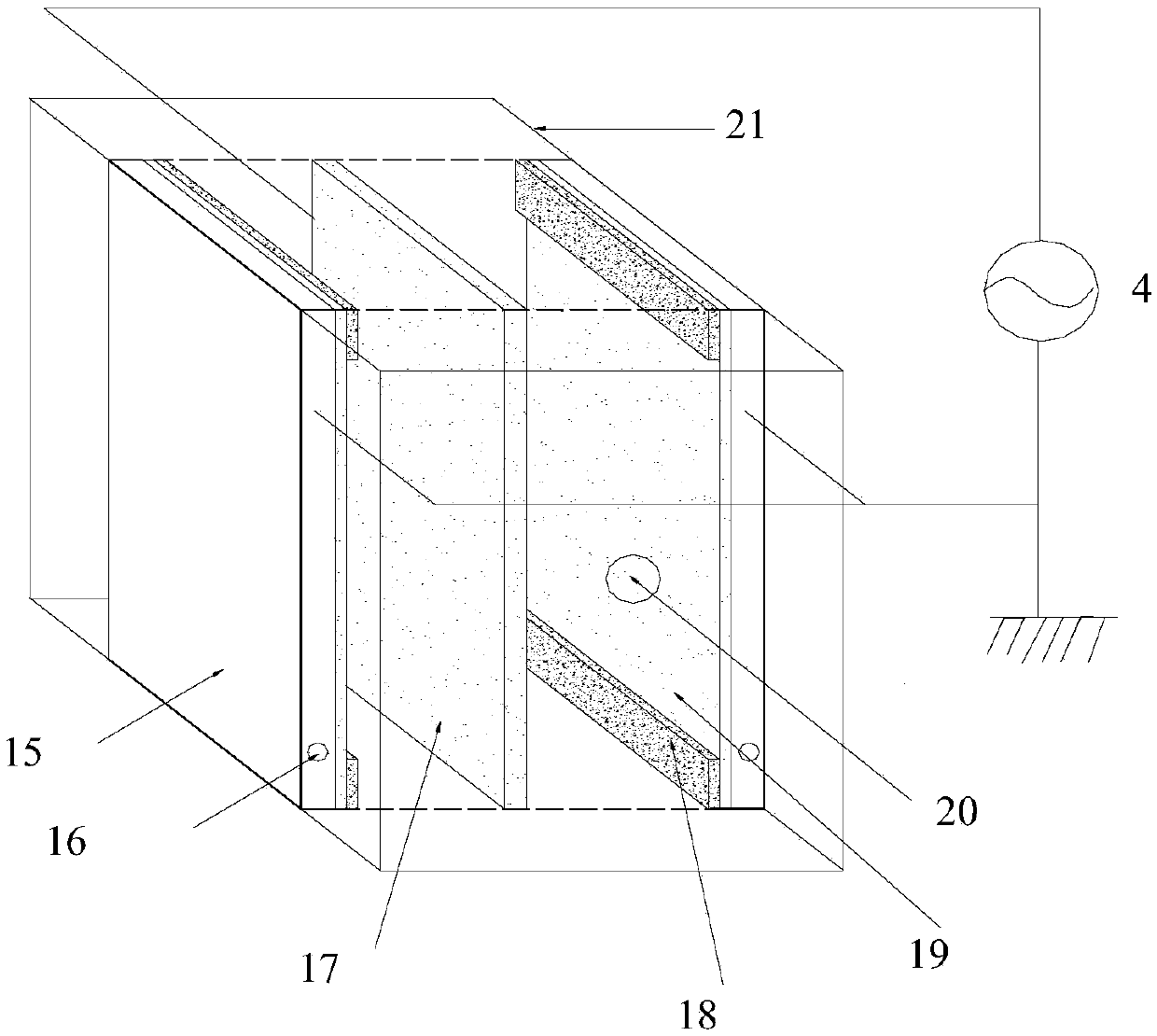

Method for eliminating secondary particle precursors with particle size less than 2.5 microns in smoke

InactiveCN103691264ASolve pollutionEliminate air pollutionDispersed particle separationAir quality improvementParticle injectionPlasma technology

The invention discloses a method for eliminating secondary particle precursors with the particle size less than 2.5 microns in smoke, belongs to such fields as combustion science, environmental engineering, high voltage technology, gas ionization discharge and plasma technology, and relates to the method for eliminating secondary particle atmospheric pollutants with the particle size less than 2.5 microns in the smoke by injecting oxygen active particles in a flue. The method is characterized in that the oxygen active particles O2<+> and O3 are injected in the flue; the O2<+> is reacted with water in the smoke to generate hydroxyl radicals OH; the O3 is reacted with NO in the gas to generate NO2; the OH is reacted with NO2 and SO2 in the smoke to generate nitric acid and sulfuric acid mist; the acid mist is recovered to resource materials-nitric acid and sulfuric acid solution by an electric acid mist remover; the OH is reacted with VOC to generate CO2 and H2O; the elimination ratio of the secondary particle precursors with the PM of 2.5 is high above 85%. The method has the following effects and benefits: large equipment is not required to be added, and any catalysts, oxidants and reducing agents are not used, so that the one-time investment and operation costs are largely reduced.

Owner:DALIAN MARITIME UNIVERSITY

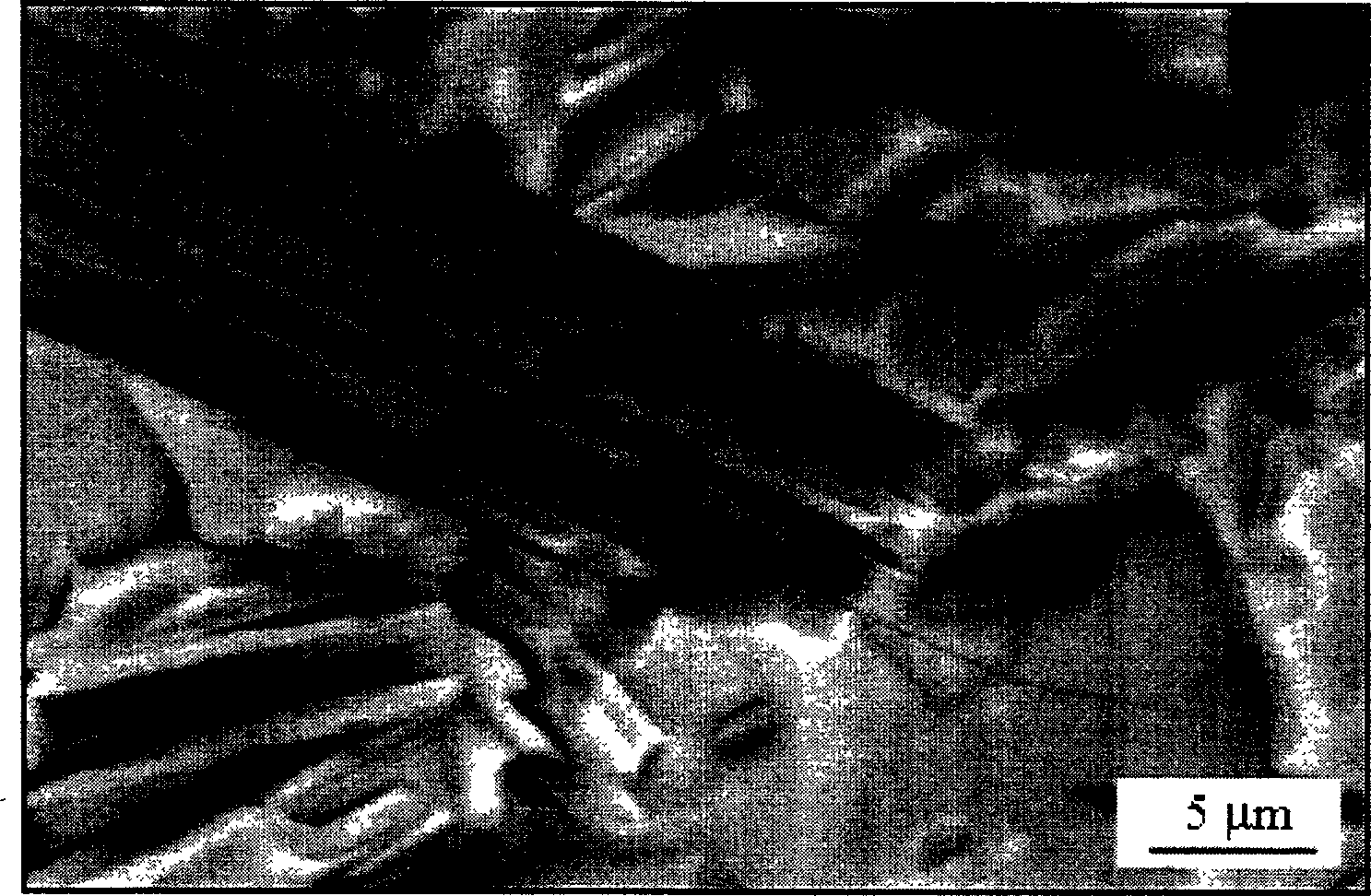

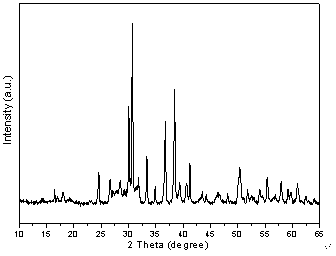

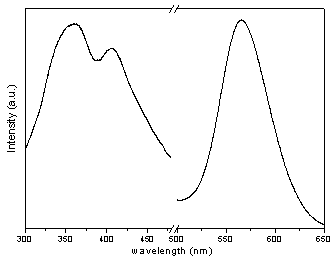

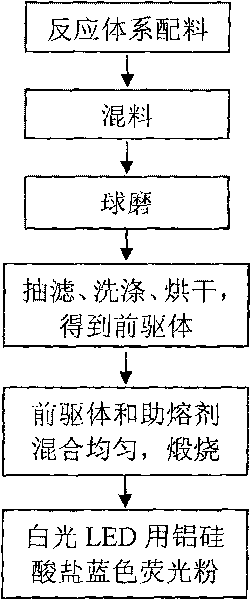

Aluminosilicate blue phosphor powder used for LEDs with near ultraviolet excitation and method for preparing same

InactiveCN101735807ALarge specific surface areaIncrease the speed of diffusionGas discharge lamp usageLuminescent compositionsAlkaline earth metalLuminous intensity

The invention provides aluminosilicate blue phosphor powder used for white LEDs with near ultraviolet excitation and belongs to the technique of preparing rare earth phosphor powder. The chemical formula of the aluminosilicate blue phosphor powder is: M1-x-yAyAl2Si2O8: xEu2+, wherein the M is one of Ca, Sr and Ba, and A is one of Ca, Sr and Ba except the M element; and x is more than 0 and less than 0.1, and y is more than or equal to 0 and less than or equal to 0.2. The preparation method comprises the following steps of: in a stoichiometric ratio of the chemical formula, weighing up needed alkaline earth metal compounds, aluminum compounds, silicic acid, europium nitrate and a proper amount of surface active agent and fluxing agent; fully mixing the alkaline earth metal compounds, the aluminum compounds, the silicic acid, the europium nitrate, the surface active agent and a proper amount of ligands, ball-milling the mixture, and adding a proper amount of lubricants while ball-milling; performing pumping filtration, washing and drying to obtain a precursor; and mixing the precursor and the fluxing agent, and calcining the mixture under a reducing atmosphere to obtain the phosphor powder. The phosphor powder has the advantages of wide excitation wavelength, high luminous intensity, good crystallinity, small grain size and narrow grain size distribution and is suitable for the white LEDs.

Owner:SICHUAN UNIV

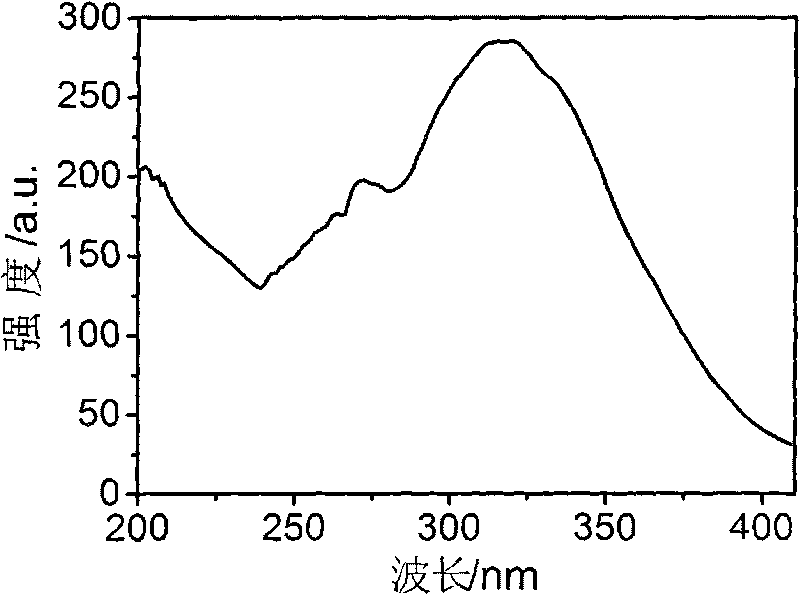

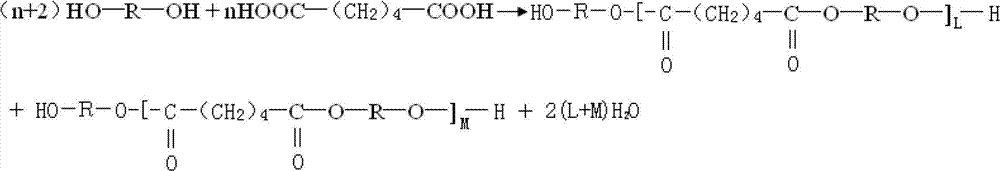

Hydrolysis-resistant polyester polyol and preparation process thereof

The invention relates to a hydrolysis-resistant polyester polyol and a preparation process of the polyester polyol, which belongs to the technical fields of polyester polyol and polyester polyol preparation process. The preparation process comprises the following steps of: 1. feeding; 2.esterifying; 3. transesterifying; and 4. adjusting and filtering. The prepared hydrolysis-resistant polyester polyol by using the preparation process provided by the invention has a low melting point, can maintain liquid state at a low temperature and has good hydrolysis resistance.

Owner:烟台万华超纤股份有限公司

Chemical mechanical polishing device, polishing method and system for wafer

InactiveCN101879700BLess bendingShorten the timeSemiconductor/solid-state device manufacturingLapping machinesChemical reactionSlurry coating

A chemical mechanical polishing (CMP) device for processing a wafer is provided which includes a plate for supporting the wafer to be processed in a face-up orientation, a polishing head opposing the plate, wherein the polishing head includes a rotatable polishing pad operable to contact the wafer while the polishing pad is rotating, and a slurry coating system providing a slurry to the polishing pad for polishing the wafer.

Owner:TAIWAN SEMICON MFG CO LTD

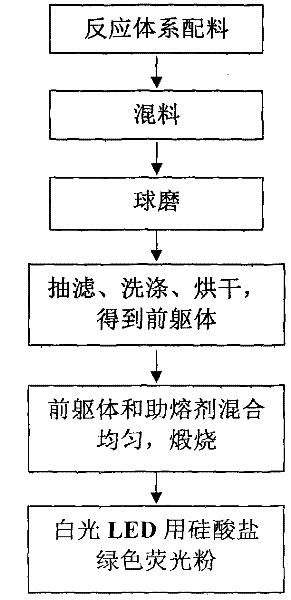

Silicate green fluorescent powder for white light emitting diode (LED) and preparation method for fluorescent powder

InactiveCN102533259ALarge specific surface areaIncrease the speed of diffusionGas discharge lamp usageLuminescent compositionsLuminous intensityAlkaline earth metal

The invention relates to a method for synthesizing silicate green fluorescent powder for a white light emitting diode (LED), and belongs to a technology for preparing rare-earth fluorescent powder. The chemical formula of the fluorescent powder is Ca2-xMgSi2O7:xEu<2+>, wherein x is more than 0 and less than 0.1. The method comprises the following steps of: weighing the required alkali earth metal compound, silicic acid, europium nitrate, an appropriate amount of surfactant and a flux in a stoichiometric ratio; fully mixing the alkali earth metal compound, the silicic acid, the europium nitrate, the surfactant and an appropriate amount of ligand, performing ball milling, and adding an appropriate amount of lubricant during ball milling; performing suction filtering, washing, and drying to obtain a precursor; and mixing the precursor and the flux, and calcining in reducing atmosphere to obtain the required fluorescent powder. The fluorescent powder prepared by the method is large in excitation wavelength, high in luminous intensity and crystallinity, narrow in particle size distribution and suitable to be used as the green fluorescent powder for the white LED.

Owner:CHONGQING UNIV OF ARTS & SCI

Preparation method of starch sodium octenyl succinate

The invention discloses a preparation method of starch sodium octenyl succinate. The method comprises the following steps: (1) starch pretreatment: preparing starch and deionized water into a starch milk solution, carrying out ultrasonic treatment on the starch milk solution in an ice-water bath by using an ultrasonic cell disruptor, carrying out suction filtration on the pretreated starch milk, and drying for later use; and (2) synthesis of starch sodium octenyl succinate: adding deionized water into the starch treated in the step (1) to prepare starch milk, diluting octenyl succinic anhydride with absolute ethyl alcohol, slowly adding the diluted octenyl succinic anhydride into starch milk, performing esterification reaction while stirring, controlling the reaction temperature to be 30-35 DEG C and the pH value to be 8-8.5, regulating the pH value of the system to be 6-6.5 after the reaction is finished, stopping the esterification reaction, performing suction filtration and washing on reactants with ethyl alcohol, performing centrifugal washing with distilled water, drying, crushing and sieving to obtain OSA starch. The method is simple in process, mild in process condition, short in production period, high in product substitution degree and high in synthesis efficiency.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Process for preparing rare-earth nano oxide by ball grinding and solid-phase chemical reaction

InactiveCN1159226CQuick smashIncrease surface areaRare earth metal compoundsRare-earth elementSodium bicarbonate

A nano rare-earth oxide is prepared from the inorganic salt of rare-earth element (Ce, La, Pr, Nd, or Tb) and ligand (oxalic acid, sodium oxalate, dicarbonate, 8-hydroxyquinoline, complexon, etc) through proportioning, mixing, and ball grinding while solid-phase chemical reaction to obtain precursor, removing impurities, drying, and medium-temp thermal decomposition. Its advantages are simple process, low cost, saving energy, high purity (more than 99%) and narrow size distribution (10-30 nm).

Owner:SICHUAN UNIV

Electroplating sewage treatment method

InactiveCN112062411AIncrease the intensity of chemical reactionsEasy to handleWater aerationTreatment involving filtrationChemical treatmentActivated carbon

The invention discloses an electroplating sewage treatment method which comprises the following steps: carrying out preliminary filtration, carrying out chemical reduction, carrying out sedimentationin a sedimentation tank, carrying out secondary filtration, carrying out microbiological treatment, carrying out disinfection treatment, carrying out activated carbon adsorption, carrying out detection and discharge, carrying out detection of sewage treated in an activated carbon adsorption tank, carrying out discharge if the detection reaches the standard, reintroducing the sewage into the filtertank for secondary treatment if the detection does not reach the standard, arranging a screen frame in the activated carbon adsorption tank, and filling activated carbon particles in the screen frame, so that the sewage is effectively adsorbed and filtered by activated carbon. The sewage is subjected to chemical treatment in the aeration tank and aeration treatment at the same time, the chemicalreaction intensity in the sewage is improved, the chemical reaction time is saved, heavy metals in the sewage are precipitated by adding alkaline substances, and meanwhile, the sewage is further slowly adsorbed by utilizing the activated carbon adsorption tank, the sewage treatment effect is improved.

Owner:深圳市粤昆仑环保实业有限公司

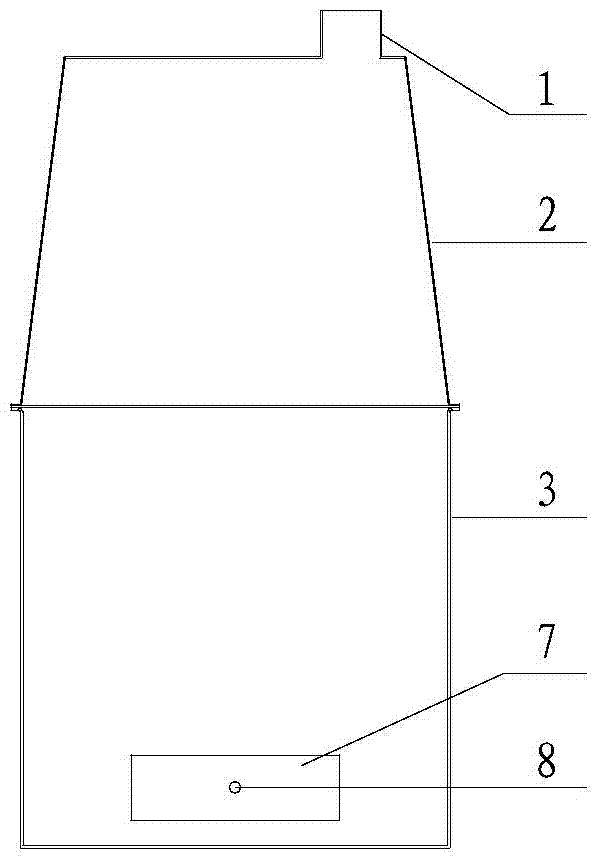

A camping multi-fuel heating stove

ActiveCN105222177BRaise the combustion temperatureEmission reductionDomestic stoves or rangesLiquid heating fuelHigh altitude acclimationKerosene

A camping multi-fuel heating stove, including a furnace body, the furnace body is provided with a movable fuel furnace, a number of air inlet holes are opened on the wall of the fuel furnace, and a vaporization device for evaporating and vaporizing the fuel is arranged in the fuel furnace. A coal-fired hearth that can move is set inside the fuel furnace; the lower part of the furnace body is provided with an ash outlet, the upper part of the furnace body is provided with a furnace panel, the furnace panel is provided with a chimney seat, and the side wall of the furnace body is provided with an additional coal mouth. When the fuel oil of the present invention is used, take out the coal-fired furnace and put it into the fuel-fired furnace and fire gathering cover; , Solid fuel, strong fuel adaptability, can ensure good combustion effect in areas with an altitude of 4500m, good adaptability to high altitude, high thermal efficiency, and strong service support capabilities. The invention is also applicable in plain areas, and has low manufacturing cost, low maintenance cost and stable and reliable performance.

Owner:中国人民解放军32181部队

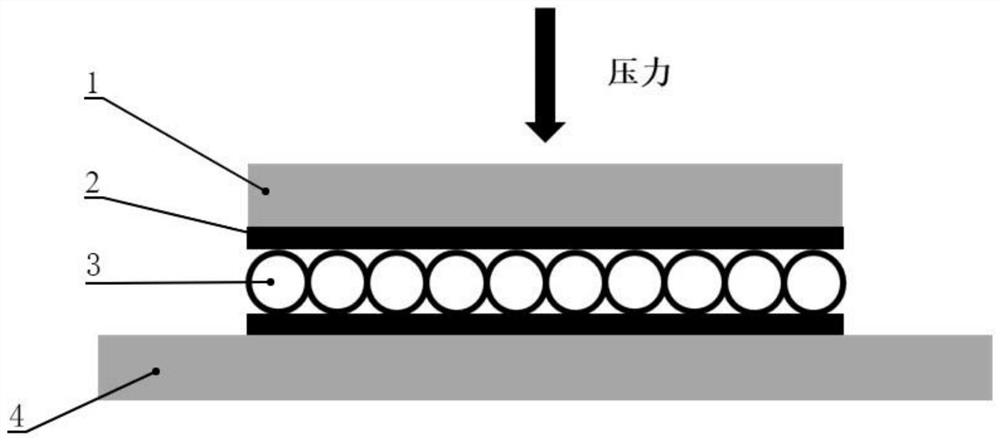

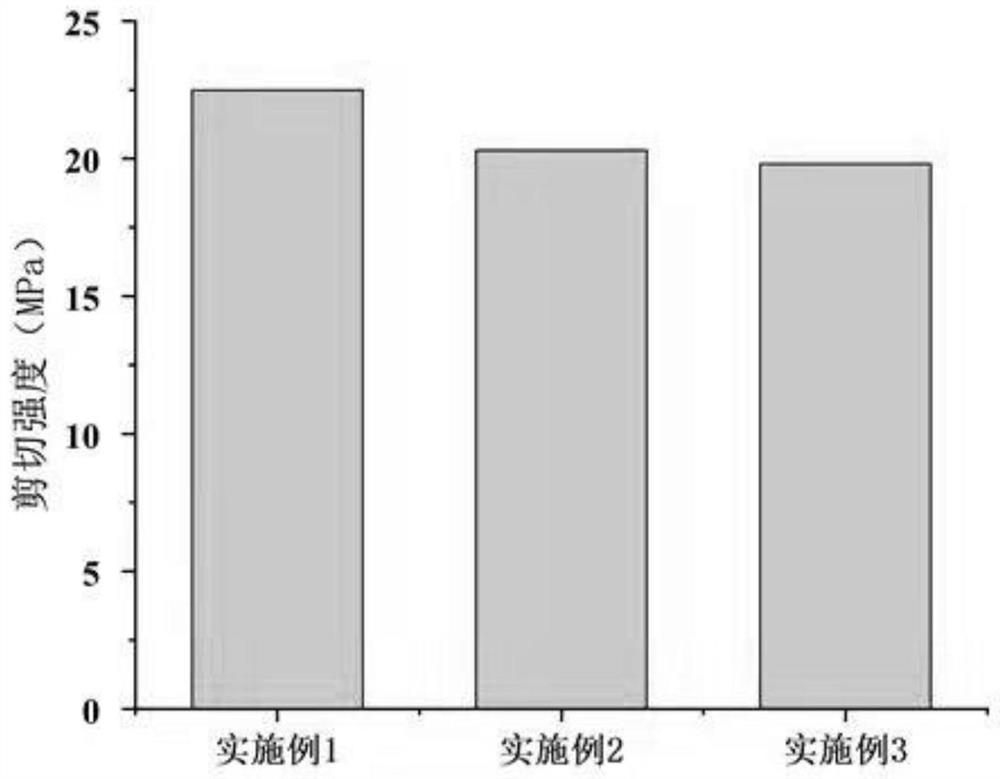

Self-sintering nano-copper soldering paste and preparation method and use method thereof

PendingCN114535863APromote sinteringImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaBenzoic acidChemical reaction

The invention belongs to the technical field of welding materials, and particularly relates to self-sintering nano-copper soldering paste and a preparation method and using method thereof.The self-sintering nano-copper soldering paste comprises a nano-copper particle layer and a sintering aid layer, the surfaces of nano-copper particles are coated with citric acid layers, and the sintering aid layer comprises a complexing agent and a reducing agent; the complexing agent comprises at least one of sodium alginate, o-hydroxybenzoic acid and acrylic resin, and the reducing agent comprises at least one of hydrazine, hydrazine hydrate and ethylenediamine. According to the method, sintering can be achieved only by means of heat release of a chemical reaction, expensive specific equipment and a reducing atmosphere without extra atmosphere and heating, high-temperature sintering is avoided, meanwhile, high-temperature service is guaranteed, and the sintering performance is good.

Owner:重庆平创半导体研究院有限责任公司

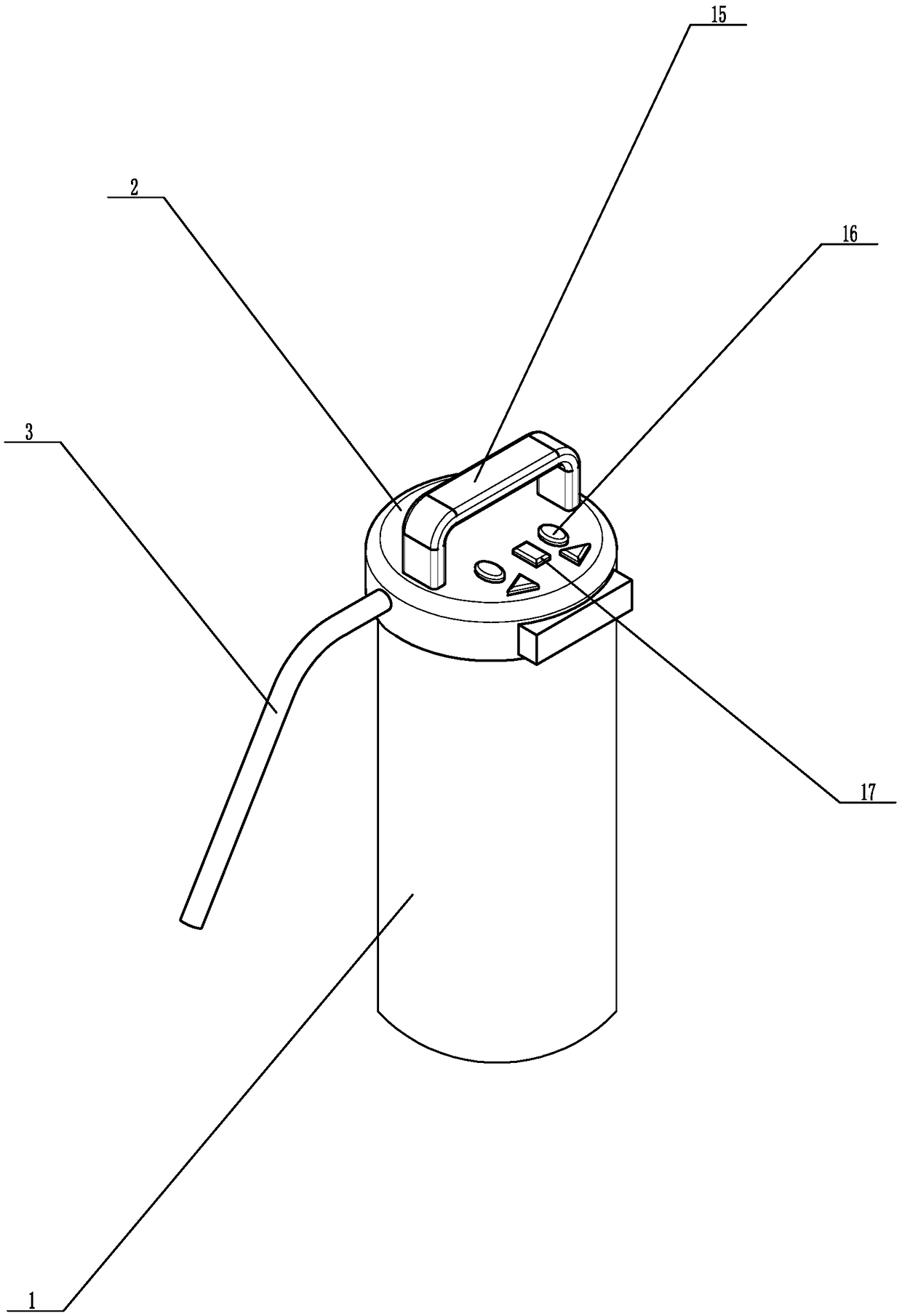

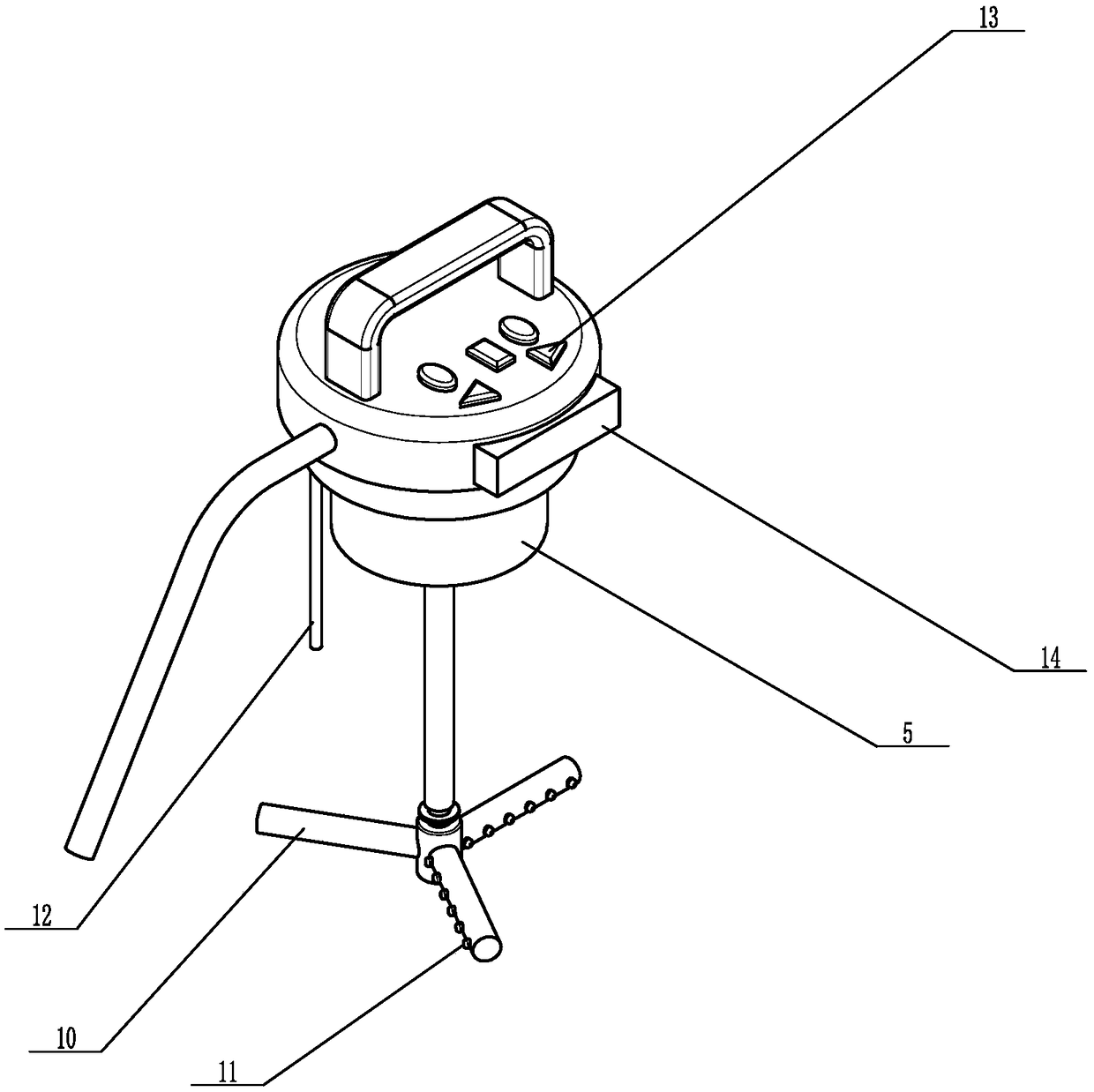

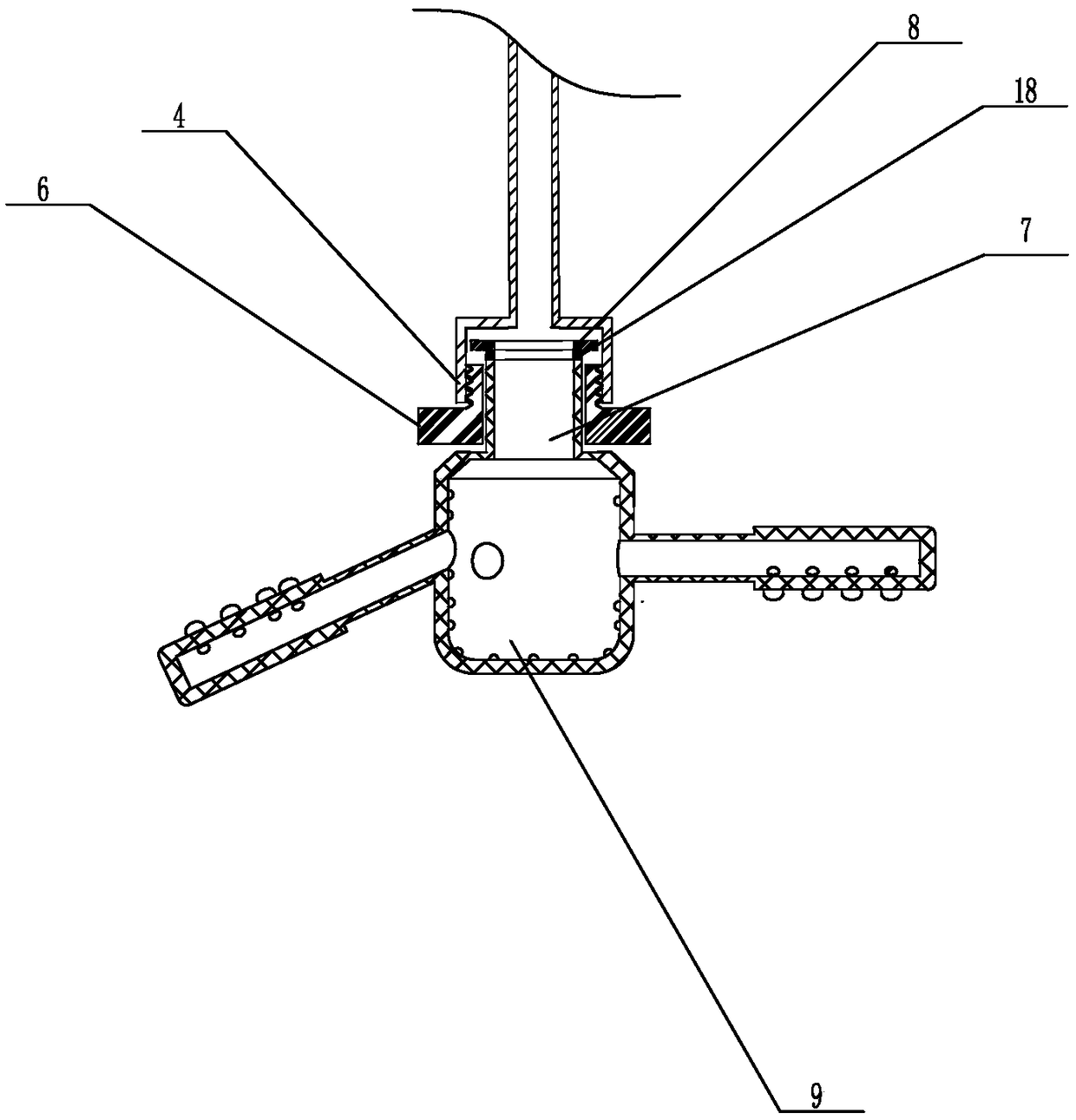

Liquid-liquid reaction experimental apparatus based on hydraulic rotary spraying

PendingCN109261112AIncrease contact areaEasy to observeChemical/physical/physico-chemical stationary reactorsLiquid jetReaction rate

The invention provides a liquid-liquid reaction experimental apparatus based on hydraulic rotary spraying, comprising a reaction cylinder, a cylinder cover, and a liquid incoming pipe. The liquid incoming pipe is passed into the cylinder cover from outside and extended into the reaction cylinder; the bottom end of the liquid incoming pipe is provided with a connection terrace; a rotary spraying mechanism is arranged in the connection terrace. The rotary spraying mechanism connected with the liquid incoming pipe is arranged in the reaction cylinder herein; the liquid incoming pipe is connectedwith a miniature water pump; the rotary spraying mechanism sprays a liquid reaction material to the reaction cylinder in rotational manner under the action of liquid pressure, the liquids in the reaction cylinder is driven in compound multidirectional motions, such as vertical motion, anticlockwise and clockwise motions and rolling; contact area is effectively enlarged for the liquid reaction materials; mixing is uniform; reaction is complete. The spraying rate of liquids can be flexibly adjusted by adjusting the power of the miniature water pump, so that reaction rate can be effectively adjusted. Observing the reaction process is convenient for experimental personnel; operation is mechanically automated; experimental data are precise; safety is high.

Owner:QINZHOU UNIV

Method for preparing 1,4-diethyleno dioxide ketone

InactiveCN101367789AReduce separate preparationReduce purificationOrganic chemistryAcetic acidChloroacetic acids

The present invention relates to a preparation method of 1, 4-dioxane alkone, and provides a highly efficient, rapid method of preparing high-purity 1, 4-dioxane alkone, which has no heavy metal ions. In the method, glycol and chloroacetic acid or the chloroacetate are used as raw materials. The method is characterized in that the intermediate beta-hydroxyl ethoxy acetate of the 1, 4-dioxane alkone is synthesized in one step, and the 1, 4-dioxane alkone can be produced through acidification and ring formation. Because the beta-hydroxyl ethoxy acetate is synthesized in one step, the present invention has the advantages that the reaction time is greatly shortened, the reaction yield is improved, and the production cost is reduced.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

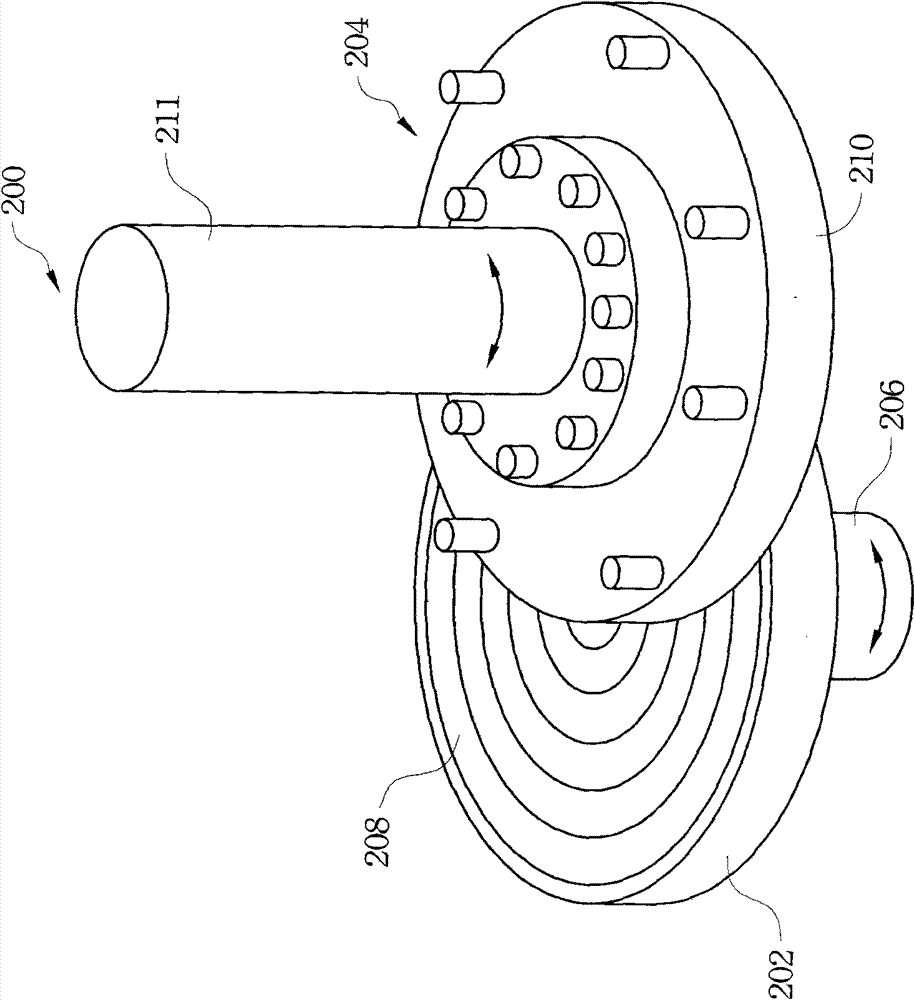

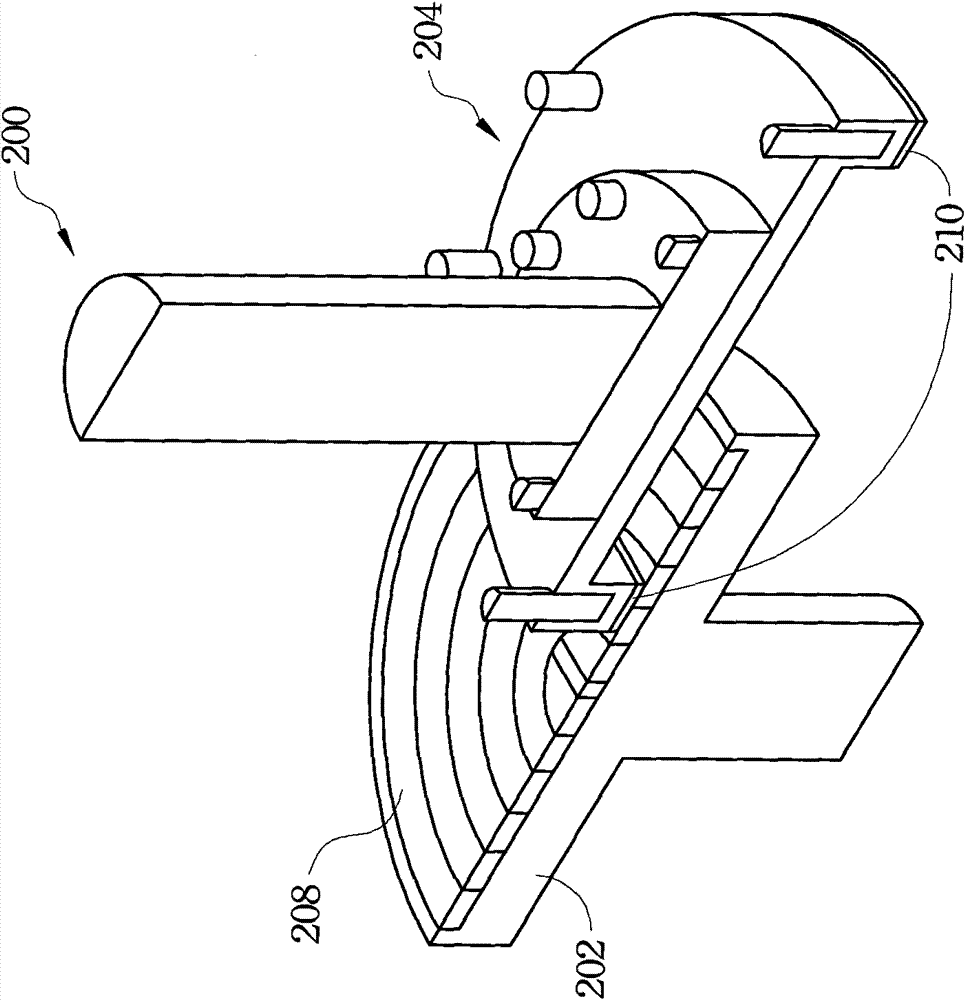

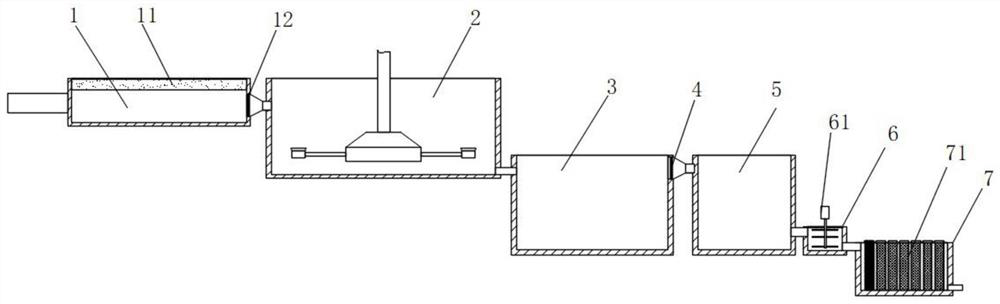

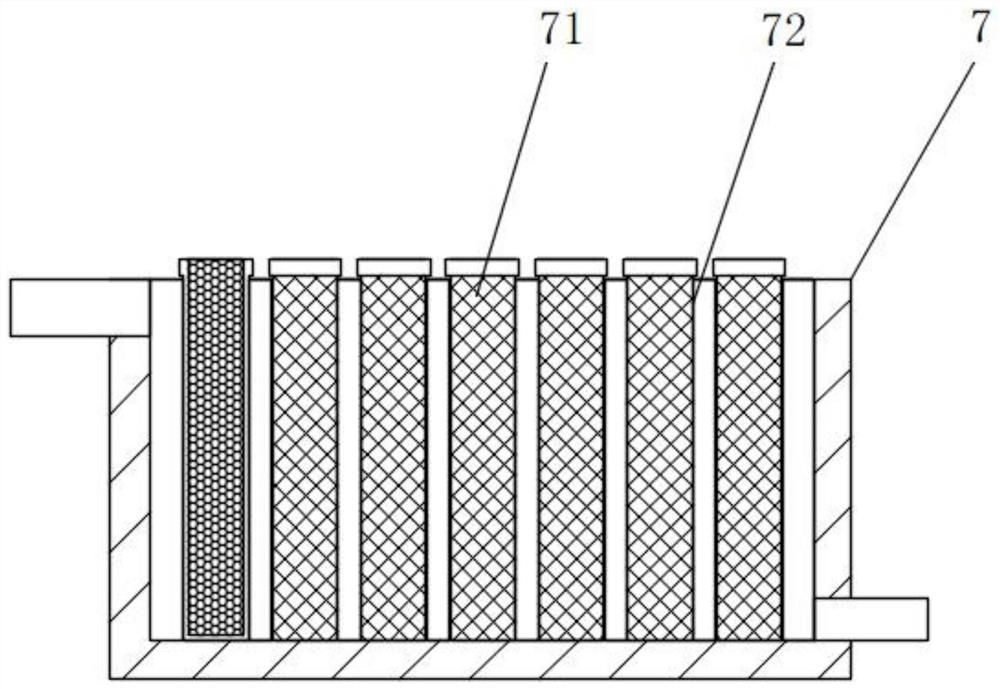

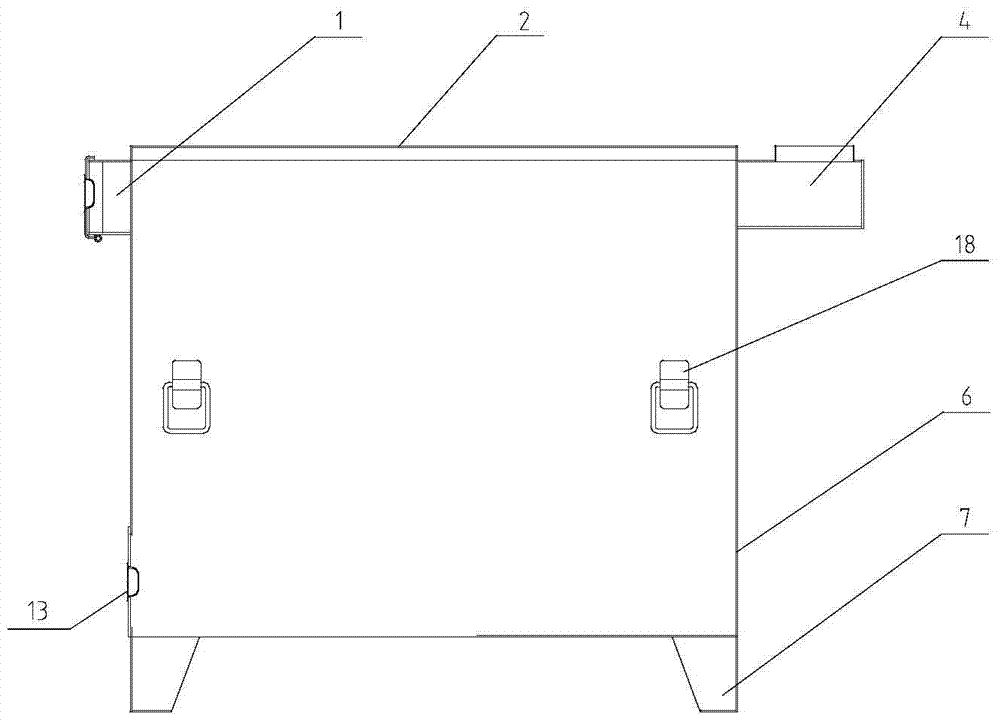

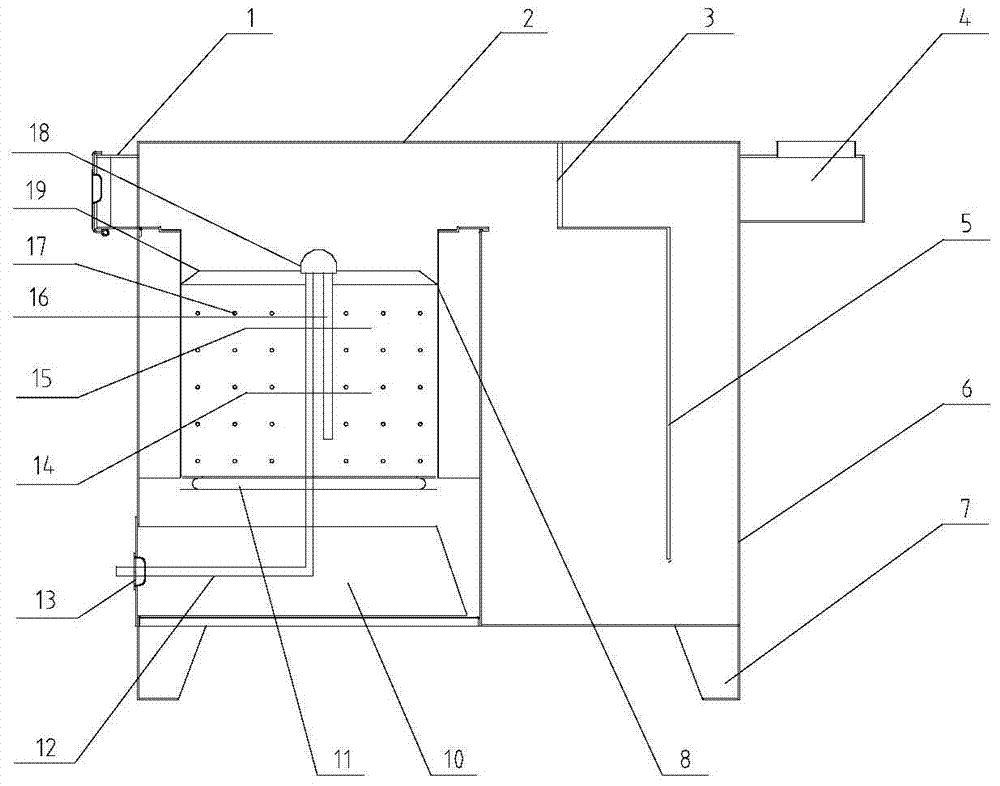

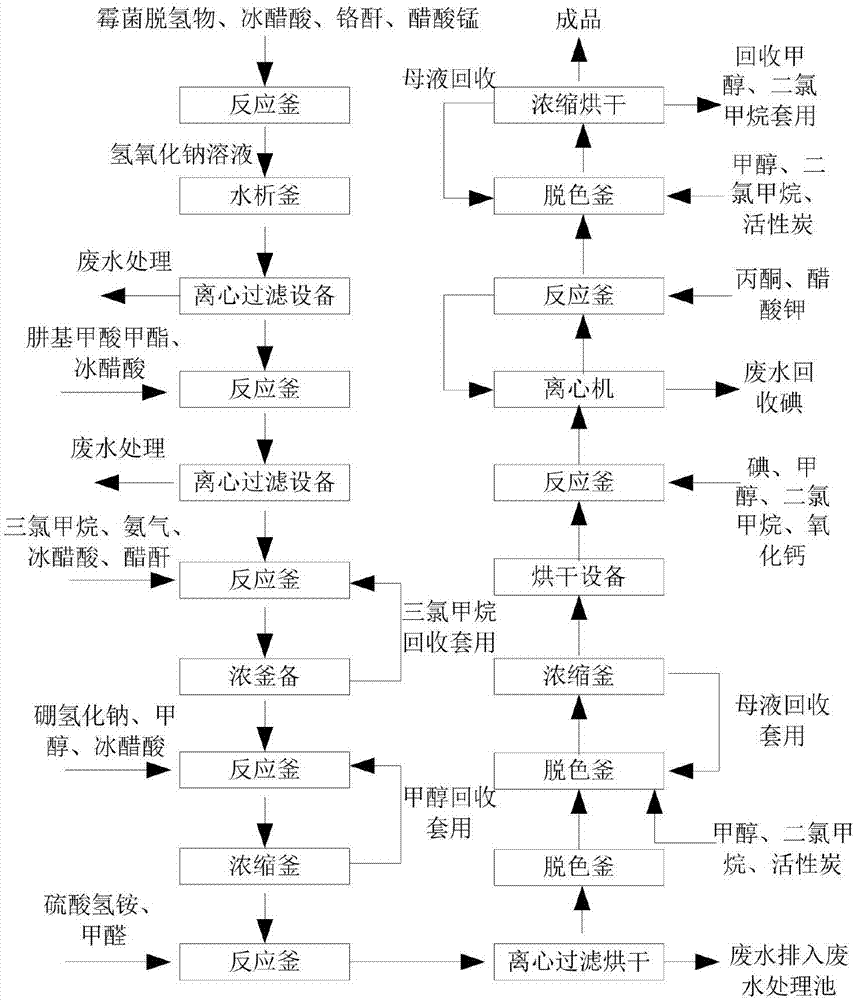

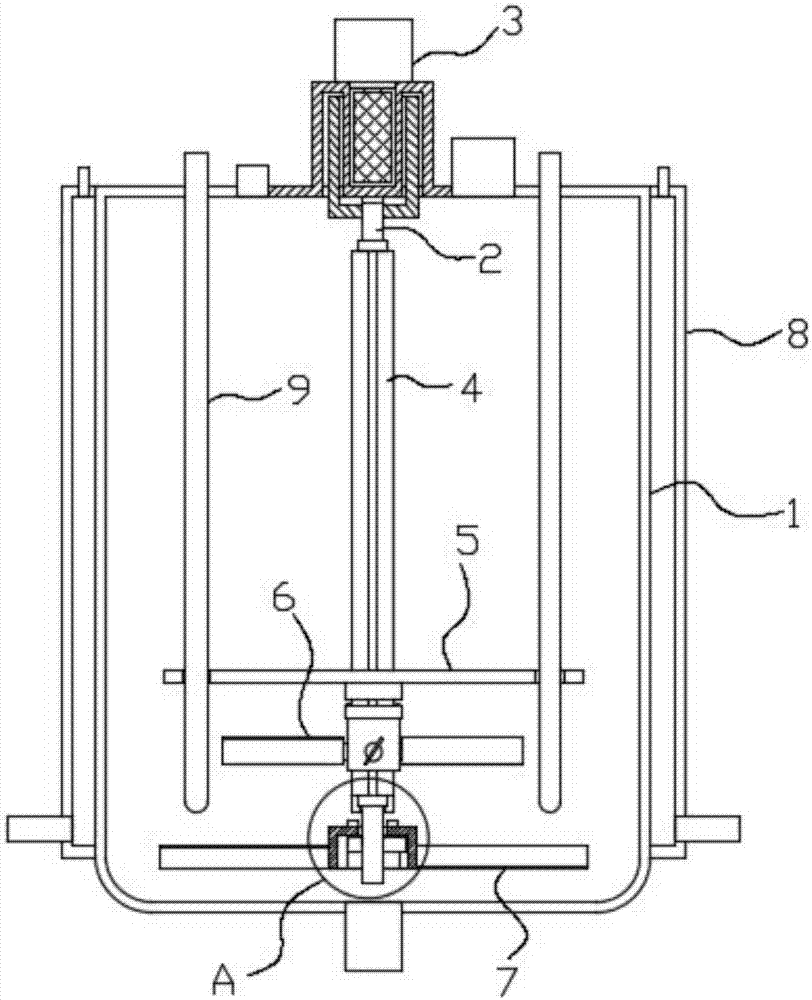

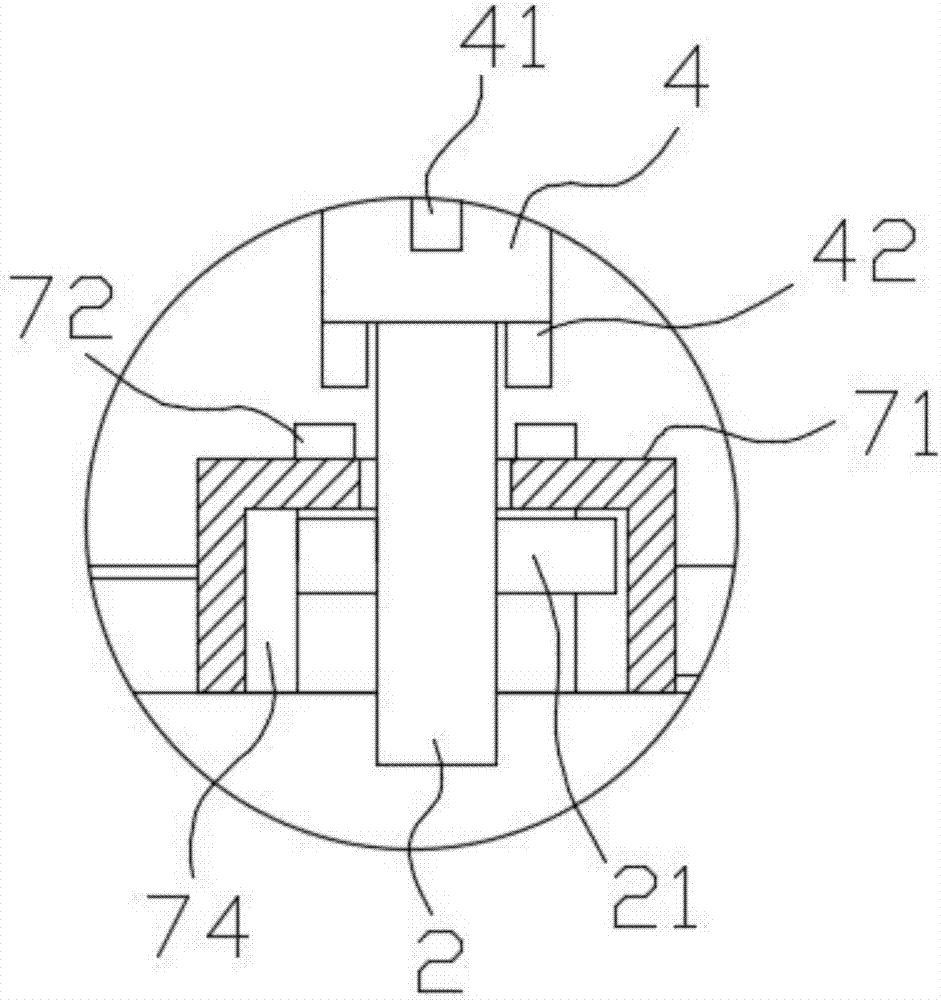

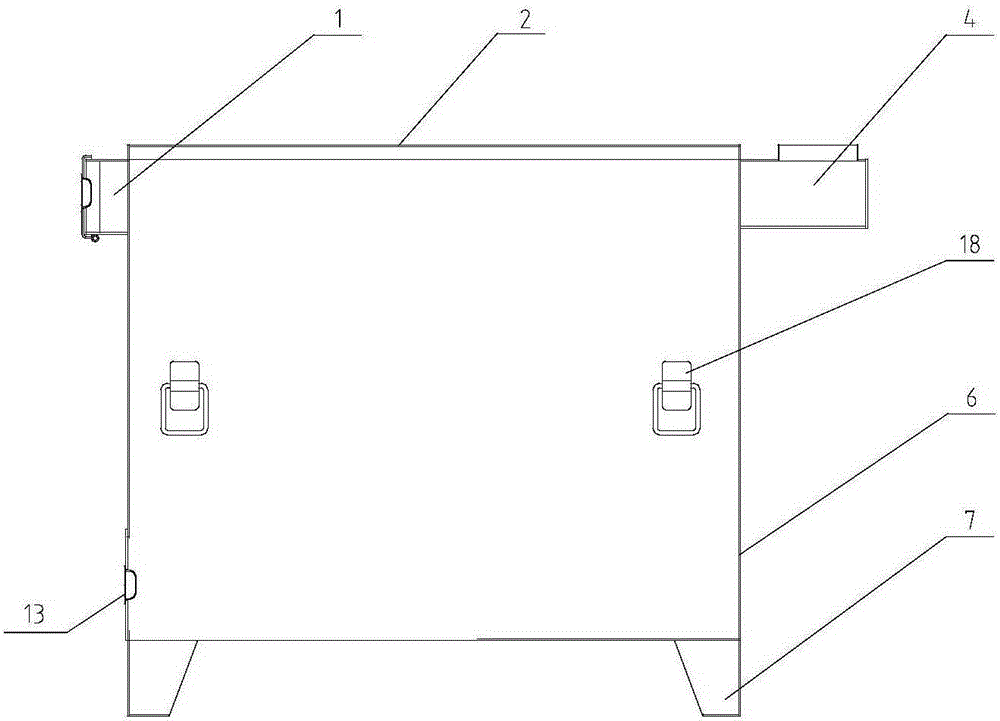

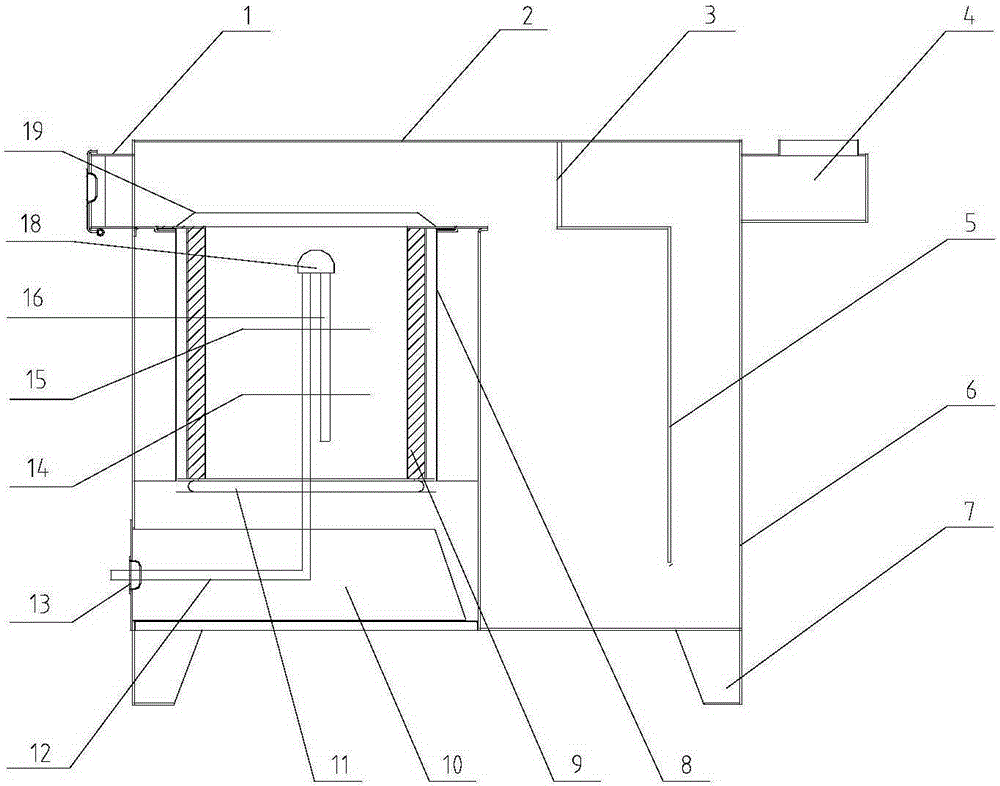

Quick reaction technology and production system for deflazacort

The invention discloses a quick reaction technology and a production system for deflazacort. The production system comprises a reaction kettle, an elutriation kettle, centrifugal filtering equipment, a concentration kettle, drying equipment and a discoloring kettle which are mutually connected according to procedures, wherein the reaction kettle comprises a tank body, and an interlayer cavity is arranged at the outer wall of the tank body; a temperature adjusting tube is arranged in the tank body; a stirring shaft is arranged at the center of the interior of the tank body; the upper end of the stirring shaft is connected with a magnetic coupling rotary device, and a stirring impeller is arranged at the lower end of the stirring shaft; a rotary cylinder is arranged on the stirring shaft; a buoyancy impeller is arranged on the rotary cylinder; a lifting tray is arranged at the upper end of the buoyancy impeller; a circular hole is formed in the lifting tray; water filtering holes are uniformly distributed in the lifting tray; a vertical slide groove is arranged in the outer wall of the rotary cylinder; a rolling shaft is arranged at the inner wall of a base of the buoyancy impeller; an upper key board is arranged at the upper end of a rotary cover of the stirring impeller; a lower key board is arranged at the lower end of the rotary cylinder. The production system and the technology have the advantages that the multi-azimuth flowing of reaction liquid is realized, the reaction time of the deflazacort in each step is shortened, and the quick production of the deflazacort is realized.

Owner:YUEYANG HUANYU PHARMA

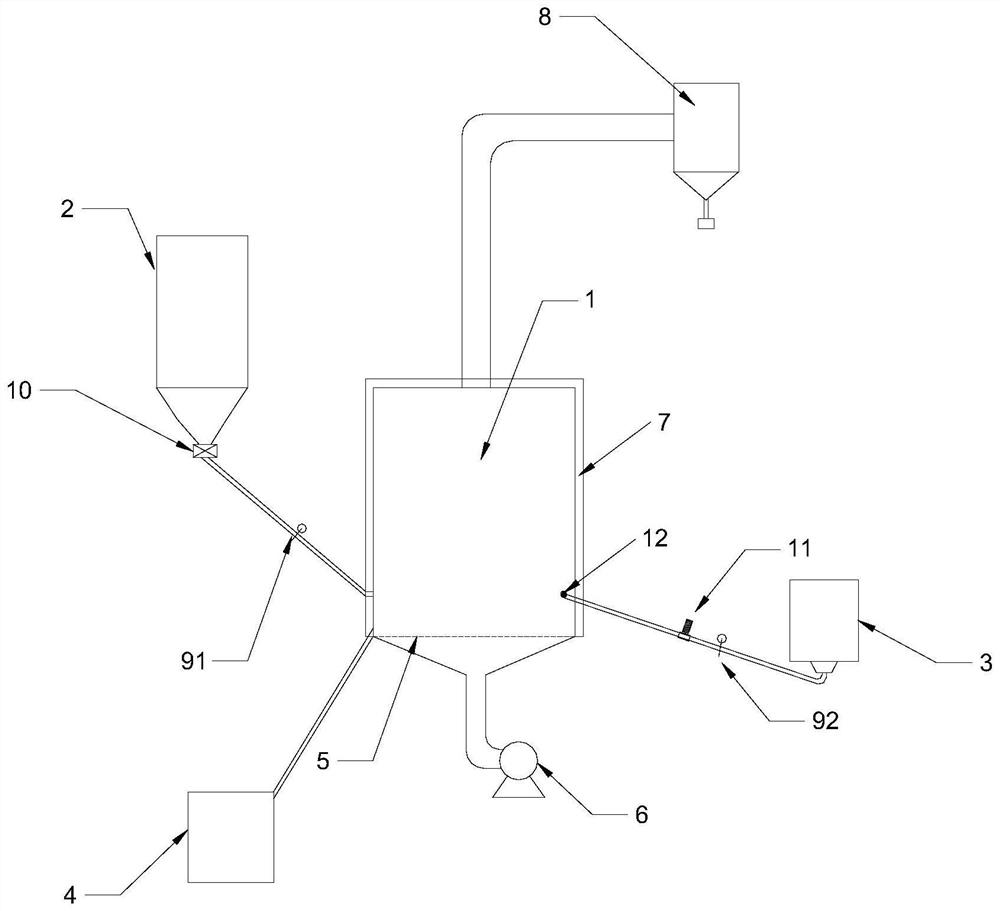

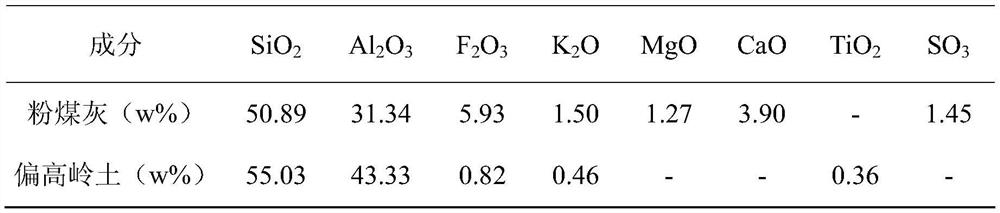

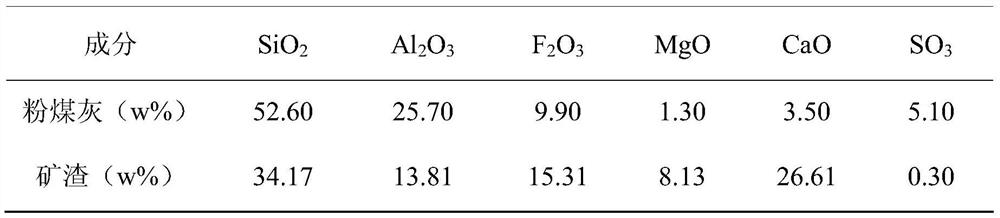

A method for preparing artificial sand using fly ash base polymer

ActiveCN111718142BQuality improvementRealize resource utilizationDispersed particle filtrationMaterial granulationGeopolymerGranulation

The invention discloses a method for preparing artificial sand by using fly ash base polymer, which belongs to the technical field of waste utilization. The present invention comprises the following steps: (1) Ingredients: Weigh the following raw materials in parts by weight: 55 to 60 parts of fly ash, 40 to 45 parts of an alkaline activator; the basic activator consists of the following raw materials in parts by weight Composition: 20 to 25 parts of water glass, 20 to 25 parts of water; (2) Granulation: Spray fly ash and alkaline activator into the reaction container, and the sprayed alkaline activator contacts with fly ash and agglomerates into a spherical shape Granules; (3) Curing: After curing the spherical particles, geopolymer particles are obtained; (4) Screening: the geopolymer particles are screened to obtain the finished artificial sand. The invention can recycle and utilize resources by using a large amount of solid waste fly ash; the artificial sand prepared by the invention meets the production requirements.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Oil production well neutral plugging remover composition and preparation method thereof

ActiveCN104194758BLow corrosion rateReduce chemical reaction timeDrilling compositionButanedioic acidSuccinic acid

Owner:兰州熙瑞化工科技有限公司

Ti3AlC2/Ti5Si3 compound material and its preparation method

The invention relates to a method for synthesizing titanium silicide (Ti5Si3) granule in original position to intensify the composite material based on titanium carbide aluminum (Ti3AlC2). Adding a certain amount of silicon, to prepare the Ti3AlC2 / Ti5Si3 composite material of different volume ratio, the volume percentage of the titanium silicide granule is 10-40%. The specific preparing method comprises: employing titanium powder, aluminium powder, silicon powder and graphite powder as raw material, the mole ratio of Ti:Al:Si:C is 3: (1.1-x): (1.8-2.0), and x is 0.1-0.5, mixing the raw material powder with physical-mechanical means for 8-24 hours, loading into the graphite mould, the forced pressure is 10-20 Mpa, calcinating in the heating furnace under protective atmosphere, the heating-up speed is 10-50 Deg C / min, the calcining temperature is 1400-1600 Deg C and lasting for 0.5-2 hours, the calcinating pressure is 20-40 Mpa. The titanium carbide aluminium / titanium silicide of high purity and high intensity can be produced under lower temperature and in shorter time by applying this invention.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Camping multi-fuel warming stove

ActiveCN105222177ARaise the combustion temperatureEmission reductionDomestic stoves or rangesLiquid heating fuelFirewoodHigh altitude acclimation

A camping multi-fuel warming stove comprises a stove body. A movable oil-fired hearth is arranged inside the stove body. A plurality of gas inlets are formed in the wall of the oil-fired hearth. A gasification device for enabling fuel oil to be evaporated and gasified is arranged inside the oil-fired hearth. A movable coal-fired hearth is sleeved with the oil-fired hearth. An ash outlet is formed in the lower portion of the stove body. A stove panel is arranged at the upper portion of the stove body. A smokestack base is arranged on the stove panel. A coal adding opening is formed in the side wall of the stove body. When oil is fired, the coal-fired hearth is taken out, and the oil-fired hearth and a fire gathering cover are placed in; when coal or firewood is fired, the oil-fired hearth is taken out, and the coal-fired hearth is placed in; and various liquid and solid fuels such as diesel oil, coal oil, coal, firewood and excrement can be used, the fuel adaptability is high, the good combustion effect can be ensured at the areas with the altitude being 4500 m, the high-altitude adaptability is good, the thermal efficiency is high, and the duty assurance capacity is strong. The camping multi-fuel warming stove is applicable to a plain area, low in manufacturing cost and using and maintenance cost and stable and reliable in performance.

Owner:中国人民解放军32181部队

Anti-wear and anti-friction composite additive for lubricating oil (grease)

InactiveCN104046407BIncrease surface areaIncrease the speed of diffusionAdditivesReaction rateRare earth

The invention discloses an antiwear antifriction composite powder for lubricating oil (grease) and a preparation method thereof and relates to a nano-rare earth oxide-cladding ultrafine muscovite composite powder for the fields of lubricating oil, lubricating grease and the like. the invention is characterized in that a muscovite powder, rare-earth salt and its ligand are used as raw materials; a solid-phase reaction system is crushed by shear force and impact force generated during the ball-milling process, specific surface area of reactants is increased, and reaction rate is raised so as to raise ratio of nucleation rate to growth rate; a fine and uniform precursor is prepared, and then washing, drying and control of thermal decomposition temperature and time are carried out so as to obtain the nano-rare earth oxide-cladding ultrafine muscovite composite powder with different particle sizes and cladding systems; and after undergoing surface modification, the nano-rare earth oxide-cladding ultrafine muscovite composite powder is added into base oil or lubricating grease at different proportions of (0.5%-3%). In four-ball friction, friction coefficient can be reduced, and friction-pair wear scar diameter is minimized.

Owner:SICHUAN UNIV

Method for preparing oligomeric proanthocyanidins by enhanced degradation under pulsed electric field

ActiveCN102924422BHigh purityReduce chemical reaction timeOrganic chemistryEnhanced degradationImpurity

The invention discloses a method for preparing oligomeric proanthocyanidins by enhanced degradation under a pulsed electric field. According to the method, polymeric proanthocyanidins serving as raw materials are degraded under the assistance of the pulsed electric field to prepare the oligomeric proanthocyanidins. The method comprises the following steps of: dissolving the polymeric proanthocyanidins, adding sulfite, treating by the pulsed electric field, separating, performing alcohol leaching to remove impurities, purifying, concentrating and drying to obtain the oligomeric proanthocyanidins, wherein in the step of treating by the pulsed electric field, a polymeric proanthocyanidin solution is pumped in a pulse treatment chamber and is treated for 3 to 20 milliseconds under the conditions that the electric field intensity is 40 to 60 kV / cm, the pulse width is 50 to 120 microseconds and the pulse frequency is 100 to 3,000 Hz, and a pulse waveform is a square wave. The method is feasible, short in treatment time of the electric field, high in practicality, energy-saving and environment-friendly, so that the application range of the polymeric proanthocyanidins in fields of medicines, food, cosmetics and health-card products is expanded.

Owner:SOUTH CHINA UNIV OF TECH

A kind of preparation method of silicate fluorescent powder with good stability

ActiveCN105733568BLarge specific surface areaIncrease the speed of diffusionLuminescent compositionsSurface-active agentsCrystallinity

Owner:CHONGQING UNIV OF ARTS & SCI

A camping oil heating stove

ActiveCN105114992BRaise the combustion temperatureReduce flow rateBurnersDomestic stoves or rangesTube furnaceEvaporation

Owner:中国人民解放军32181部队

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com