Preparation method of starch sodium octenyl succinate

A technology of octenyl succinic acid and starch ester, applied in the field of preparation of modified starch, can solve the problems of long reaction time, decreased product substitution degree, high process condition control requirements, etc. The effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

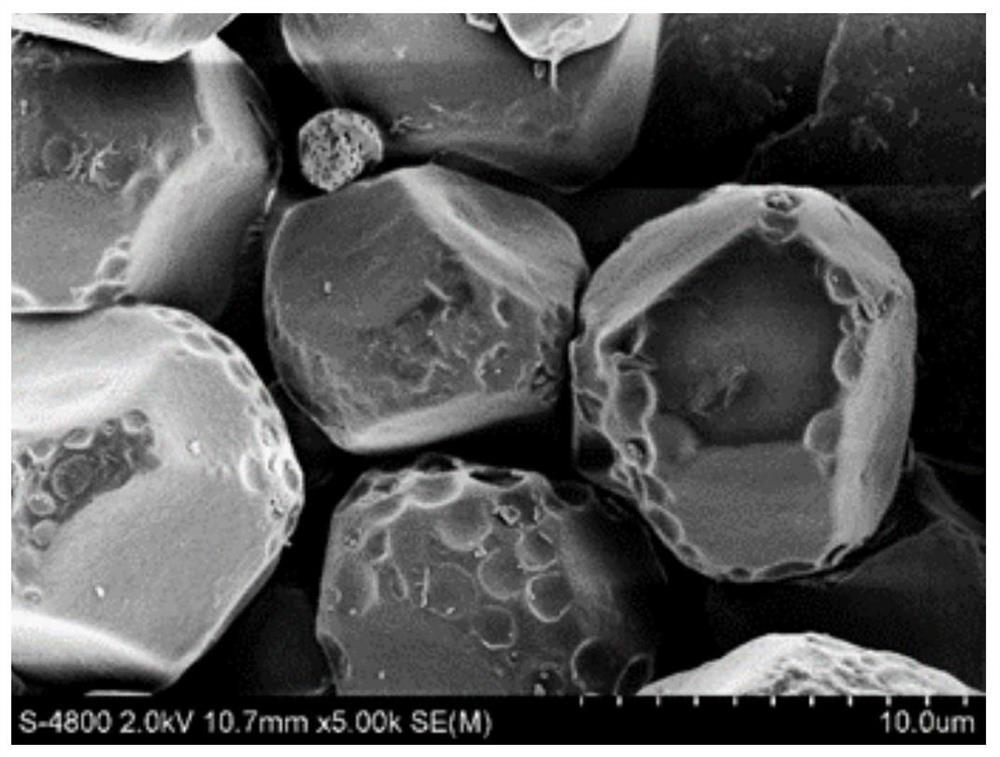

Image

Examples

Embodiment 1

[0021] (1) Starch pretreatment: using millet starch as raw material, millet starch and deionized water were prepared into 100mL 20% (w / w) starch milk solution, using ultrasonic cell breaker, ultrasonic power 250W, ultrasonic 40min, every Working for 5s and 5s apart, the starch milk solution was treated with an ice-water bath during the ultrasonic process. After pretreatment, the starch milk was dried at 40° C. for 48 hours after suction filtration, and was set aside.

[0022] (2) Synthetic of octenyl succinic acid starch ester: get the starch of certain quality step (1) pretreatment, add appropriate amount of deionized water and be mixed with the starch milk of 35% (w / w), get octenyl succinic anhydride ( The addition amount is 3% of the starch dry base) after being diluted 5 times with absolute ethanol, it is slowly added to the starch milk within 1h, stirred with a constant temperature magnetic stirrer, and the reaction temperature is controlled at 35°C, and 3 % NaOH solutio...

Embodiment 2

[0028] (1) Starch pretreatment: using millet starch as raw material, millet starch and deionized water were prepared into 100mL 20% (w / w) starch milk solution, using ultrasonic cell breaker, ultrasonic power 250W, ultrasonic 40min, every Working for 5s and 5s apart, the starch milk solution was treated with an ice-water bath during the ultrasonic process. After pretreatment, the starch milk was dried at 40° C. for 48 hours after suction filtration, and was set aside.

[0029] (2) Synthetic of octenyl succinic acid starch ester: get the starch of certain quality step (1) pretreatment, add appropriate amount of deionized water and be mixed with the starch milk of 35% (w / w), get octenyl succinic anhydride ( The addition amount is 3% of the starch dry base) diluted 5 times with absolute ethanol and slowly added to the starch milk within 0.5h, stirred with a constant temperature magnetic stirrer, controlled the reaction temperature at 30°C, and added continuously during the reactio...

Embodiment 3

[0031] (1) Starch pretreatment: using millet starch as raw material, millet starch and deionized water were prepared into 100mL 20% (w / w) starch milk solution, using ultrasonic cell breaker, ultrasonic power 250W, ultrasonic 40min, every Working for 5s and 5s apart, the starch milk solution was treated with an ice-water bath during the ultrasonic process. After pretreatment, the starch milk was dried at 40° C. for 48 hours after suction filtration, and was set aside.

[0032] (2) Synthetic of octenyl succinic acid starch ester: get the starch of certain quality step (1) pretreatment, add appropriate amount of deionized water and be mixed with the starch milk of 35% (w / w), get octenyl succinic anhydride ( The addition amount is 3% of the dry base of starch) diluted 5 times with absolute ethanol and slowly added to the starch milk within 0.5h, stirring with a constant temperature magnetic stirrer, controlling the reaction temperature to 32°C, and continuously adding during the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com