Aluminum oxide granule reinforced aluminum titanium carbide base composite material and its preparation method

A technology of aluminum oxide particles and aluminum titanium carbide, applied in the field of ceramic matrix composite materials and preparation, can solve the problems of complex process, generation of titanium carbide impurities, affecting the high temperature oxidation resistance of materials, etc., and achieves simple process, enhanced enhancement effect, and denser The effect of easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

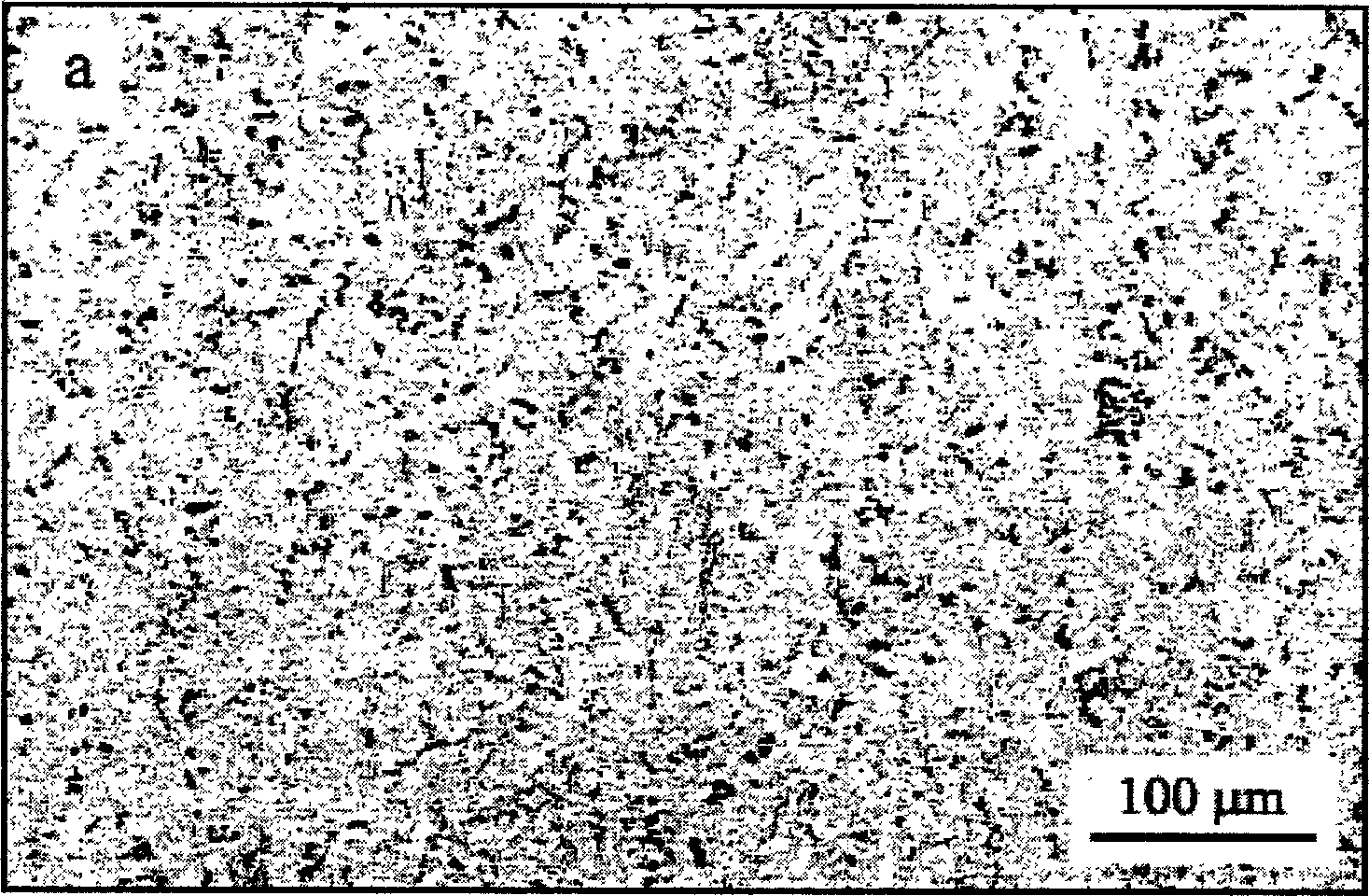

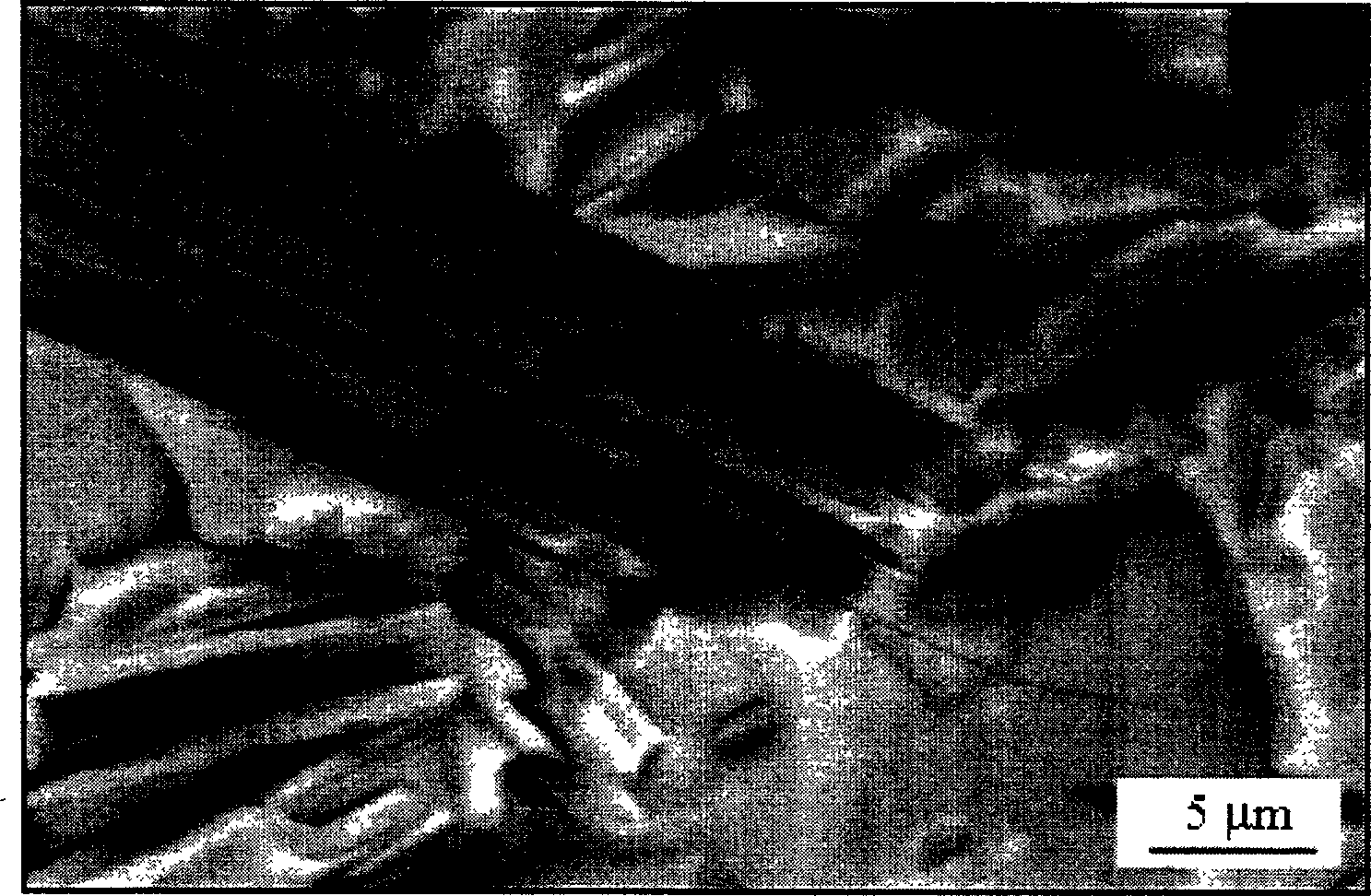

Embodiment 1

[0016] 140.5 g of titanium powder, 28.01 g of aluminum powder, 21.28 g of graphite, and 9.48 g of alumina powder (5vol.%, particle diameter of 2-5 microns) in the particle size range of 200-400 mesh were ball milled in an alcohol medium for 8 hours, and then loaded It is cold-pressed into a graphite mold, and the applied pressure is 10MPa, and then it is put into a hot-pressing furnace for hot-pressing and sintering. The heating rate is 10°C / min, and the temperature is heated to 1500°C for 1 hour while the pressure is gradually increased to 25MPa. The entire sintering process is carried out under the protection of argon, and the obtained reaction product is analyzed as Ti by X-ray diffraction 3 AlC 2 And Al 2 O 3 . The density measured by Archimedes method is 4.18g / cm 3 , Which is 99.2% of the theoretical density. Ti 3 AlC 2 / 5vol.%Al 2 O 3 The Vickers hardness of the composite material is 3.93GPa; the compressive strength is 781MPa; the bending strength is 386MPa, and the fractur...

Embodiment 2

[0018] 135.4 g of titanium powder, 23.52 g of aluminum powder, 22.08 g of graphite and 19 g of alumina powder (10 vol.%, particle diameter of 5-10 microns) in the particle size range of 200-400 mesh were ball milled in an alcohol medium for 16 hours, and then loaded It is cold-pressed into a graphite mold, and the applied pressure is 15MPa, and then it is put into a hot-pressing furnace for hot-pressing and sintering. The heating rate is 20°C / min, and the temperature is heated to 1550°C for 1 hour while the pressure is gradually increased to 30MPa. The entire sintering process is carried out under the protection of argon, and the obtained reaction product is analyzed as Ti by X-ray diffraction 3 AlC 2 And Al 2 O 3 . The density measured by Archimedes method is 4.17g / cm 3 , Is 99.5% of theoretical density. Ti 3 AlC 2 / 10vol.%Al 2 O 3 The Vickers hardness of the composite material is 4.46GPa; the compressive strength is 879MPa; the bending strength is 423MPa, and the fracture toughn...

Embodiment 3

[0020] 119.24g of titanium powder, 24.48g of aluminum powder, 19.86g of graphite and 38.22g of alumina powder (20vol.%, particle diameter of 0.1-2 microns) with a particle size ranging from 200 to 400 mesh were ball milled in an alcohol medium for 24 hours, and then loaded It is cold pressed into a graphite mold, and the applied pressure is 20 MPa, and it is put into a hot pressing furnace for hot isostatic pressing and sintering. The heating rate is 50°C / min, and the temperature is heated to 1600°C for 1 hour while the pressure is gradually increased to 40MPa. The entire sintering process is carried out under the protection of argon, and the obtained reaction product is analyzed as Ti by X-ray diffraction 3 AlC2 Alone 2 O 3 . The density measured by the Aqui Mid method is 4.15g / cm 3 It is 99.6% of theoretical density. Ti 3 ALC 2 / 20vol.% 2 O 3 The Vickers hardness of the composite is 5.47 GPa; the compression strength is 1138 MPa; the anti-bending strength is 500 MPa, the fract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com