Quick reaction technology and production system for deflazacort

A technology of Diflucort and production system, which is applied in the field of Diflucort rapid response process and production system, can solve problems such as poor fluidity of raw materials, long chemical reaction time, and low production efficiency, so as to improve sealing performance and improve production Purity, the effect of improving production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

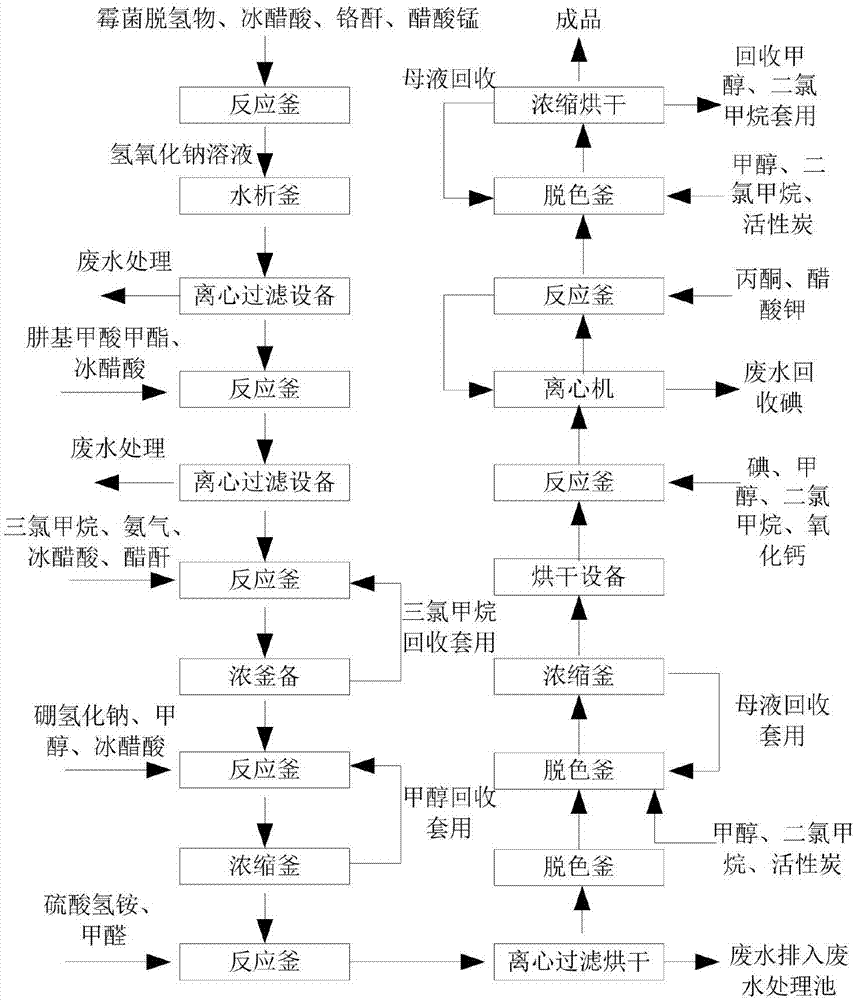

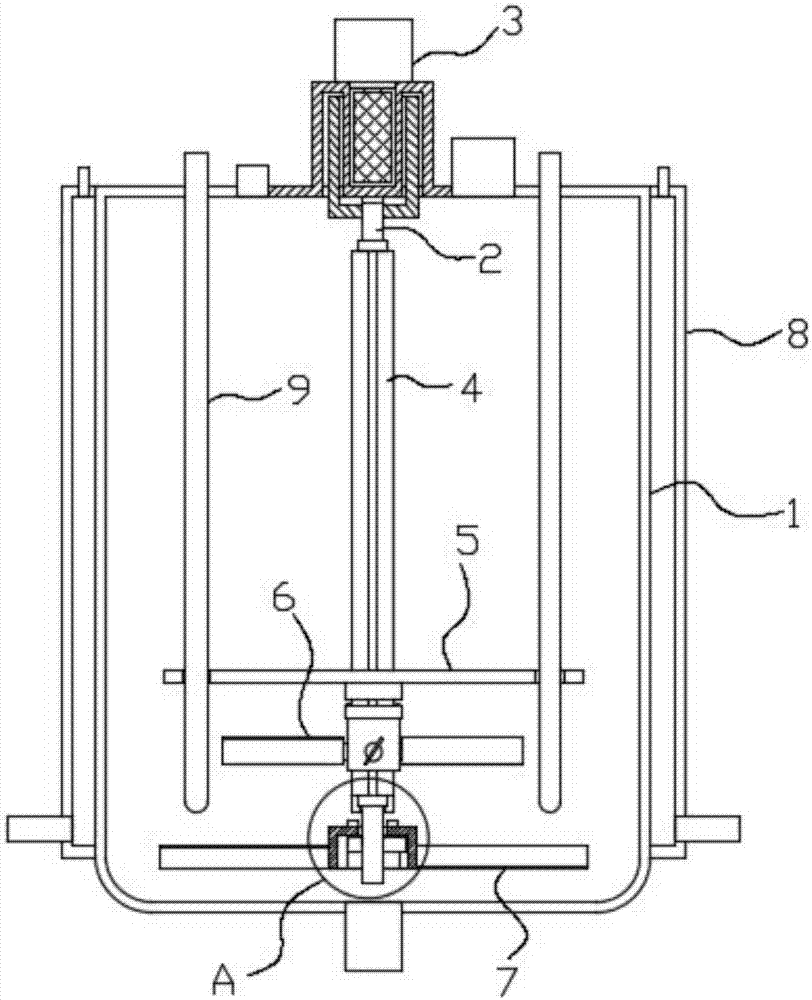

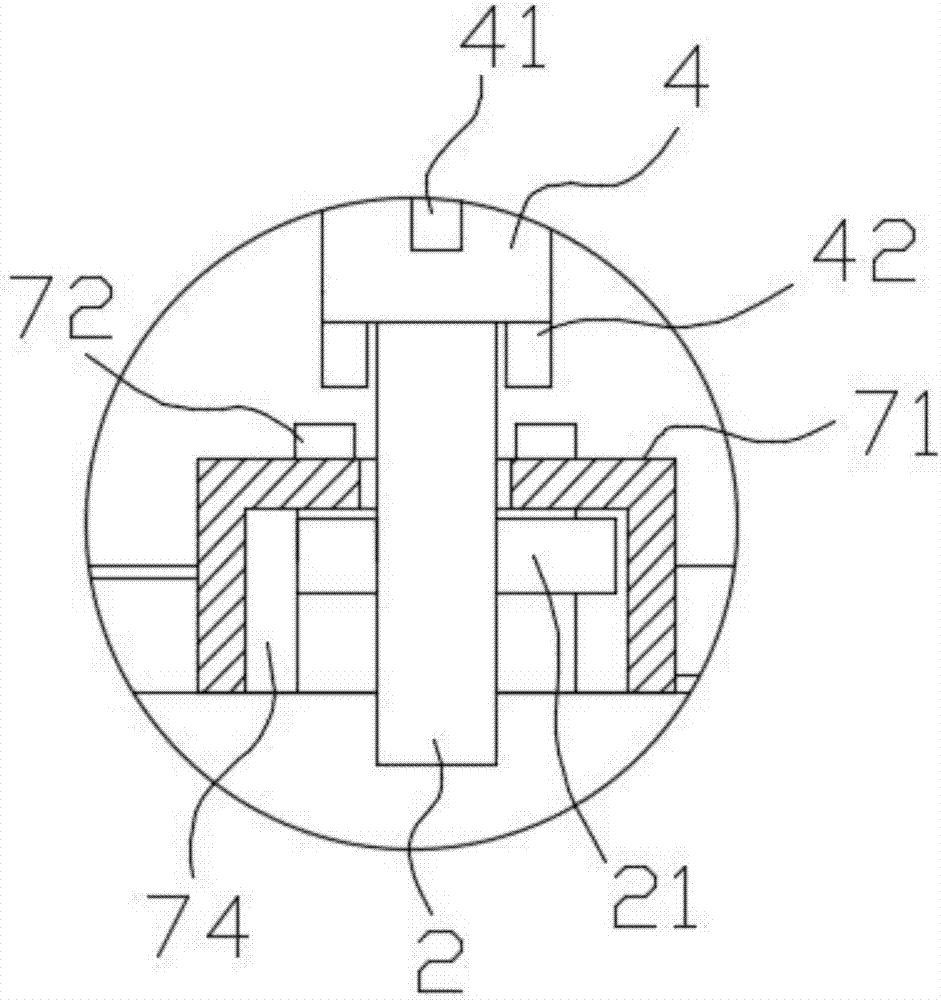

[0084] Preparation of oxides: Add 80 parts of mold dehydrogenation products, 150 parts of glacial acetic acid, 20 parts of chromic anhydride, and 8 parts of manganese acetate into the reactor, maintain the temperature in the reactor at 35-38°C, and control the rotation speed of the stirring shaft of the reactor from 30 -180r / min alternate transformation, wherein the lowest speed lasts for 5 minutes each time, and the highest speed lasts for 2 minutes each time. After stirring and reacting for 2 hours, add 1500 parts of sodium hydroxide solution with a mass percentage concentration of 5.4% for water analysis. , to obtain oxides by centrifugal filtration;

[0085] The reaction formula is:

[0086]

[0087] Preservation preparation: Add 80 parts of the oxide, 30 parts of glacial acetic acid, 1200 parts of water, and 20 parts of methyl carbazate into the reactor, control the temperature of the reactor to 20-25°C, and control the rotation speed of the stirring shaft of the react...

Embodiment 2

[0103] Preparation of oxides: Add 120 parts of mold dehydrogenation products, 250 parts of glacial acetic acid, 50 parts of chromic anhydride, and 20 parts of manganese acetate into the reactor, maintain the temperature in the reactor at 35-38°C, and control the rotation speed of the stirring shaft of the reactor from 30 -180r / min alternate transformation, wherein the lowest speed lasts for 5 minutes each time, and the highest speed lasts for 2 minutes each time. After stirring and reacting for 3 hours, add 2000 parts of sodium hydroxide solution with a mass percentage concentration of 5.4% for water analysis. , to obtain oxides by centrifugal filtration;

[0104] Preservation preparation: Add 100 parts of the oxide, 70 parts of glacial acetic acid, 2000 parts of water, and 60 parts of methyl carbazate into the reactor, control the temperature of the reactor to 20-25°C, and control the rotation speed of the stirring shaft of the reactor by 30-240r / min alternation, wherein the ...

Embodiment 3

[0112] Preparation of oxides: Add 100 parts of mold dehydrogenation products, 200 parts of glacial acetic acid, 40 parts of chromic anhydride, and 14 parts of manganese acetate into the reactor, maintain the temperature in the reactor at 35-38°C, and control the rotation speed of the stirring shaft of the reactor from 30 -180r / min alternating transformation, wherein the lowest speed lasts for 5 minutes each time, and the highest speed lasts for 2 minutes each time. After stirring and reacting for 2-3 hours, add 1650 parts of sodium hydroxide solution with a concentration of 5.4% in mass percent for water After analysis, the oxide was obtained by centrifugal filtration;

[0113] Preservation preparation: Add 98 parts of the oxide, 50 parts of glacial acetic acid, 1500 parts of water, and 40 parts of methyl carbazate into the reactor, control the temperature of the reactor to 20-25°C, and control the rotation speed of the stirring shaft of the reactor by 30-240r / min alternation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com