A method for preparing artificial sand using fly ash base polymer

A fly ash and artificial sand technology, applied in the field of waste resource utilization, can solve the problems of resource waste, low efficiency of fly ash utilization, environmental pollution, etc., to improve quality, accelerate chemical reaction speed, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

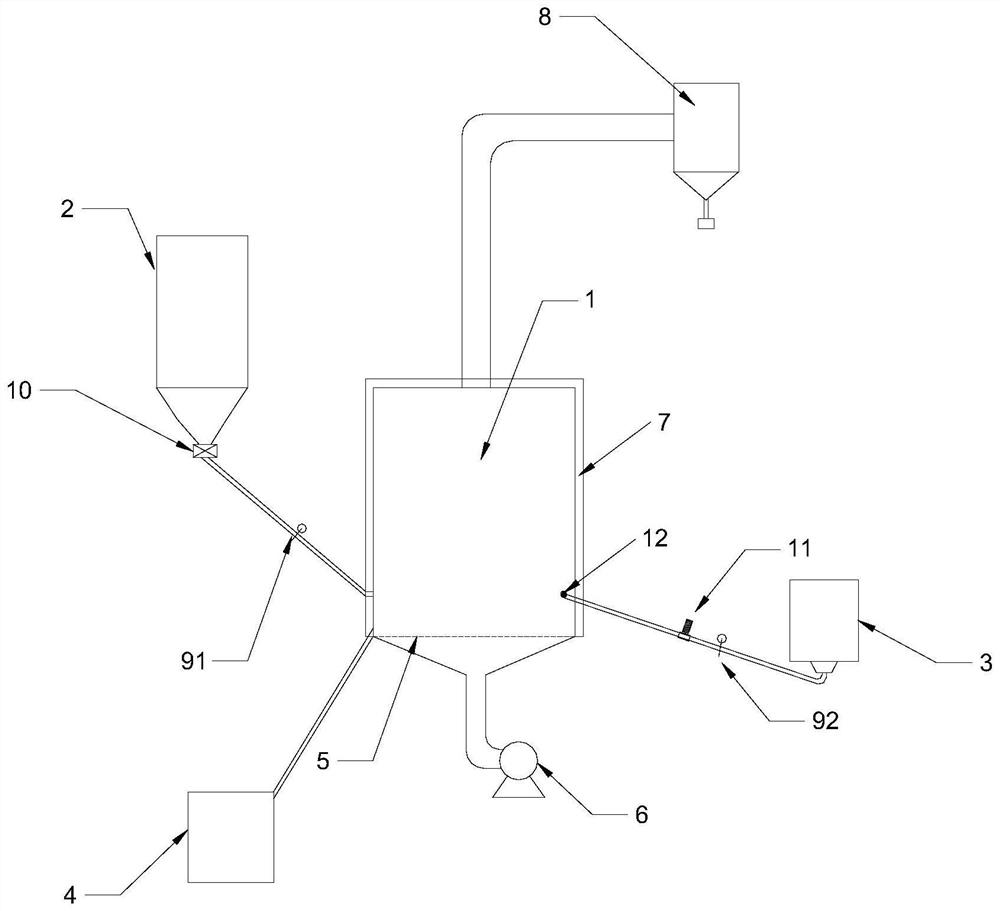

Method used

Image

Examples

Embodiment 1

[0051] A kind of method utilizing fly ash base polymer to prepare artificial sand, comprises the steps:

[0052] (1) Ingredients

[0053] Take by weight the following raw materials: 57 parts of fly ash, 43 parts of alkaline activator;

[0054] The basic activator is made up of the following raw materials in parts by weight: 23 parts of water glass, 23 parts of water;

[0055] The modulus (SiO 2 with Na 2 The molar ratio of O) is 1.3; The preparation steps are: sodium water glass (ω(SiO 2 )=26%, ω(Na 2 (O)=8.2%, modulus 3.28) and pure NaOH are mixed according to the mass ratio of 100:18.32, and stirred at a low speed for 1 hour, and then left to stand for 1 hour, waiting for cooling and aging.

[0056] The preparation method of the basic activator is as follows: water glass and water are mixed and stirred for 1 minute to make the basic activator;

[0057] (2) Granulation

[0058] According to the weight ratio of step (1), the fly ash is sprayed into the reaction vessel, ...

Embodiment 2

[0077] A kind of method utilizing fly ash base polymer to prepare artificial sand is basically the same as embodiment 1, the difference is:

[0078] The basic activator consists of the following raw materials in parts by weight: composite activator KOH-Na 2 SiO 3 : 12 parts, water: 33 parts; the composite activator KOH-Na 2 SiO 3 KOH, Na 2 SiO 3 The molar ratio is 5:1.

Embodiment 3

[0080] A kind of method utilizing fly ash base polymer to prepare artificial sand is basically the same as embodiment 1, the difference is:

[0081] The fly ash is an admixture fly ash, and the admixture fly ash is mixed with metakaolin in the fly ash, and the admixture ratio is as follows by mass percentage: 65% of fly ash, 35% of metakaolin; After the fly ash is mixed with metakaolin, a mixture is obtained, and the mixture is ground into a powder with a particle size of 8.05 microns to obtain the admixed fly ash.

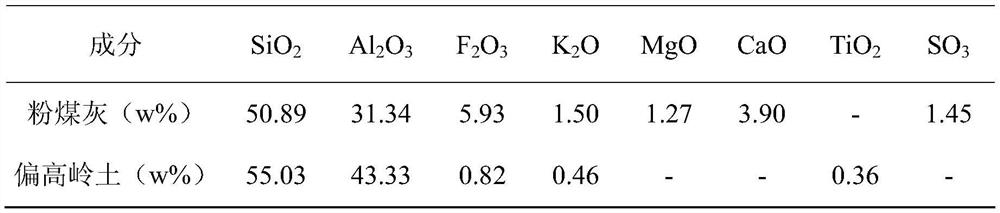

[0082] The main components of fly ash and metakaolin in this example are shown in Table 1 below.

[0083] Table 1

[0084]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com