Method for eliminating secondary particle precursors with particle size less than 2.5 microns in smoke

A secondary particle, 2.5 technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of low removal efficiency, bulky, high one-time investment, reduce operating costs, chemical reactions The effect of fast speed and one-time investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Describe the embodiment of the present invention in detail below in conjunction with technical scheme and accompanying drawing:

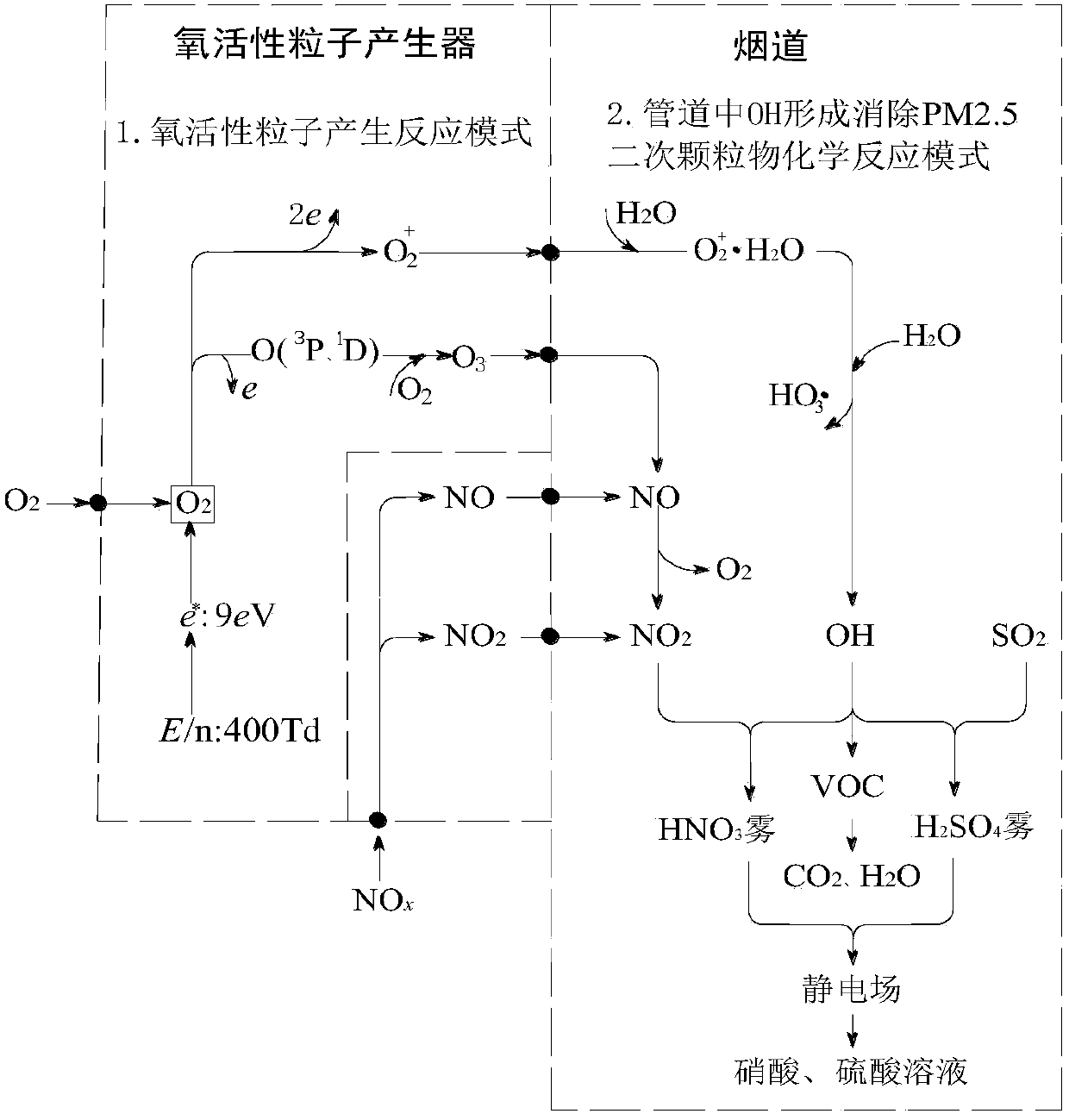

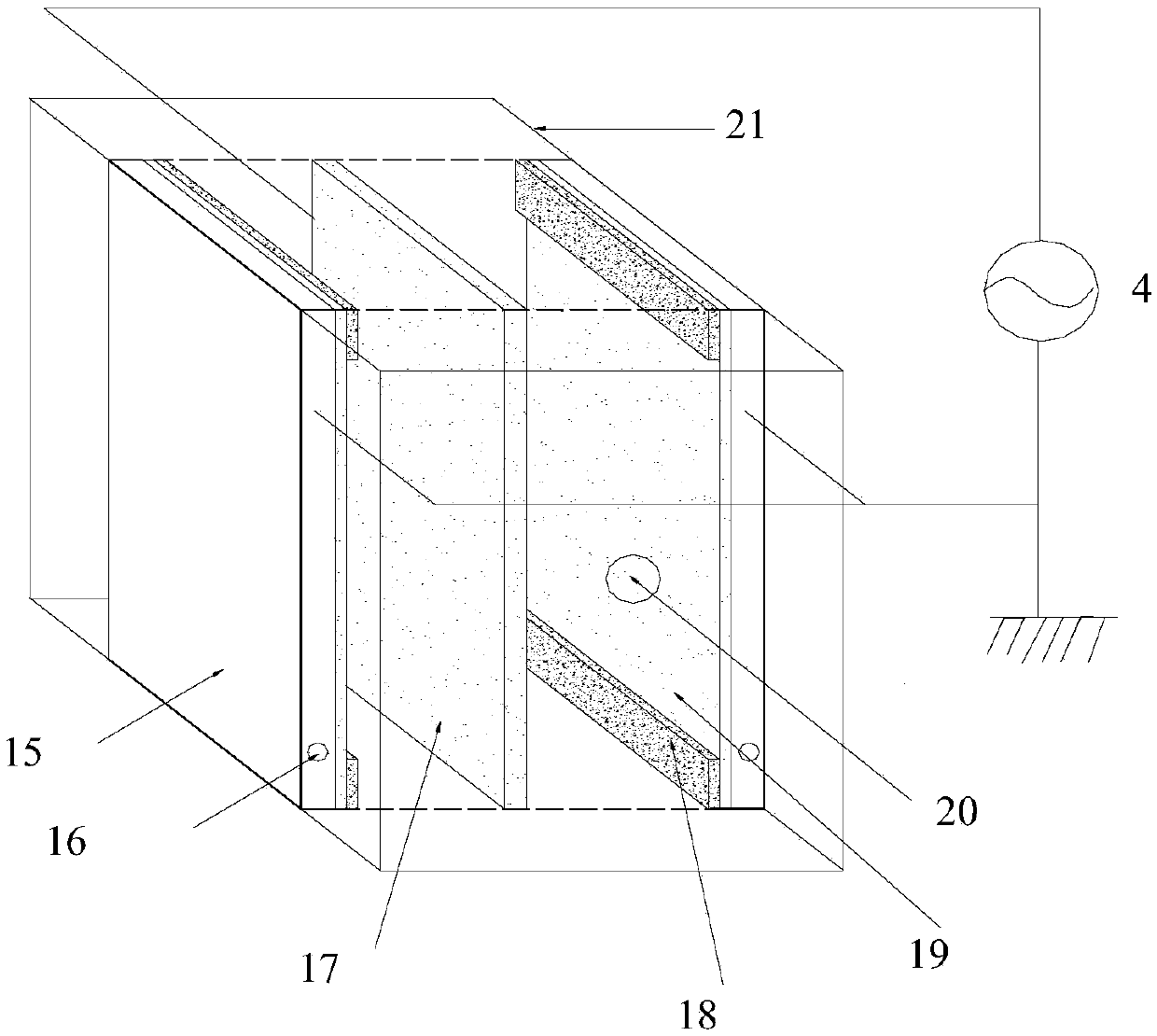

[0038] The structure of the oxygen active particle generator of the embodiment of the oxygen active particle generation of the present invention is as follows image 3 shown. The high-frequency high-voltage power supply 4 outputs a high-frequency high voltage and applies it to the discharge electrode plate 17, forming a strong ionizing electric field with a reduced electric field strength of 40Td to 100Td in the discharge gap between the discharge electrode plate 17 and the ground electrode 15, O 2 by O 2 The gas inlet 20 enters the strong ionization electric field, O 2 After dissociation and ionization, oxygen active particles 7O with a concentration of 80mg / L-400mg / L are formed 2 + , O 3 . General embodiment of the present invention is as figure 1 shown. Containing NOx, SO 2 and VOC gas 1 and oxygen active particles 7O 2 + , O ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com