A kind of preparation method of silicate fluorescent powder with good stability

A phosphor and silicate technology, which is applied in chemical instruments and methods, luminescent materials, etc., can solve the problems such as the decline of the luminescence performance and use performance of phosphors, and achieve the effect of shortening the chemical reaction time, finer particles, and increasing the specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

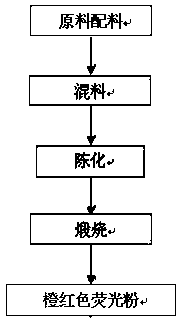

Method used

Image

Examples

Embodiment 1

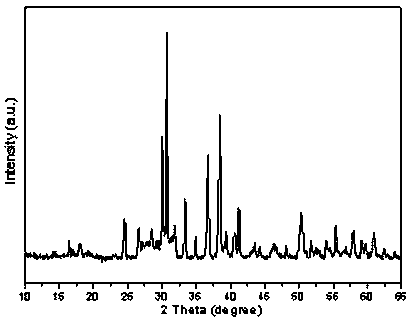

[0022] According to the general chemical formula Sr 2.94 SiO 5 : 0.06Eu 2+ Weigh first (C 2 h 5 ) 4 SiO 4 0.1mol and dissolve it in 100ml of water, add 1ml of ethanol and a few drops of nitric acid, then stir vigorously to make (C 2 h 5 ) 4 SiO 4 fully hydrolyzed and form a transparent, clear solution; then weigh Sr(NO 3 ) 2 4H 2 O(A.R.)0.294mol and Eu(NO 3 ) 3 ·6H 2 O (A.R.) 0.006mol, then respectively take by weighing 0.1wt% surfactant sodium dodecylbenzene sulfonate and chelating agent (ratio of reactant and chelating agent is 1: 2) of the above drug gross mass; Dissolve in water to make solution 2 of 1mol / L; then add solution 2 dropwise into vigorously stirred solution 1, and finally form a clear solution, then age at a constant temperature of 80°C, and finally place the formed gel on The precursor powder is obtained in an oven; after mixing the precursor powder and flux evenly, calcining in a reducing atmosphere provided by the combustion of activated carbo...

Embodiment 2

[0024] According to the general chemical formula Sr 2.90 Ca 0.04 SiO 5 : 0.06Eu 2+ Weigh first (C 2 h 5 ) 4 SiO 4 0.1mol and dissolve it in 100ml of water, add 1ml of ethanol and a few drops of nitric acid, then stir vigorously to make (C 2 h 5 ) 4 SiO 4 fully hydrolyzed and form a transparent, clear solution; then weigh Sr(NO 3 ) 2 (A.R.)0.29mol, Ca(NO 3 ) 2 4H 2 O(A.R.)0.29mol and Eu(NO 3 ) 3 ·6H 2 O (A.R.) 0.006mol, then respectively take by weighing 0.1wt% surfactant sodium dodecylbenzene sulfonate and chelating agent (ratio of reactant and chelating agent is 1: 2) of the above drug gross mass; Dissolve in water to make solution 2 of 1mol / L; then add solution 2 dropwise into vigorously stirred solution 1, and finally form a clear solution, then age at a constant temperature of 80°C, and finally place the formed gel on The precursor powder is obtained in an oven; after mixing the precursor powder and flux evenly, calcining in a reducing atmosphere provided...

Embodiment 3

[0026] According to the general chemical formula Sr 2.90 Mg 0.04 SiO 5 : 0.06Eu 2+ Weigh first (C 2 h 5 ) 4 SiO 4 0.1mol and dissolve it in 100ml of water, add 1ml of ethanol and a few drops of nitric acid, then stir vigorously to make (C 2 h 5 ) 4 SiO 4 fully hydrolyzed and form a transparent, clear solution; then weigh Sr(NO 3 ) 2 4H 2 O(A.R.)0.29mol, Mg(NO 3 ) 2 ·6H 2 O(A.R.)0.29mol and Eu(NO 3 ) 3 ·6H 2O (A.R.) 0.006mol, then respectively take by weighing 0.1wt% surfactant sodium dodecylbenzene sulfonate and chelating agent (ratio of reactant and chelating agent is 1: 2) of the above drug gross mass; Dissolve in water to make solution 2 of 1mol / L; then add solution 2 dropwise into vigorously stirred solution 1, and finally form a clear solution, then age at a constant temperature of 80°C, and finally place the formed gel on The precursor powder is obtained in an oven; after mixing the precursor powder and flux evenly, calcining in a reducing atmosphere p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com