Fluorous synthesis method of betamethasone

A technology of betamethasone and synthetic methods, applied in the direction of steroids, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

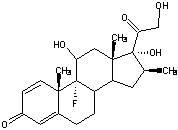

Image

Examples

Embodiment 1

[0035] Pour 50g of hydrogen fluoride into 24g of water, cool down to -30°C, then slowly add 20g of betamethasone epoxy, and control the internal temperature of the fluorine reaction at -20°C, after the reaction is complete, cool the feed solution to -30°C ℃, standby;

[0036] Take the feed solution obtained above and heat it up to 20°C, then add 100g of sodium carbonate and 400ml of aqueous solution for water analysis, and filter the precipitated products in turn, flush with water until neutral, and dry to obtain a wet product of fluoride on betamethasone;

[0037] Put the wet product of betamethasone fluoride into 400ml of methanol, add 4g of activated carbon to reflux for 30 minutes, filter, concentrate to 40ml mother liquor, cool to 10°C and filter to obtain the wet product of betamethasone.

[0038] Get the wet product of betamethasone obtained above and dry it at 55° C. for 2 hours to obtain 17.2 g of betamethasone.

[0039] Embodiment 1 The yield of betamethasone is 86%...

Embodiment 2

[0041] Pour 36g of hydrogen fluoride into 30g of water, cool down to -32°C, then slowly add 20g of betamethasone epoxy, and control the internal temperature of the fluorine reaction at -20°C, after the reaction is complete, cool the feed solution to -32°C ℃, standby;

[0042] Take the feed liquid obtained above and heat it up to 25°C, then add 125g of sodium carbonate and 375ml of aqueous solution for water analysis, and filter the precipitated products in turn, flush with water until neutral, and dry to obtain a wet product of fluoride on betamethasone;

[0043] Put the wet product of betamethasone fluoride into 400ml of methanol, add 4g of activated carbon to reflux for 30 minutes, filter, concentrate to 40ml mother liquor, cool to 10°C and filter to obtain the wet product of betamethasone.

[0044] Get the wet product of betamethasone obtained above and dry at 60° C. for 3 hours to obtain 17.2 g of betamethasone.

[0045] Embodiment 2 The yield of betamethasone is 87%, and...

Embodiment 3

[0047] Pour 36g of hydrogen fluoride into 24g of water, cool down to -34°C, then slowly add 20g of betamethasone epoxy, and control the internal temperature of the fluorine reaction to -10°C, after the reaction is complete, cool the feed solution to -35°C ℃, standby;

[0048] Take the feed solution obtained above and heat it up to 30°C, then add 75g of sodium carbonate and 425ml of aqueous solution for water analysis, and filter the precipitated products in turn, flush with water until neutral, and dry to obtain a wet product of fluoride on betamethasone;

[0049] Put the wet product of betamethasone fluoride into 400ml of methanol, add 4g of activated carbon to reflux for 30 minutes, filter, concentrate to 40ml mother liquor, cool to 10°C and filter to obtain the wet product of betamethasone.

[0050] Get the wet product of betamethasone obtained above and dry it at 58° C. for 4 hours to obtain 17.4 g of betamethasone.

[0051]Embodiment 3 The yield of betamethasone is 87%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com