Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

384results about How to "Low corrosion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bulk metallic glass medical instruments, implants, and methods of using same

InactiveUS20020162605A1Good mri signatureHigh susceptibilityIncision instrumentsSurgical needlesMri guidedMetal

MRI-compatible medical instruments and appliances are made using bulk metallic glass alloys. MRI-guided methods include the use of articles that include bulk metallic glass alloys.

Owner:UT BATTELLE LLC

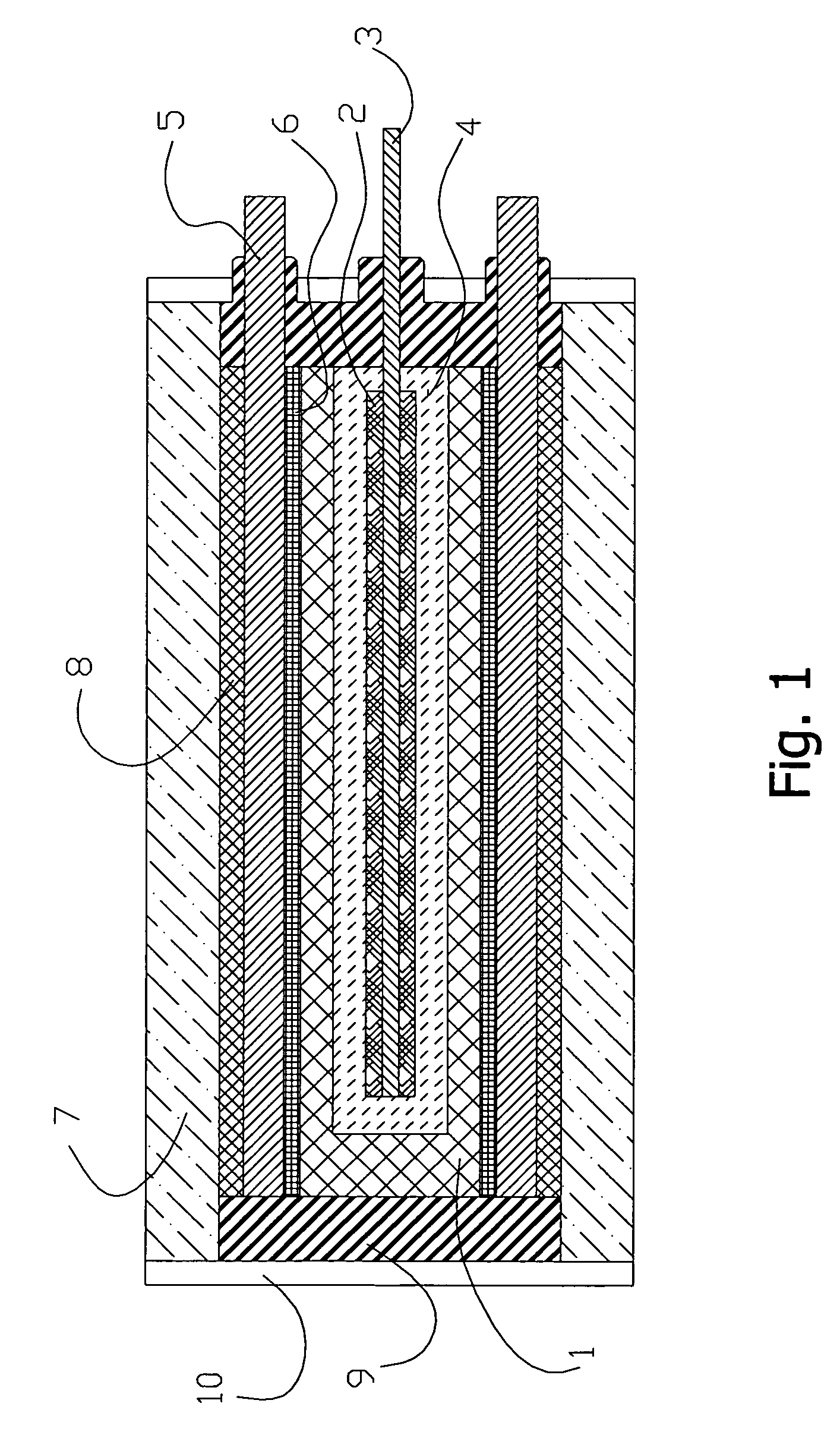

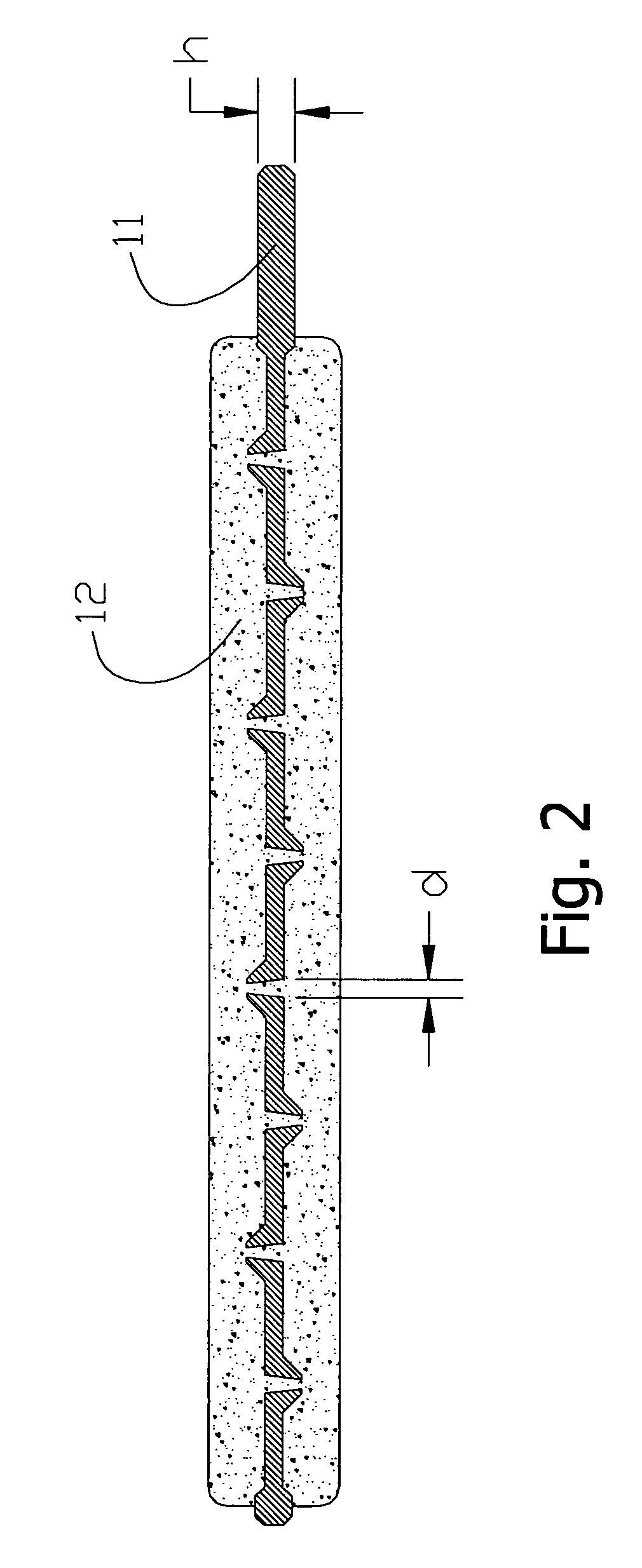

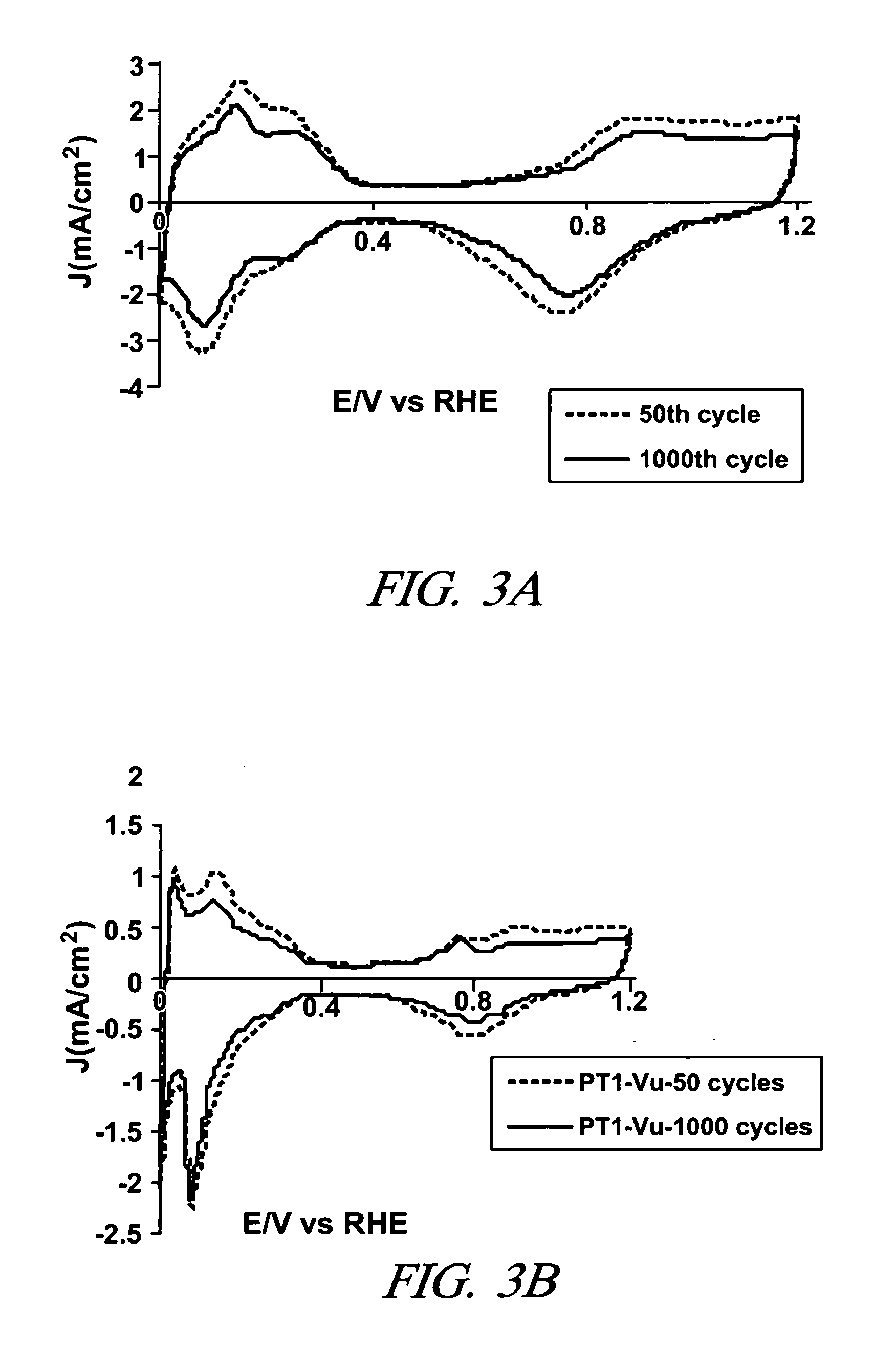

Positive electrode of an electric double layer capacitor

InactiveUS7006346B2Inhibit sheddingLow corrosion rateHybrid capacitor electrolytesHybrid capacitor electrodesEngineeringElectric double-layer capacitor

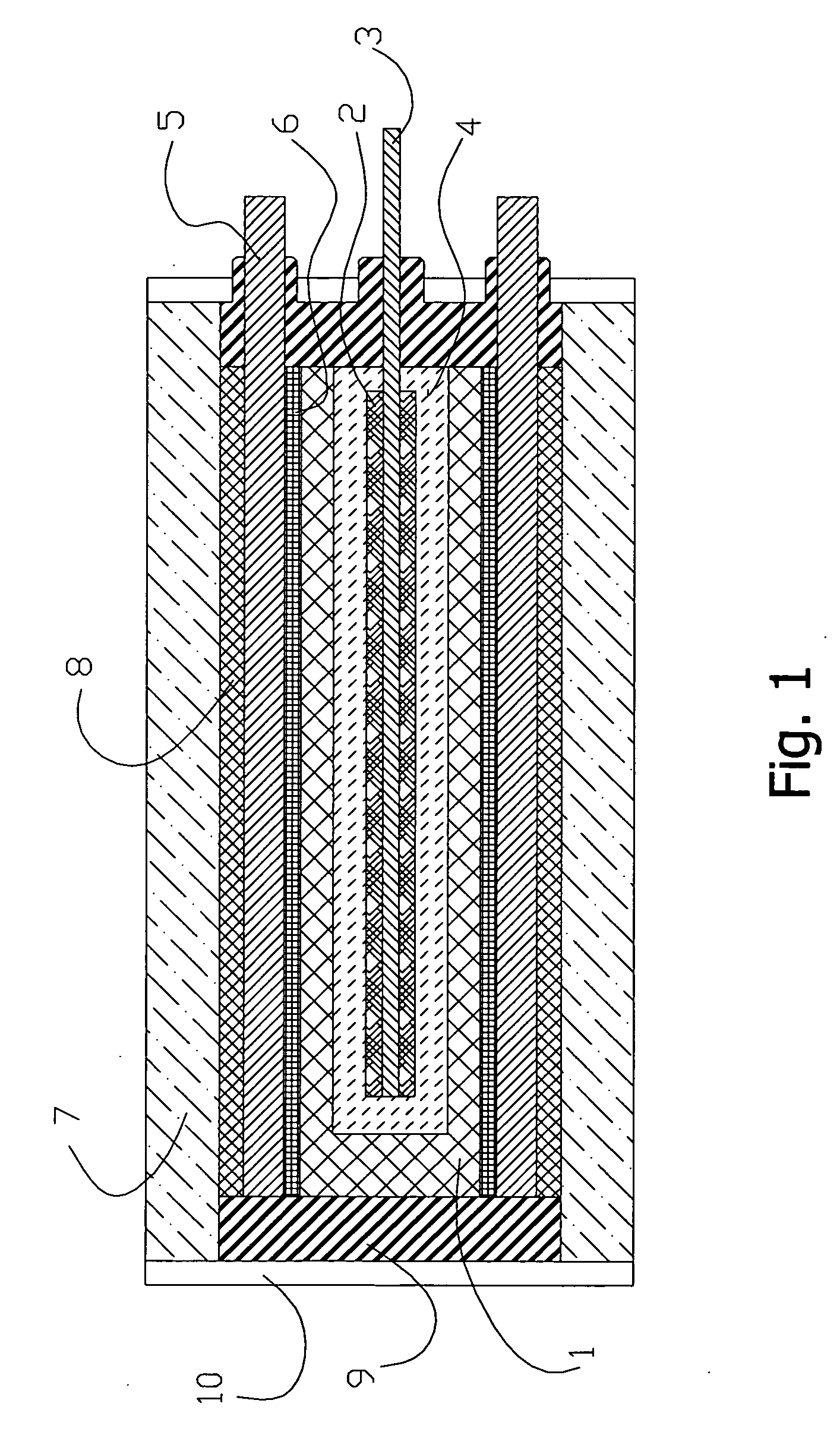

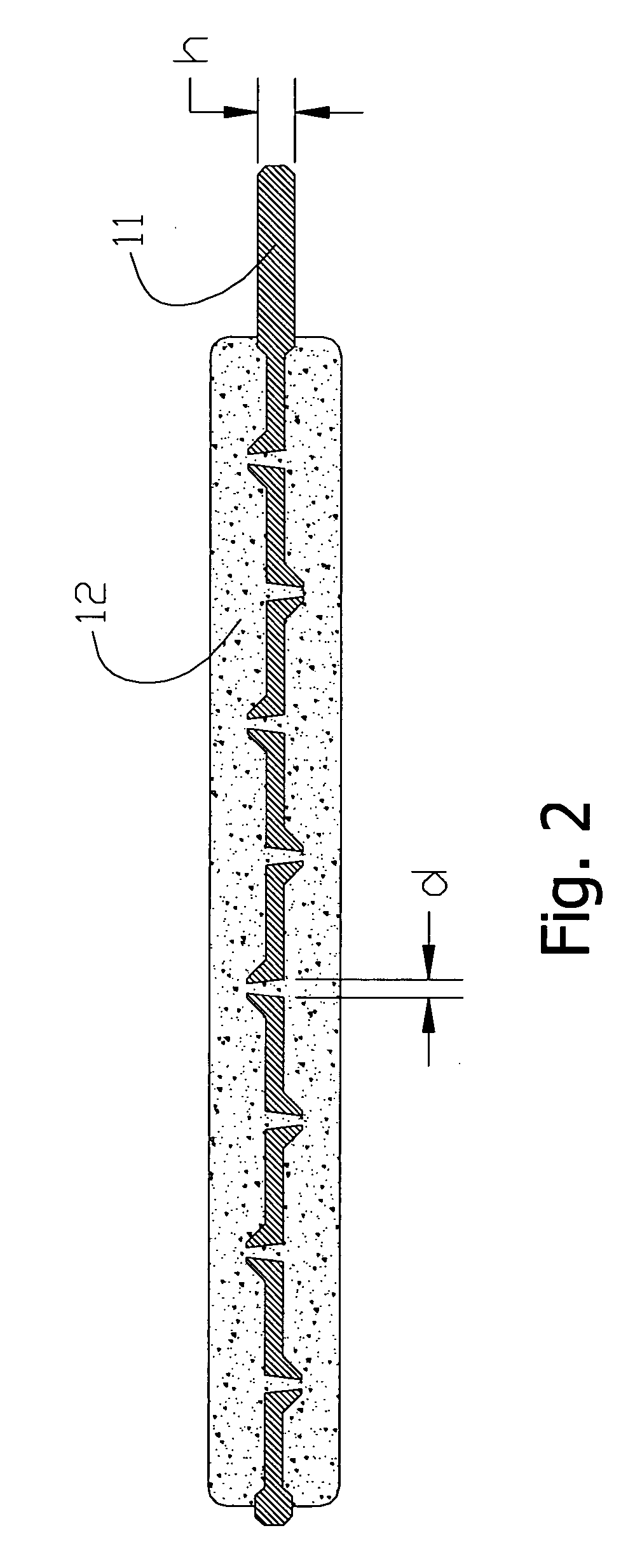

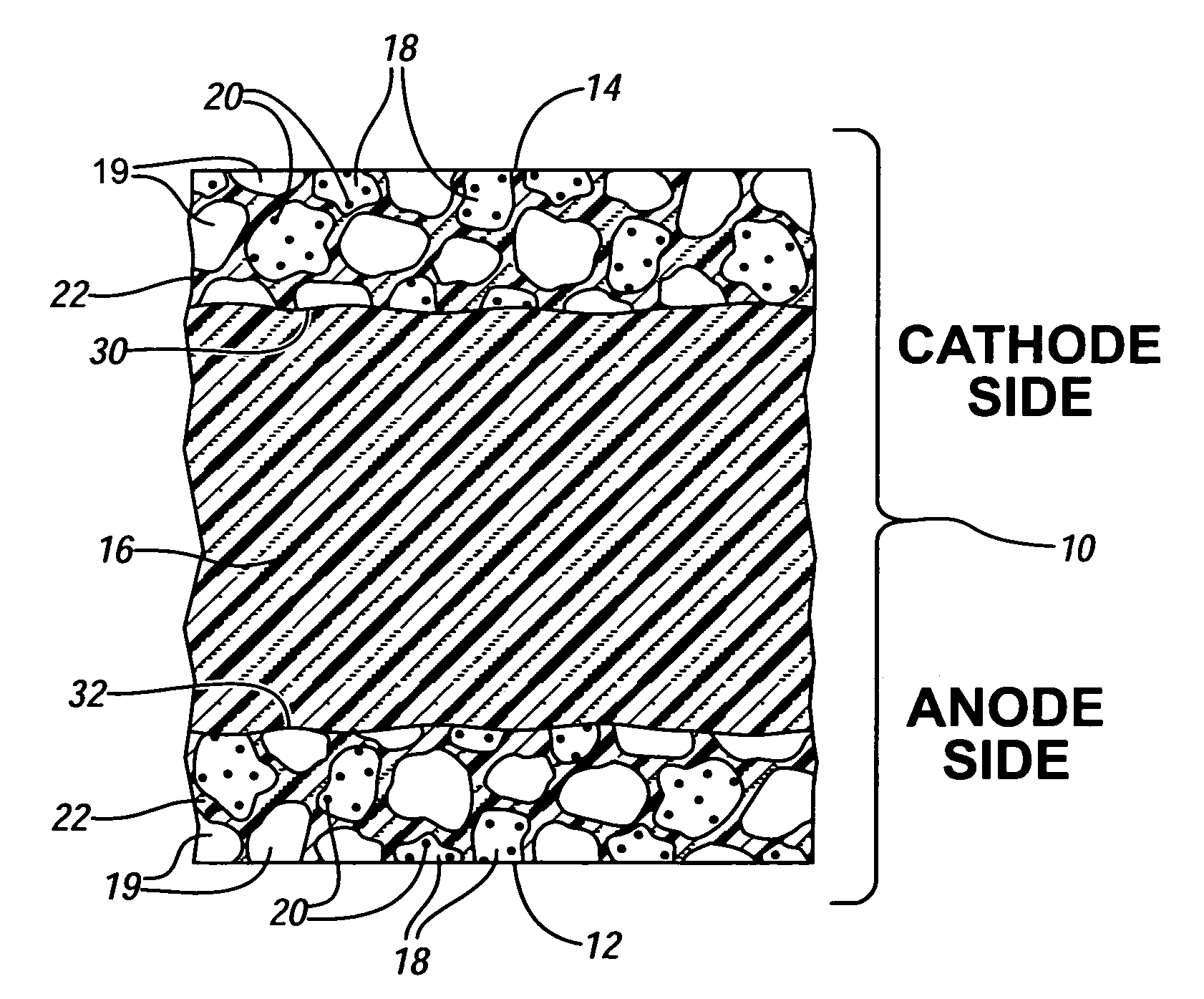

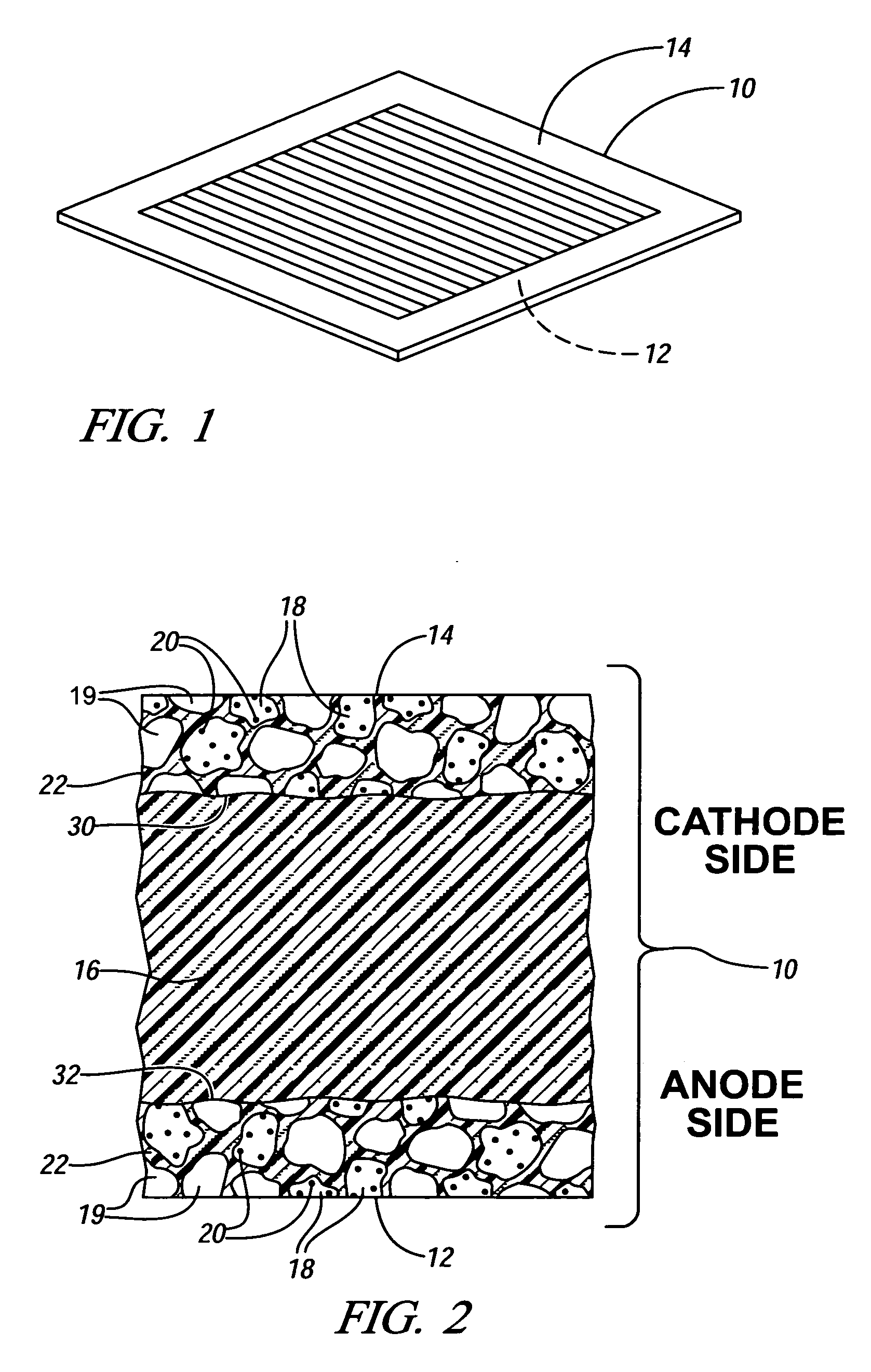

Provided in the present invention is a positive electrode for use in an Electric Double Layer (EDL) Hybrid Electrochemical Capacitor (HEC). Embodiments of the invention can be further adapted produce an EDL HEC with a high specific energy value and a high maximum voltage value. Some aspects of an embodiment of the present invention, including the aforementioned positive electrode, also cooperate to provide an EDL HEC that has a relatively high cycleability.

Owner:AXION POWER INT

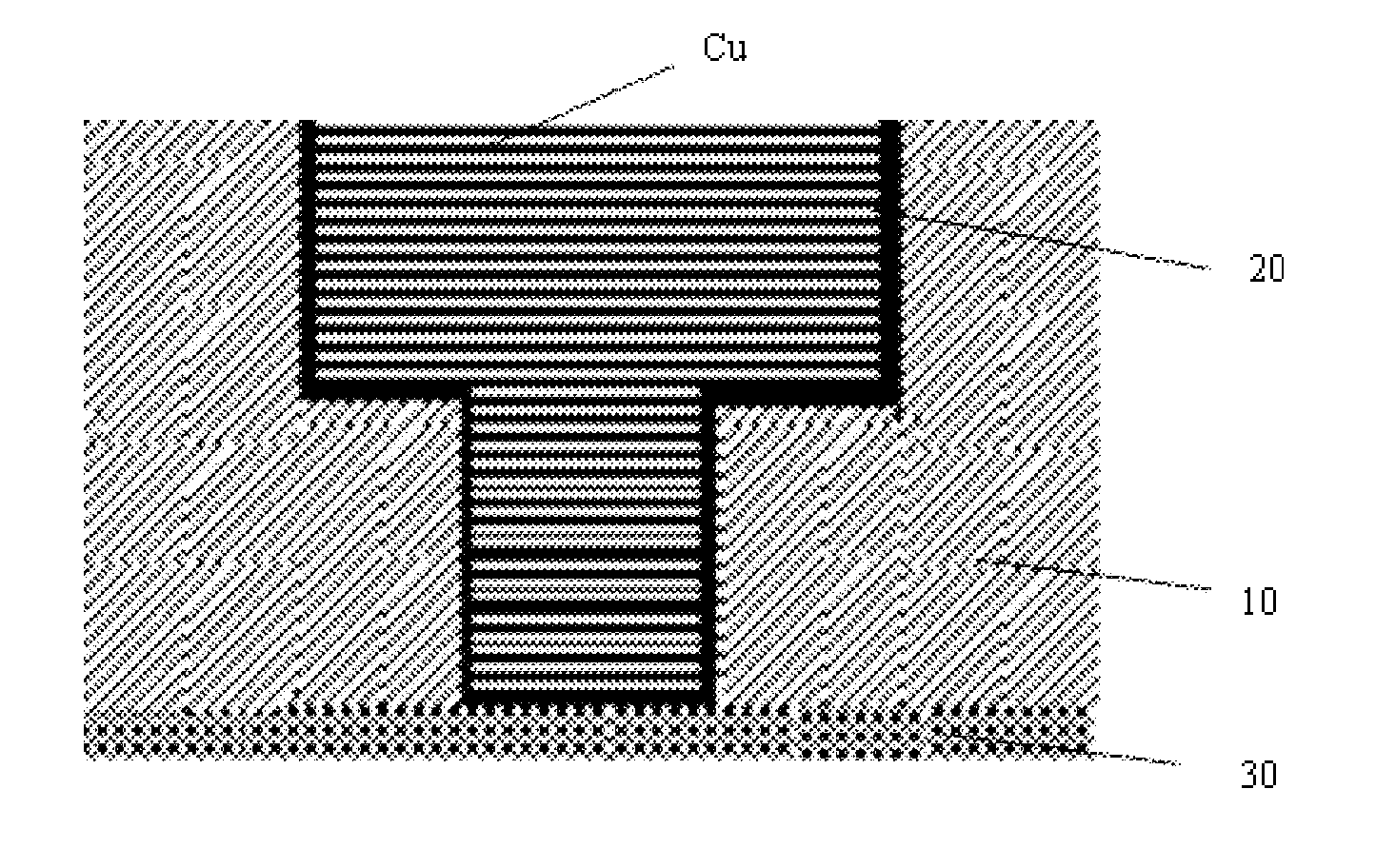

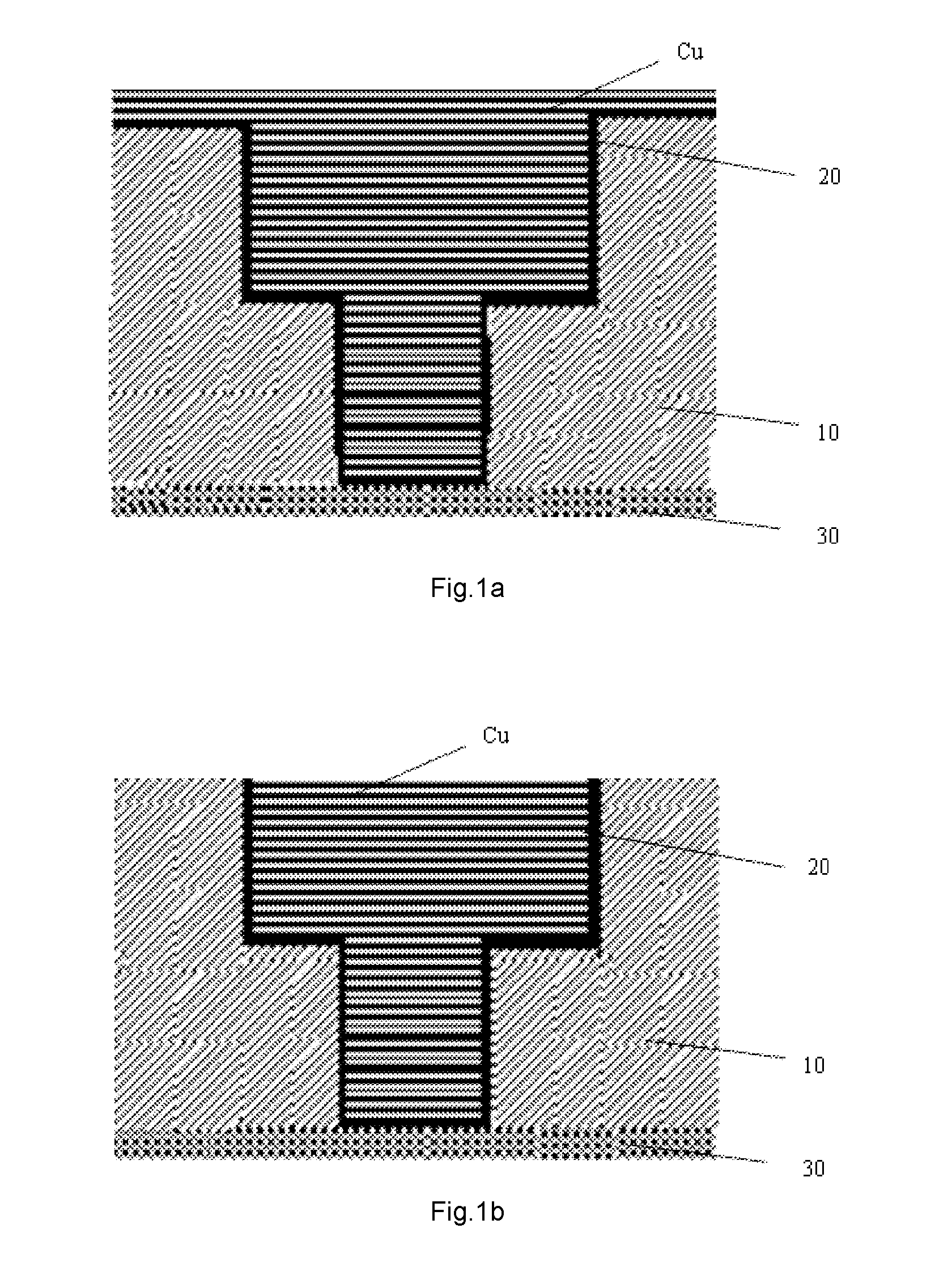

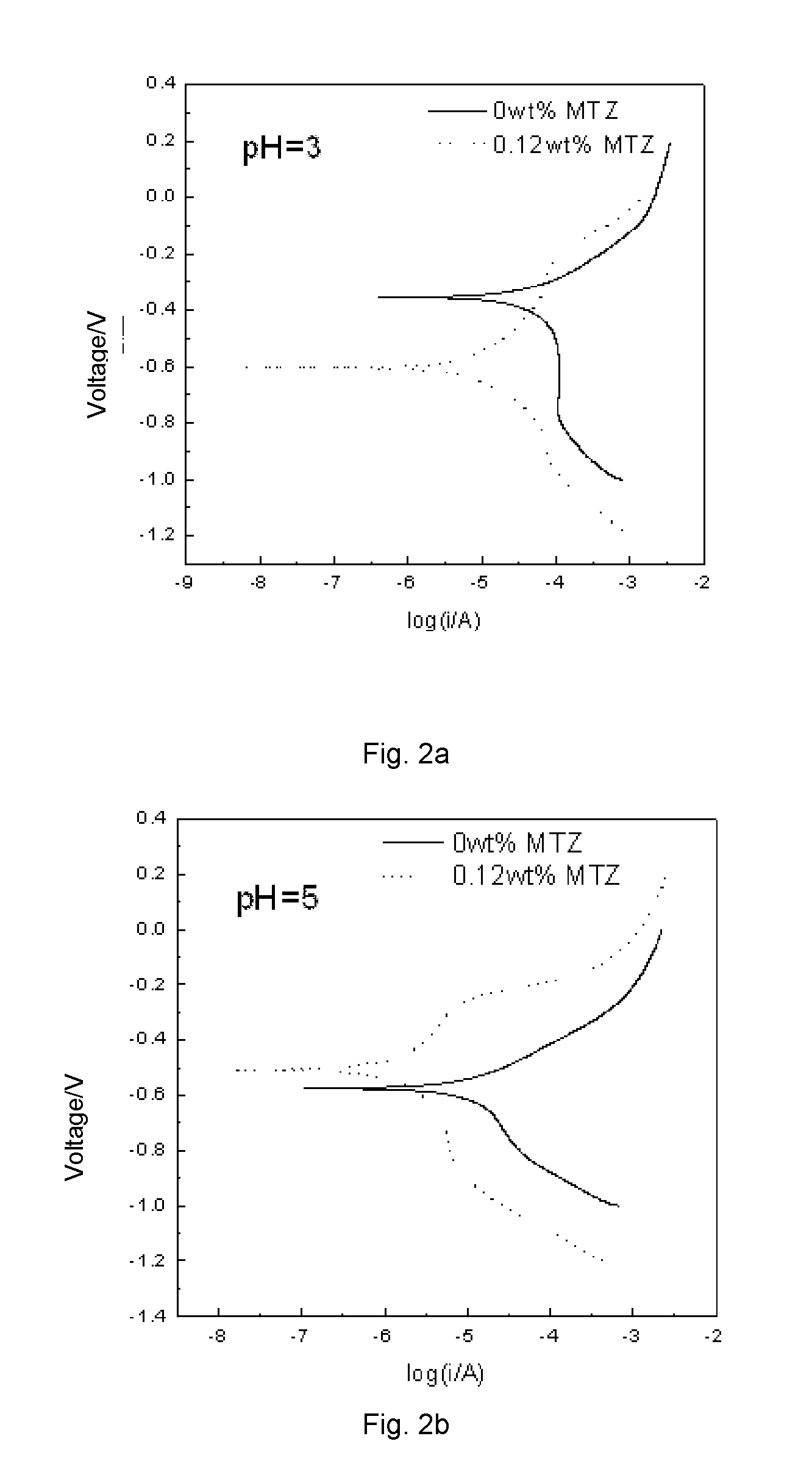

Slurry for chemical mechanical polishing of cobalt

InactiveUS20130140273A1Inhibition of corrosion rateLow corrosion rateOther chemical processesDecorative surface effectsSlurryCobalt

A slurry for chemical mechanical polishing of Co. The slurry comprises components by weight as follows, Inhibitor 0.01-2%, Oxidant 0-5%, Abrasive 0.1-10%, Complexing agent 0.001-10%, and the rest of water. The pH value of the slurries is adjusted to 3-5 by a pH value adjustor. The inhibitor is chosen from one or more kinds of five-membered heterocycle compound containing S and N atoms or containing S or N atom. The oxidant is one or more chosen from H2O2, (NH4)2S2O8, KIO4, and KClO5. The abrasive is one or more chosen from SiO2, CeO2, and Al2O3. The complexing agent is one or more chosen from amino acid and citric acid. The slurry can effectively prevent Co over corrosion and reduce the polishing rate of Co in the polishing process.

Owner:FUDAN UNIV

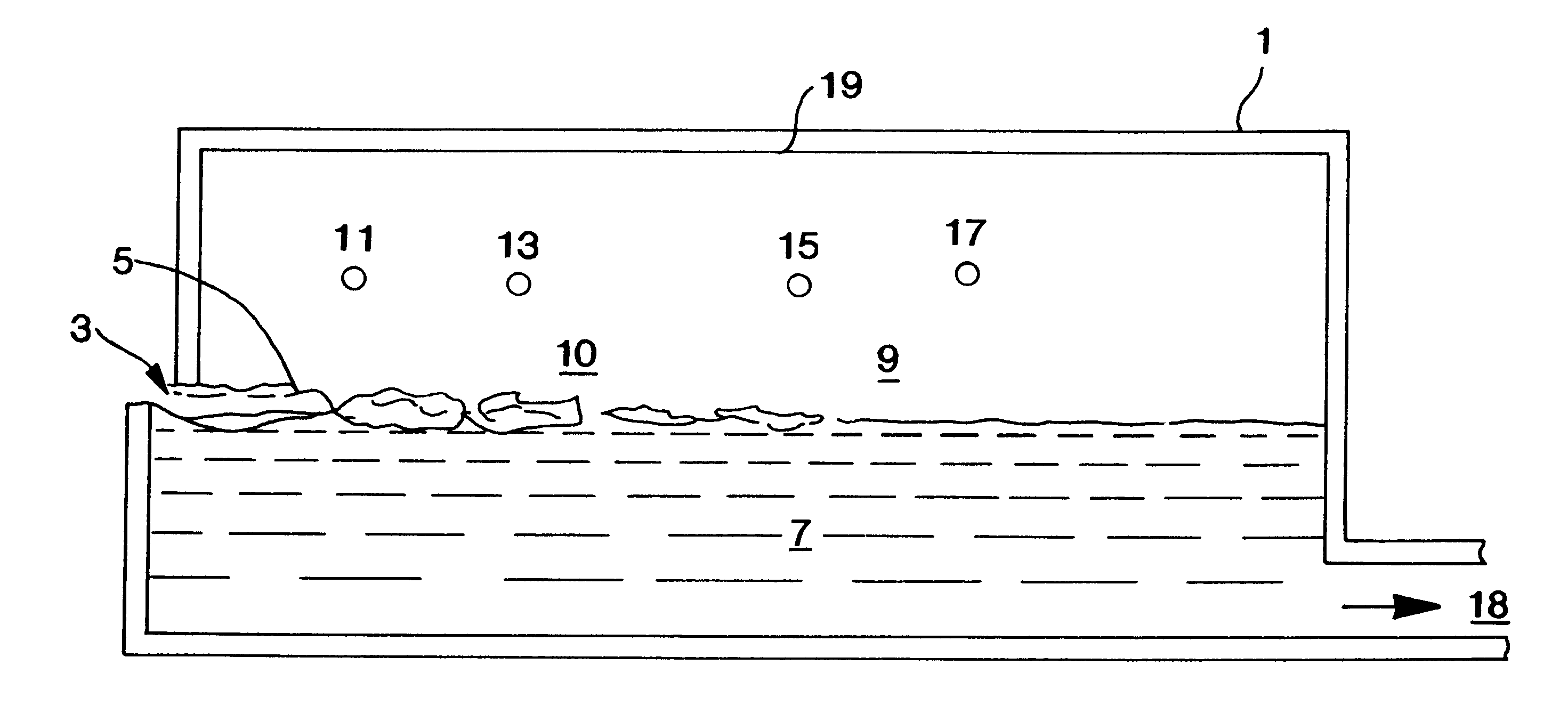

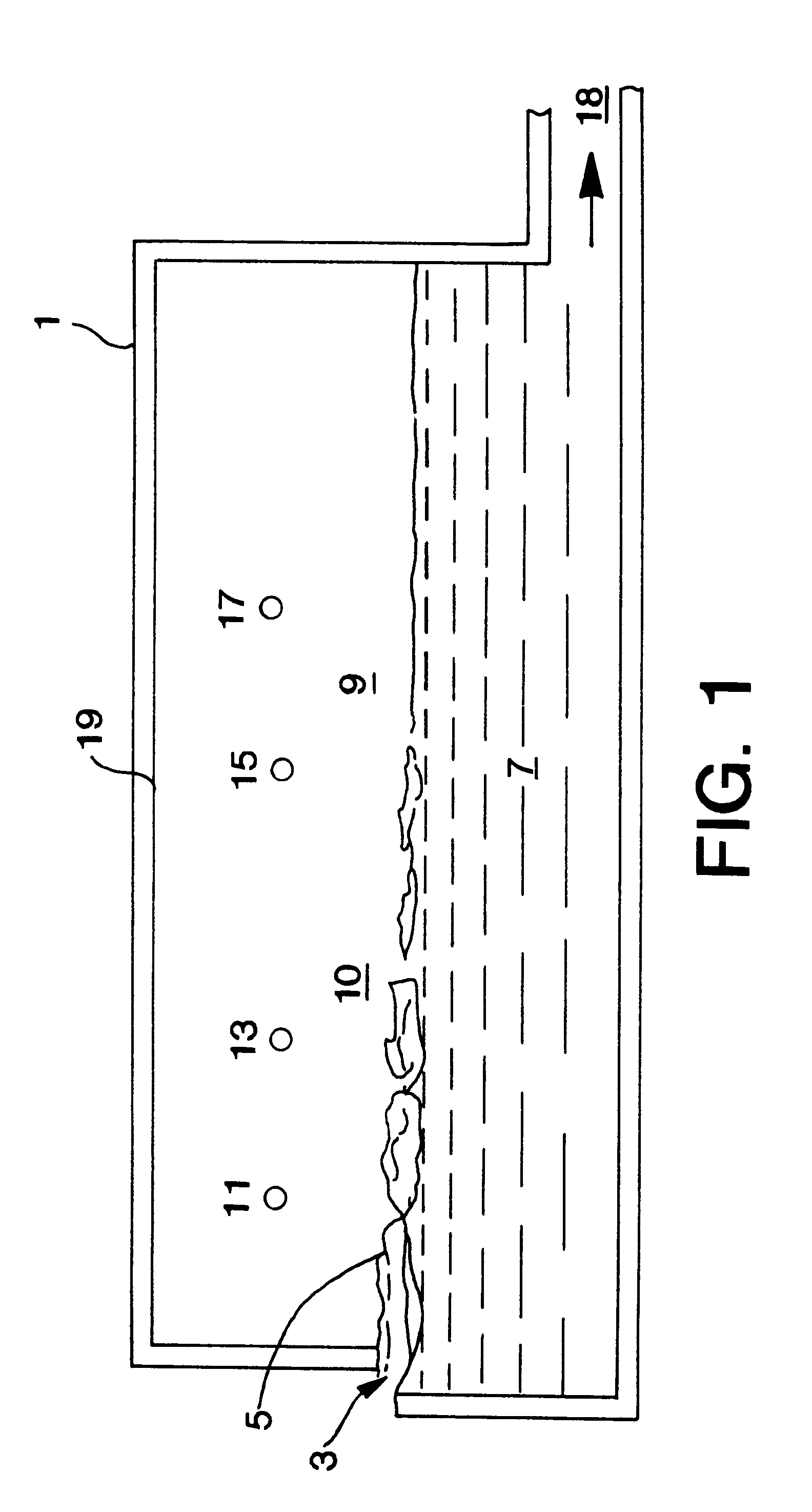

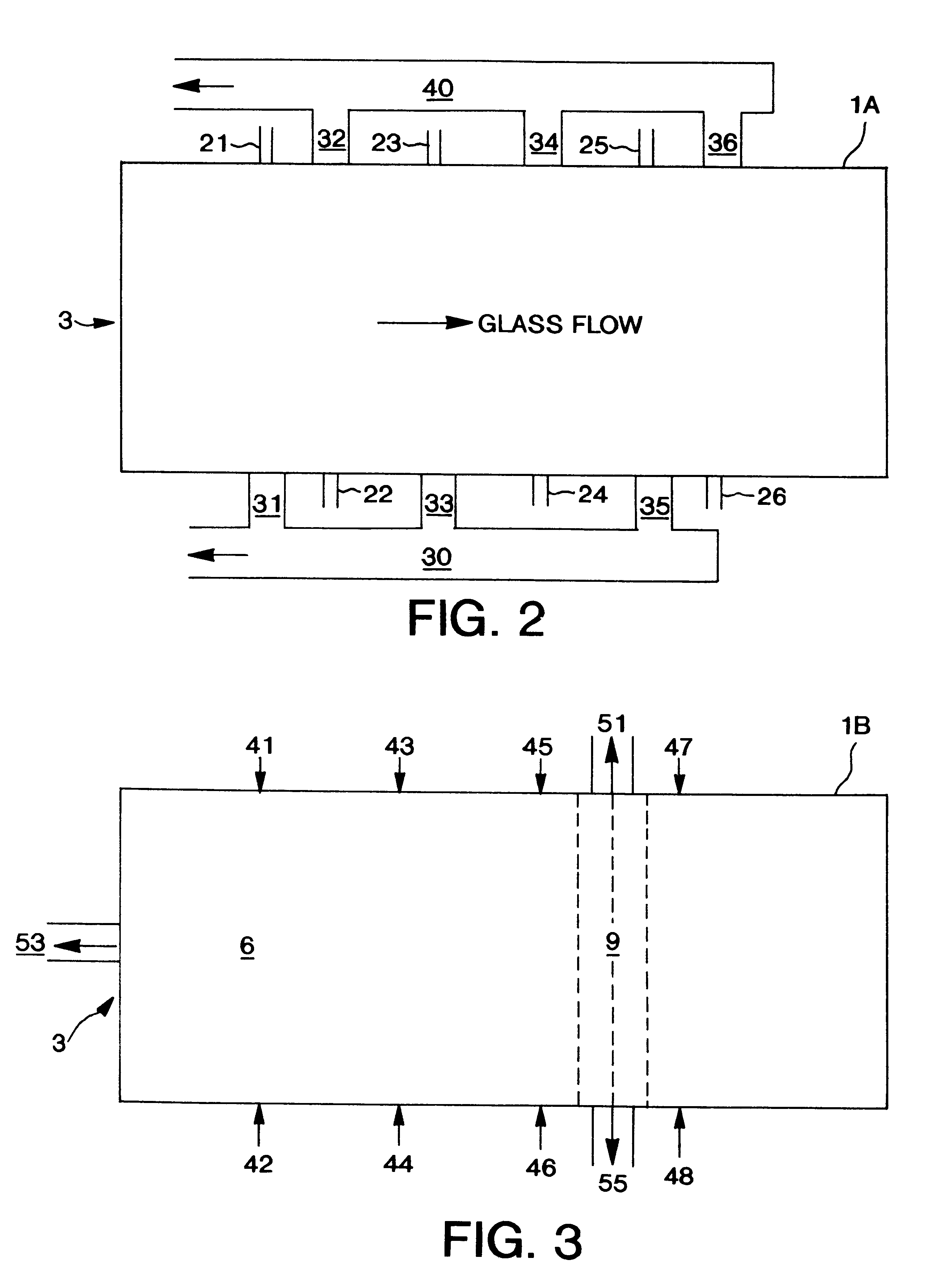

Glass melting process and apparatus with reduced emissions and refractory corrosion

A glassmelting apparatus which reduces alkali corrosion comprising: a glassmelting furnace having a plurality of walls, a crown, a charge end, a batch melting area and a fining area; at least two low momentum oxy-fuel burners located in at least one of the walls of the glassmelting furnace, each burner having at least one gas exit port, the lowest point of each gas exit port of each burner having a vertical position that is raised to a height of about 18 inches to about 36 inches above the surface of the glass; each oxy-fuel burner generating a flame along a path directed towards an opposite vertical wall of the glassmelting furnace; and said interior intersection of said walls and said crown of said glassmelting furnace being located at a height of between about 5.5 feet and 9 feet above the glassmelt surface.

Owner:PRAXAIR TECH INC

Bulk metallic glass medical instruments, implants, and methods of using same

InactiveUS20030111142A1Reduce capacityLow corrosion rateIncision instrumentsSurgical needlesMri guidedAlloy

MRI-compatible medical instruments and appliances are made using bulk metallic glass alloys. MRI-guided methods include the use of articles that include bulk metallic glass alloys.

Owner:HORTON JOSEPH A JR +1

Positive electrode of an Electric Double Layer capacitor

InactiveUS20050002150A1Increased durabilityReduce negative impactHybrid capacitor electrolytesLiquid electrolytic capacitorsEngineeringElectric double-layer capacitor

Provided in the present invention is a positive electrode for use in an Electric Double Layer (EDL) Hybrid Electrochemical Capacitor (HEC). Embodiments of the invention can be further adapted produce an EDL HEC with a high specific energy value and a high maximum voltage value. Some aspects of an embodiment of the present invention, including the aforementioned positive electrode, also cooperate to provide an EDL HEC that has a relatively high cycleability.

Owner:AXION POWER INT

Catalyst for fuel cell electrode

InactiveUS20060257719A1Reduce performanceReduce rate of corrosionFuel cell auxillariesActive material electrodesCorrosionTitanium oxide

The durability of a PEM fuel cell is improved by replacing carbon catalyst support materials in the cathode (and optionally both electrodes) with a titanium oxide support. The electrode thus preferably contains noble metal containing catalyst particles carried on catalyst support particles of titanium oxide. The catalyst-bearing titanium oxide particles are mixed with electrically conductive material such as carbon particles. The combination of platinum particles deposited on titanium dioxide support particles and mixed with conductive carbon particles provides an electrode with good oxygen reduction capacity and corrosion resistance in an acid environment.

Owner:GM GLOBAL TECH OPERATIONS LLC

Treating method of sea water as circulating cooling water

InactiveCN1636891ALow corrosion rateTreatment using complexing/solubilising chemicalsWater/sewage treatment using germicide/oligodynamic-processWater useWater saving

The treatment of sea water as circulating cooling water solves the problem of corrosion and scaling of cooling water system of admiralty brass, carbon steel and other material and the problem of jamming caused by microbes and clay in sea water. The treatment method is to add corrosion inhibitor 40-50 mg, antiscaling agent 30-40 mg, oxidizing biocide 20-30 mg and non-oxidizing biocide 80-120 mg to each liter of sea water used as circulating cooling water. The treatment method coincides with relevant specification and reaches very high water saving effect.

Owner:NANJING UNIV OF TECH

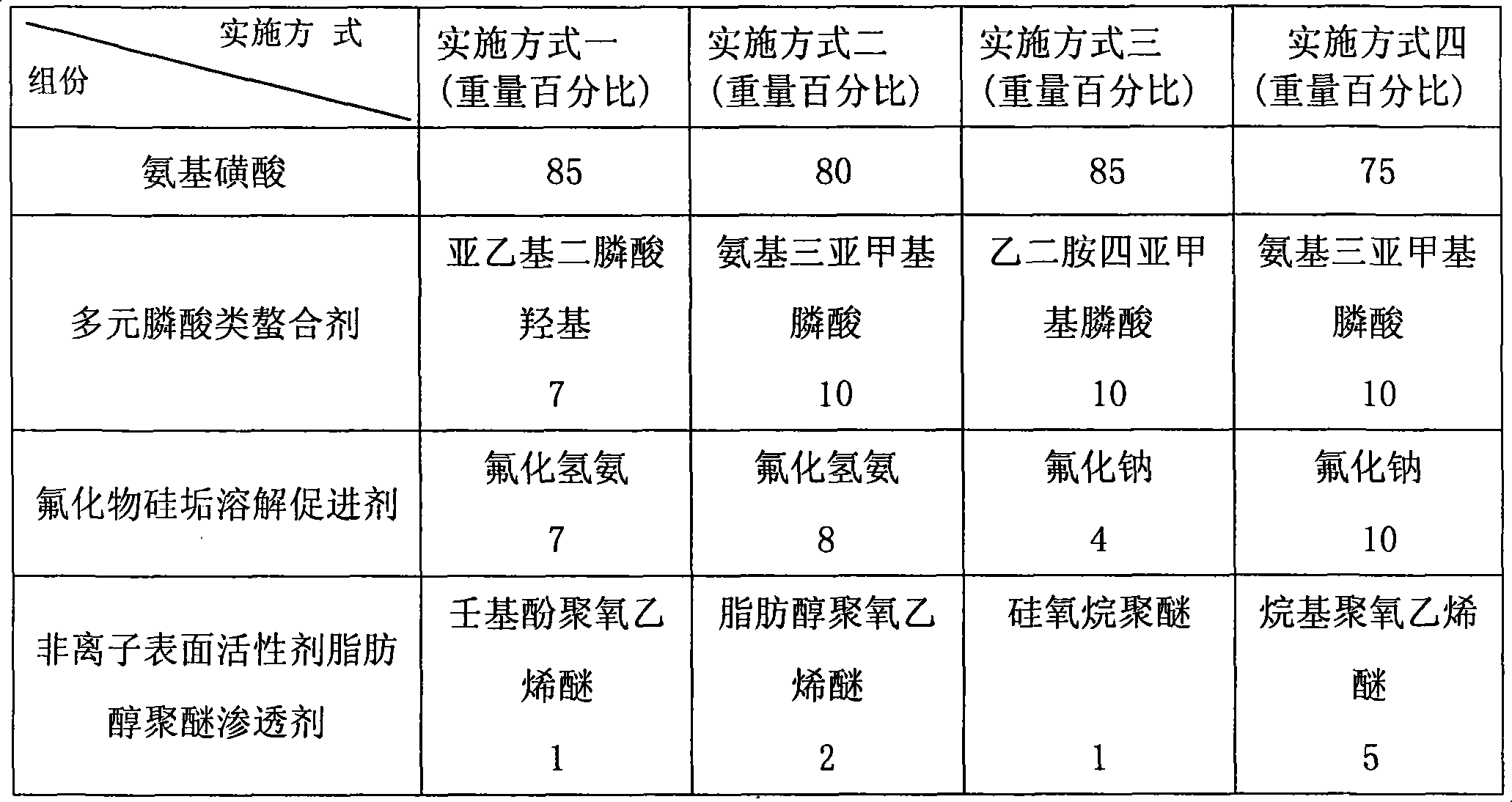

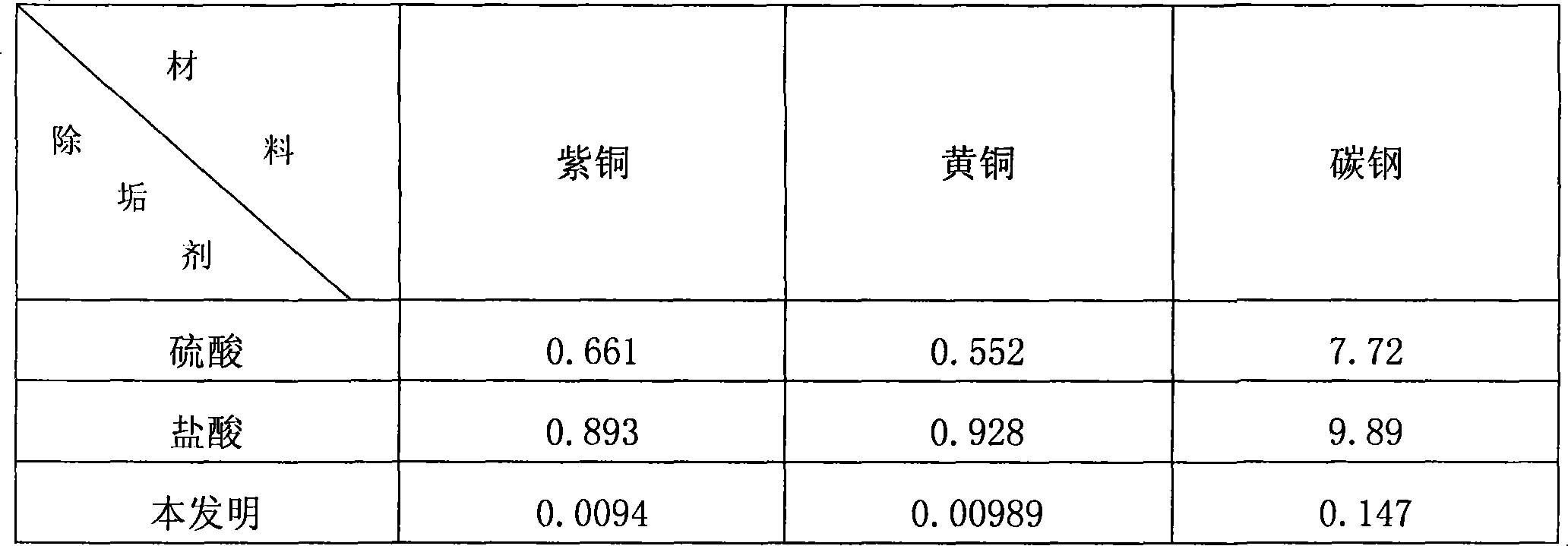

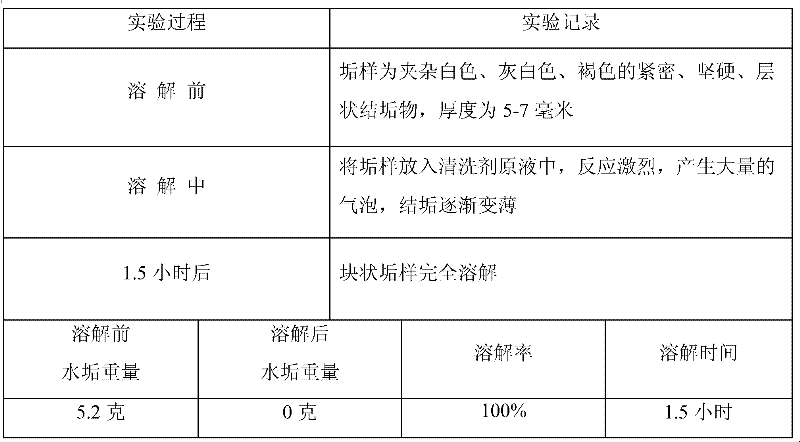

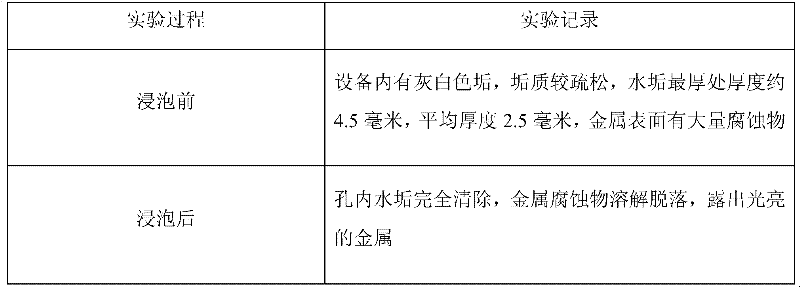

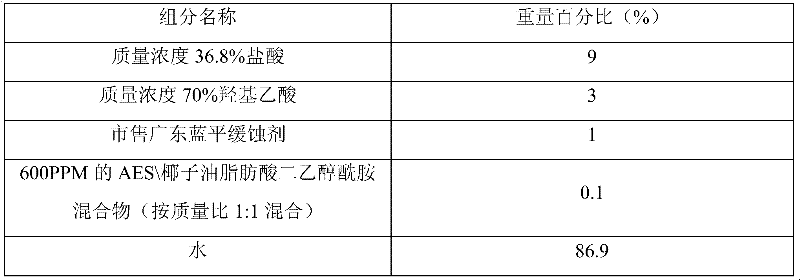

Descaling agent for cleaning central air conditioner main machine

InactiveCN101086065ASolve cleaning problemsStrong acidity of solid organic acidPolyesterHexamethylenetetramine

The invention relates to a scale and rust remover used for cleaning main frame of central air-conditioner. It is characterized in that it comprises solid mixture and liquid inhibitor; said solid mixture comprises amidosulfonic acid, polyphosphinic acid chelating agent, silicofluoride scale and rust dissolution promotor, non-ionic surface activator aliphatic alcohol polyester penetrant, their weight proportions in order are as follows: 75%-85%, 5%-10%, 5%-10%, 1%-5%; said inhibitor is liquid and comprises hexamethylene tetramin, aniline and methyl azimido-benzene according to weight proportion of 2: 2: 1. Said inhibitor is added into acidic washing solution with its weight amount being 0.3% of that of water amount. The product can dissolve carbonate, silicate, sulfate and iron oxide, the descaling speed at room temperature is fast, and is increased within 60 Deg. C, the corrosive rate to metal is pretty low, and there is no acid mist and harmful gas generation during desaling process.

Owner:长沙科惠洁水质处理服务有限公司

Photoresist stripping liquid

InactiveCN101295144AEfficient degreasing abilityControl etch ratePhotosensitive material processingOrganic solventCleansing Agents

The invention discloses a cleaning agent which has simple preparation method, low cost and low corrosion rate on substrate material and metallic wiring, and no pollution on environment and is used for removing the residues of photoresist. According to the weight percentage, the cleaning agent comprises the following raw materials: 1%-15% of surfactant, 5%-40% of organic amine, 5%-30% of organic solvent, 0.1%-5% of chelating agent, 0.01%-5% of corrosion inhibitor and residual quantity of pure water.

Owner:DALIAN SANDAAOKE CHEM

Physical grounding resistance reducing agent

InactiveCN1472750AWill not pollutePhysical health hazardConductive materialElectrical resistance and conductanceSoil resistivity

The agent mainly consists of electrode graphite and cement, which is an ideal conduction material for earthing and has low resistivity for durative action and stability service. It can satisfy earthing protective requirements for various electric or microelectronic equipment with in quite long period under the various environmental conditions.

Owner:成都圣威电气有限公司

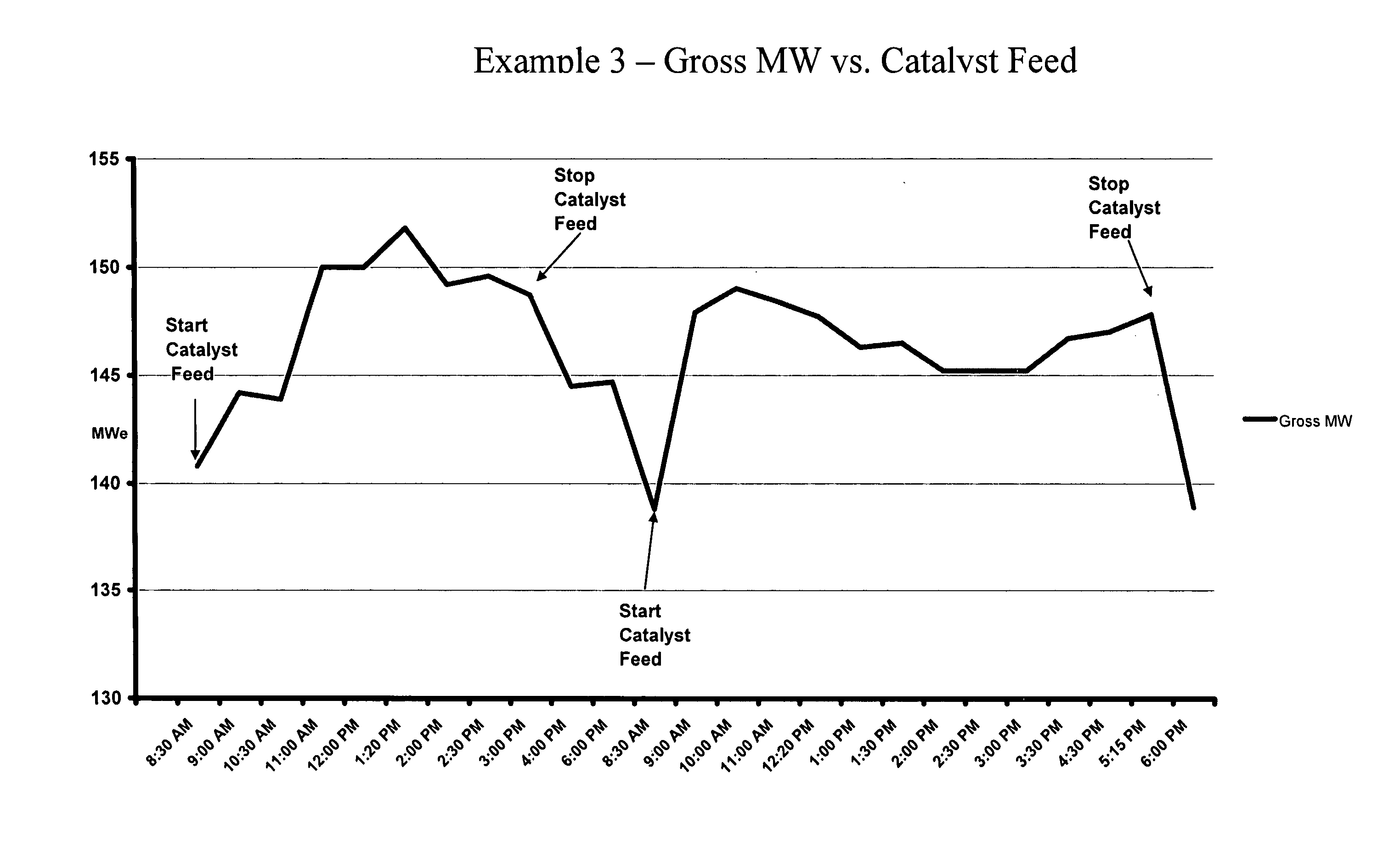

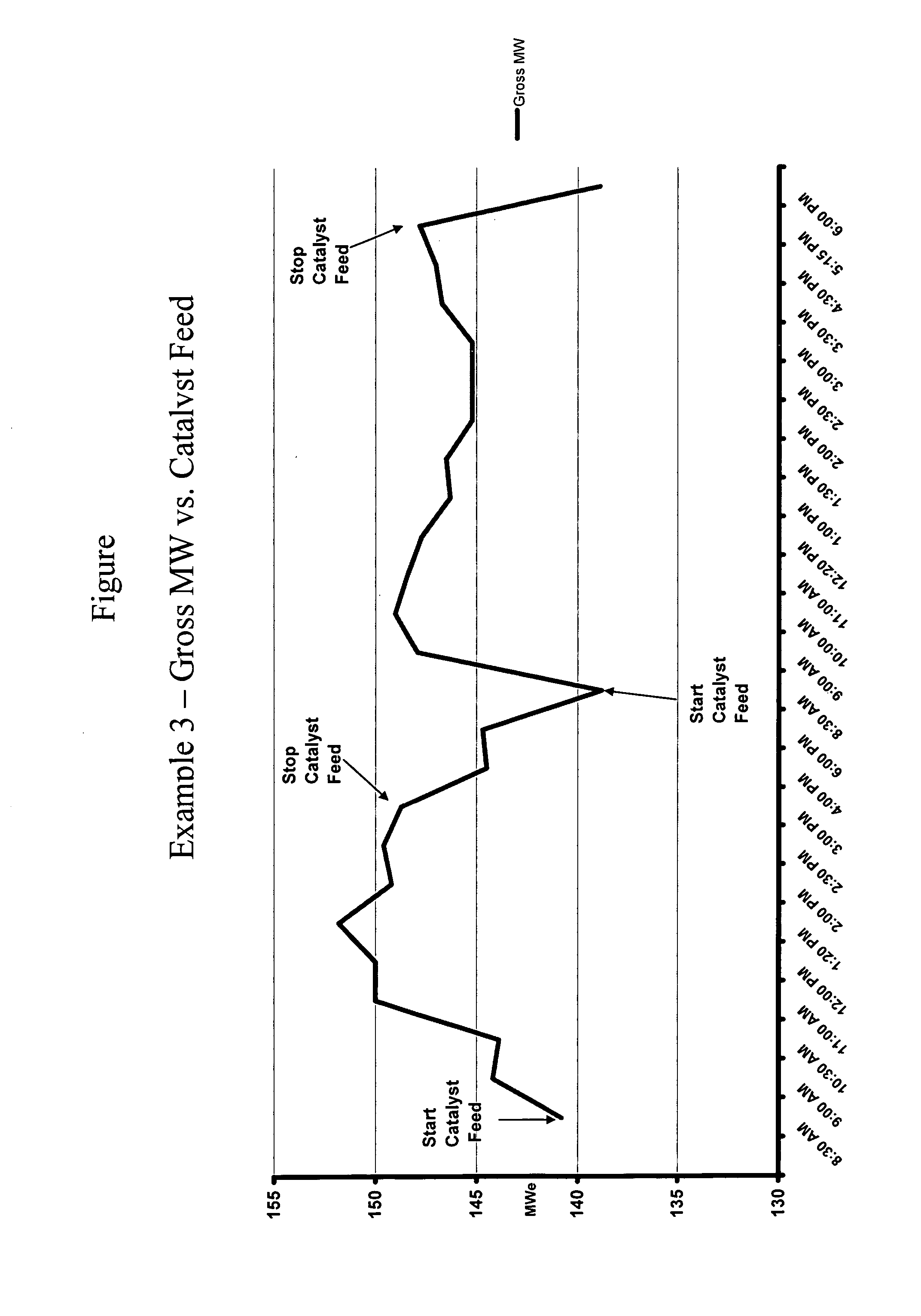

Process for improving operation of large-scale combustors

InactiveUS20070044693A1Save moneyImprove efficiencySolid fuelsSolid fuel combustionChemical treatmentCombustor

The heat output, e.g., megawatt product or steam generation, of a combustor is increased, preferably while plume is mitigated, by targeting treatment chemicals to locations in a furnace. The process improves heat output from the fuel in the region of the combustor optimum for heat recovery and also maintains good heat transfer characteristics for the heat exchange surfaces. The effectiveness of targeted in furnace injection, in-fuel introduction and in-furnace introduction of slag and / or corrosion and / or plume control chemicals are preferably determined, as are the effectiveness of targeted in furnace injection, in fuel introduction and in furnace introduction of combustion catalysts. Then, the effectiveness of various combinations of the above treatments are determined, and a treatment regimen employing one or more of the above treatments is selected. Preferred treatment regimens will contain at least two and preferably three of the treatments. Chemical utilization and boiler maintenance can improved as LOI carbon, slagging and / or corrosion are also controlled. In one preferred embodiment, the invention enables increasing by determining the positions for effective introduction of slag controlling chemical, introducing targeted slag controlling chemical treatment in an amount effective to reduce slag and introducing a combustion catalyst into the flame in an amount effective to improve combustion.

Owner:FUEL TECH INC

Stainless steel for oil well, stainless steel pipe for oil well, and method of manufacturing stainless steel for oil well

ActiveUS20120031530A1High strengthImprove corrosion resistanceFurnace typesHeat treatment process controlMicro structureChemical composition

The chemical composition of a stainless steel in accordance with the present invention consists of C: not more than 0.05%, Si: not more than 0.5%, Mn: 0.01 to 0.5%, P: not more than 0.04%, S: not more than 0.01%, Cr: more than 16.0 and not more than 18.0%, Ni: more than 4.0 and not more than 5.6%, Mo: 1.6 to 4.0%, Cu: 1.5 to 3.0%, Al: 0.001 to 0.10%, and N: not more than 0.050%, the balance being Fe and impurities, and satisfies Formulas (1) and (2). Also, the micro-structure thereof contains a martensitic phase and a ferritic phase having a volume ratio of 10 to 40%, and the ferritic phase distribution ratio is higher than 85%.Cr+Cu+Ni+Mo≧25.5 (1)−8≦30(C+N)+0.5Mn+Ni+Cu / 2+8.2−1.1(Cr+Mo)≦−4 (2)

Owner:NIPPON STEEL CORP

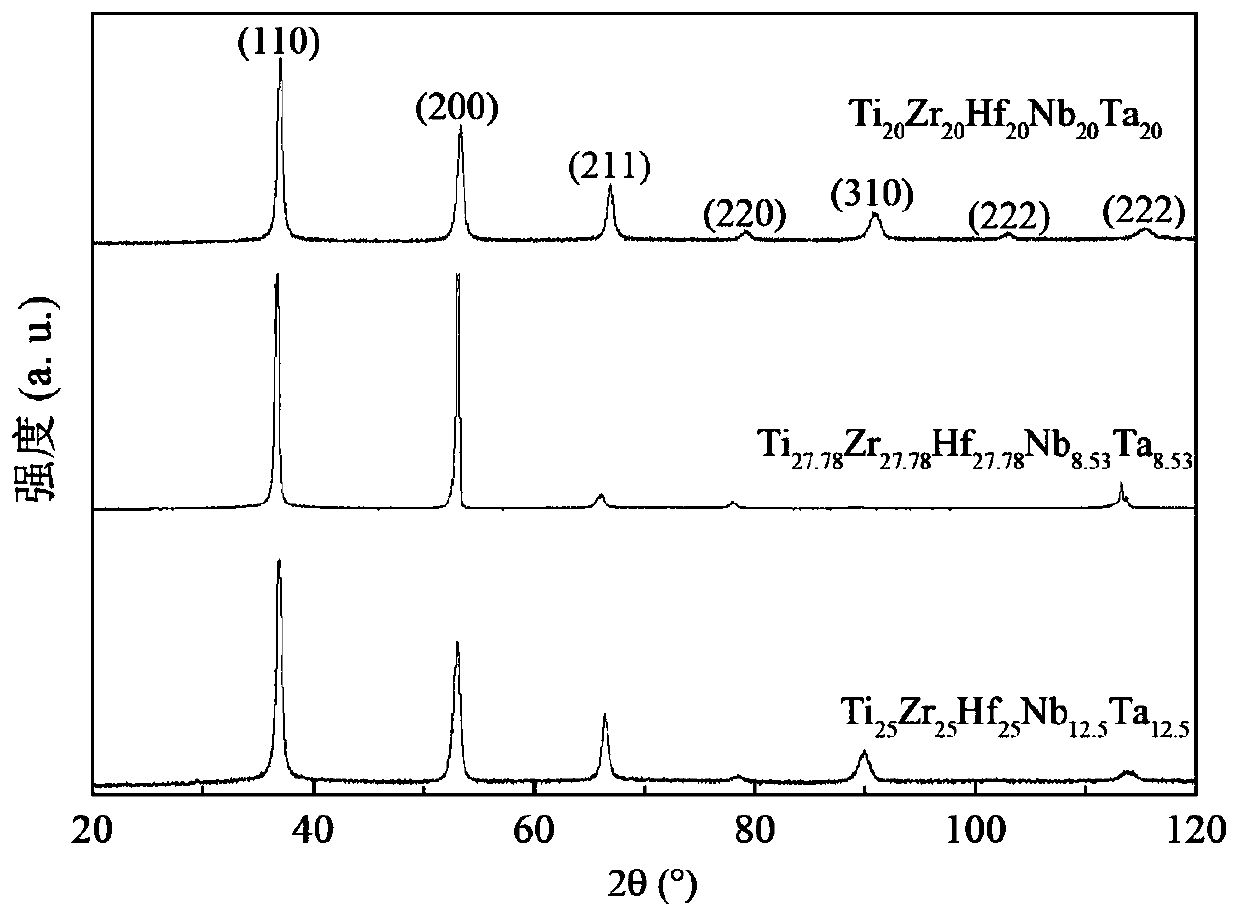

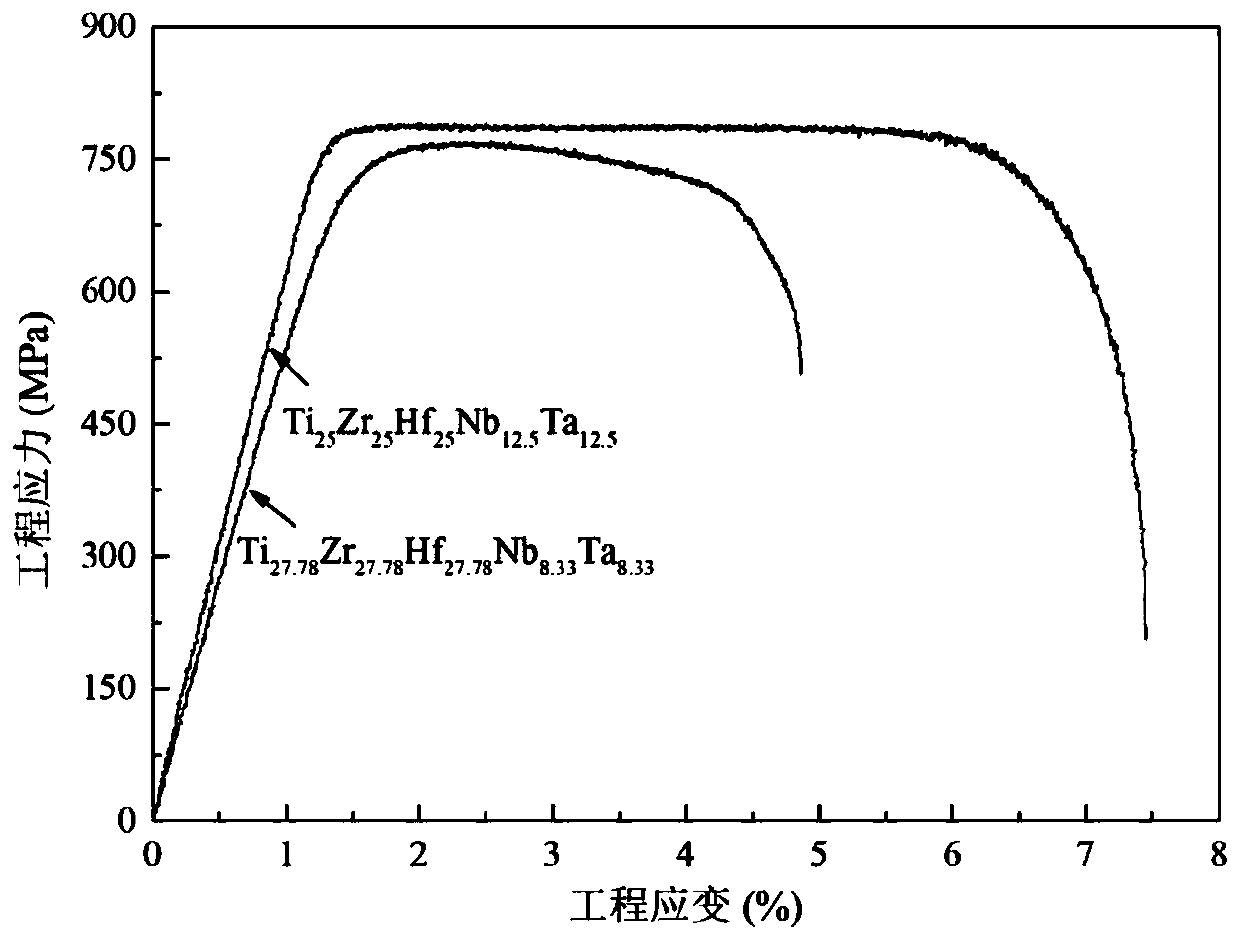

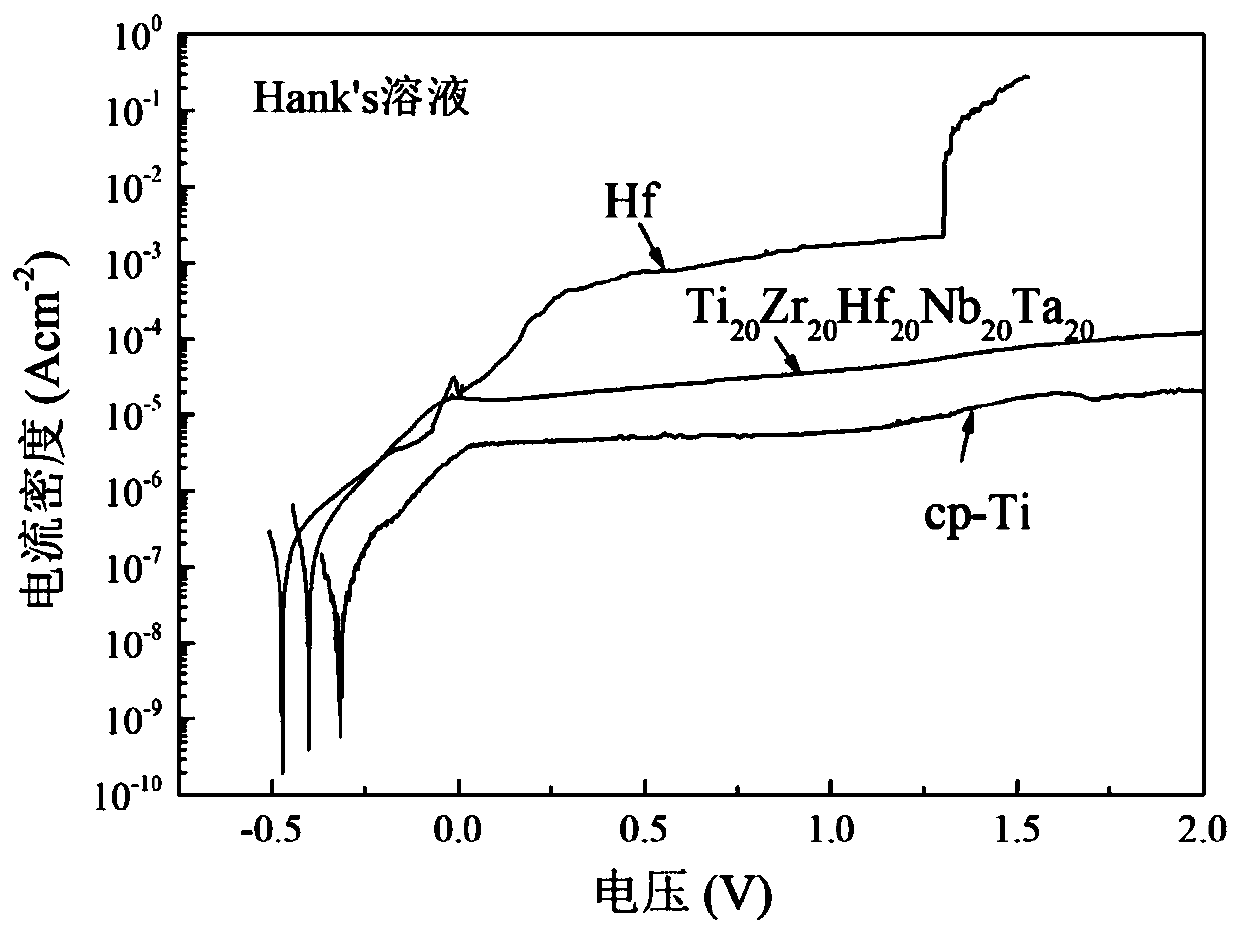

Biomedical Ti-Zr-Hf-Nb-Ta series high-entropy alloy and preparing method

InactiveCN110423933AHigh elastic modulusLow elastic modulusTissue regenerationProsthesisHigh entropy alloysUnit model

The invention relates to a biomedical Ti-Zr-Hf-Nb-Ta series high-entropy alloy. The composition general formula of the high-entropy alloy is TiZrHf<c>Nb<d>Ta<e>, wherein a, b, c, d and e are atomic percents, a is larger than or equal to 5 and smaller than or equal to 40, b is larger than or equal to 5 and smaller than or equal to 40, c is larger than or equal to 5 and smaller than or equal to 40, d is larger than or equal to 5 and smaller than or equal to 40, e is larger than or equal to 5 and smaller than or equal to 40, and the sum of a, b, c, d and e is 100. Starting from a TiZr-transition group high-entropy alloy system, a cluster type structure unit model is combined for component design, a low-modulus and high-corrosion-resistance biomedical TiZr-transition group high-entropy alloy with more excellent comprehensive mechanical performance is prepared, and the elasticity modulus of the Ti-Zr-Hf-Nb-Ta series high-entropy alloy is low to 54GPa.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

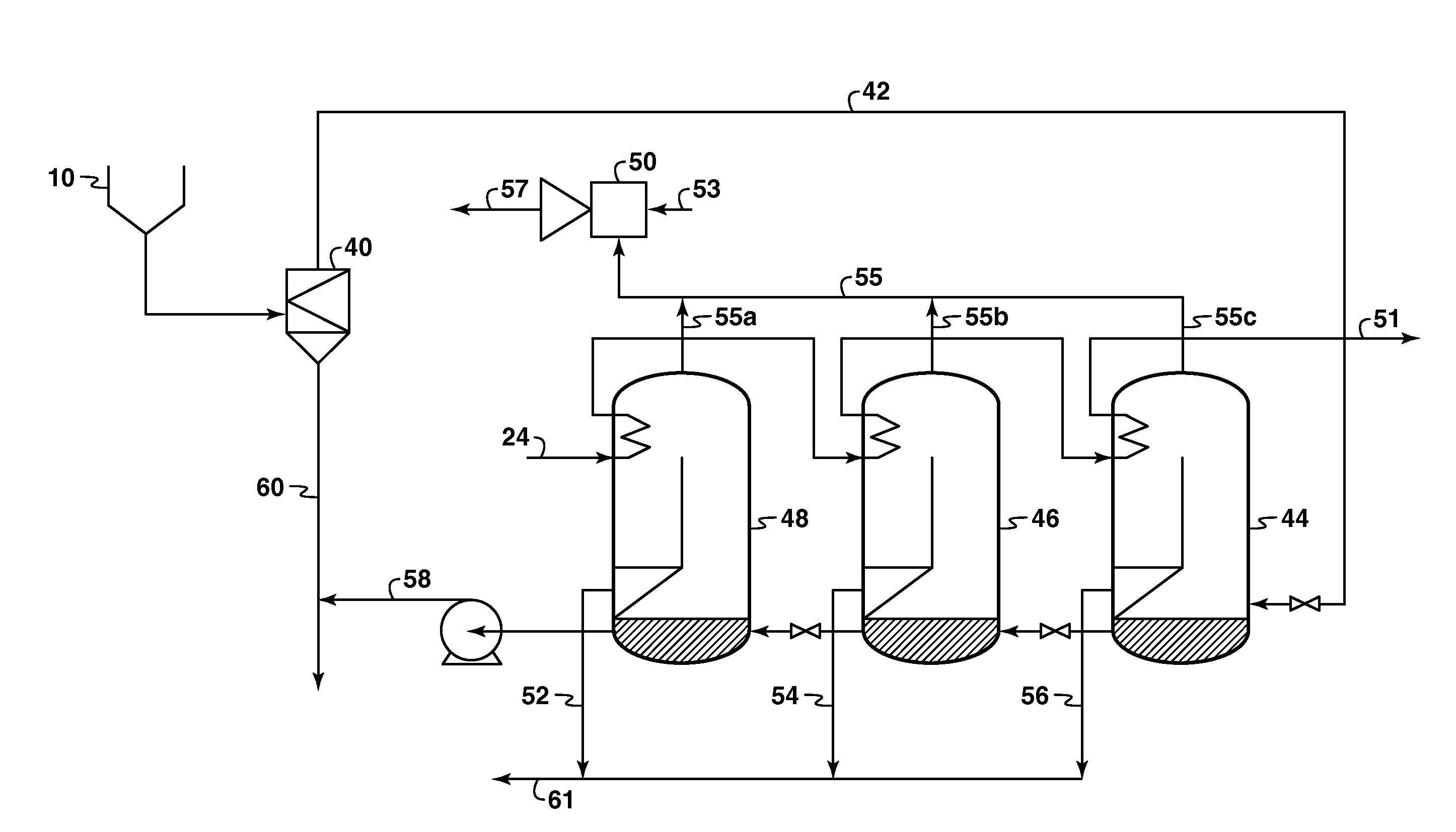

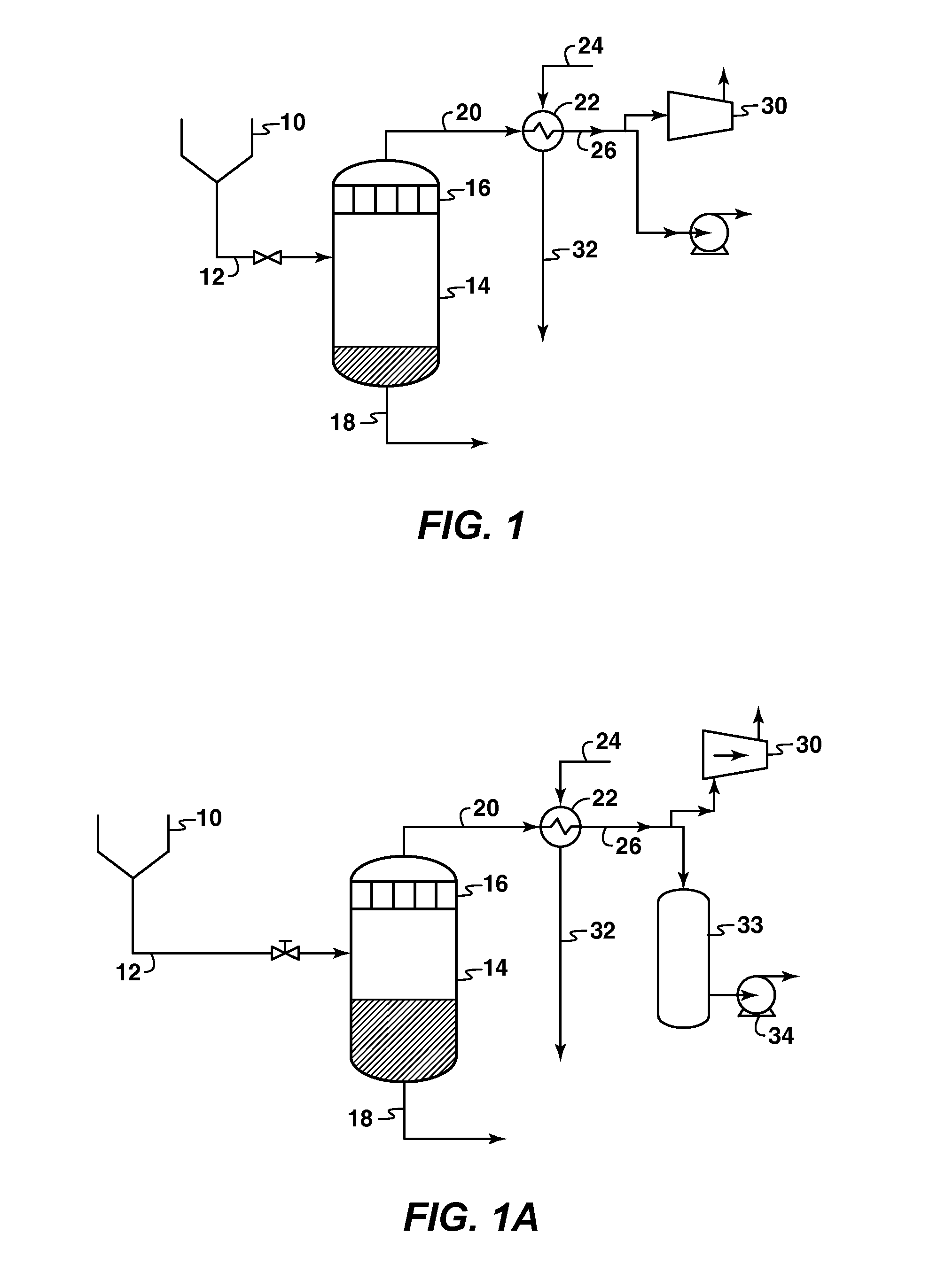

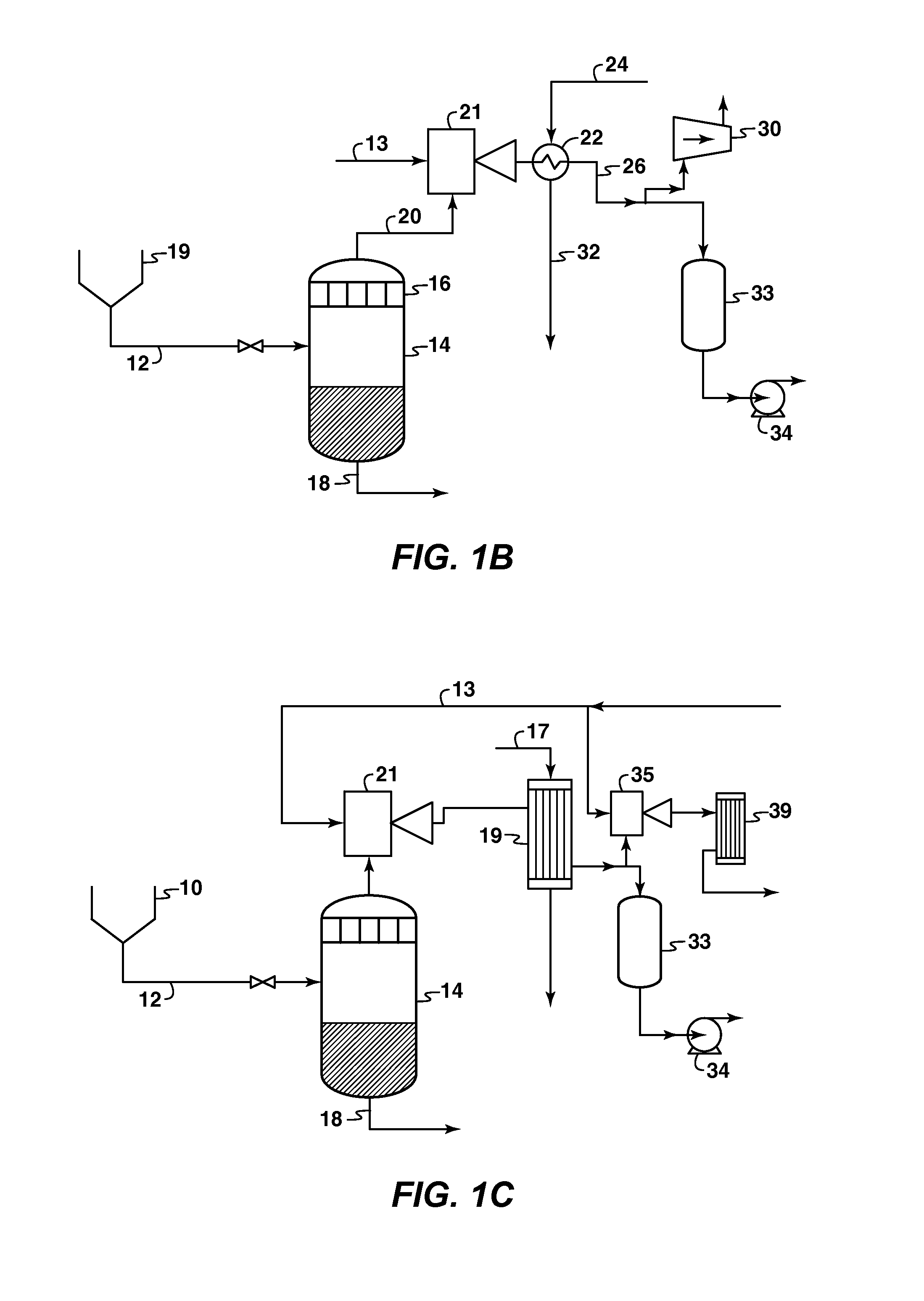

System and method of recovering heat and water and generating power from bitumen mining operations

InactiveUS20100275600A1Improve environmental performanceReducing greenhouse gas emissionThermal non-catalytic crackingAuxillariesEngineeringSlurry

A method recovering heat and water from a warm slurry, such as warm tailings from a oil sands extraction mining operation, is provided. The method comprises providing the tailings to a vacuum vessel, removing, from the vacuum vessel, warm vapor derived from the tailings, condensing the warm vapor in a condenser to produce water, and recovering the water from the condenser. Cool river or pond water can be warmed with the heat from the vapor for additional uses in the mining operation. Essentially pure water can be obtained in the process. This can also be achieved using one or flash vessels in series to condense the vapor. Power can also be generated from the vapor using a turbine.

Owner:EXXONMOBIL UPSTREAM RES CO

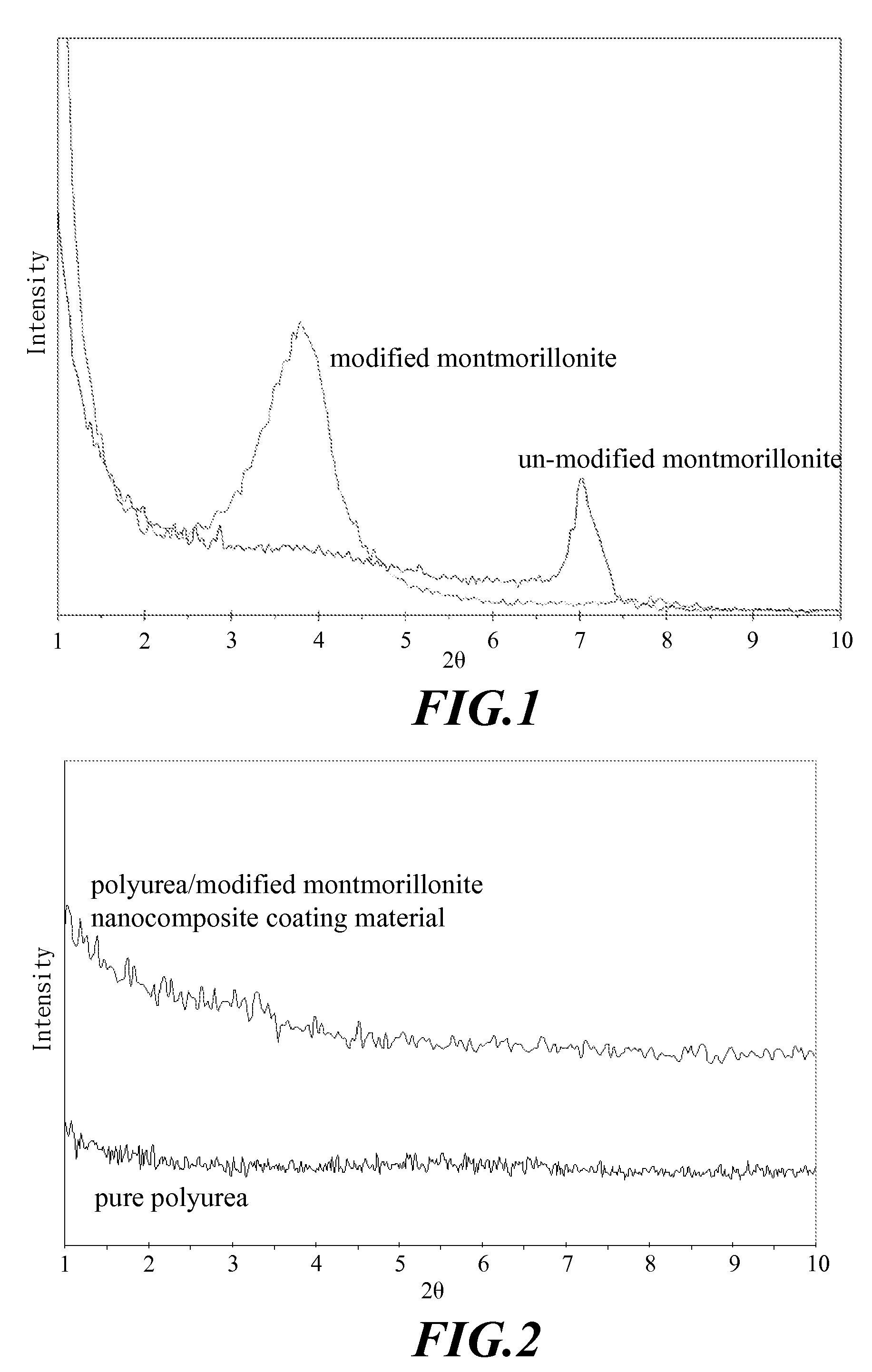

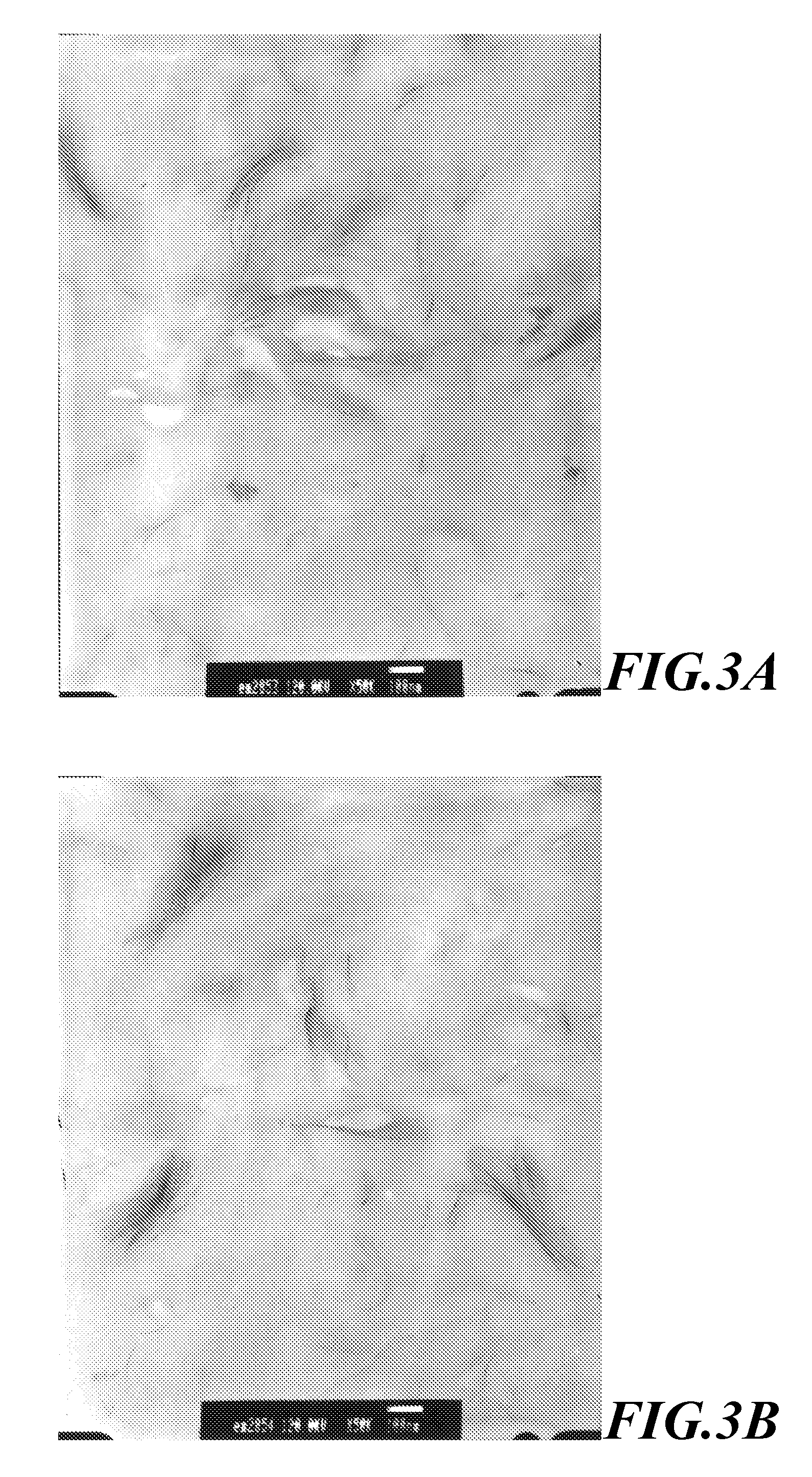

Anticorrosive Nanocomposite Coating Material, and a Preparation Process Thereof

InactiveUS20100119796A1Low corrosion rateSynthetic resin layered productsAnti-corrosive paintsOrganoclayNanocomposite coating

The invention relates to an anticorrosive nanocomposite coating material that comprises polyurea, organophilic clay and suitable additives, and is useful for preparing a polyurea / clay nanocomposites; whereby said nanocomposite coating material is coated on a substrate to greatly decrease the corrosion rate of the substrate; wherein said polyurea is combined from an amino terminated compounds and a isocyanate compound. The invention also provides a process for preparing said nanocomposite coating material, said process comprising: mixing homogeneously said amino terminated compound and an organophilic clay, followed by mixing homogeneously with isocyanate compound and suitable additives at a proper ratio, wherein, after a polymerization reaction, said organophilic clay can achieve a nano-scale dispersion extent, thereby obtaining said anticorrosive nanocomposite coating material.

Owner:BRIGHTEN ENG

Cleaning agent for strong adhesion stain and its application

InactiveCN1597896ASimple production processLow costOrganic detergent compounding agentsNon-ionic surface-active compoundsInorganic saltsFuel oil

The invention is a strongly adhesive fouling detergent and its application, composed of inorganic salt, anionicsurfactant, nonionic surfactant, dispersant, penetrating agent, and anti-sedimentation agent, and as used, it is only necessary to mix with water in a certain proportion. It can effectively eliminate fouling on the pipeline wall to make the pipeline smooth, reducing oil transporting pressure and increasing oil output, the corrosivity is extremely low, and it forms passive film on the pipeline wall to reduce fouling speed, having no pollution to the environment. It can be used to wash other metal surfaces, fuel oil devices.

Owner:山东恒冠化工科技有限公司

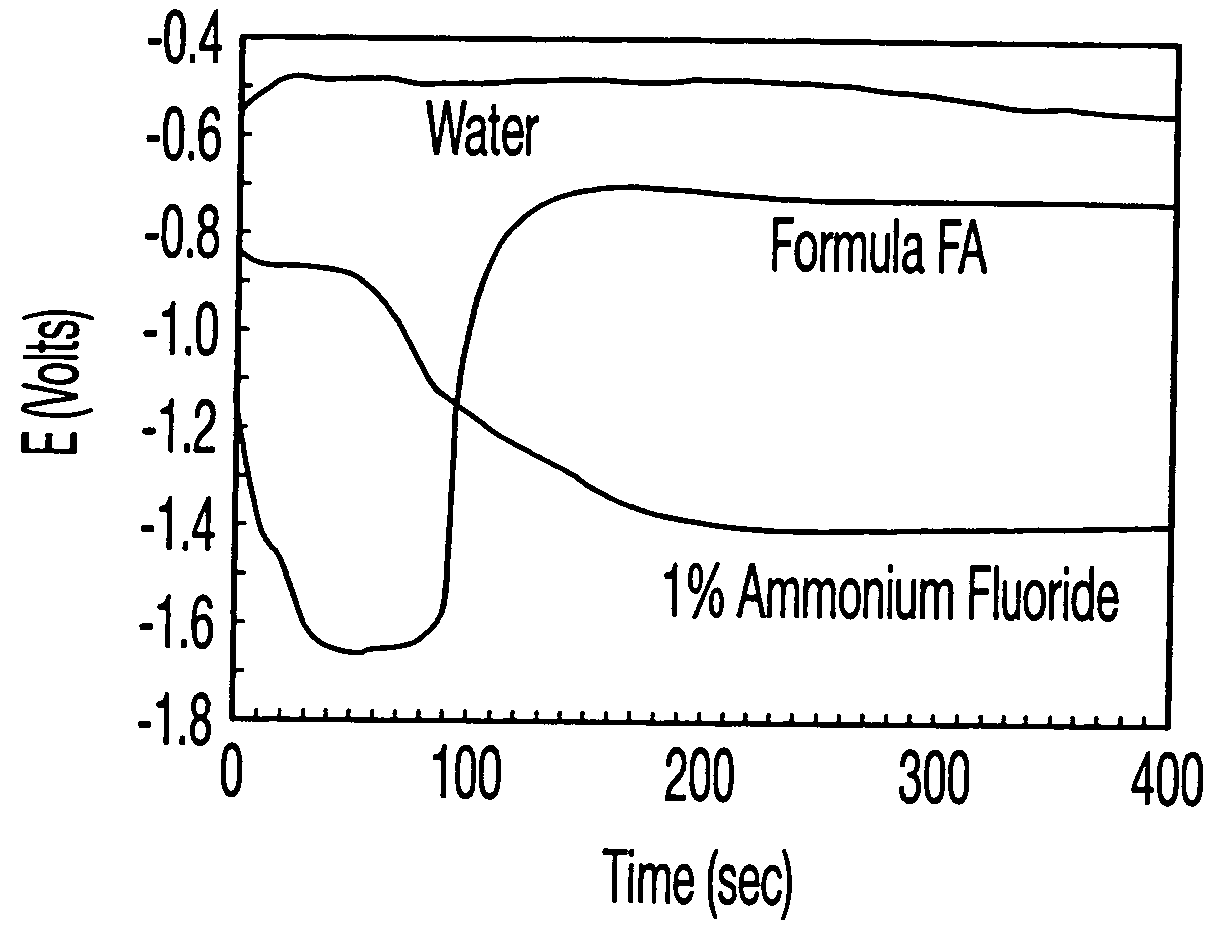

Forming a passivating aluminum fluoride layer and removing same for use in semiconductor manufacture

InactiveUS20060000492A1Enhance clean action and cleaning capabilityEffective temperatureDetergent mixture composition preparationSemiconductor/solid-state device manufacturingSolventFluoride salt

A composition for the cleaning of residues from substrates can contain from about 0.01 percent by weight to about 5 percent by weight of one or more fluoride compounds, from about 20 percent by weight to about 50 percent by weight water, from about 20 percent by weight to about 80 percent by weight of an organic amide solvent and from 0 to about 50 weight percent of an organic sulfoxide solvent. The composition can have a pH between about 7 and about 10, alternately from greater than 8 to about 10. Additionally, the composition optionally can contain corrosion inhibitors, chelating agents, surfactants, acids, and / or bases. In use of the composition, a substrate can advantageously be contacted with the composition for a time and at a temperature that permits cleaning of the substrate.

Owner:EKC TECH

Photoresist stripping solution

InactiveCN102012645AEasy to removeReduce corrosionPhotosensitive material processingResistPhysical chemistry

The invention relates to a photoresist stripping solution, in particular to a stripping solution suitable for residual photoresist on a semiconductor substrate. The photoresist stripping solution comprises the following raw materials in parts by weight: 1-15 parts of hydrazine hydrate or organic amines, 10-45 parts of solvent, 0.1-5 parts of etchant resist and the balance of pure water. The invention has the following advantages: 1, the photoresist stripping solution is suitable for stripping etched photoresist in an integrated circuit and an oversized integrated circuit; 2, the photoresist stripping solution can be used for eliminating etched photoresist films easily, has minimized corrosion on metal wires and is environment-friendly; and 3, the photoresist stripping solution can be used for rapidly washing the photoresist and residual photoresist on wafers so that no residues are on the wafers, and the photoresist stripping solution has low corrosion rate on substrate materials and metal wires.

Owner:东莞市智高化学原料有限公司

Light composite electro-catalysis energy-saving anode for non-ferrous metal electro-deposition and preparation method thereof

The invention relates to a light composite electro-catalysis energy-saving anode for non-ferrous metal electro-deposition, which is composed of a metal substrate, an interlayer and a composite electro-catalysis superficial layer in sequence from inside to outside, wherein the metal substrate is Al or Al base alloy (Al-M1), the interlayer is a composite layer Al2O3-(Pb-M2) composed of Al2O3 or Pb base alloy, and the composite electro-catalysis superficial layer is a composite deposite (Pb-M2)-M3Ox composed of Pb or Pb base alloy and oxide catalyst or a composite deposite PbO2-M3Ox composed of PbO2 and oxide catalyst. The preparation method of the anode comprises the following steps: preparation of the metal substrate: carrying out anodic oxidation on the metal substrate surface and prefabricating a multihole Al2O3 layer; then performing an electro-deposition Pb or Pb base alloy layer on the multihole Al2O3 layer; and plating a (Pb-M2)-M3Ox or PbO2-M3Ox composite superficial layer on the surface of the Pb or Pb base alloy layer. The anode prepared by the invention can effectively reduce production energy consumption, improve cathode product quality, lower labor intensity, is suitable for industrialized production and can replace the Pb base alloy anode applied in the existing industry.

Owner:KUNMING HENDERA SCI & TECH

Process for reducing plume opacity

Plume is mitigated by targeting treatment chemicals to locations in a furnace, which are connected with plume opacity. The effectiveness of targeted in furnace injection, in fuel introduction and in furnace introduction of slag and / or corrosion and / or plume control chemicals are determined, as are the effectiveness of targeted in furnace injection, in fuel introduction and in furnace introduction of combustion catalysts. Then, the effectiveness of various combinations of the above treatments are determined, and a treatment regimen employing one or more of the above treatments is selected. Preferred treatment regimens will contain at least two and preferably three of the treatments. Chemical utilization and boiler maintenance can improved as LOI carbon, slagging and / or corrosion are also controlled.

Owner:FUEL TECH

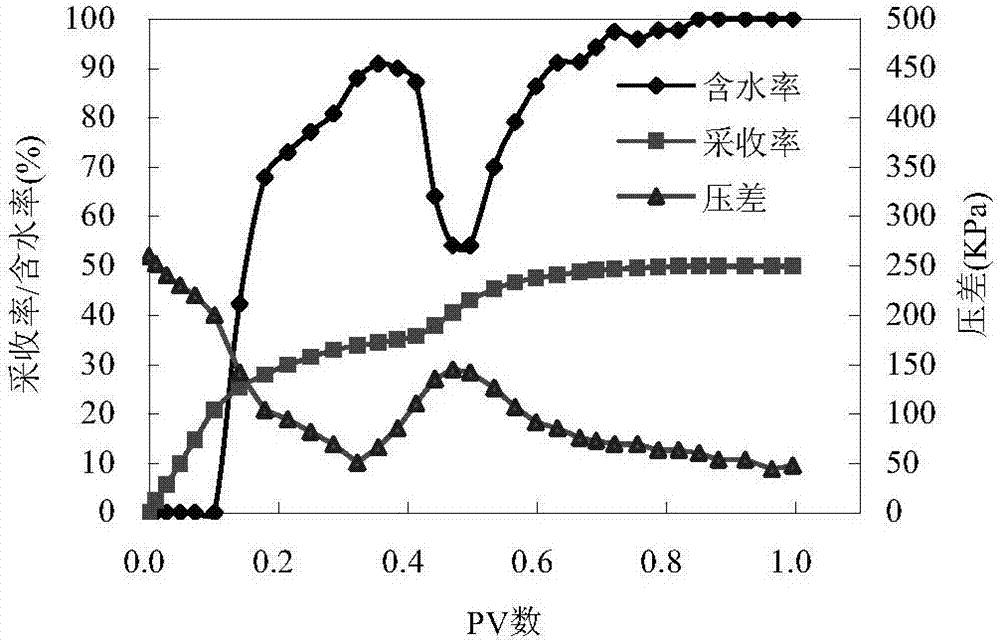

Foamer and foam gas flooding method

ActiveCN107227147APlugged channelingFoaming fastFluid removalDrilling compositionAlcoholInjection equipment

The invention relates to the field of foam flooding and discloses a foamer and a foam gas flooding method. The foamer comprises a weak-cationic amphoteric surfactant, water and at least one of cationic surfactant, amphoteric surfactant and alcohol. The foam gas flooding method comprises the steps of injecting the weak-cationic amphoteric surfactant containing foamer and gas into an oil reservoir, and carrying out foam profile control and oil displacement. According to the foamer and the method, disclosed by the invention, the foamer has high foamability, stability and profile control and oil displacement capability, so that the corrosion action on injection equipment and an oilfield injection-production system caused by air foam in an air foam flooding profile control and oil displacement process can be obviously lowered; and the foamer not only can be applied to a foam profile control and oil displacement process of ordinary strata, but also can be applicable to the foam profile control and oil displacement process under the condition that stratum water is high in degree of mineralization and high in calcium and magnesium ion content.

Owner:CHINA PETROLEUM & CHEM CORP +1

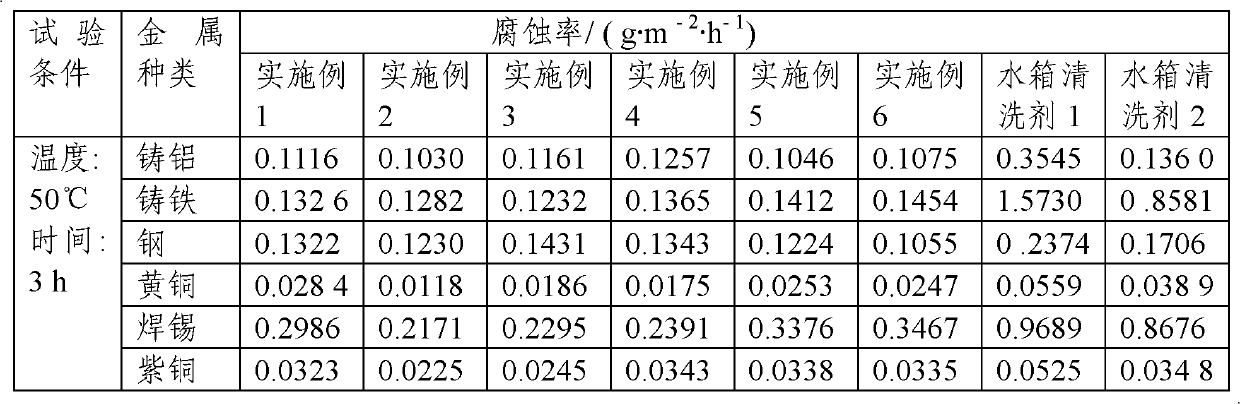

Cleaning agent for automobile cooling system

The invention provides a cleaning agent for an automobile cooling system. The cleaning agent comprises, by weight, 3 to 20% of glycolic acid, 2 to 9% of citric acid, 2 to 10% of methanesulfonic acid, 1 to 10% of ammonium citrate, 0.5 to 7% of a corrosion inhibitor and 0.01 to 2% of a surfactant, with the balance being deionized water. The cleaning agent for the automobile cooling system in the invention can effectively remove calcium scale, magnesium scale and iron rust in the cooling system, is applicable to cleaning of a variety of materials like carbon steel, iron, copper and aluminum in a cooling system of an engine and has the advantages of high efficiency, mildness and a low corrosion rate. The cleaning agent is applicable to general repair and maintenance of an automobile and is used for removing dirt generated due to usage of water as a cooling medium so as to increase the efficiency of heat transfer between the engine and the cooling medium and enable operation of the engine to be smoother.

Owner:CHINA PETROLEUM & CHEM CORP

Composite scale and rust cleaning agent

The invention relates to a chemical cleaning agent, in particular to a composite scale and rust cleaning agent, which comprises a corrosion inhibitor, a water-based surfactant and water. The composite scale and rust cleaning agent is characterized by being prepared from the following raw materials in percentage by mass: 0.3 to 1 percent of corrosion inhibitor, 0.05 to 0.1 percent of water-based surfactant, 80 to 94 percent of water, 5 to 15 percent of inorganic acid and 1 to 5 percent of glycollic acid. The inorganic acid is combined with the glycollic acid in a certain ratio, so that the composite scale and rust cleaning agent can effectively integrate advantages of various pickling cleaning agents, ensures descaling efficiency and can be prevented from corroding pipelines and equipment.

Owner:淄博福世蓝高分子复合材料技术有限公司

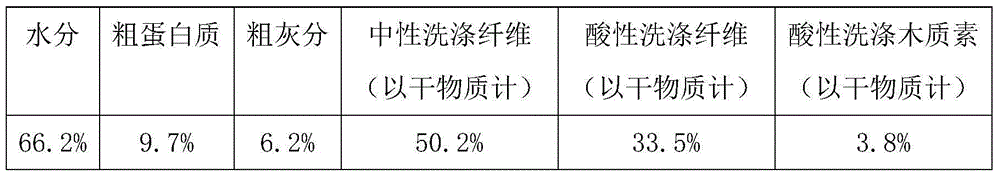

Preparation method of whole corn silage

The invention provides a preparation method of whole corn silage. The preparation method comprises the following steps: cleaning and disinfecting a silage silo, digging drains around the silage silo, paving plant fibers on the bottom of the silo and paving a separating membrane on the wall of the silo; harvesting corn plants and chopping the whole plants in the milk-ripe stage of corn; filling and compacting silage raw materials layer by layer until the height of the silage raw materials exceeds the silo depth, and after filling, sprinkling table salt on the top layer of the silage raw materials; and covering the silage raw materials with the part of the separating membrane outside the silage silo, sequentially paving a waterproof membrane and a light-shading membrane on the separating membrane, placing a balancing weight on the light-shading membrane, and fermenting the silage raw materials in the silage silo so as to obtain silage. The silage prepared by the method disclosed by the invention is free from the addition of any silage additive, therefore preparation cost is low; and the silage prepared by the method disclosed by the invention is good in palatability and high in nutritive value, and corrosion rate is less than 1%.

Owner:QICHUN HENGLI ANIMAL HUSBANDRY

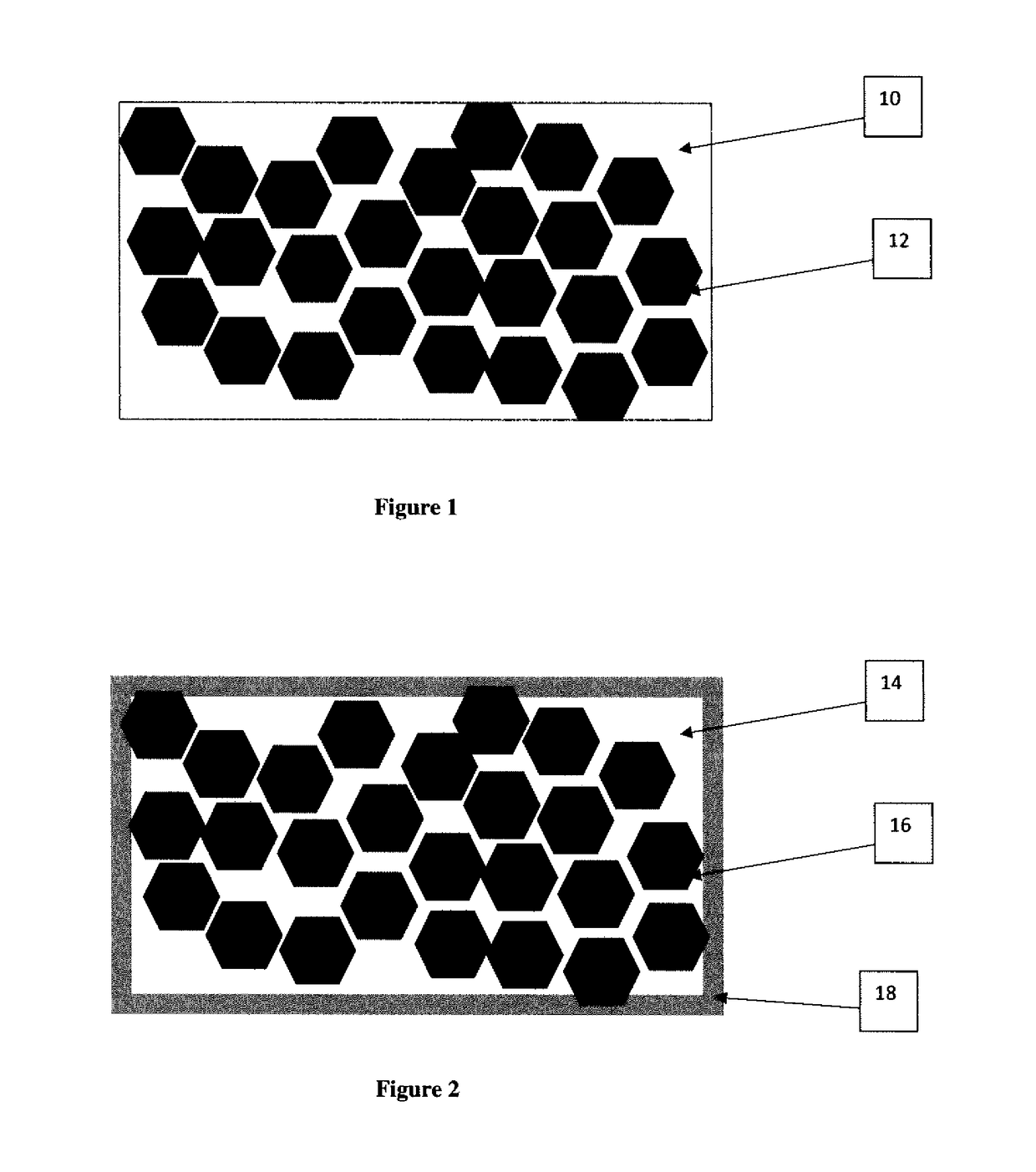

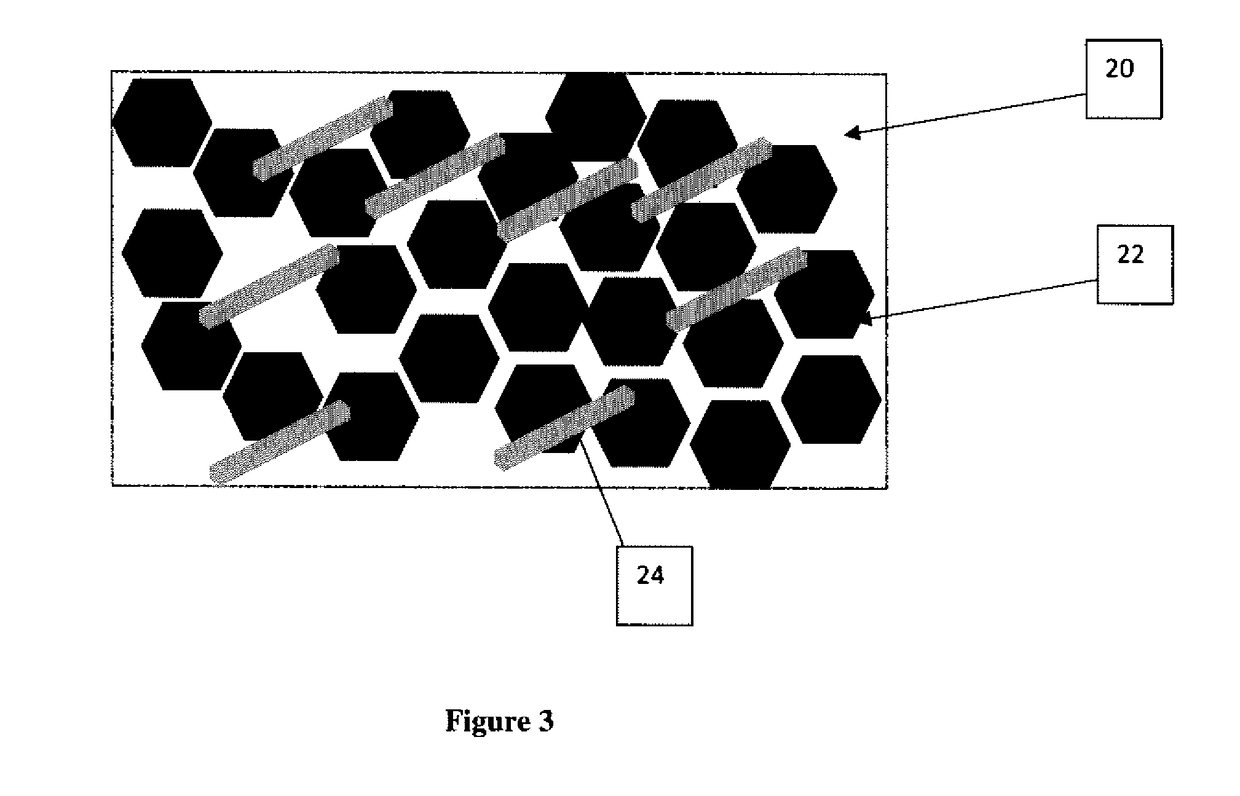

Degradable Metal Matrix Composite

The present invention relates to the composition and production of an engineered degradable metal matrix composite that is useful in constructing temporary systems requiring wear resistance, high hardness, and / or high resistance to deformation in water-bearing applications such as, but not limited to, oil and gas completion operations.

Owner:TERVES

Neutral blockage removing agent composition used for oil recovery formation in oilfield and preparation method thereof

ActiveCN104194758ALow corrosion rateUnblocking safetyDrilling compositionButanedioic acidSuccinic acid

The invention relates to a neutral blockage removing agent composition used for an oil recovery formation in an oilfield. The neutral blockage removing agent composition is prepared from the following raw materials in parts by weight: 10-14 parts of polyepoxysuccinic acid amine, 35-40 parts of diethylenetriaminepentaacetic acid amine, 33-37 parts of hydroxyl succinic acid amine, 20-25 parts of polyacrylamide, 7-10 parts of sodium polyaspartate, 10-14 parts of sodium gluconate, 10-15 parts of activated clay, 20-25 parts of potassium peroxodisulfate, 9-11 parts of hydroxyl butanedioic acid amine, 4-7 parts of sodium salicylate, 5-9 parts of hexamethylene tetramine, 0.2-0.3 part of vanadium pentoxide, 2-5 parts of starch, 5-8 parts of alpha-sulphonated fatty acid methyl ester and derivative thereof (MES) and 0.1-0.3 part ofdiethyl ethanolamine. The neutral blockage removing agent composition is used for the blockage removal of an oil pumping well and a screw pump well in the oilfield, can effectively solve the problems of cleaning blockage removal of the oil pumping well and the screw pump well in the oilfield and the corrosion of oil recovery equipment, has high blockage removing speed, is neutral and is free of corrosion; waste liquid for blockage removal can be degraded and does not need to be discharged onto the ground to be subjected to sewage treatment, no corrosion, dead angle, precipitation or secondary well blockage are generated, and more safety and more reliability are realized as compared with traditional pickling blockage removing, biological blockage removing and solvent blockage removing.

Owner:兰州熙瑞化工科技有限公司

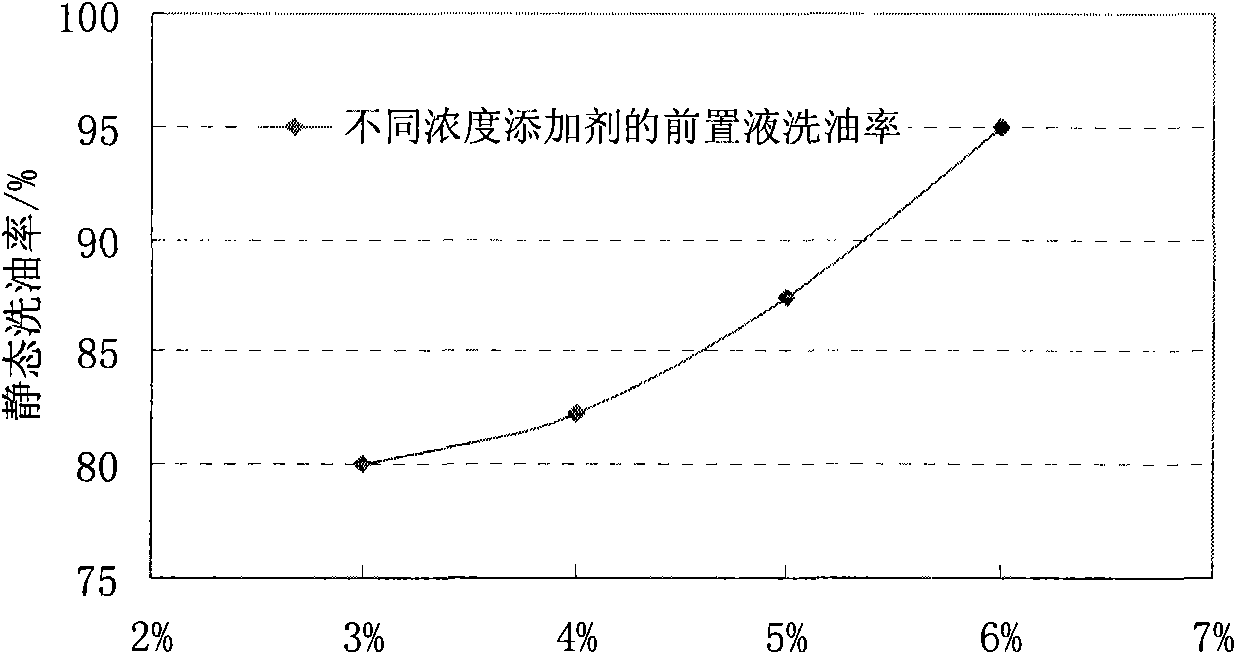

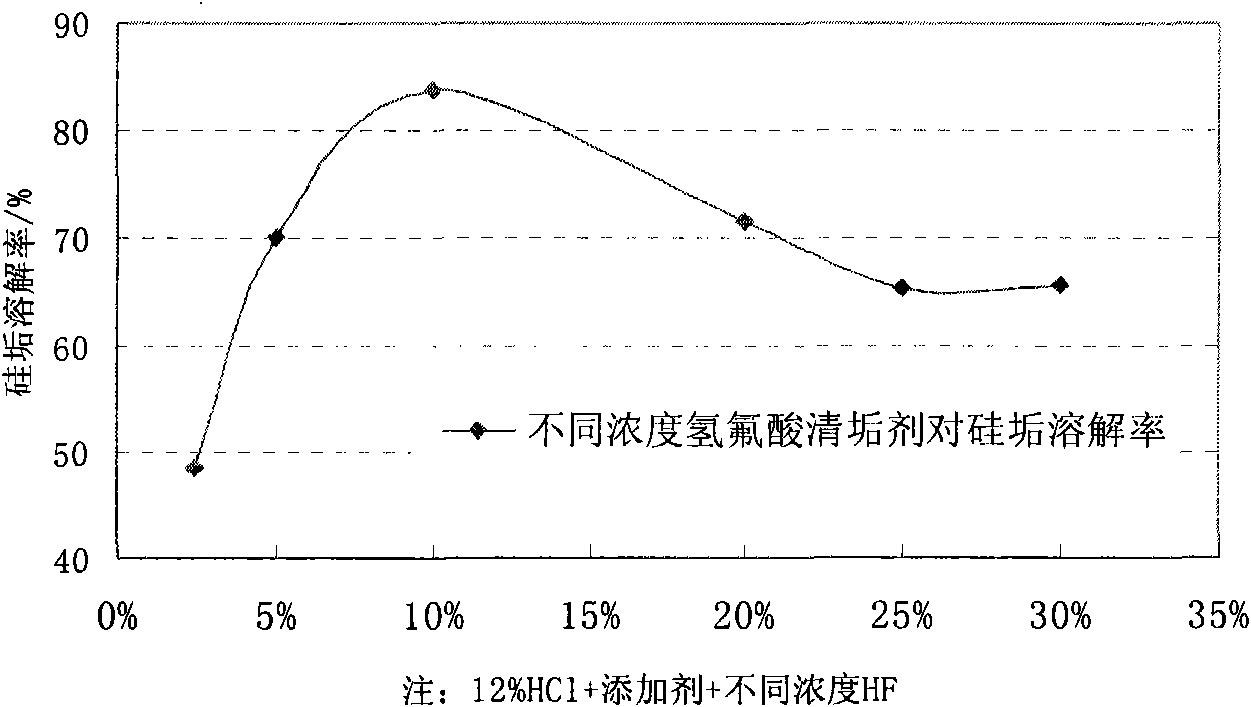

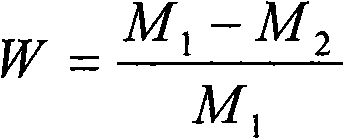

Silicate scale clearing agent for ternary combination flooding extraction well

The invention discloses a silicate scale clearing agent for a ternary combination flooding extraction well. The silicate scale clearing agent consists of prepad fluid and scale clearing main agent. The prepad fluid consists of 6% of additive (SYQ-II) and the balance of water. The additive (SYQ-II) consists of sodium dodecyl benzene sulfonate (ABS), nonyl phenol polyethenoxy ether (OP10) and ethylene glycol monobutyl ether with the ratio of 3:1:2. The scale clearing main agent consists of 12% of hydrochloric acid, 10% of hydrofluoric acid, 2% of glacial acetic acid, 0.2% of citric acid, 0.5% indoor-synthesized imidazoline type corrosion inhibitor (YC-II) and the balance of water. The scale clearing agent achieves a silicate scale clearing rate up to 80%, and can effectively clear silicate scale at an oil well pump cylinder, a rod pipe and other positions and prolong the pump examination period of the extraction well.

Owner:PETROCHINA CO LTD +1

Preparation method of control agent for coal dust pollution

InactiveCN101575500ALow costWide variety of sourcesOther chemical processesBuilding constructionsPolyvinyl alcoholDust control

The invention relates to a preparation method of a control agent for coal dust pollution. The preparation method adopts the components with the following weight portions: 1 to 3 portions of polyvinyl alcohol (PVA), 2 to 3 portions of industrial starch, 1 to 1.5 portions of glutinous rice flour, 85 to 95 portions of water, 1 to 2 portions of polyoxyethylene nonylphenol ether and 1 to 2 portions of sodium humate. The control agent is prepared by mixing and evenly stirring the materials. The sodium humate contains 40 percent to 60 percent of humic acid and 10 percent to 20 percent of natrium. The control agent is characterized by low cost, wide material source, stable performance, wide application, innocuity and harmlessness, low corrosion rate, no odor and the like, as well as high inhibition rate, remarkable dust suppression effect, good frost resistance performance and the like. The technique that blending the control agent and spraying the control agent on the surface are combined is adopted in large-sized coal mines, ports and coal storage in China, thus realizing dust control and flame retardancy during production, storing and transporting processes of coals.

Owner:SHIJIAZHUANG XINBANGER ENERGY SAVING TECH CO LTD

CuC1 thermochemical cycle for hydrogen production

InactiveUS20080283390A1Low corrosion rateLow production costSludge treatmentElectrostatic separatorsCross-linkEthylene vinyl alcohol copolymer

An electrochemical cell for producing copper having a dense graphite anode electrode and a dense graphite cathode electrode disposed in a CuCl solution. An anion exchange membrane made of poly(ethylene vinyl alcohol) and polyethylenimine cross-linked with a cross-linking agent selected from the group consisting of acetone, formaldehyde, glyoxal, glutaraldehyde, and mixtures thereof is disposed between the two electrodes.

Owner:GAS TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com