Descaling agent for cleaning central air conditioner main machine

A technology of central air conditioner and rust remover, applied in the field of descaling and rust remover, can solve the problems of unsatisfactory descaling effect, lowering refrigeration effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

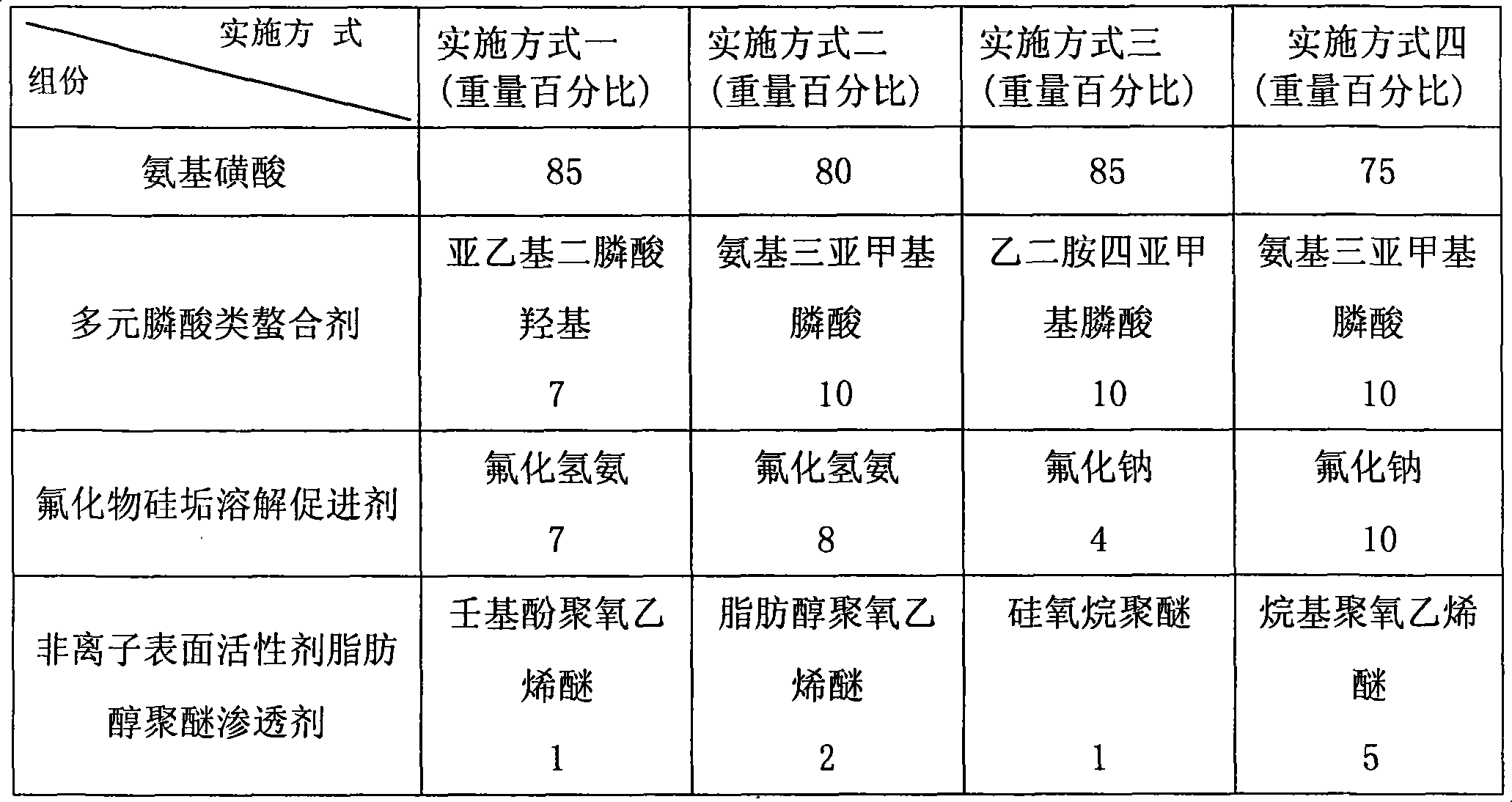

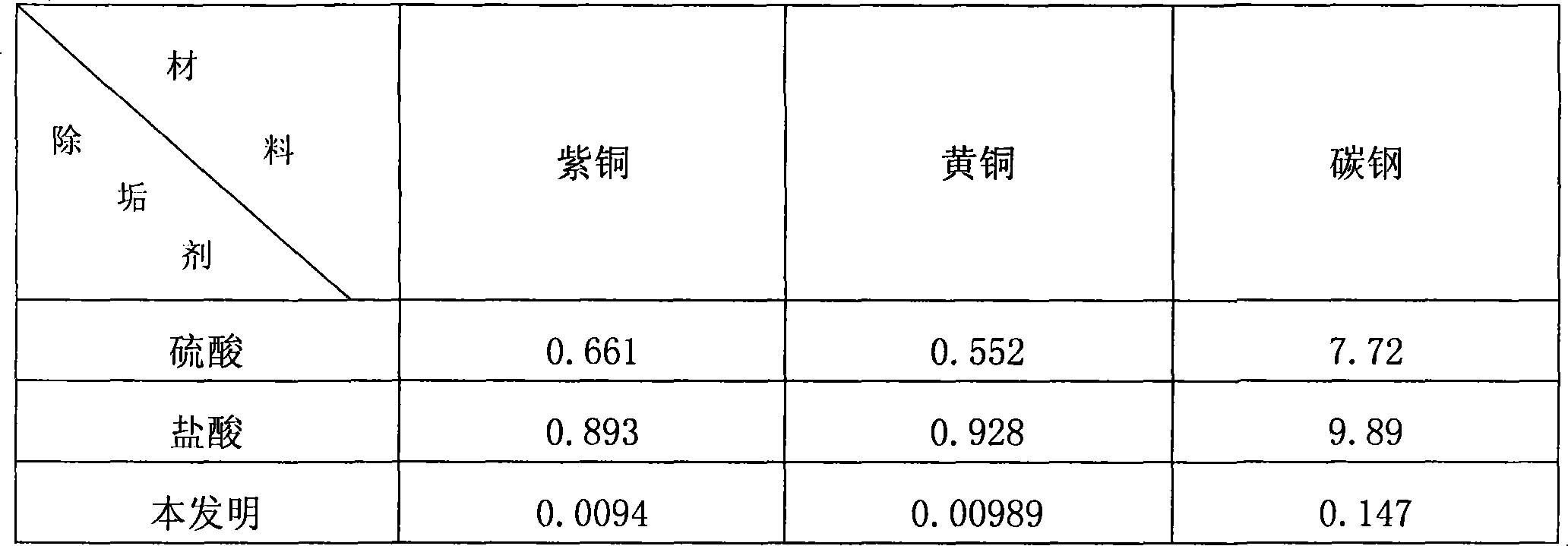

[0015] The descaling and rust removing agent of the present invention comprises a solid mixture and a liquid corrosion inhibitor, and the solid mixture consists of 75%-85% sulfamic acid, 5%-10% polyphosphonic acid chelating agent, 5%-10% fluoride It is prepared by mixing a silicon scale dissolution accelerator and 1%-5% non-ionic surfactant fatty alcohol polyether penetrating agent, and the percentages of the above-mentioned components refer to the percentages of each component in the total weight of the mixture. The polyphosphonic acid chelating agent can be selected from any one of hydroxyethylene diphosphonic acid, amino trimethylene phosphonic acid, and ethylenediamine tetramethylene phosphonic acid, and the fluoride silicon scale dissolution accelerator can be selected from fluorine One of sodium chloride and ammonium hydrogen fluoride; non-ionic surfactant fatty alcohol polyether penetrating agent can choose nonylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com