Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "Strong corrosion inhibition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clean viscous acid for acid fracturing of carbonate reservoir

ActiveCN102453480AGood retarding performanceExtended service lifeDrilling compositionAcid etchingHydrogen-Ion Concentrations

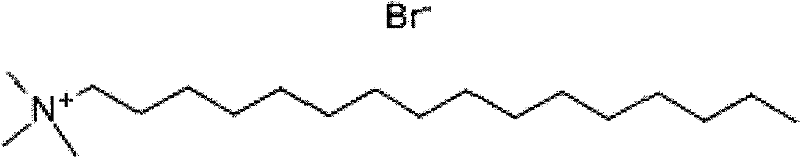

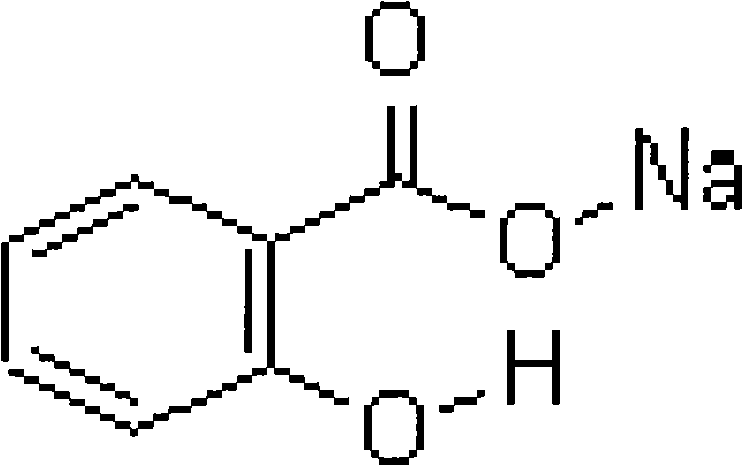

The invention discloses a clean viscous acid for acid fracturing of a carbonate reservoir, which is applied to the technical fields of acidification and acid fracturing of petroleum carbonate reservoirs. The clean viscous acid consists of the following components in percentage by weight: 3-7 percent of hexadecyl trimethyl ammonium bromide, 0.3-0.7 percent of sodium salicylate, 15-28 percent of hydrochloric acid, 0.125-0.25 percent of citric acid or 0.05-0.1 percent of CX-301 or 0.3-0.5 percent of TW-1 serving as an iron ion stabilizing agent, 0.2-0.25 percent of a diimidazoline quaternary ammonium salt and the balance of water. The clean viscous acid has high retardative property, the retarding rate can reach 42-56 percent, the fresh acid viscosity is 25-40 mPa.S, and the acid liquor viscosity rises during acid fracturing of the carbonate reservoir. When the hydrogen ion concentration falls till the pH is more than or equal to 2, the acid liquor viscosity rises for forming viscoelastic gel, the permeation resistance of an acid liquor in a high permeation layer is increased, and the length of an acid etching crack is prolonged. Reacted residual acid gel can undergo gel breaking automatically, is free from residues, is easy for discharging, and has small damage to stratums.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

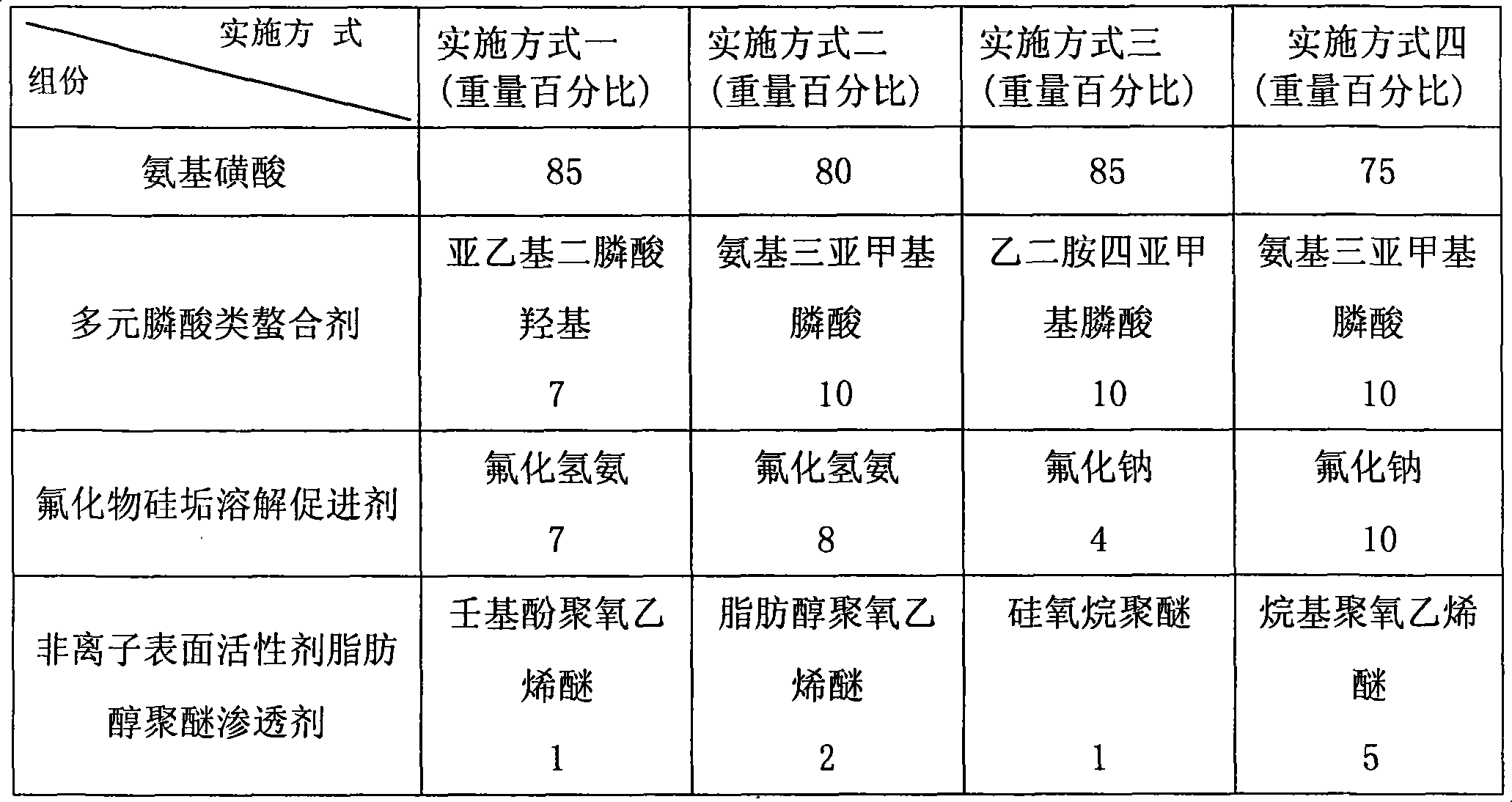

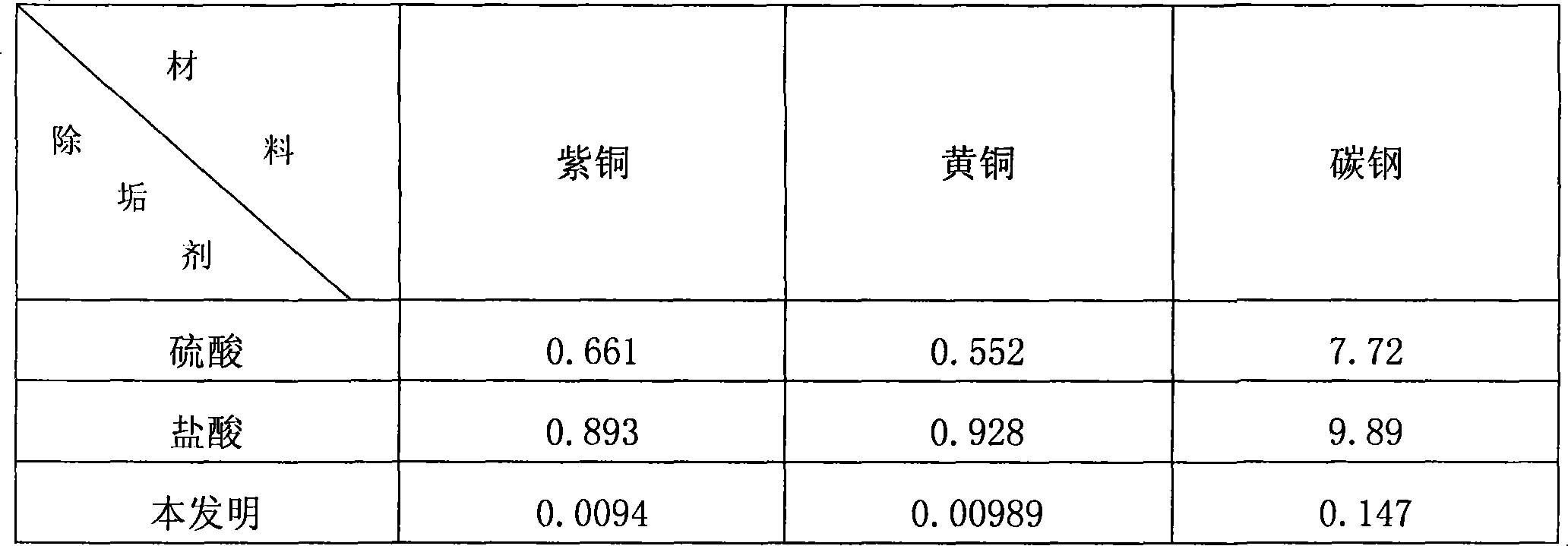

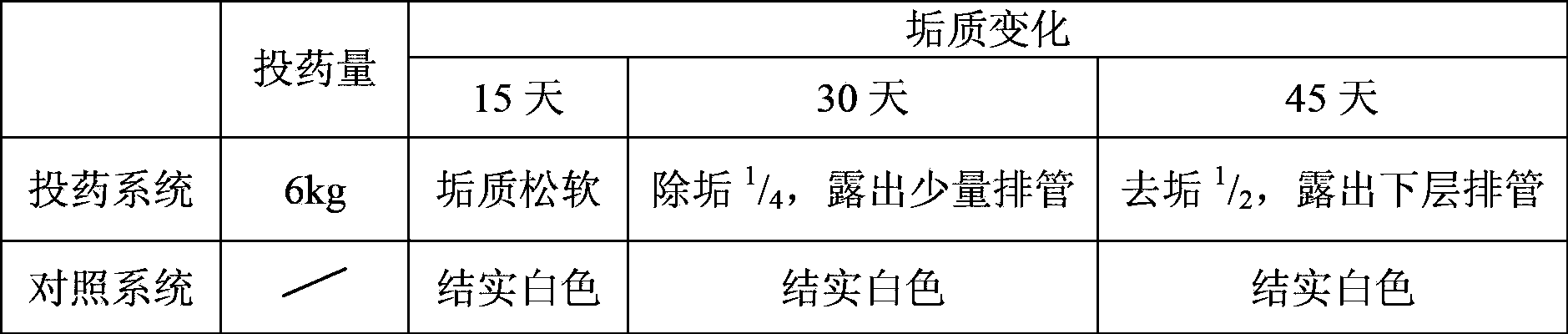

Descaling agent for cleaning central air conditioner main machine

InactiveCN101086065ASolve cleaning problemsStrong acidity of solid organic acidPolyesterHexamethylenetetramine

The invention relates to a scale and rust remover used for cleaning main frame of central air-conditioner. It is characterized in that it comprises solid mixture and liquid inhibitor; said solid mixture comprises amidosulfonic acid, polyphosphinic acid chelating agent, silicofluoride scale and rust dissolution promotor, non-ionic surface activator aliphatic alcohol polyester penetrant, their weight proportions in order are as follows: 75%-85%, 5%-10%, 5%-10%, 1%-5%; said inhibitor is liquid and comprises hexamethylene tetramin, aniline and methyl azimido-benzene according to weight proportion of 2: 2: 1. Said inhibitor is added into acidic washing solution with its weight amount being 0.3% of that of water amount. The product can dissolve carbonate, silicate, sulfate and iron oxide, the descaling speed at room temperature is fast, and is increased within 60 Deg. C, the corrosive rate to metal is pretty low, and there is no acid mist and harmful gas generation during desaling process.

Owner:长沙科惠洁水质处理服务有限公司

Austenitic stainless steel cleaning and passivating agent

InactiveCN109487280AAccelerated corrosionLess corrosiveMetallic material coating processesPhosphoric acidYttrium

The invention discloses an austenitic stainless steel cleaning and passivating agent. The austenitic stainless steel cleaning and passivating agent is composed of, by mass, 30%-40% of citric acid, 0.1%-1% of ethylene diamine tetraacetic acid disodium, 1%-5% of 1-hydroxyethylidene-1,1-diphosphonic acid (HEDP), 3%-8% of glycollic acid, 3%-8% of phosphoric acid, 0.1%-2% of a non-ionic surface activeagent, 0.5%-3% of 322H, 0.5%-1% of sodium dodecylbenzenesulfonate, 0%-0.5% of yttrium nitrate, 0.1%-1% of corrosion inhibitor and the balance water. The prepared degreasing, rust removing and passivating agent has the characteristics of being environment-friendly, free of pungent smell and free of toxicity, harm to people and the environment can be remarkably reduced, and the production cost is effectively reduced.

Owner:安徽笃舜智能装备有限公司

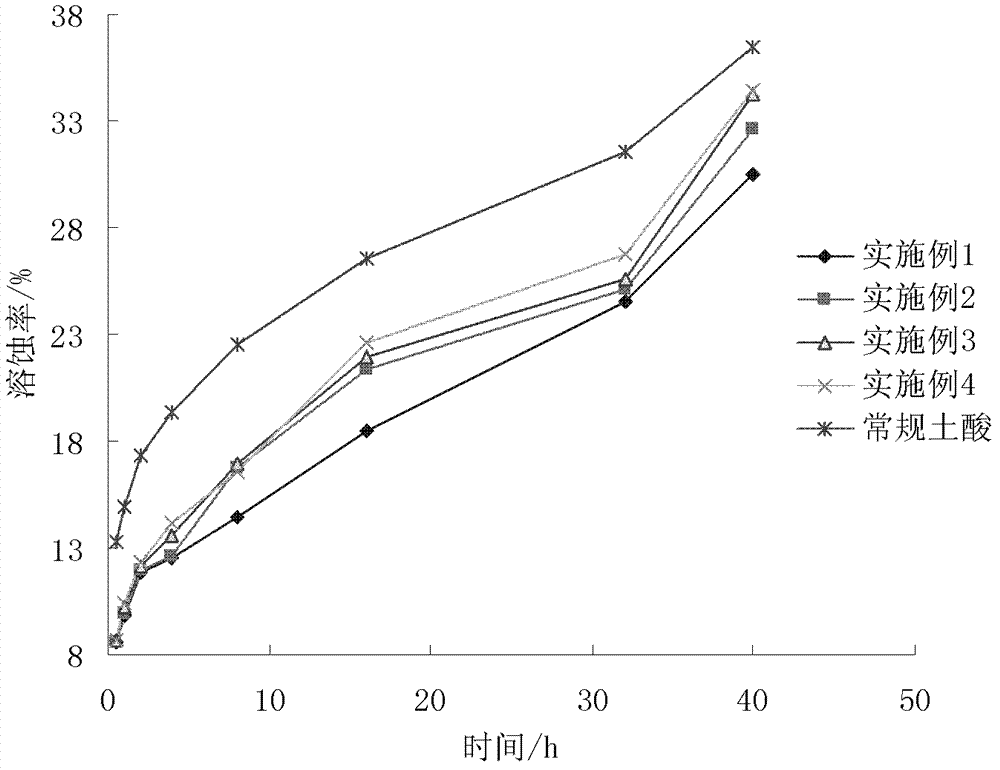

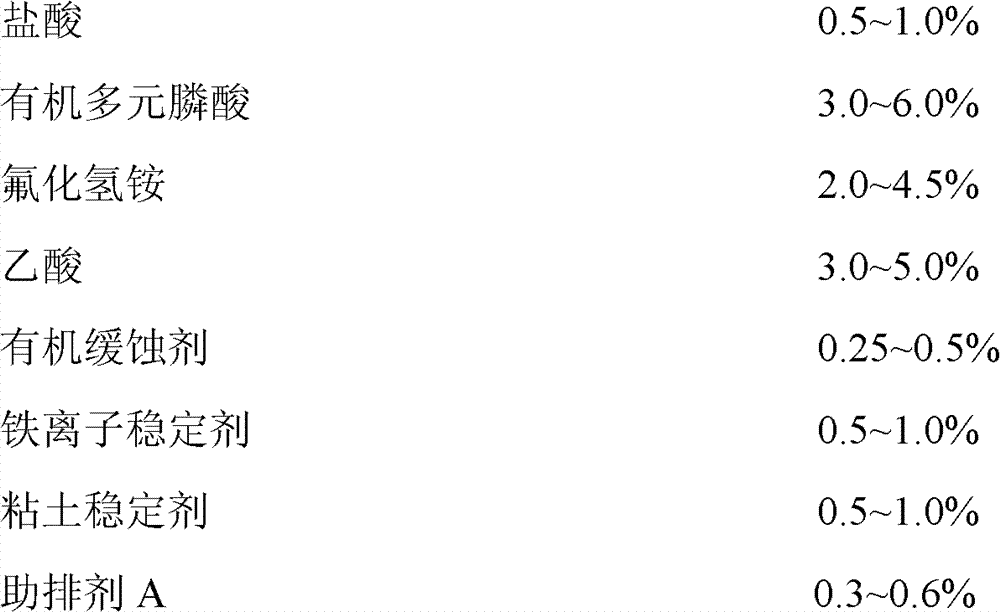

Clastic sandstone gas reservoir acidizing fluid

InactiveCN102899013AEnsure safetyIncrease test throughputDrilling compositionAcetic acidFluorocarbon

The invention relates to a clastic sandstone reservoir acidizing fluid, which comprises, by weight, 0.5-1.0% of hydrochloric acid, 3.0-6.0% of HEDP, 2.0-4.5% of ammonium bifluoride, 3.0-5.0% of acetic acid, 0.25-0.5% of an organic acid corrosion inhibitor Lan-926, 0.5-1.0% of nitilotriacetic acid or iso ascorbic acid, 0.5-1.0% of a polyquaternary anti-swelling agent, 0.3-0.6% of a hydrocarbon chain surfactant peregal O-15 or O-20, 0.3-0.6% of a fluorocarbon chain surfactant FSO-100 or FSN-100 and the balance of water. The acidizing fluid has little corrosion and good cleanup effect, hardly produces secondary precipitation, and has little damage to reservoir.

Owner:PETROCHINA CO LTD

Phosphorus-free corrosion and scale inhibitor for treating strong corrosive water and use concentration detection method thereof

ActiveCN102092863AStable storageStrong corrosion inhibitionScale removal and water softeningFluorescence/phosphorescenceFluorescenceWater quality

The invention provides a phosphorus-free corrosion and scale inhibitor for treating strong corrosive water and application and a use concentration detection method thereof. The phosphorus-free corrosion and scale inhibitor for treating strong corrosive water comprises 20-60% by weight of polyepoxysuccinic acid, 5.5-25% by weight of S-carboxyethyl thiodisuccinic acid, 5-43% by weight of long-chain alkyl polyether amide, 10-35% by weight of quadripolymer containing AMPS (1-Acrylanmido-2-Methylpropanesulfonic Acid), 0.2-1% by weight of benzotriazole, 0.5-5% by weight of water soluble fluorescent compound, 1.5-3% by weight of pH value regulator, 0-15% by weight of zinc salt and 10-40% by weight of deionized water. The phosphorus-free corrosion and scale inhibitor has remarkable corrosion inhibition property. The concentration of the phosphorus-free corrosion and scale inhibitor can be detected by a fluorescent analysis method, and the phosphorus-free corrosion and scale inhibitor is particularly suitable for treating strong corrosive water. The phosphorus-free corrosion and scale inhibitor for treating strong corrosive water is used in industrial circulating cooling water and combined with the use concentration detection method, so that the successful application of the phosphorus-free corrosion and scale inhibitor for treating strong corrosive water in the industrial circulating cooling water becomes possible.

Owner:MAOMING SUNION GUOSONG FINE CHEM

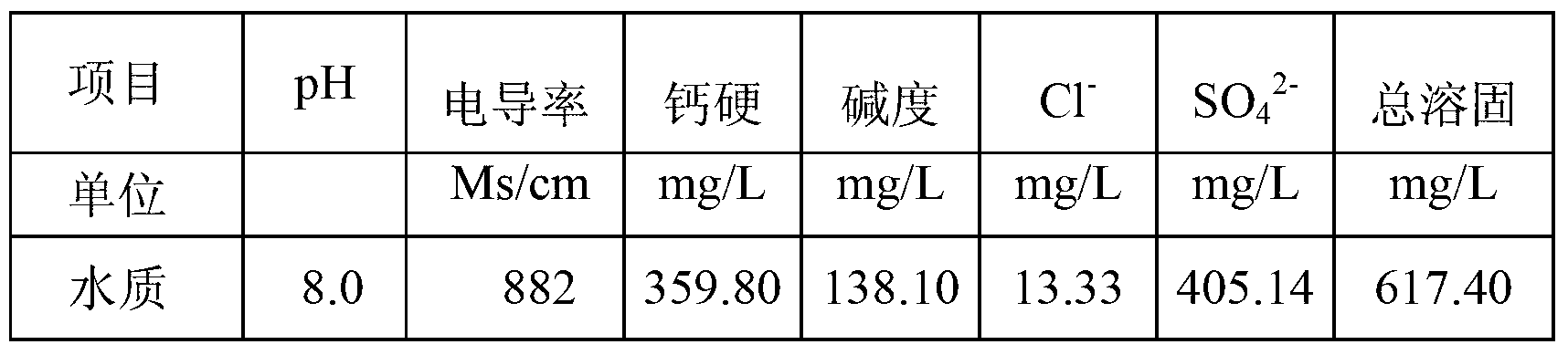

High-efficiency low-phosphorus corrosion and scale inhibiting dispersant and its preparation method

InactiveCN102745825AEasy to realize online automatic dosingImprove controllabilityScale removal and water softeningTungstateTurbidity

The invention discloses a high-efficiency low-phosphorus corrosion and scale inhibiting dispersant and its preparation method. The high-efficiency low-phosphorus corrosion and scale inhibiting dispersant comprises: 2%-12% of sodium benzoate, 1%-5% of molybdate (or tungstate), 1%-2% of thiazole, 3%-6% of anhydrous zinc chloride, 8%-18% of polyphosphonocarboxylate, 5%-15% of acrylic acid-2-methyl-2-acrylamido propane sulfonic acid copolymer, 3%-6% of a stabilizer, 3%-6% of a tracer, and the balance deionized water. The dispersant of the invention can be widely applicable to water quality treatment of circulating water with a sum of hardness and alkalinity of less than 1100mg / L, a chloride ion concentration of less than 1000mg / L, pH of 6.8-9.5, and turbidity of less than 20NTYU. The dispersant provided in the invention has scale and corrosion inhibiting performances able to meet the requirements of industrial circulating water design specifications and a wide source water quality application range, and has the advantages of low phosphorus, environmental protection, strong chlorine resistance, applicability for auto-medicating control, as well as convenient use, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

Non-mercury pulp layered paper of zinc-manganese battery containing high-polymer solid electrolyte

InactiveCN1673455ALower internal resistanceIncrease short circuit currentNon-fibrous pulp additionCell seperators/membranes/diaphragms/spacersInternal resistanceThiourea

The present invention relates to one kind of slurry paper for no-mercury Zn-Mn cell with polymer electrolyte. The slurry paper includes base paper and slurry, and the slurry consists of one kind of polymer gel prepared with coordination ion liquid and organic mercury-replacing buffer liquid. The coordination ion liquid is prepared with urea, thiourea, zinc chloride and ammonium chloride; and the polymer gel is prepared with coordination ion liquid, PVA, PAM, PEG and crosslinking starch in certain proportion. The no-mercury Zn-Mn cell with polymer electrolyte can decrease the internal resistance of cell, improve dynamic discharge performance of cell, prolong the maintenance time and avoid environmental pollution caused by mercury.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

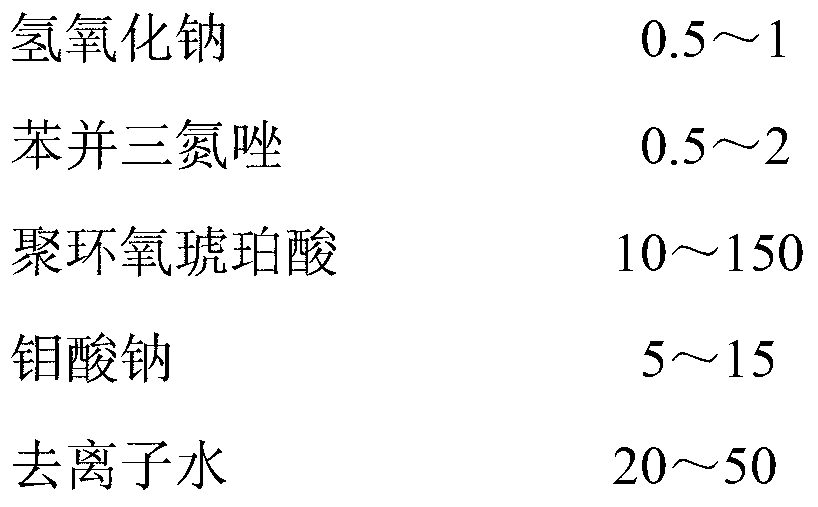

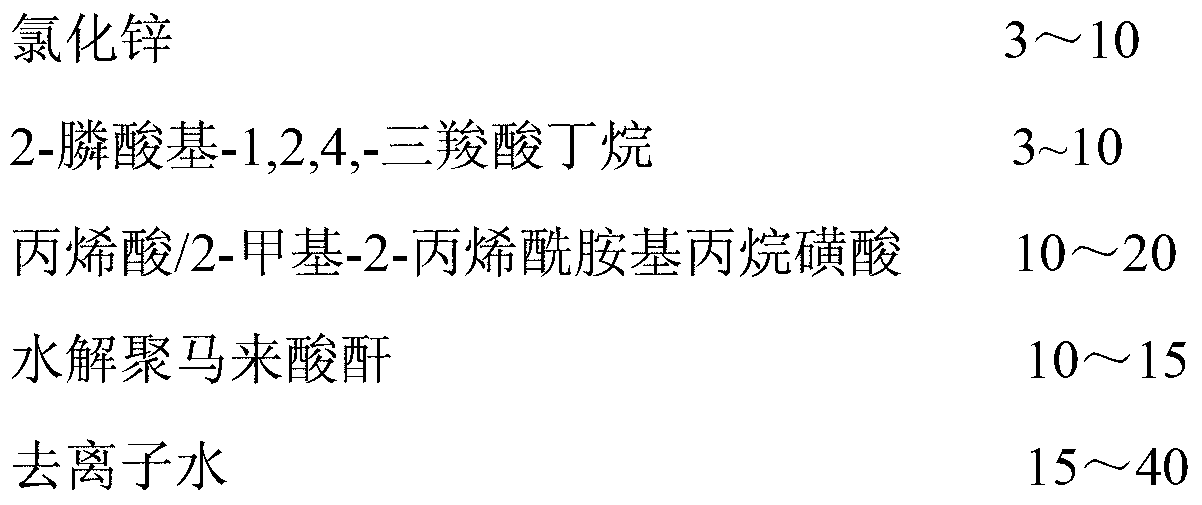

Low-phosphorous environment-friendly composite scale and corrosion inhibitor

InactiveCN103319011AReduce usageImprove complexation effectScale removal and water softeningWater qualityTricarboxylic acid

The invention discloses a low-phosphorous environment-friendly composite scale and corrosion inhibitor. The scale and corrosion inhibitor is characterized by comprising component A and component B, wherein component A includes sodium hydroxide, benzotriazol, polyepoxysuccinic acid, sodium molybdate and deionized water, and the component B includes zinc chloride, 2-phosphonobutane-1,2,4-tricarboxylic acid, acrylic acid / 2-methyl-2-acrylamido-propanesulfonic acid, hydrolytic polymaleic anhydride and deionized water. The scale and corrosion inhibitor provided by the invention is applicable to a recirculating cooling water system with high hardness and high alkalinity, especially has powerful complexation performance on carbonate scale, includes low-content phosphorous, poses no pollution to the environment and accords with requirements of environmental protection. The scale and corrosion inhibitor is applicable to carbon steel and stainless steel recirculating cooling water systems with a pH value in a range of 7.5 to 9.3 and does not need addition of an acid for adjustment of the pH value. As water quality of industries differs, the scale and corrosion inhibitor has a corrosion inhibition effect in a recirculating cooling water system with a small concentration multiple and good scale inhibition performance in a recirculating cooling water system with a great concentration multiple of 3 to 4 times.

Owner:北京市龙源科创石油技术有限公司

Production technology of anti-static fabric

ActiveCN110396753AImprove anti-static performanceIncreased durabilityBiochemical fibre treatmentSingeingPolyesterEscherichia coli

The invention discloses a production technology of an anti-static fabric. An electric conduction wire and a polyester cotton yarn are double-twisted to obtain a conductive yarn, the conductive yarn iswoven at intervals to obtain an anti-static gray fabric, and through singeing, shape setting and dyeing, the dyed gray fabric is obtained; through anti-static after-finishing of an anti-static finishing solution, two-time soaking and two-time rolling, the anti-static gray fabric is obtained; finally, through antibacterial anti-mite finishing of an antibacterial anti-mite finishing agent, two-timesoaking and two-time rolling, the anti-static fabric is obtained. The prepared anti-static fabric has good anti-static performance, can achieve moisture absorption and air permeation, has antibacterial and anti-mite performance and is good in comfort and particularly suitable for being used as a fabric of outdoor sports wear and climbing wear. The point-to-point resistance of the anti-static fabric reaches 2.8*1,010 omega, the rate of resisting staphylococcus aureus reaches 89.7%, the rate of resisting escherichia coli reaches 86.8%, the rate of resisting candida albicans reaches 73.6%, the water absorption rate reaches 106%, and the amount of water vapor transmission reaches 8,125 g / m<2>.24 h.

Owner:保定澳森制衣股份有限公司

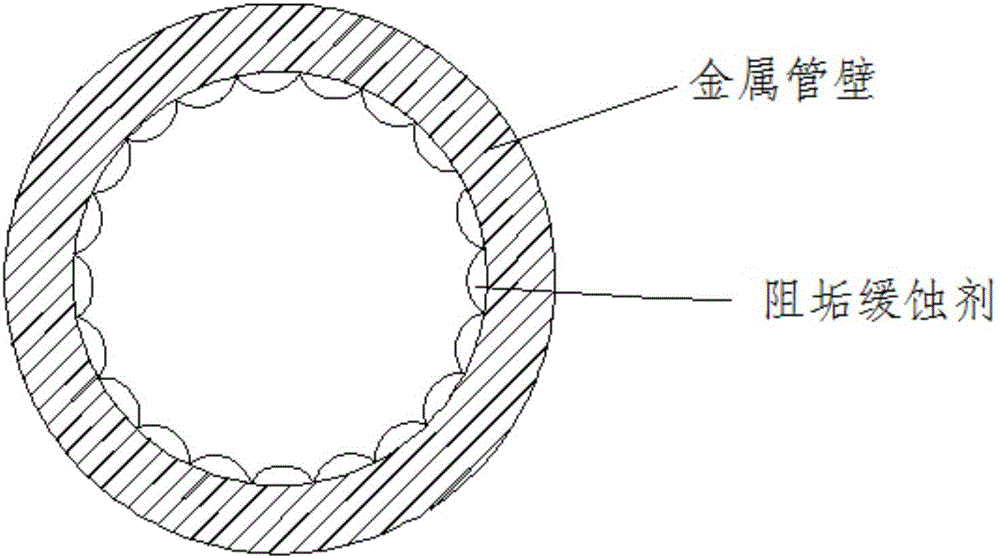

Scaling corrosion inhibitor and preparation method thereof

InactiveCN106315880ALow costSimple configurationSpecific water treatment objectivesScale removal and water softeningTricarboxylic acidButane

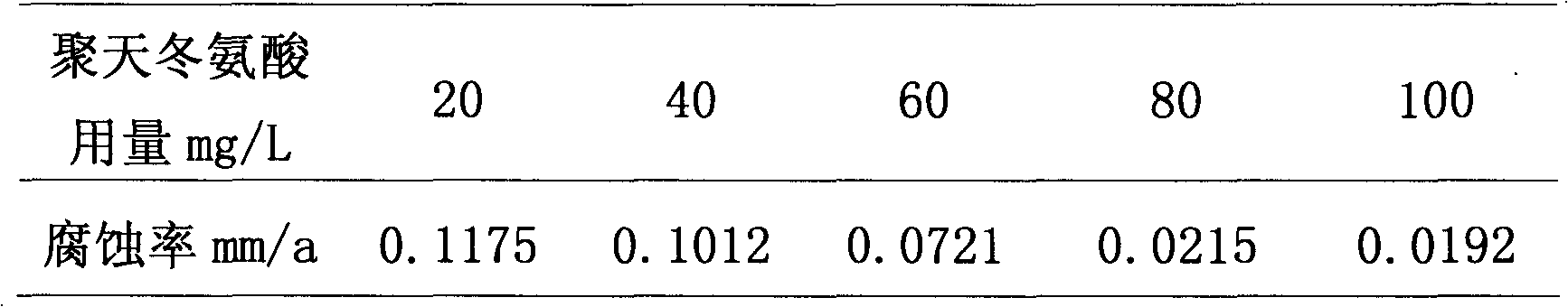

The invention provides a scaling corrosion inhibitor and a preparation method thereof, and relates to the technical field of a water treatment chemical. The scaling corrosion inhibitor is prepared from the following raw materials of 2-phosphono-butane-1,2,4-tricarboxylic acid (PBTCA), 2-hydroxyphosphonoacetic acid (HPAA), acrylate copolymers (HB-901), polyaspartic acid (PASP) and a foam discharging agent according to the matter quantity ratio of (2 to 3):(2 to 3) :(5 to 8) :(10 to 15) :(5 to 8). The preparation method of the scaling corrosion inhibitor comprises the steps of 1, mixing the materials to obtain a mixed solution; 2, preparing the foam discharging agent; 3, adding the mixed solution into a polyaspartic acid water solution; performing reaction for 50 to 60 minutes; adding the foam discharging agent; performing stirring for 5 to 6 hours at 40 to 50 DEG C; preparing the scaling corrosion inhibitor. The scaling corrosion inhibitor belongs to a scaling corrosion inhibitor for preventing corrosion of the pipeline and equipment; the dual efficacies of scale inhibition and corrosion inhibition are achieved; the scaling corrosion inhibitor is a complex reagent; certain biodegradability is realized; green and environment-friendly effects are achieved; the application range is wide.

Owner:SHENYANG JIANZHU UNIVERSITY

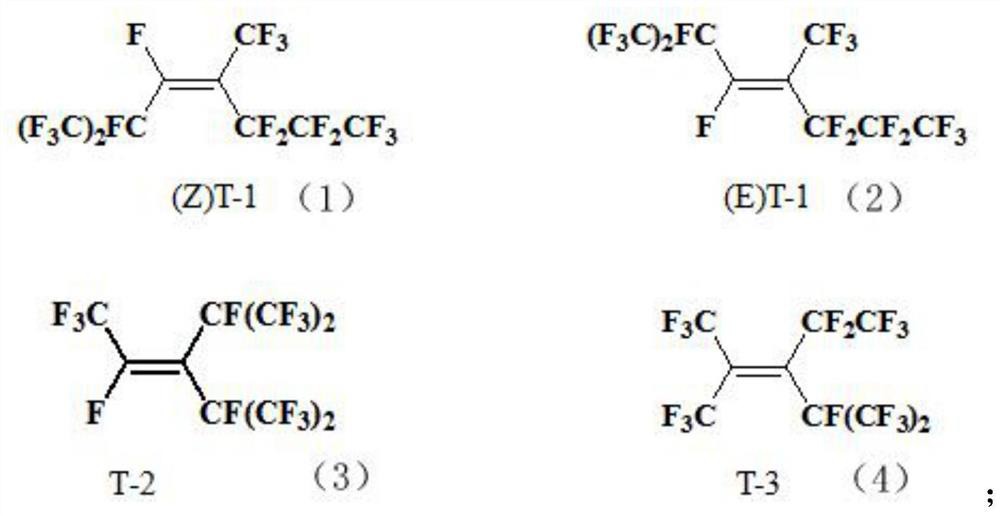

Multi-effect organic cooling liquid composition and application thereof

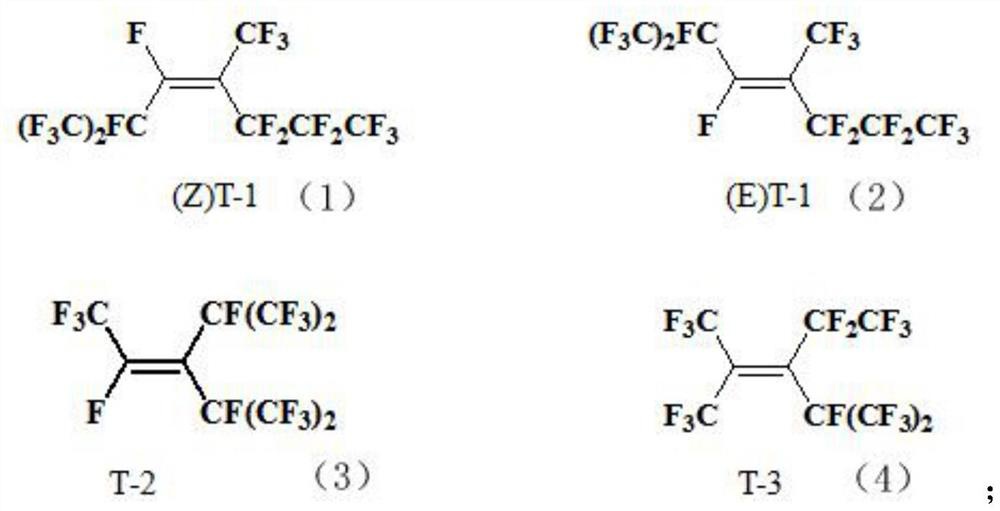

The invention discloses a multi-effect organic cooling liquid composition and application thereof. The multi-effect organic cooling liquid composition comprises four components, wherein the four components are composed of any four of hexafluoropropylene dimer, hexafluoropropylene trimer, perfluorohexanone, perfluoroheptane, perfluorooctane, perfluoropentane, perfluorohexane, perfluorotripropylamine, perfluorotributylamine, perfluorotripentylamine, perfluoro-N-methylmorpholine and the like. The cooling liquid composition can achieve corrosion protection of multi-metal materials and welding fluxin liquid cooling systems such as radar and electronic laser, has good adaptability to non-metal materials and long service life, is free of corrosion and pollution, can be used in the environment of65 DEG C below zero to 115 DEG C, is non-conductive or low in conductivity, is nonflammable but easy to clean, has a good cooling effect in the fields of electronic radars, electronic lasers and thelike, and can be applied to cooling systems of low-temperature environment equipment such as radars, lasers, etc.

Owner:浙江诺亚氟化工有限公司

Spent meal for treating surface of non-ferrous metal and method for preparing same

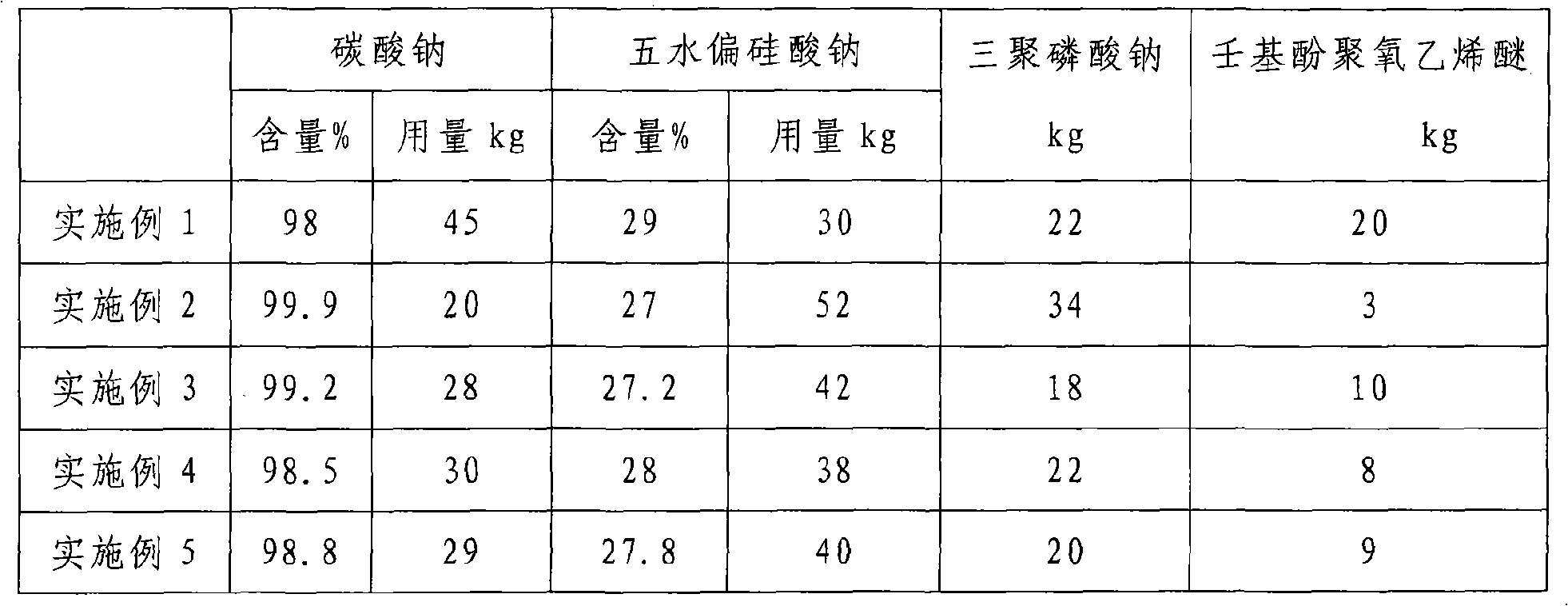

The invention discloses degreasing powder used for surface treatment of nonferrous metals and a method for preparing the same. The compositions by weight portion of the degreasing powder are: 20 to 45 portions of sodium carbonate, 30 to 55 portions of sodium metasilicate pentahydrate, 20 to 35 portions of trimeric sodium phosphate, and 3 to 20 portions of nonyl phenol polyethenoxy ether. The method for preparing the degreasing powder is as follows: firstly, the sodium carbonate and the trimeric sodium phosphate are uniformly mixed and stirred; secondly, the nonyl phenol polyethenoxy ether and the sodium metasilicate pentahydrate are added, and then the finished product is obtained after uniform stirring. The degreasing powder has strong inhabitation ability, is applied to surface treatment of copper, zinc and a plurality of nonferrous metals and alloys of the nonferrous metals, has good cleaning effect on various oil stains such as engine oil, lubricating oil, anticorrosive oil, animal and vegetable oil and so on, and is nontoxic, nonflammable, wide in application range, easy to process waste solution and favorable for environmental protection.

Owner:JIANGSU DEMEI TECH

Seawater corrosion inhibitor

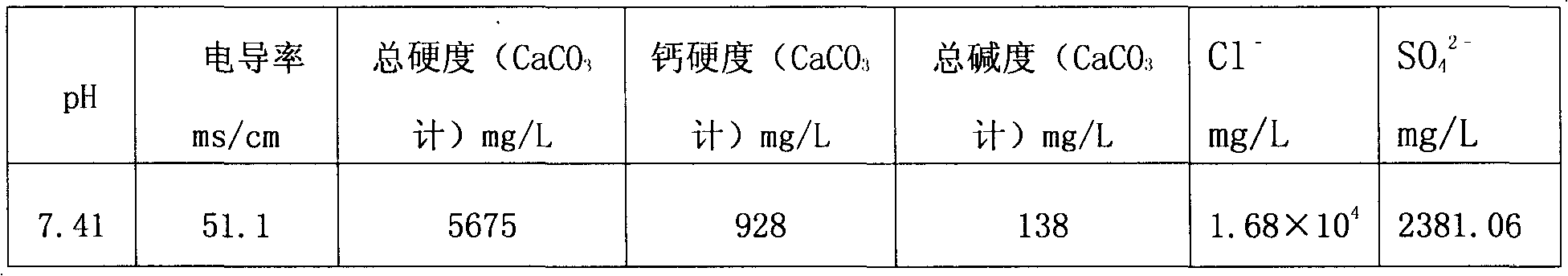

InactiveCN102674565AHigh hardnessIncreased concentration of chloride ionsSeawater treatmentTreatment using complexing/solubilising chemicalsWater qualityChemical products

The invention discloses an environmental-friendly seawater corrosion inhibitor for seawater circulating cooling water treatment, belonging to the technical field of chemical products. The seawater corrosion inhibitor is formed by mixing polyaspartic acid, hexadecyldimethyl (2-sulphite) ethyl ammonium, zinc sulfate and 2-hydroxy phosphonoacetic acid according to mass ratio of (4-8): (0.6-1): (3-5): (0.25-0.5). The seawater corrosion inhibitor has excellent corrosion inhibition performance in high-hardness, high-chloride-ion-concentration and high-corrosion water such as seawater, the dosage of the seawater corrosion inhibitor in a seawater circulating cooling water system is 78.5mg / L-145mg / L, the seawater corrosion inhibitor is biodegradable, the degradation ratio after 28 days can reach more than 80 percent and the seawater corrosion inhibitor is an environmental-friendly product. The seawater corrosion inhibitor is not required to be pre-filmed during use and is convenient to use, and the cost is saved.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

Non-phosphorus slow-dissolving glass water treatment agent

InactiveCN103466812AUnique and excellent corrosion resistanceUnique and excellent descaling and antiscaling effectTreatment using complexing/solubilising chemicalsSulfateSilicon oxide

The invention discloses a non-phosphorus slow-dissolving glass water treatment agent. The water treatment agent is prepared through using a glass matrix and an additive, the glass matrix comprises 9-18wt% of sodium oxide, 23-28wt% of silicon oxide, 46-55wt% of boron oxide, 0.6-1.2wt% of potassium oxide and 1.0-2.0wt% of alumina, and the additive comprises, by total amount of the glass matrix, 10-12.5% of zinc sulfate (ZnSO4), 6.5-9.5% of sodium tungstate (Na2WO4) and 0.16-0.18% of silver nitrate (AgNO3). A preparation method of the water treatment agent comprises the following steps: fully stirring the glass matrix and the additive, uniformly mixing, melting at 1400-1500DEG C for 2-3h, carrying out cold curing fragmentation, drying, and screening to obtain the non-phosphorus slow-dissolving glass water treatment agent. The water treatment agent has excellent ingrained dirt removing, corrosion and scale inhibition, organism killing and cleaning effects.

Owner:蒋剑秋

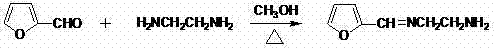

Corrosion inhibitor used for oil field water, preparation method and detection method

ActiveCN104762075AEasy to synthesizeRaw materials are easy to obtainWeighing by removing componentDrilling compositionThioureaHexamethylenetetramine

A corrosion inhibitor used for oil field water, a preparation method and a detection method are provided. The corrosion inhibitor is composed of a main agent and a compounding agent, wherein the main agent is a Schiff base synthesized from aromatic aldehyde and ethylene diamine, and the compounding agent is urotropine, OP-10 (alkylphenol polyoxyethylene), potassium iodide, thiourea or sodium tungstate. The Schiff base formed by the aromatic aldehyde and the ethylene diamine are compounded with the urotropine, the OP-10 (alkylphenol polyoxyethylene), the potassium iodide, the thiourea or the sodium tungstate according to mass ratio to obtain the corrosion inhibitor. The required raw materials are simple and easy to obtain. The main agent is easy to prepare and can be used directly without purification. The preparation method is simple, convenient and safe, is short in reaction time, is low in cost and is high in yield. The corrosion inhibitor is excellent in corrosion inhibition and is suitable for industrial large-scale production. By means of the corrosion inhibitor for detection, a strong practicability is achieved. The corrosion inhibitor has an excellent slow-releasing performance in the field of oil exploitation.

Owner:山东德坤工贸有限公司

Anti-corrosion post-treatment liquid for nickel coating surface and treatment process thereof

InactiveCN103132060AIncreasing the thicknessStrong corrosion inhibitionLiquid/solution decomposition chemical coatingMetallurgyWarm water

Owner:NANCHANG HANGKONG UNIVERSITY

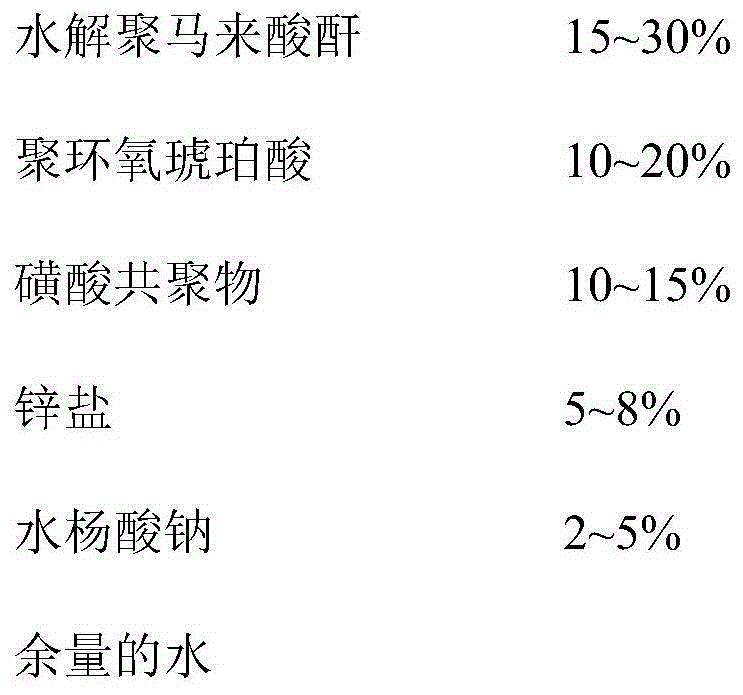

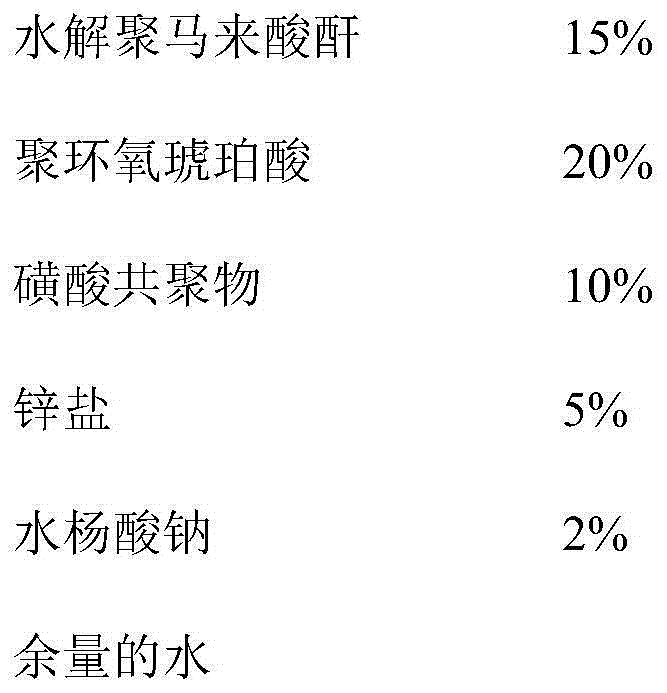

Scale and corrosion inhibitor for power cycling water system

InactiveCN105016490AImprove complexation effectEnhance the anti-scaling and dispersing effectTreatment using complexing/solubilising chemicalsElectric power systemSodium salicylate

A scale and corrosion inhibitor for a power cycling water system belongs to the technical field of water treatment of a power system. The invention aims to provide a preparation method for a composite scale inhibitor which is simple in process flow, low in production cost, stable in quality and efficient in scale prevention and corrosion deceleration, and is a phosphorus-free formula product. The scale and corrosion inhibitor comprises the ingredients in percentage by weight: 15-30% of hydrolytic polymaleic anhydride, 10-20% of polyepoxysuccinic acid, 10-15% of a sulfonic acid copolymer, 5-8% of zinc salt, 2-5% of sodium salicylate and the balance of water. The compound raw materials adopted are non-toxic, low in price and efficient, and the production process of the scale and corrosion inhibitor is simple in flow, the product quality is stable, and the corrosion and scale inhibition rate is greater than 95%. Meanwhile, the production process of the scale and corrosion inhibitor is an environmental-friendly clean process which is free of industrial three waste discharge, simple to operate, low in production cost and suitable for industrialized scale production.

Owner:安徽省蓝天能源环保科技有限公司

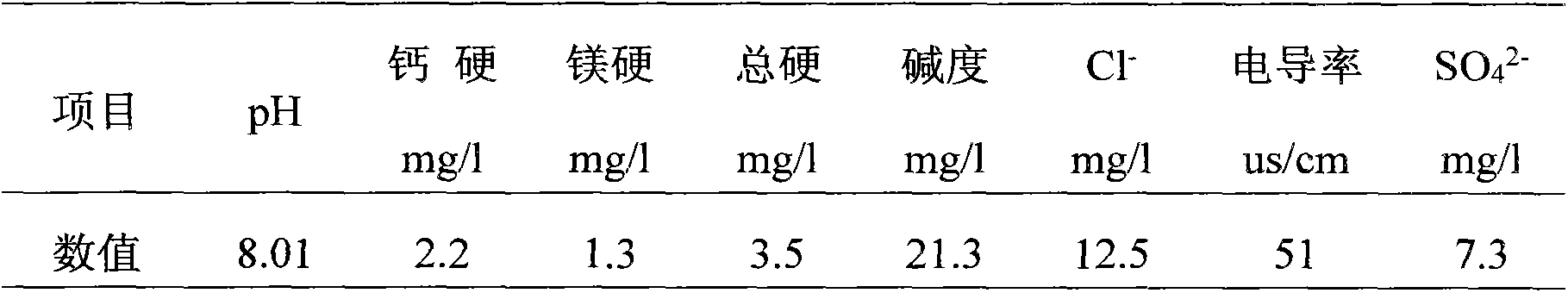

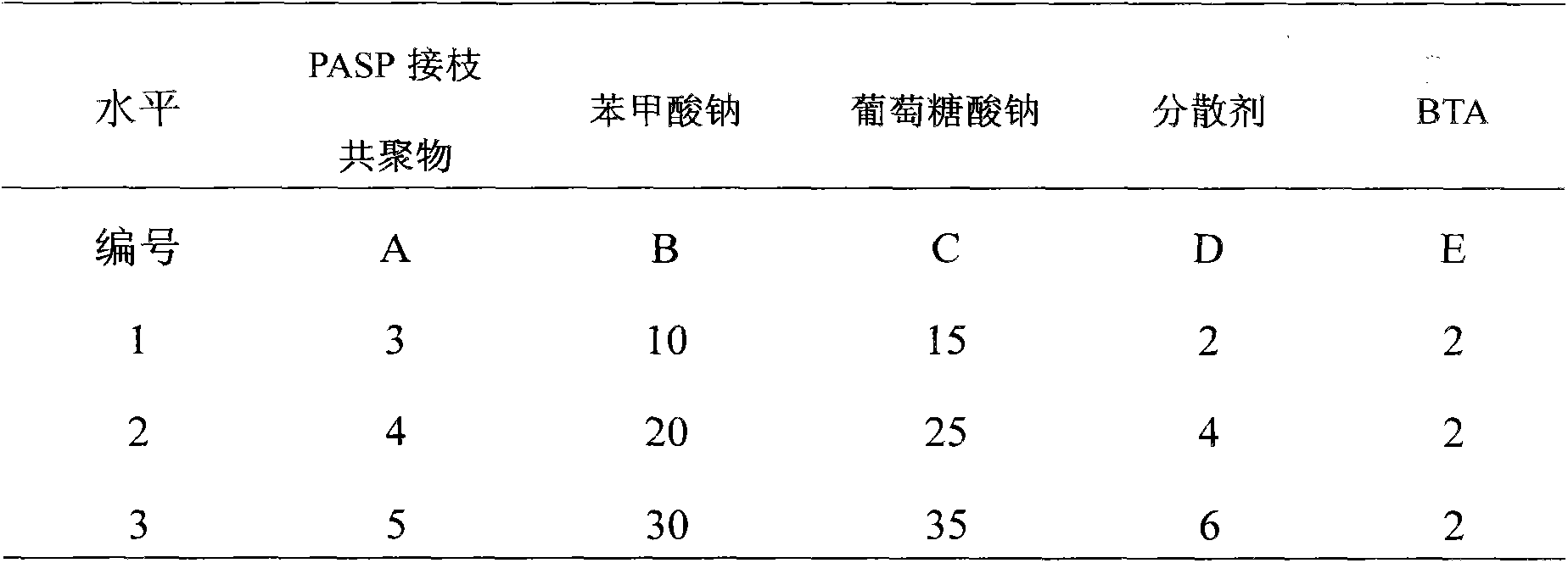

Non-phosphorus environment-friendly softening water corrosion inhibitor

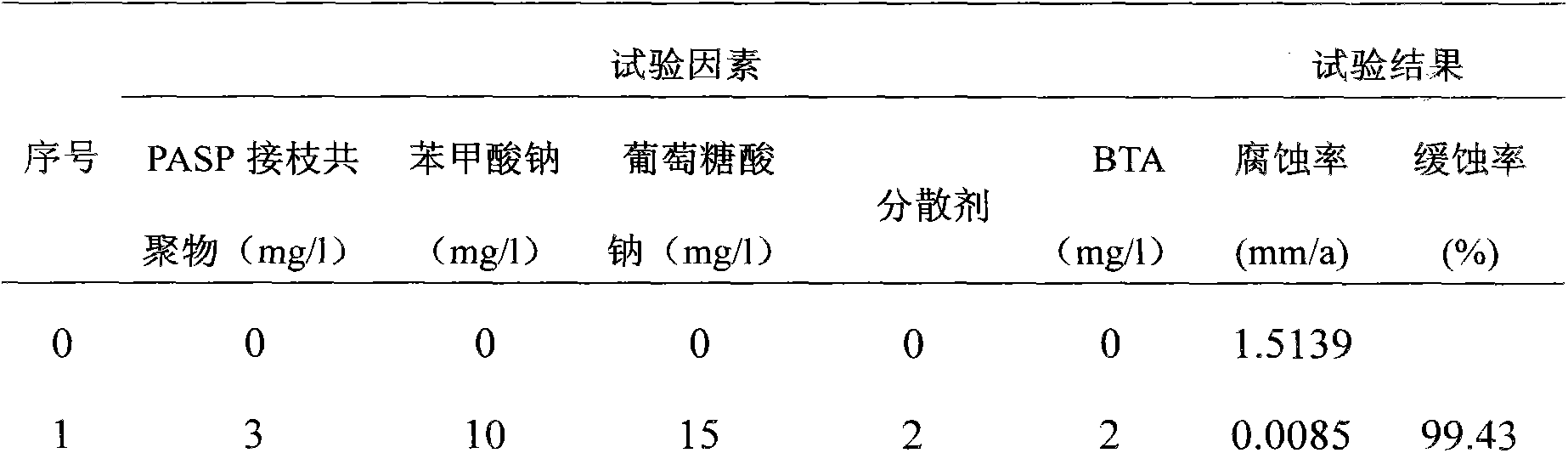

ActiveCN103265126AStrong corrosion inhibitionLong effective timeScale removal and water softeningPolyaspartic acidBenzotriazole

The invention relates to a non-phosphorus environment-friendly softening water corrosion inhibitor which is characterized in that the corrosion inhibitor is prepared by adopting the following method. The method comprises the steps of: dissolving 20-40% of sodium gluconate and 20-45% of sodium benzoate into water, then adding 5-10% of hydroxyl-containing polyaspartic acid grafted copolymer, evenly stirring, then adding 1-3% of benzotriazole, stirring, and finally adding 5-10% of dispersing agent and evenly stirring. The prepared corrosion inhibitor is a non-phosphorus environment-friendly softening water corrosion inhibitor applicable to a softening water system, and is good in property, economical, non-phosphorus, non-toxic and environment-friendly.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

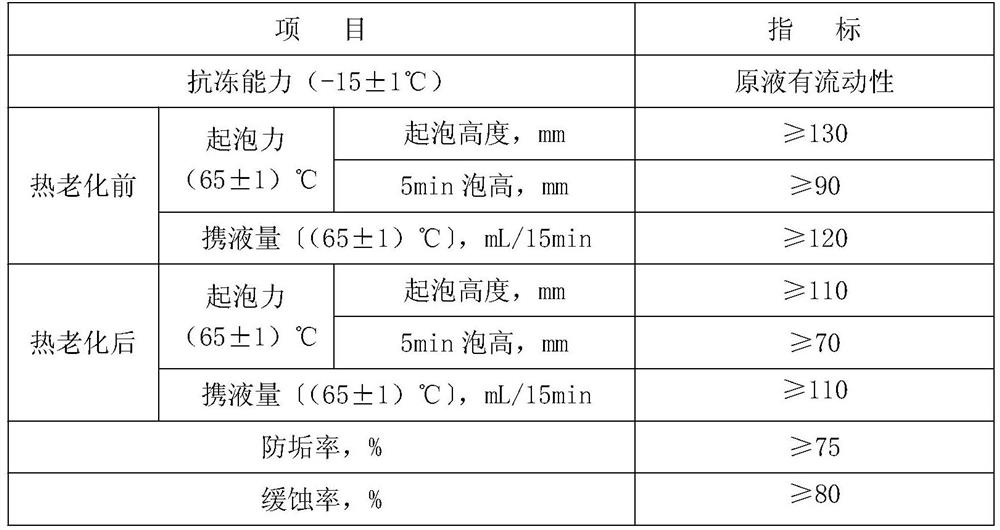

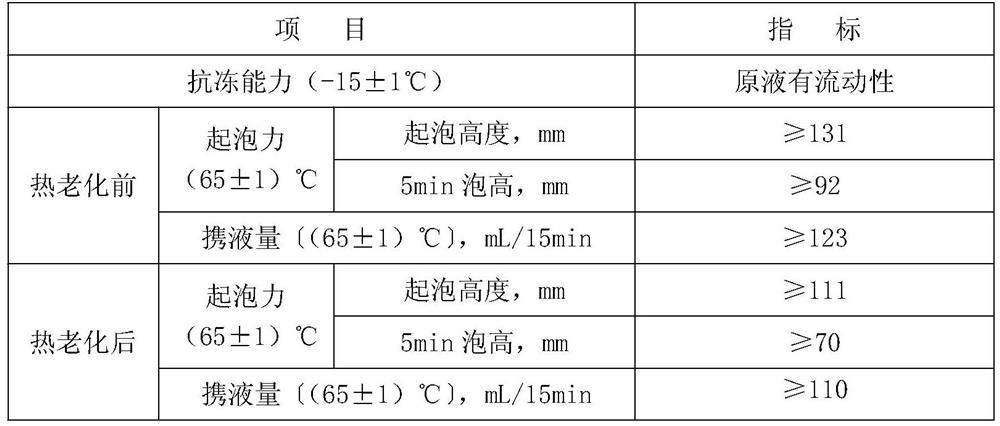

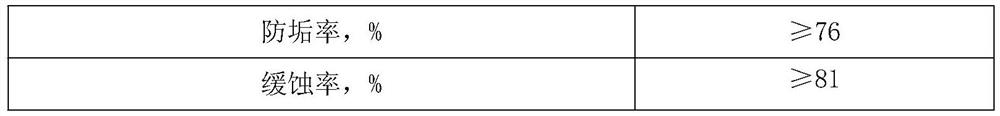

Anti-freezing corrosion inhibition foam drainage scale inhibitor and preparation method thereof

ActiveCN112266774AImprove filling efficiencyReduce workloadHeat-exchange elementsDrilling compositionCorrosion preventionSurface-active agents

The invention belongs to the technical field of natural gas extraction, and particularly provides an anti-freezing corrosion inhibition foam drainage scale inhibitor and a preparation method thereof.The anti-freezing corrosion inhibition foam drainage scale inhibitor is prepared from the following components by mass: 15-20% of an organic phosphoric acid corrosion inhibitor, 15-20% of an organic phosphine corrosion inhibitor, 25-30% of a quaternary ammonium salt corrosion inhibitor, 4-10% of a scale inhibitor, 3-5% of an emulsifier, 15-20% of an ampholytic surfactant, and 5-10% of a dispersingagent. The problems that when a large gas field aims at the problems of wellbore scaling, wellbore corrosion, gas well drainage gas recovery and the like, injected traditional scale inhibitors, corrosion inhibitors and foam drainage agents are single in agent performance, tedious in injection system and large in agent injection workload and do not have the anti-freezing effect are solved, the functions of scale prevention, corrosion inhibition, corrosion prevention, foam drainage and freezing prevention are achieved, and the application prospect is wide. One-dose multi-effect is achieved, themedicament filling efficiency is improved, the medicament filling workload is reduced, the safety risk in the medicament filling process is reduced, and the problem that a traditional medicament is frozen in winter is solved.

Owner:PETROCHINA CO LTD

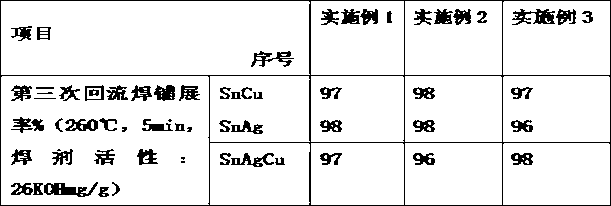

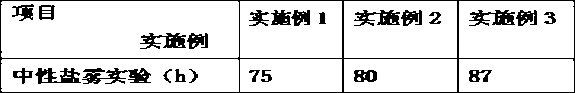

Wave-soldering brazing filler metal active agent

InactiveCN101780605AReduce manufacturing costImprove recovery ratePrinted circuit assemblingWelding/cutting media/materialsSlagActive agent

The invention relates to a wave-soldering brazing filler metal active agent containing dimer acid, trimer acid or the mixture of the dimer acid and the trimer acid. The wave-soldering brazing filler metal active agent is oily liquid and forms a layer of protective film on the surface of fused brazing filler metal to protect the fused brazing filler metal from being oxidized and prevent the brazing filler metal from adsorbing with oxygen in air, thereby reducing the forming speed of tin slag, saving the consumption of soldering tin and power consumption and reducing production cost. The wave-soldering brazing filler metal active agent can also greatly improve the quality of products, enhance the soldering force of the products and simultaneously be convenient for the maintenance of equipment.

Owner:李平荣

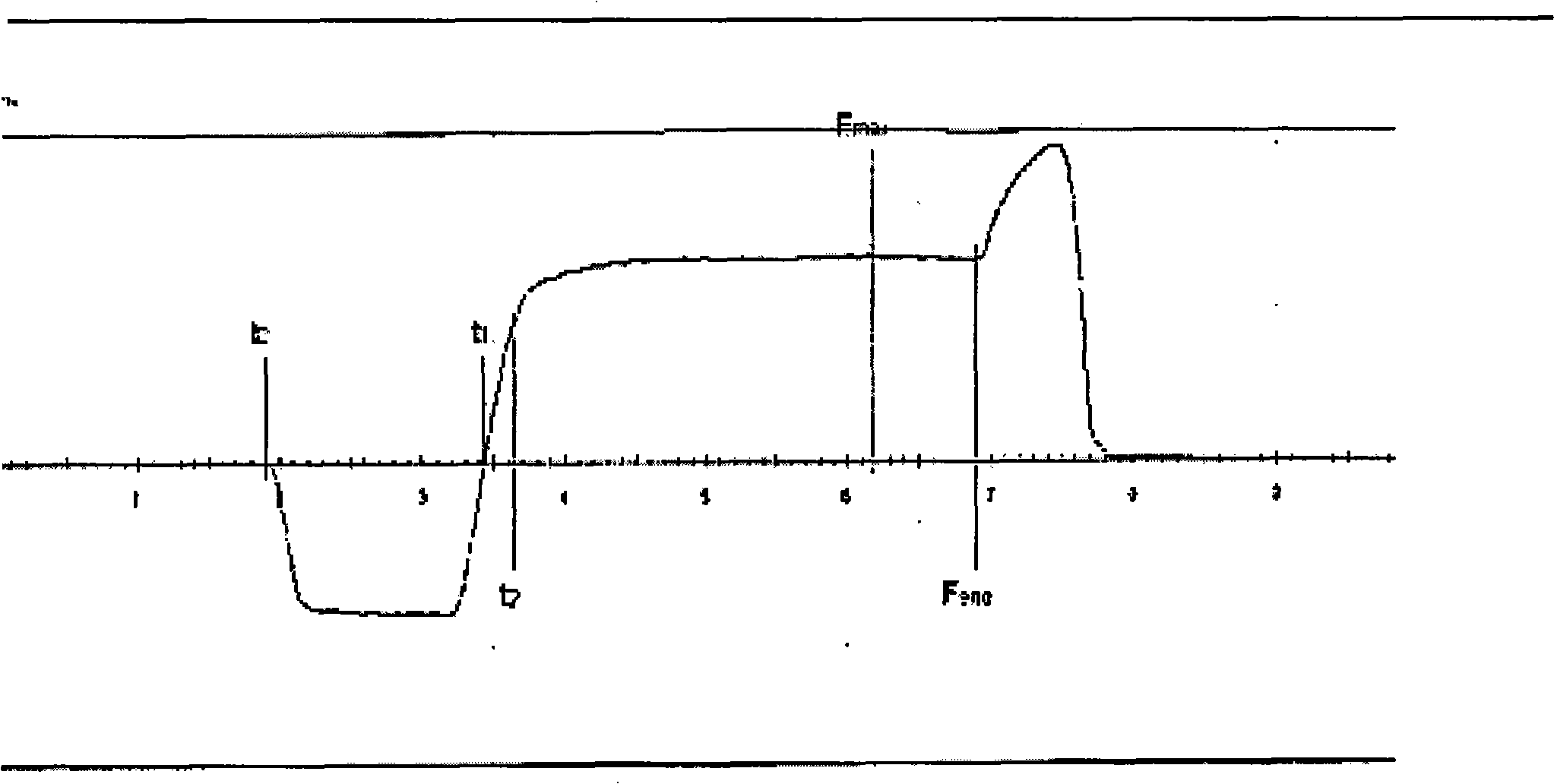

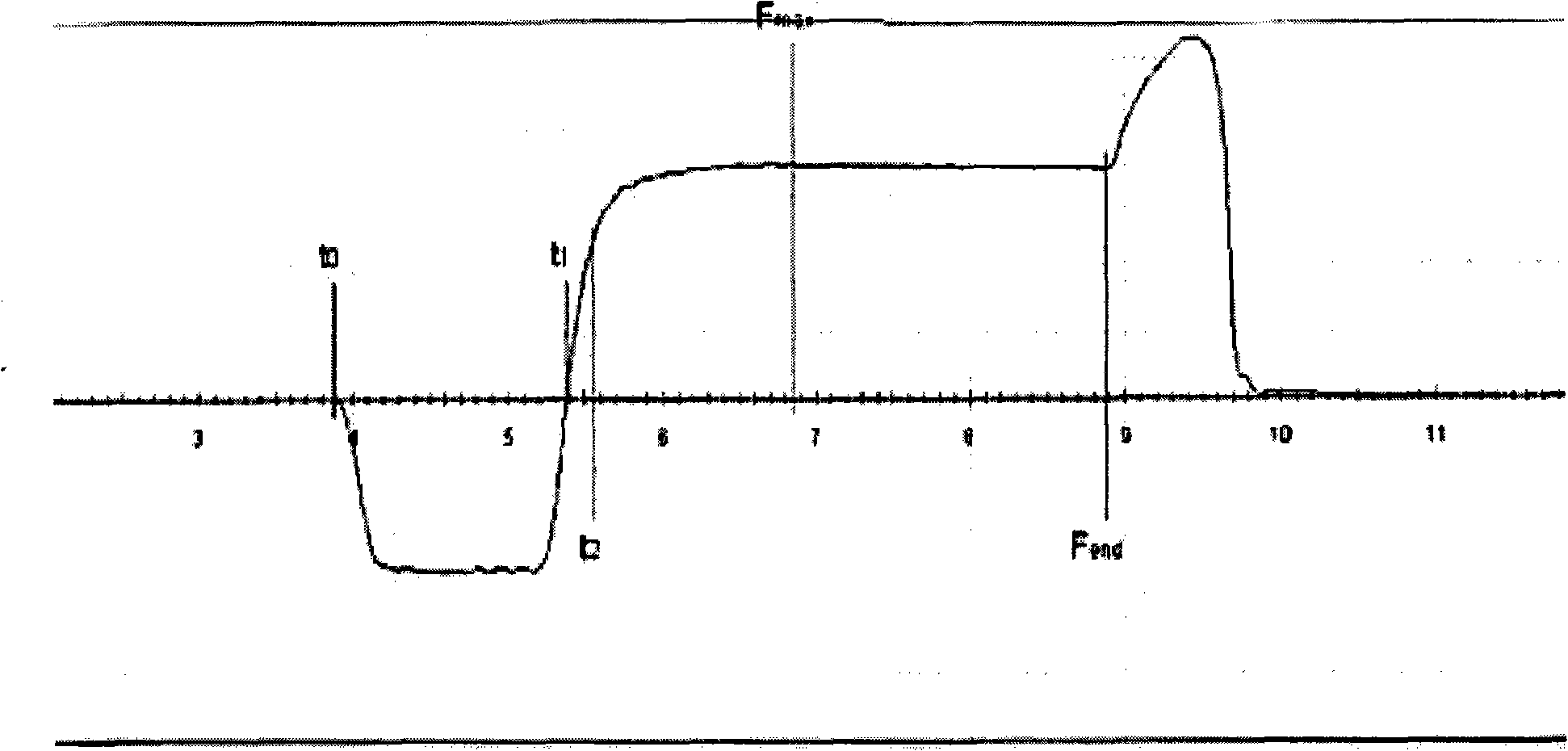

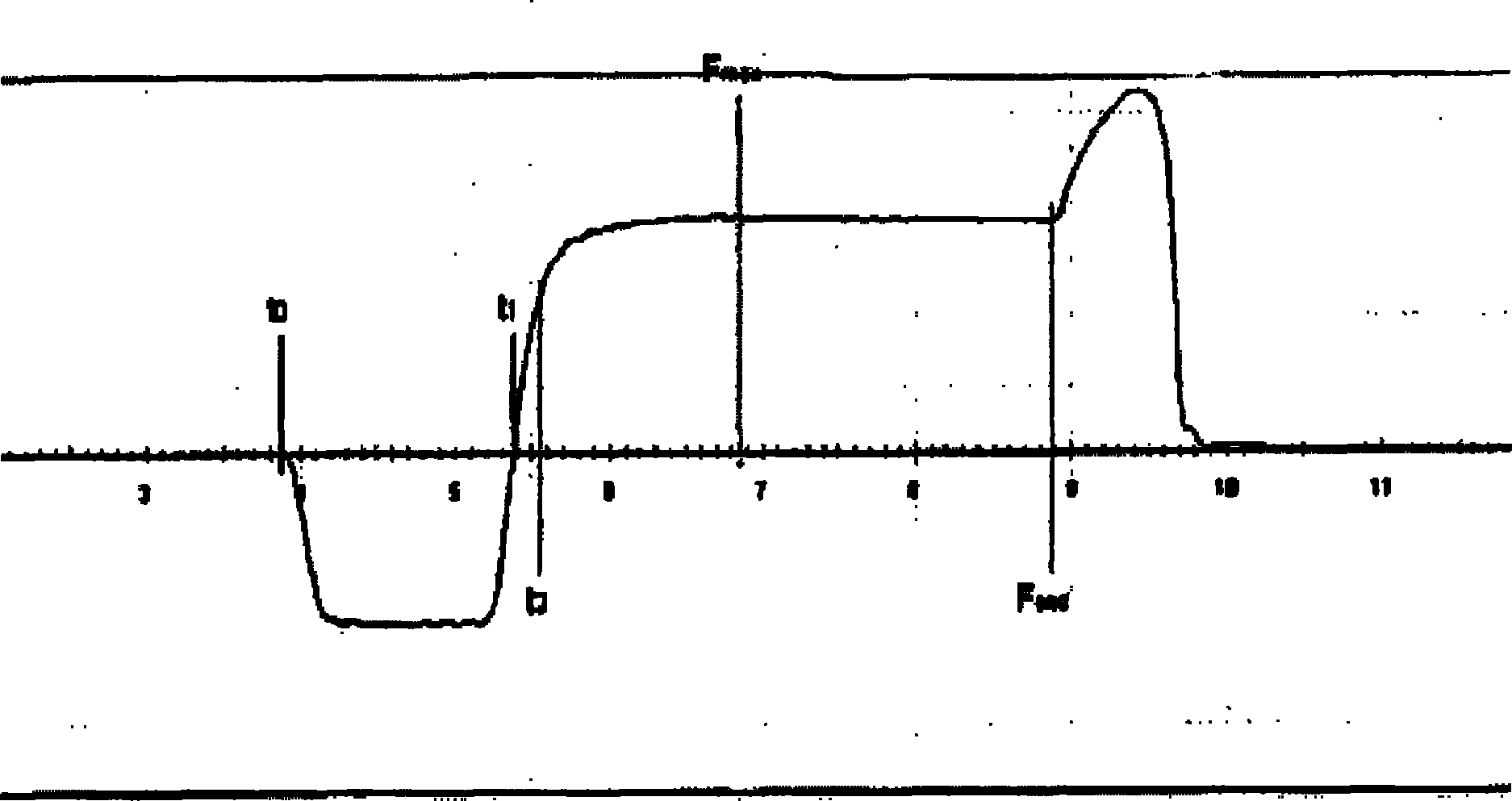

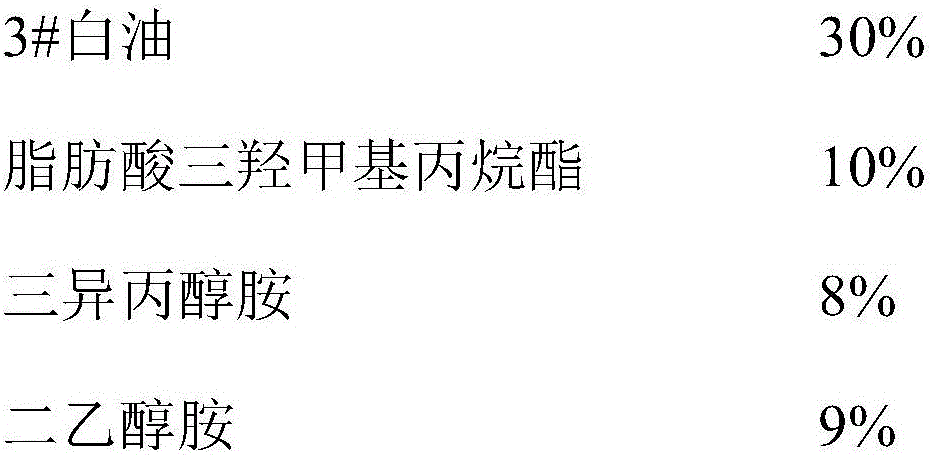

Magnesium alloy cutting liquid and preparation method thereof

InactiveCN105754690AHigh strength hard water resistanceEfficient control of corrosion and discoloration problemsLubricant compositionHard waterHigh magnesium

The invention discloses magnesium alloy cutting liquid and a preparation method thereof.Compared with the prior art, the magnesium alloy cutting liquid has high-strength hard water resisting performance, the highest magnesium hard water resistance can reach 6,000 pm, the service life of the cutting liquid is effectively prolonged, great assistance in environmental protection and energy saving advocated in the country is achieved, a liquid tank does not need to be replaced after being used for 6 month to the longest on site, and the magnesium alloy cutting liquid is environmentally friendly.

Owner:安徽华灿润滑技术有限公司

Novel use of organic phosphonite

The invention discloses novel use of organic phosphonite, in particular use of the organic phosphonite as a corrosion inhibitor of titanium in sulfuric acid solution. The organic phosphonite may be one of amino trimethylene phosphonic acid and salts thereof, 1-hydroxy ethylidene-1,1-diphosphonic acid and salts thereof, [1,2-ethanediylbis(nitrilobis-(methylene))]tetrakis-phosphonic acid and salts thereof, diethylenetriaminepenta(methylene-phosphonic acid) and salts thereof, polyhydric alcohol phosphate ester, 2-hydroxyphosphonoacetic acid, hexamethylene diamine tetra(methylene phosphonic acid) and salts thereof, polyamino polyether methylene phosphonates, bis(hexamethylene triamine penta (methylene phosphonic Aacid)) and salts thereof, and phytic acid. The invention belongs to the technical field of metal material / chemical equipment anticorrosion. The corrosion inhibitor has a good corrosion inhibition effect on sulfuric acid under the condition of low dosage and has a high application value.

Owner:JIAYING UNIV

Aviation magnalium cutting fluid and preparation method thereof

The invention relates to aviation magnalium cutting fluid and a preparation method thereof. The aviation magnalium cutting fluid comprises, by weight, 30-60% of mineral oil, 10-20% of self-emulsifying ester, 5-10% of phosphate, 2-5% of monoethanolamine, 1-2% of a corrosion inhibitor, 5-10% of sorbitan monooleate, 0.5-2% of glycerol, 5-10% of borate, 1-5% of isothiazolinone, 0.1-0.5% of a defoamer and the balance water. By precisely controlling the components and ingredients of the preparation, on the one hand, the service life of the cutting fluid and the service life of a cutter can be prolonged, the polarity lubricating effect of the cutting fluid is enhanced, machined magnalium is better in degree of finish, the product reject ratio is reduced to be 0.03% that in the prior art, the cost is reduced, and the production efficiency is improved; on the other hand, the self-emulsifying ester and the phosphate have the synergistic interaction effect in the extreme pressure lubricating aspect after being compounded, the extreme pressure lubricating performance of the product is remarkably improved, particularly, the phosphate can produce wonderful effects after being compounded with the corrosion inhibitor, the corrosion inhibitor additive amount is reduced, the cost of the cutting fluid is lower, and the product corrosion inhibition effect is better.

Owner:苏州山河星程材料科技有限公司

Circulating water closed system corrosion inhibitor as well as preparation and application methods thereof

InactiveCN107892398AStrong chemical adsorptionReduce corrosionSpecific water treatment objectivesScale removal and water softeningSoft waterCarboxylic salt

The invention discloses a circulating water closed system corrosion inhibitor as well as preparation and application methods thereof. The corrosion inhibitor is composed of the following components inpercentage by mass: 30-50% of a silicate, 10-15% of a natural dispersant, 5-15% of a carboxylate, 1-3% of a copper corrosion inhibitor, and the balance of soft water; and the preparation method of the corrosion inhibitor includes the steps of preparing the copper corrosion inhibitor, pumping a quantitative inorganic silicate or organic silicate into a reaction kettle, performing stirring until all the materials are dissolved, and adding the natural dispersant, the carboxylate and the copper corrosion inhibitor into the reaction kettle, and includes other steps, so that finally the product corrosion inhibitor is obtained. The corrosion inhibitor provided by the invention has stronger chemical adsorption at the metal surfaces, slows anode and cathode reactions, relieves the corrosion of a soft water system material, has strong corrosion inhibition performance and long effective time, and forms a composite membrane protection system to protect a device against corrosion; and the preparation method of the corrosion inhibitor is scientific, and the corrosion inhibitor has significant effects when being used for water treatment in a steel plant.

Owner:TANGSHAN JINSHA WATER TREATMENT COMPANY

Low-phosphorous composite corrosion and scale inhibitor for circulating cooling water of closed cooling tower and preparation method of low-phosphorous composite corrosion and scale inhibitor

InactiveCN105948283AStrong corrosion inhibitionInhibition of cathodic reactionSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsCooling towerEmission standard

The invention belongs to the field of water treatment, and particularly relates to a low-phosphorous composite corrosion and scale inhibitor for circulating cooling water of a closed cooling tower and a preparation method of the low-phosphorous composite corrosion and scale inhibitor. The low-phosphorous composite corrosion and scale inhibitor comprises, by weight, 5-15% of N-sulfonic amino-dimethylenephosphonic acid, 5-20% of 2-hydroxyphosphonoacetic acid, 30-50% of polyglutamic acid, 5-10% of heptahydrate and the balance deionized water. The formula components of the low-phosphorous composite corrosion and scale inhibitor have obvious synergistic interaction, and the low-phosphorous composite corrosion and scale inhibitor is particularly applicable to a circulating cooling water system of the closed cooling tower; the problems of corrosion and scale formation of the system after long-time operation of the circulating cooling water can be solved effectively, indexes such as corrosion rate of carbon steel, copper, stainless steel and the like can meet national standards, the corrosion rate of the carbon steel is lower than 0.075mm / a, and the corrosion rates of the copper and the stainless steel are lower than 0.005mm / a; the content of phosphorus in the formula is low, and emission standards can be met without treatment; the production process is simple, and product stability is high.

Owner:INLEN CHEM TECH

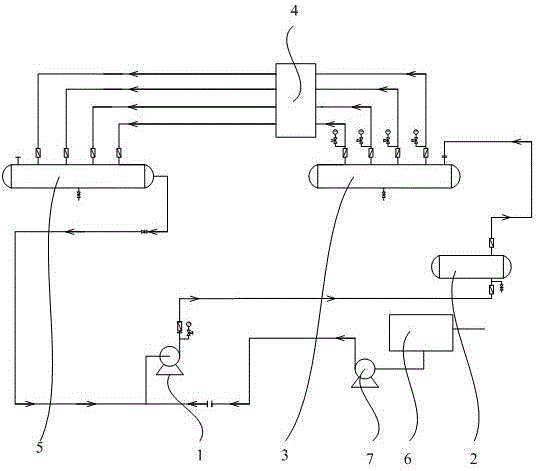

Super-molecular care agent, heating circulating water zero discharge system and use method

ActiveCN106186372AEfficient sterilization and algae killing abilityStrong corrosion inhibition abilitySpecific water treatment objectivesTreatment using complexing/solubilising chemicalsPyridoxine HydrochlorideSodium polyacrylate

The invention discloses a super-molecular care agent, a heating circulating water zero discharge system and a use method. The super-molecular care agent comprises the components, by weight, of 7%-10% of sodium alkyl benzene sulfonate, 10%-12% of sodium polyacrylate, 5%-6% of dodecyl dimethyl benzyl ammonium chloride, 2%-2.5% of alkanolamide, 4.5%-6% of fatty alcohol-polyoxyethylene ether, 4%-5% of cyanoacetic acid, 1%-1.5% of benzotriazole, 2%-3% of sodium tripolyphosphate, 2%-2.5% of sodium silicate, 1%-1.5% of trisodium phosphate, 2%-3% of ethylene glycol, 1%-1.5% of pyridoxine hydrochloride, 2%-2.5% of disodium hydrogen phosphate and the balance of water. The super-molecular care agent is added to heating circulating water, scaling produced by the circulating water and the system corrosion degree are reduced, and the effect of reducing sewage discharge is realized.

Owner:山东大斯夫材料科技有限公司

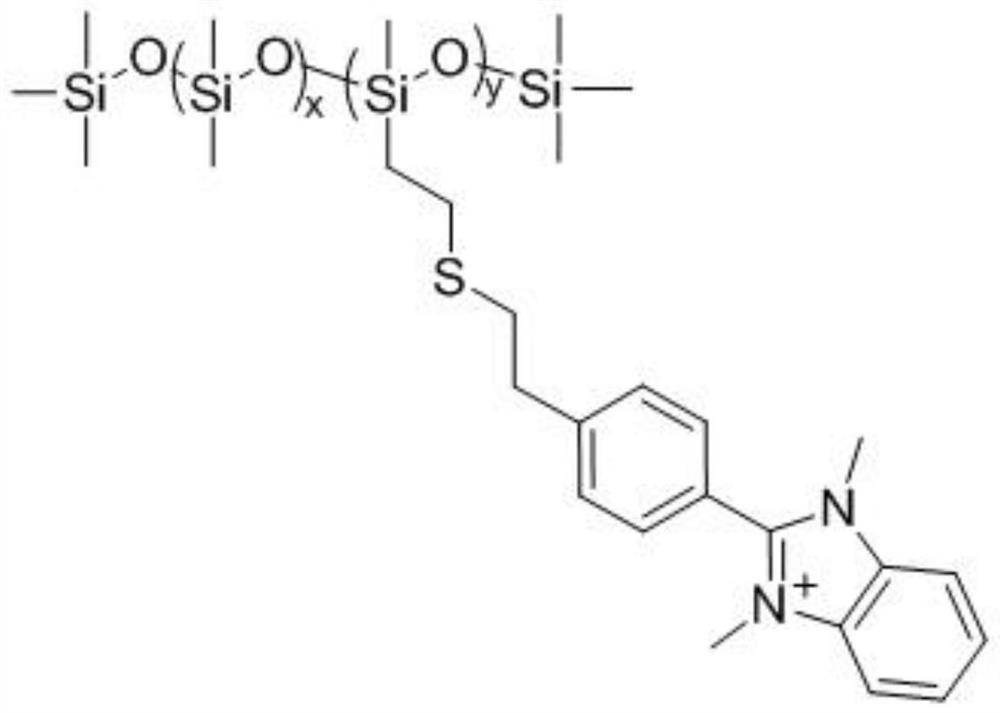

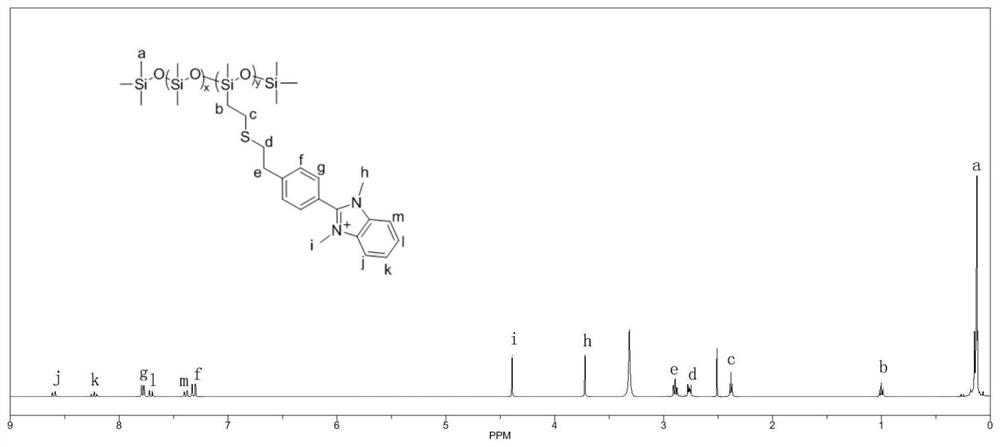

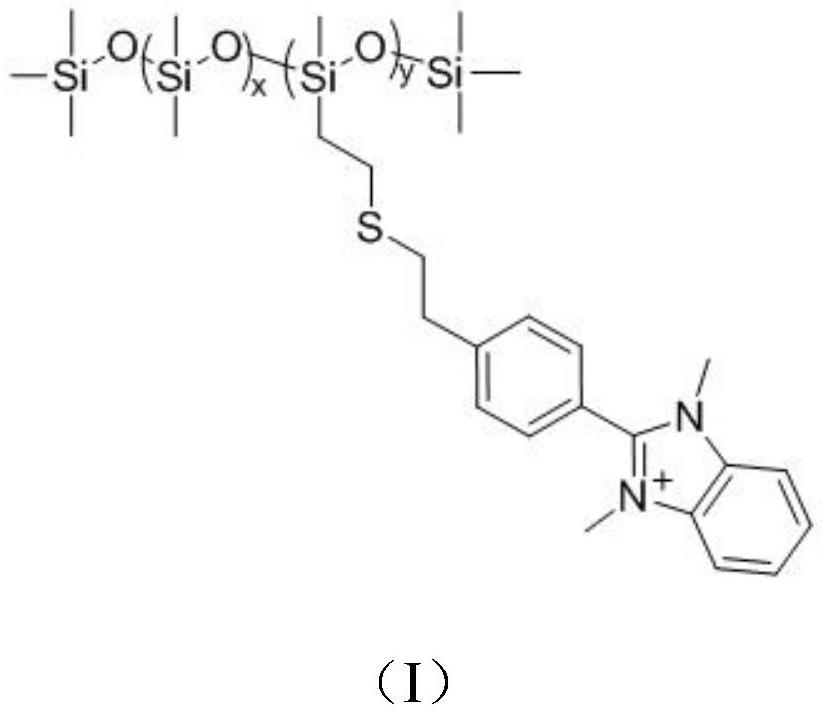

Organosilicon benzimidazole corrosion inhibitor and preparation method thereof

The invention discloses an organosilicon benzimidazole corrosion inhibitor and a preparation method thereof, and the preparation method comprises the following steps: 1) preparing a benzimidazole-containing thiol monomer, namely 2-(4-(1-methylbenzimidazole-2-yl) phenyl)ethanethiol; 2) preparing side vinyl silicone oil; and (3) carrying out sulfydryl-vinyl click reaction on the thiol monomer and vinyl silicone oil to graft a benzimidazole group on the molecular weight of polysiloxane, and then carrying out quaternization to obtain the organic silicon benzimidazole corrosion inhibitor. Compared with the prior art, the preparation method of the organic silicon benzimidazole corrosion inhibitor, provided by the invention, has the advantages of mild conditions, high yield, easiness in control and design of a molecular structure, good water solubility and thermal stability and suitability for various complex environments.

Owner:SHANDONG GUIKE NEW MATERIAL CO LTD

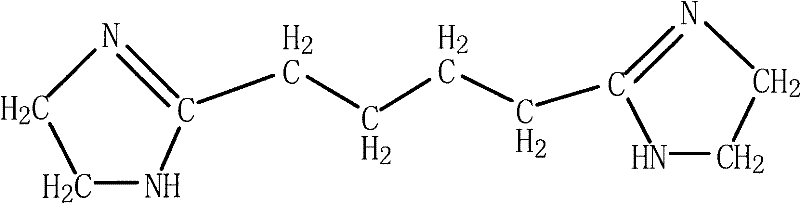

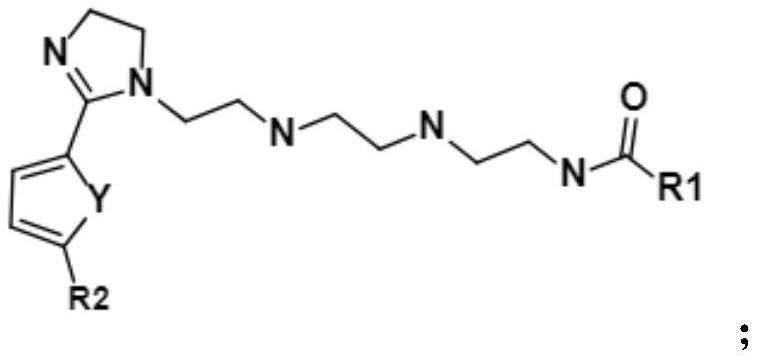

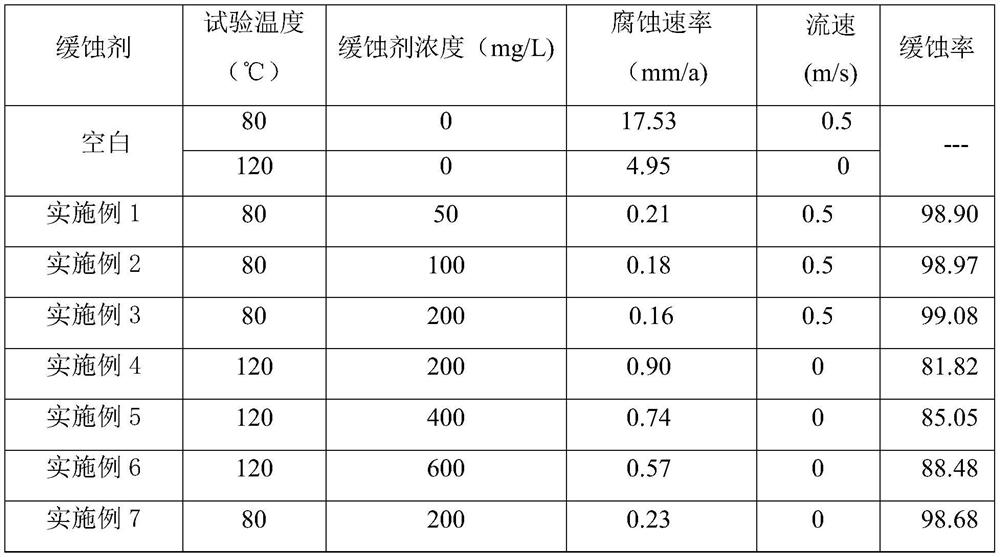

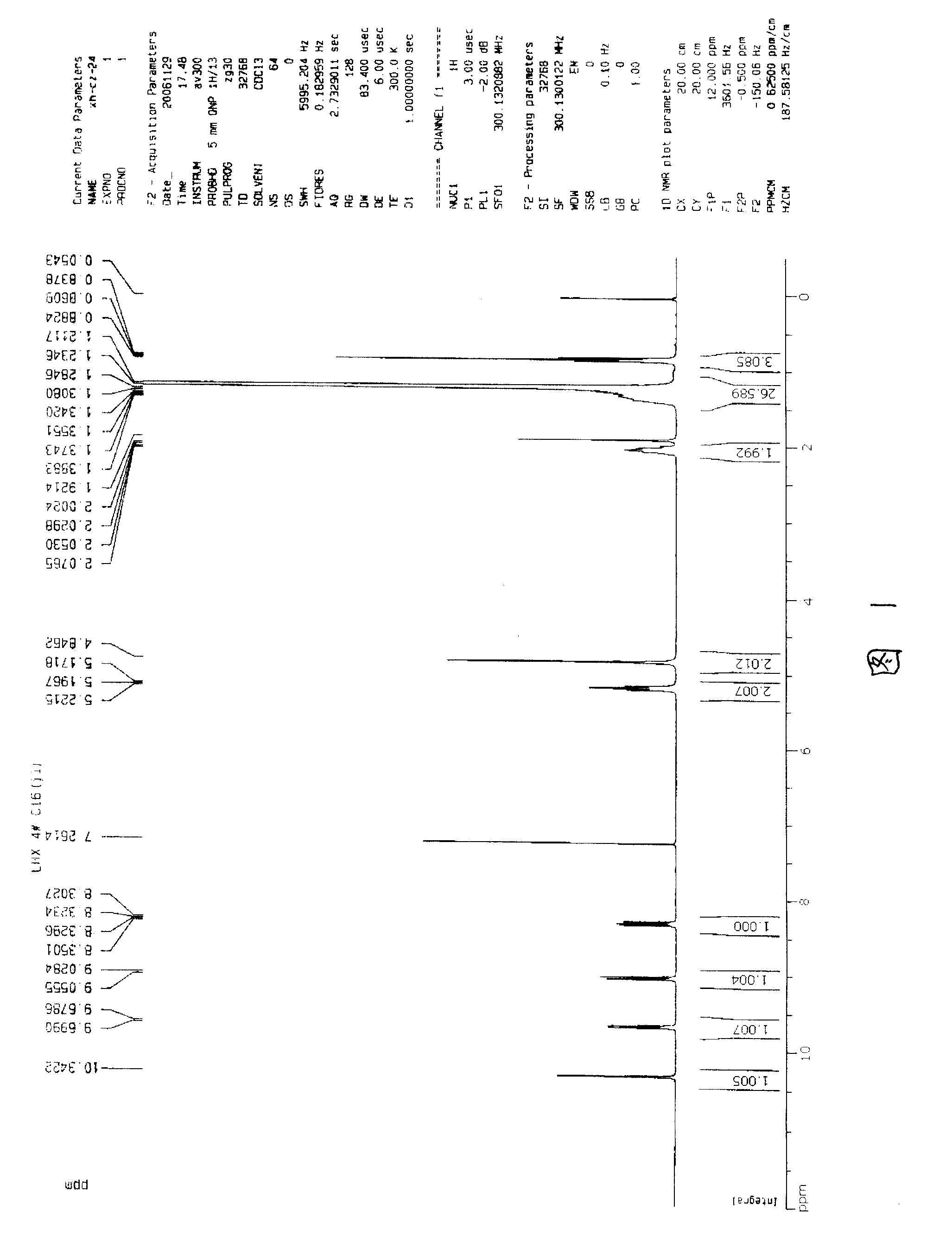

Imidazoline corrosion inhibitor with asymmetric end groups, preparation method and application thereof

ActiveCN112300131AAvoid corrosionCorrosion Protection PreventionOrganic chemistryCarbon numberSide chain

The invention belongs to the field of metal material corrosion and protection, and particularly relates to an imidazoline corrosion inhibitor with asymmetric end groups, a preparation method and application thereof. The structure of the imidazoline corrosion inhibitor with asymmetric end groups is shown as the specification, wherein Y is one of O, S and N, R1 is a long-chain alkyl group, the carbon number of a carbon chain is 12-17, R2 is H or -(CH2)m-CH3, and m is an integer not less than 0. According to the corrosion inhibitor disclosed by the invention, an imidazoline ring is synthesized from organic heterocyclic carboxylic acid and polyamine by virtue of an intramolecular synergistic adsorption barrier effect, and then the imidazoline corrosion inhibitor with asymmetric end groups is obtained by virtue of condensation and end capping of long-chain carboxylic acid and an end amino group of a side chain of the imidazoline ring, and has very strong corrosion inhibition performance ata high temperature.

Owner:HUAZHONG UNIV OF SCI & TECH

Gemini nicotinate quaternary ammonium salt and method for making same

InactiveCN101205212AImprove surface activityStrong broad-spectrum bactericidal performance and corrosion inhibition performanceOrganic chemistryTransportation and packagingSolventCorrosion

The invention relates to a gemini nicotinic acid ester quaternary ammonium salt, namely a bromide bi-N-alkyl nicotinic acid athylene glycol / diethylene glycol / triethylene glycol, the preparation method of which is given as follows: (1) the nicotinic acid and the thionyl chloride are added in a reaction bottle in a molar ratio of the nicotinic acid to the thionyl chloride ranging from 1:3 to 1:6; after the reaction between the nicotinic acid and the thionyl chloride lasts for 2 to 4 hours, the nicotinic acid acyl chloride which is in a white needle-shaped crystal is obtained; (2) the nicotinic acid acyl chloride is dissolved in the dried chloroform and then the alcohol with a molar ratio to the nicotinic acid of 1:2 is dropped slowly in the mixtures of the nicotinic acid acyl chloride; the alcohols can be ethylene glycol, diethylene glycol or teg; the alcohols are dissolved by adding a proper amount of water and the nicotinates which are the products of the alcoholysis are subject to the pumping filtration and drying; (3) the nicotinate and the alkyl bromide are added in the reaction bottle in a molar ratio of the nicotinate to the alkyl bromide ranging from 1:2 to 1:6; the number of the carbon atoms of the alkyl bromide is 8, 10, 12, 14 or 16; the anhydrous acetonitrile is used as the solvent and the mixtures in the reaction bottle are heated and refluxed for 30 to 40 hours; after the mixtures are subject to the washing and pumping filtration, the products, gemini nicotinic acid ester quaternary ammonium salts, are obtained. The gemini nicotinic acid ester quaternary ammonium salt has very high surface activity and very strong bactericidal performances and corrosion inhibition, the preparation method of the invention is simple, convenient and feasible, is easy to be operated, delivers high yield and causes no environmental contaminations.

Owner:CHINA WEST NORMAL UNIVERSITY

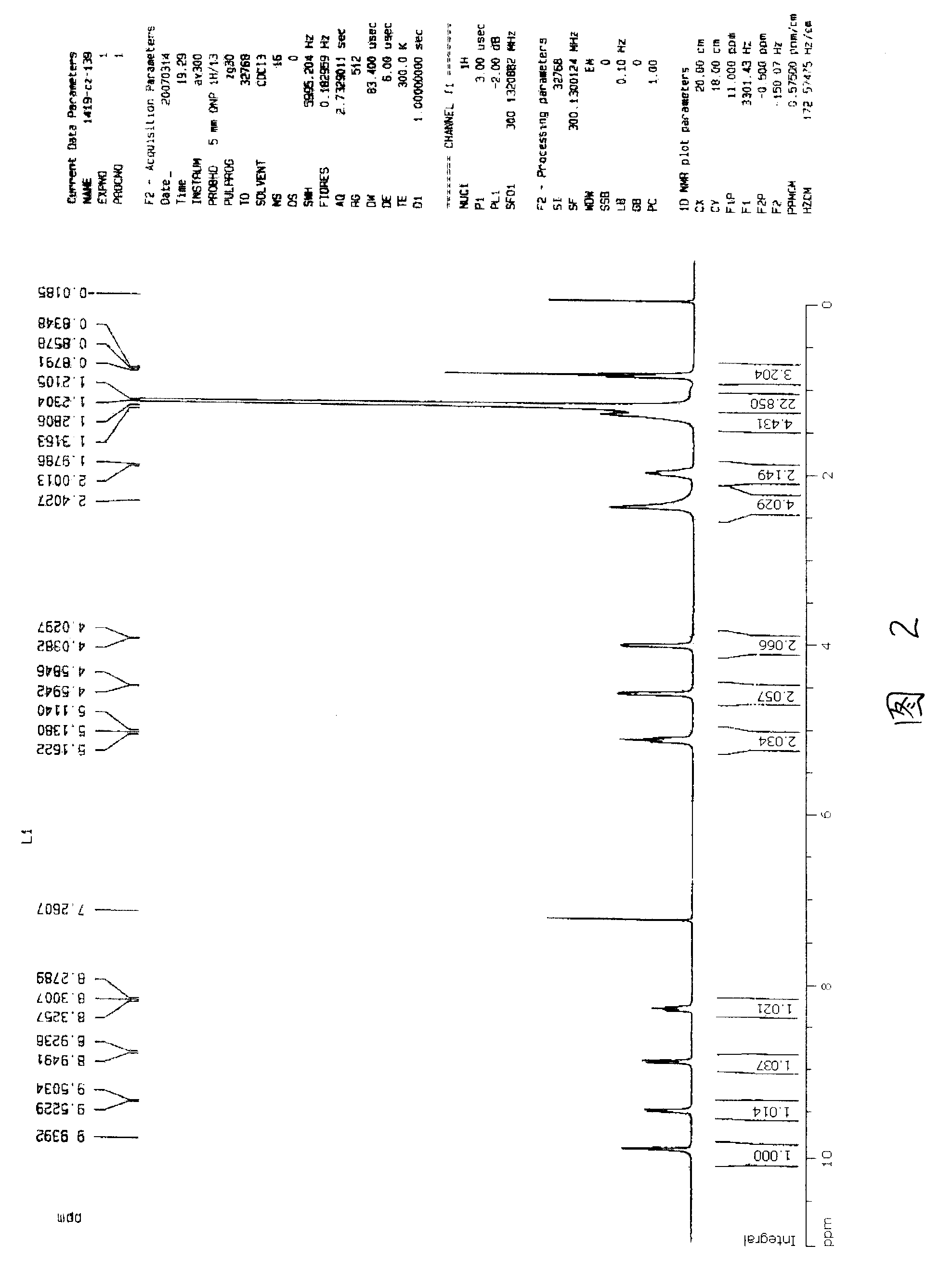

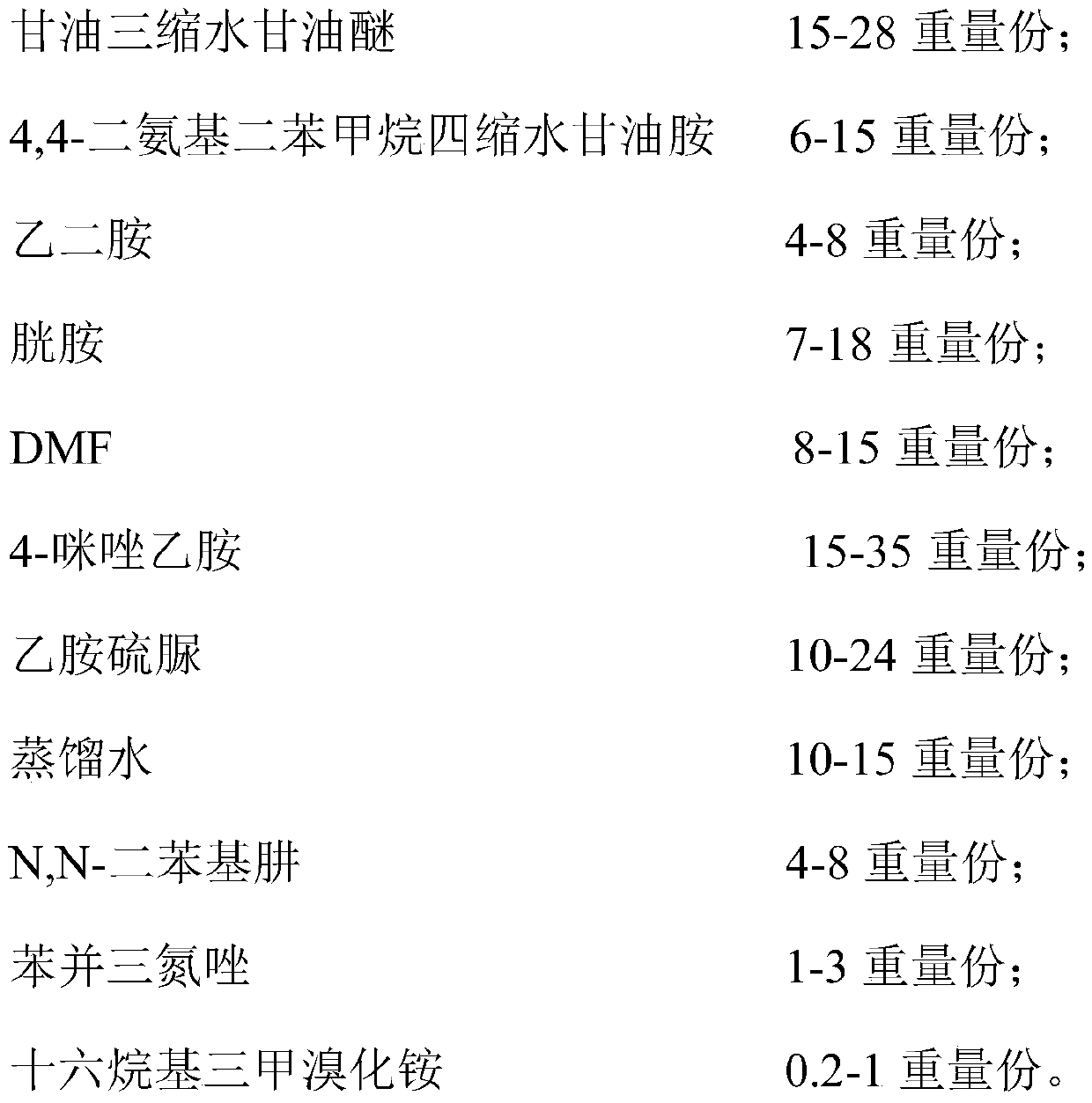

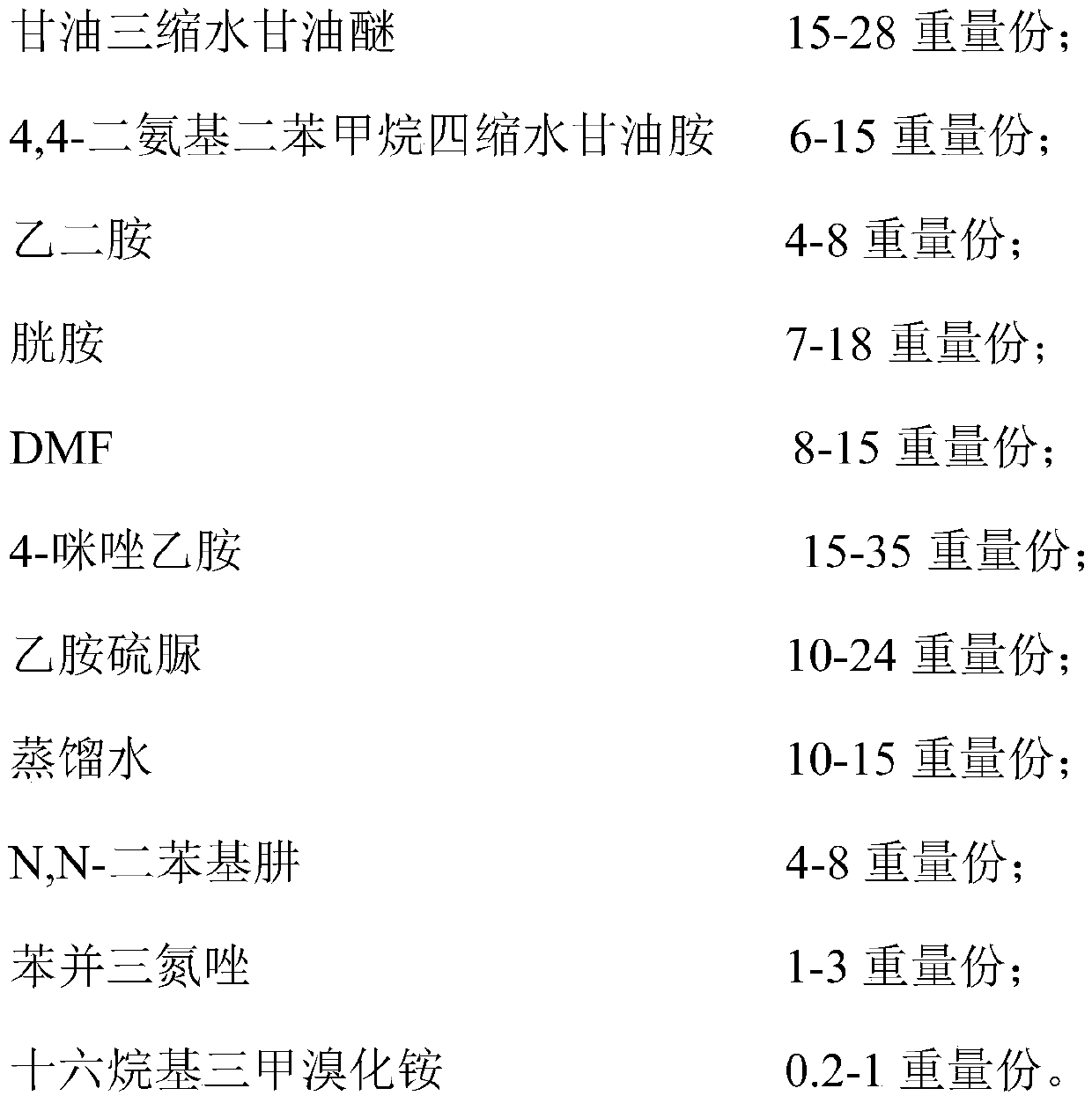

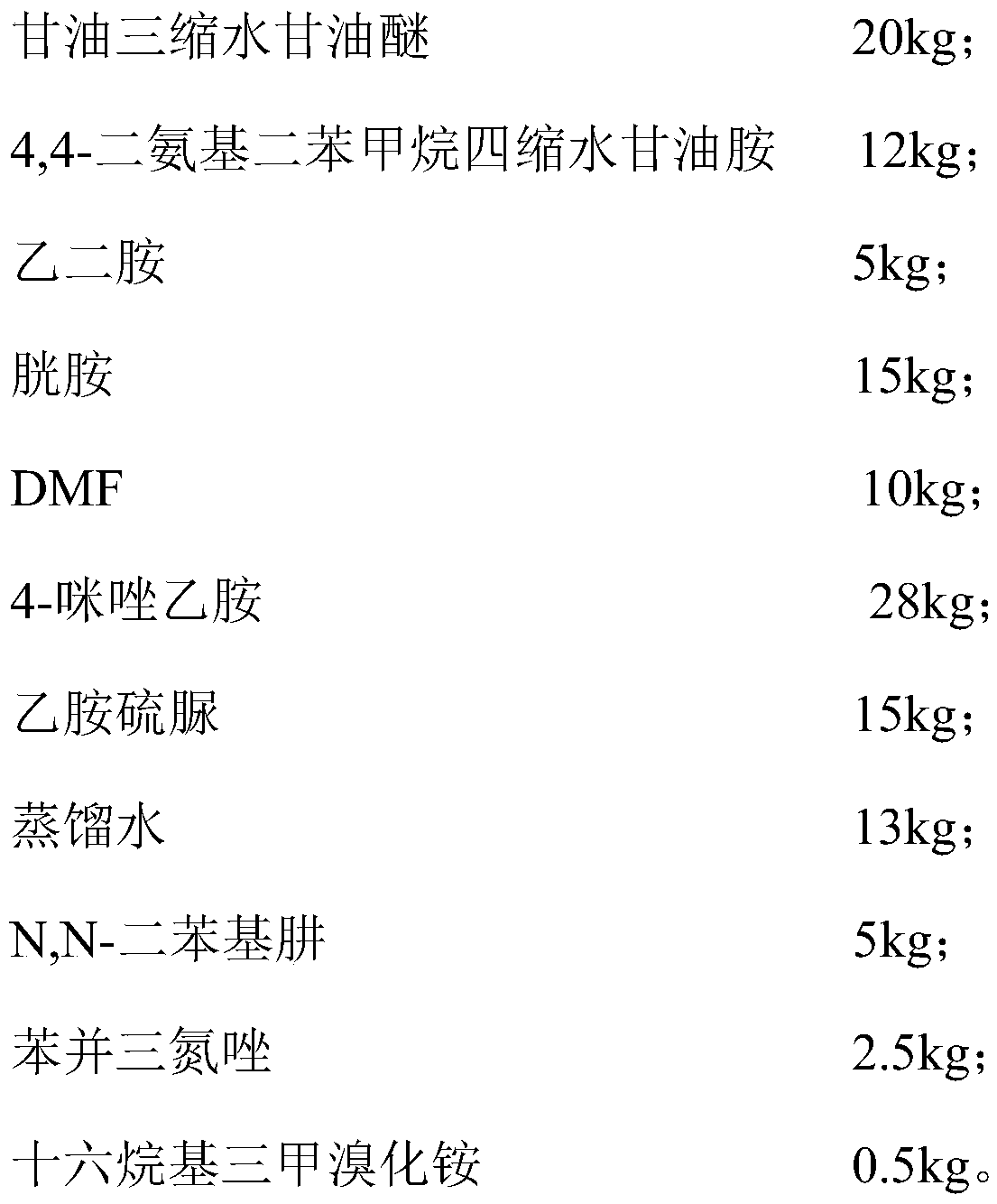

Corrosion inhibitor suitable for dynamic strong alkaline cleaning of metal workpieces and preparation method of corrosion inhibitor

ActiveCN110760863AIncrease surface adsorption capacityCorrosion stabilityMetallic materialsMaterials processing

The invention belongs to the technical field of metal material processing, particularly relates to a corrosion inhibitor suitable for dynamic strong alkaline cleaning of metal workpieces, and furtherdiscloses a preparation method of the corrosion inhibitor. The corrosion inhibitor suitable for dynamic strong alkaline cleaning of the metal workpieces is synthesized from raw materials of glycerin triglycidyl ether, 4,4-diaminodiphenylmethane tetraglycidyl amine, ethylenediamine, cystine, DMF, 4-imidazolylethylamine, aminethronii hydrobromidum, N,N-diphenylhydrazine and benzotriazole as raw materials. Through the synergistic effect between properties of all components, a corrosion inhibitor product is high in alkali resistance, can be further stirred in an alkaline environment for a long time without decomposition, can be directly used for the dynamic strong alkaline cleaning operation step of the metal workpieces such as brass, and has the more stable corrosion inhibition property and the higher corrosion inhibition effect.

Owner:HUANGSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com