Anti-corrosion post-treatment liquid for nickel coating surface and treatment process thereof

A post-treatment liquid and treatment process technology, which is applied in the direction of metal material coating process, coating, liquid chemical plating, etc., to achieve the effect of simple treatment process, increased thickness, and increased compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of liquid A: Slowly add 0.5mol γ-aminopropyltrimethoxysilane into 1 liter of water / butanol mixed solvent, the water / alcohol volume ratio is 1:17, hydrolyze for a period of time at room temperature;

[0030] 2. Preparation of liquid B: Dissolve 1 mmol of stearic acid in 1 L of water with sodium dodecyl sulfate, and adjust the pH of the solution to 2 with phosphoric acid;

[0031] 3. At room temperature, immerse the test board in liquid A for 30 seconds, take it out, immerse it in liquid B for 15 minutes, the temperature of liquid B is 70°C, take it out, rinse it with warm water, dry it, and test the corrosion resistance and electrical properties.

Embodiment 2

[0033] 1. Preparation of liquid A: Slowly add 0.2mol N-β(aminoethyl)-γ-aminopropyltriethoxysilane to 1 liter of water / isopropanol mixed solvent, the water / alcohol volume ratio is 2:17 , hydrolyzed for a period of time at room temperature;

[0034] 2. Preparation of liquid B: Dissolve 5mmol stearic acid in 1L water with polyethylene glycol octyl ether, adjust the pH of the solution with phosphoric acid

[0035] adjust to 3;

[0036] 3. At room temperature, immerse the test board in liquid A for 60 seconds, take it out, and immerse it in liquid B for 20 minutes. The temperature of liquid B is 60°C.

[0037] After washing with warm water, blow dry, and test the corrosion resistance and electrical properties.

Embodiment 3

[0039] 1. Preparation of liquid A: Slowly add 0.1 mol of polyaminoalkyltrialkoxysilane into 1 liter of water / butanol mixed solvent, the water / alcohol volume ratio is 1:11, and hydrolyze for a period of time at room temperature;

[0040] 2. Preparation of liquid B: Dissolve 10 mmol of stearic acid in 1 L of water with sodium dodecyl sulfate, and adjust the pH of the solution to 2.5 with acetic acid;

[0041] 3. At room temperature, immerse the test board in solution A for 45 seconds, take it out, immerse it in solution B for 30 minutes, the temperature of solution B is 50°C, take it out, rinse it with warm water, dry it, and test the corrosion resistance and electrical properties.

[0042]

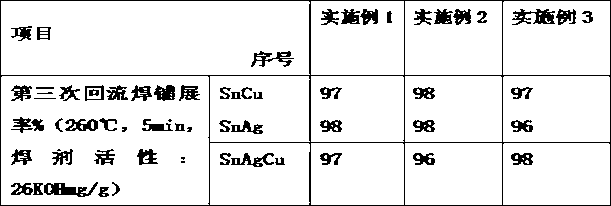

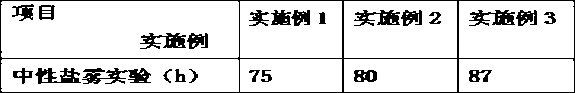

[0043] Above-mentioned embodiment sample carries out relevant test data as follows:

[0044] 1. Neutral salt spray test experiment

[0045] After the nickel-plated experimental plate was processed according to the processes of Example 1, Example 2, and Example 3, the neutral salt spray te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com