Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1881results about How to "Improve filling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

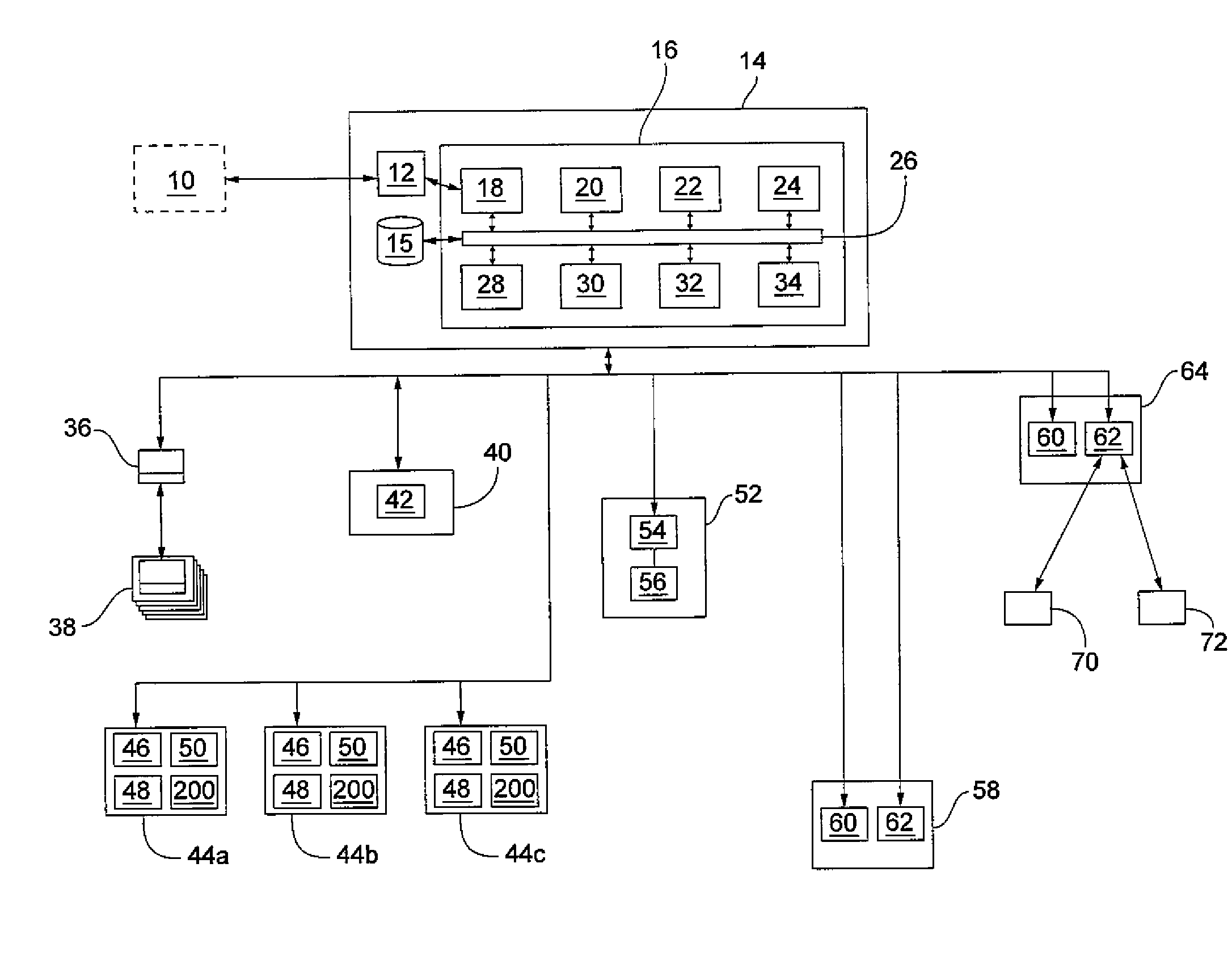

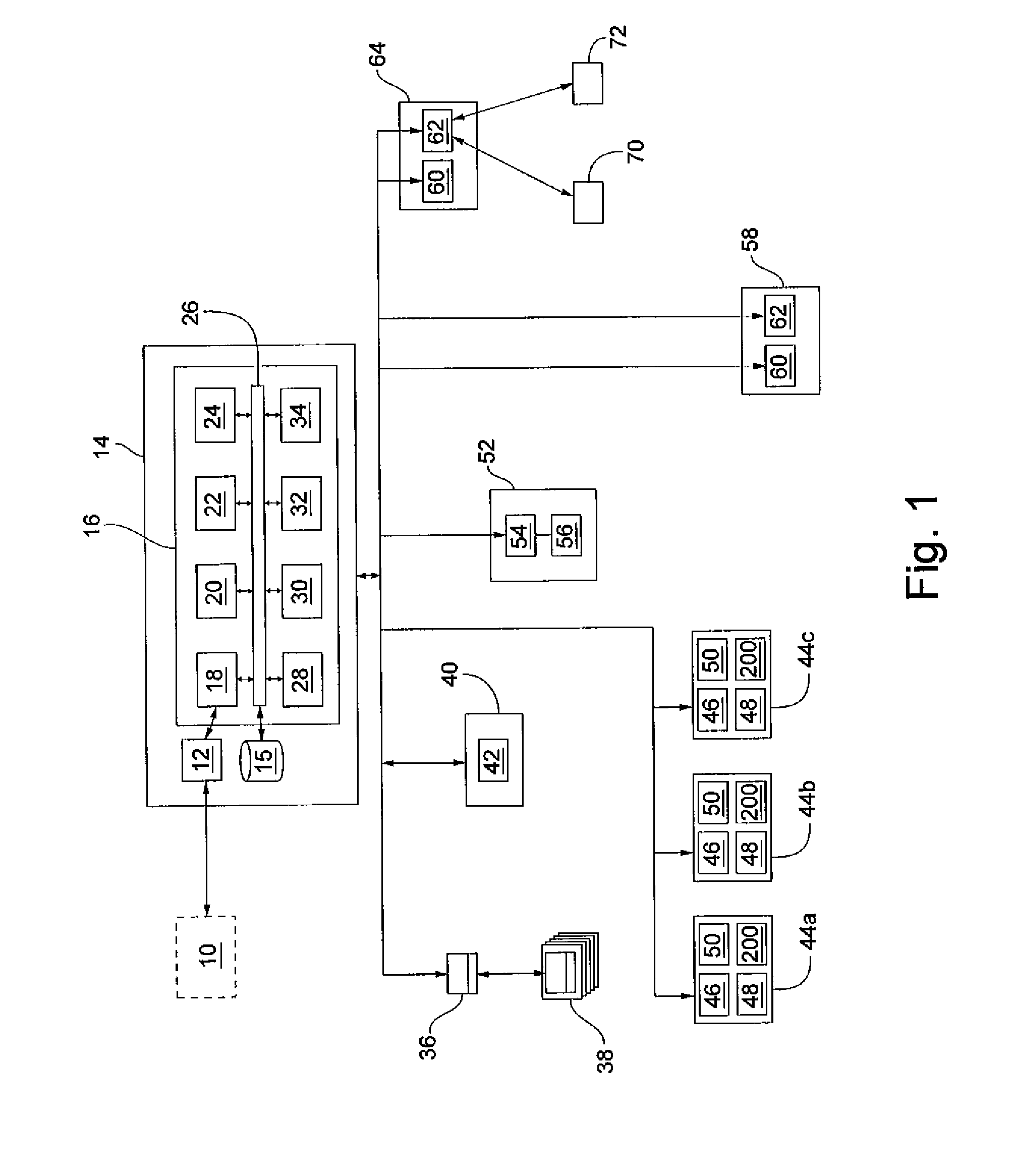

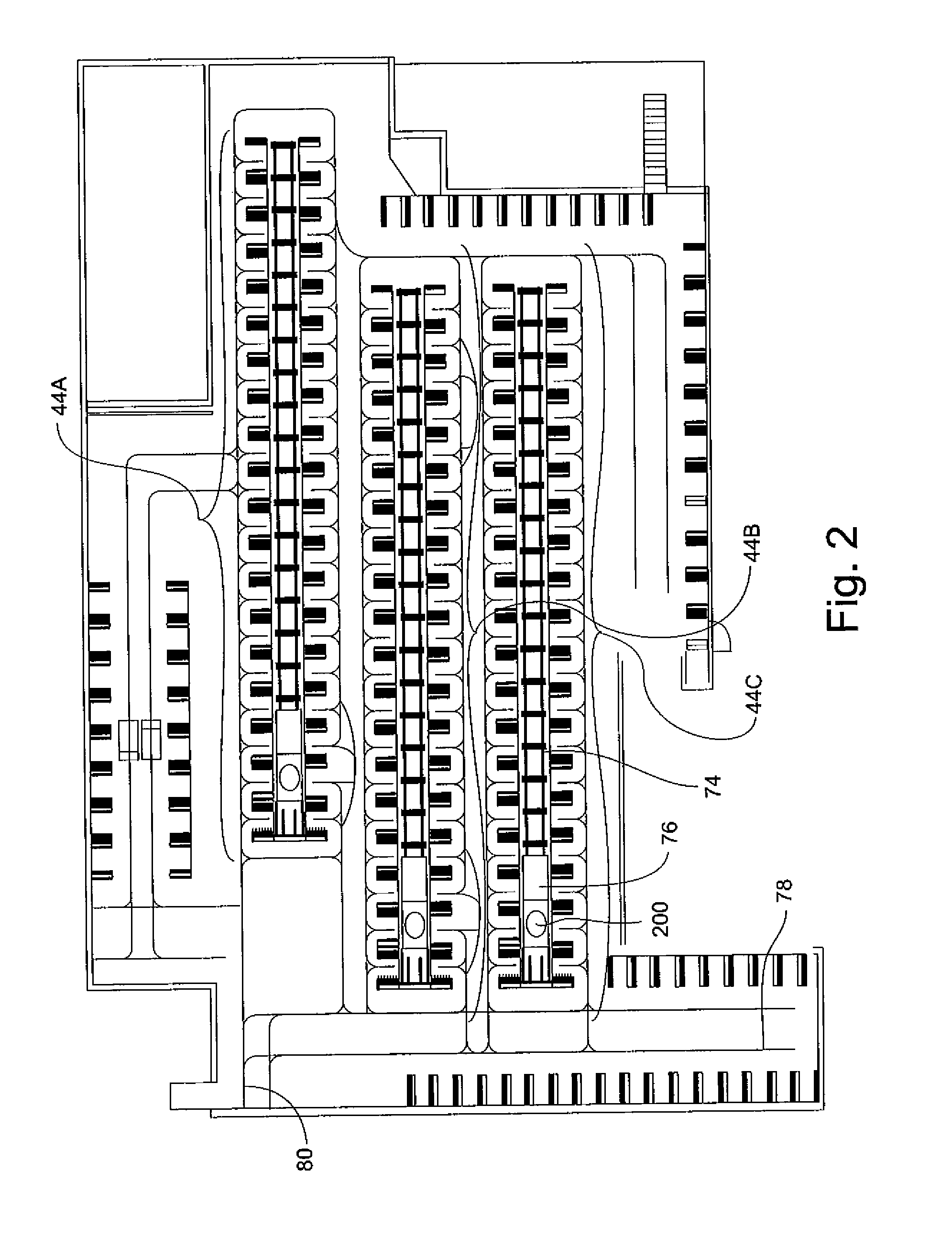

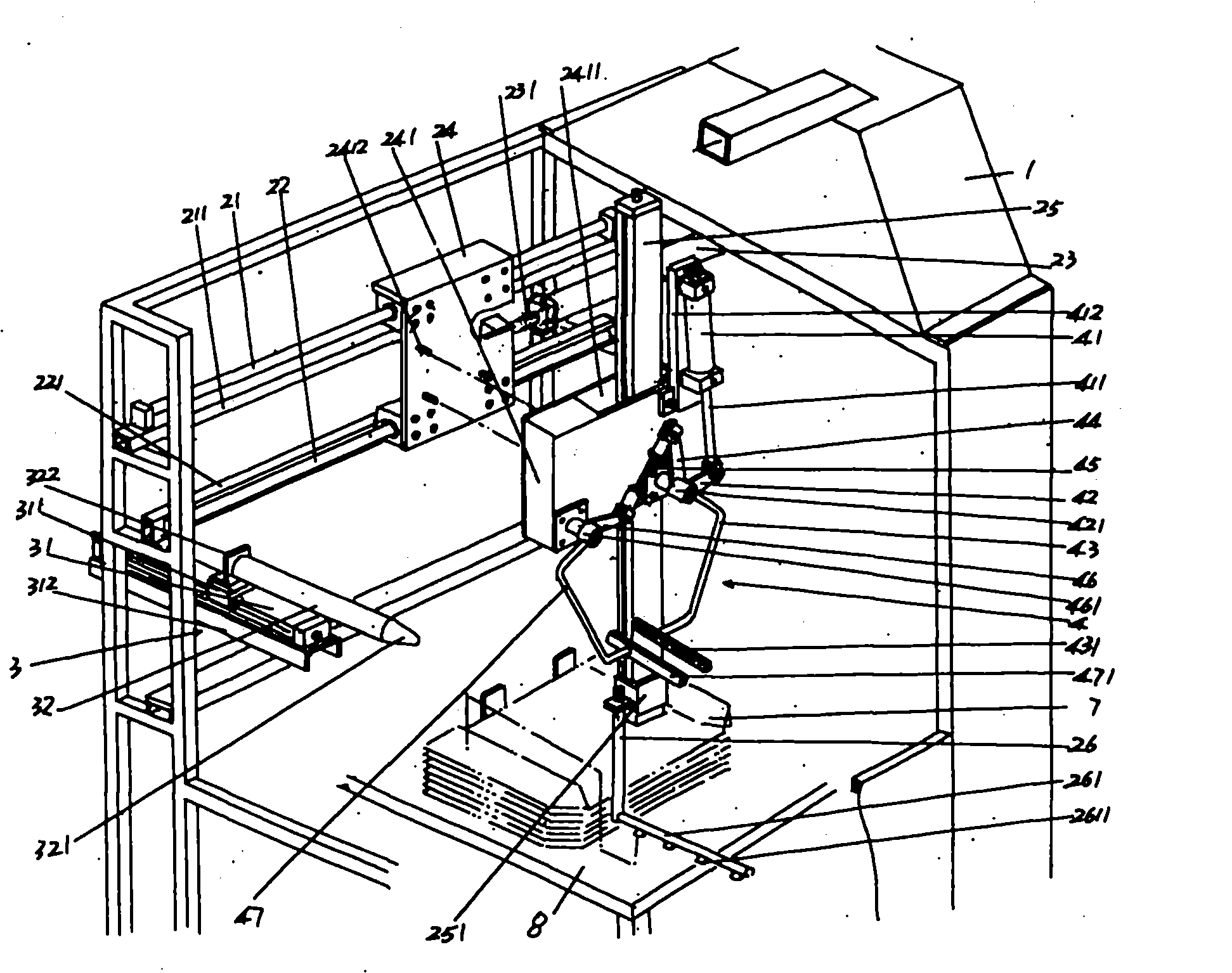

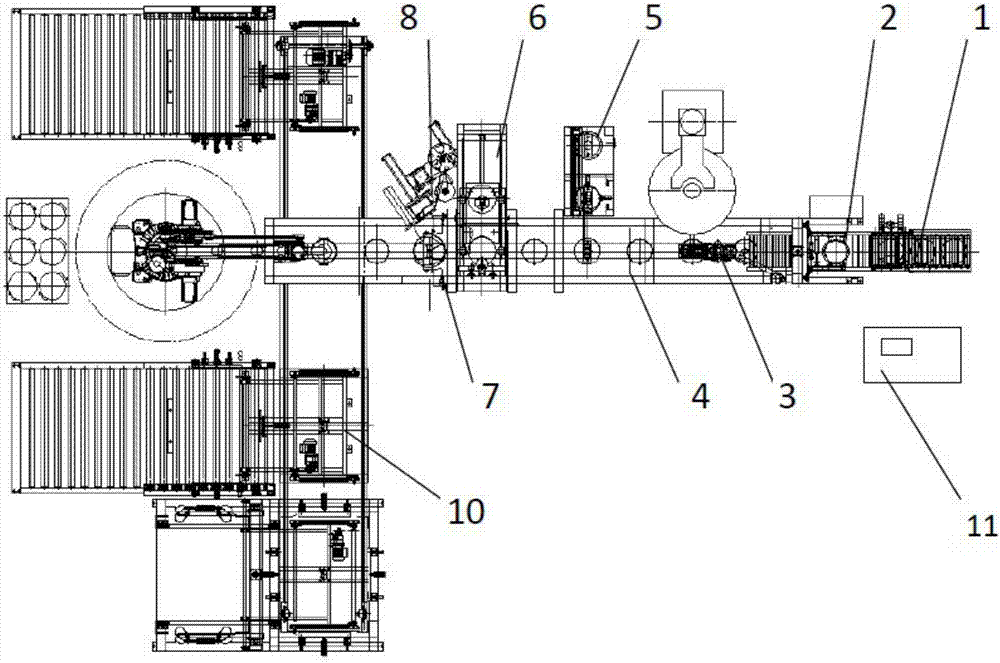

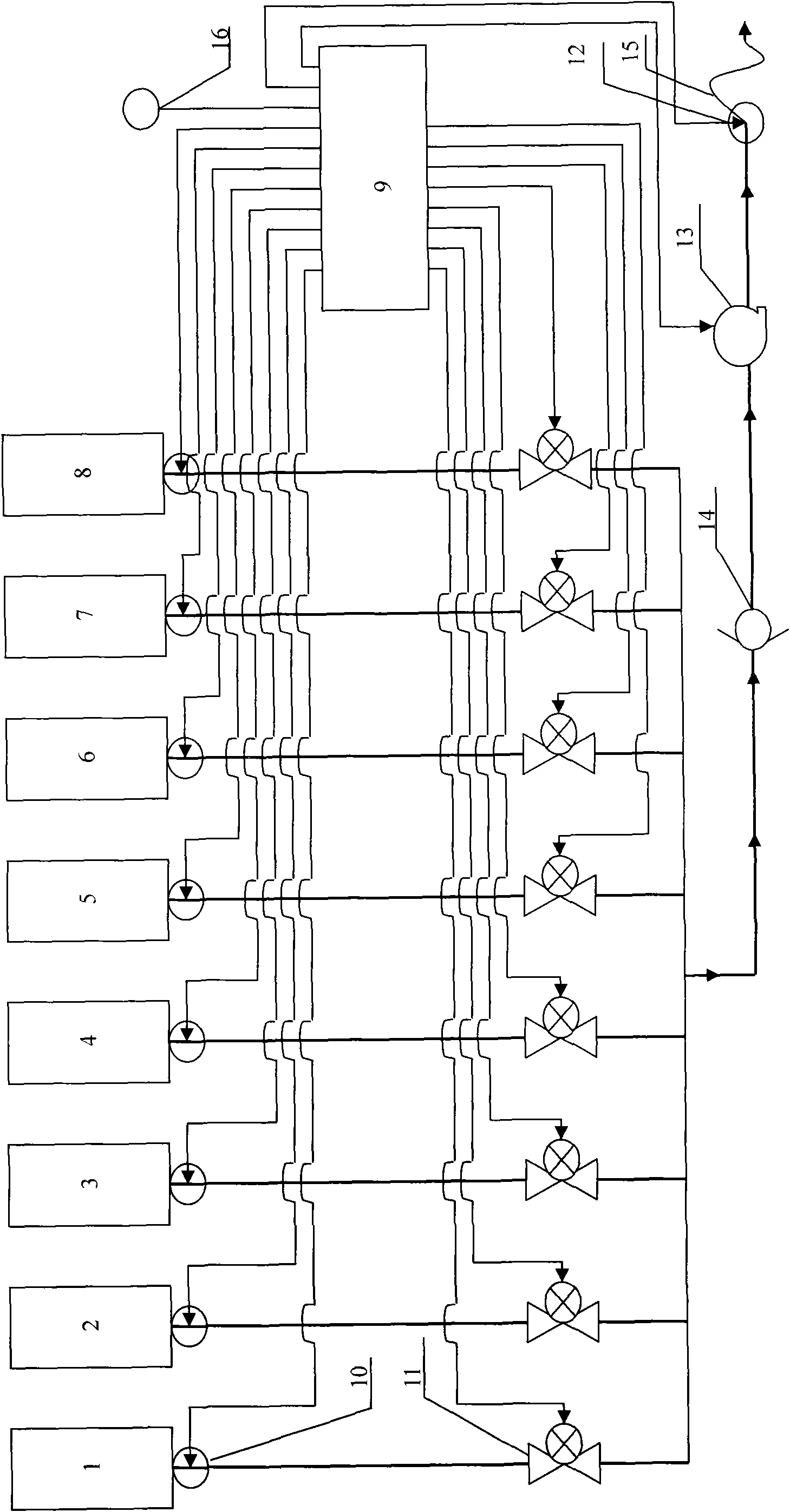

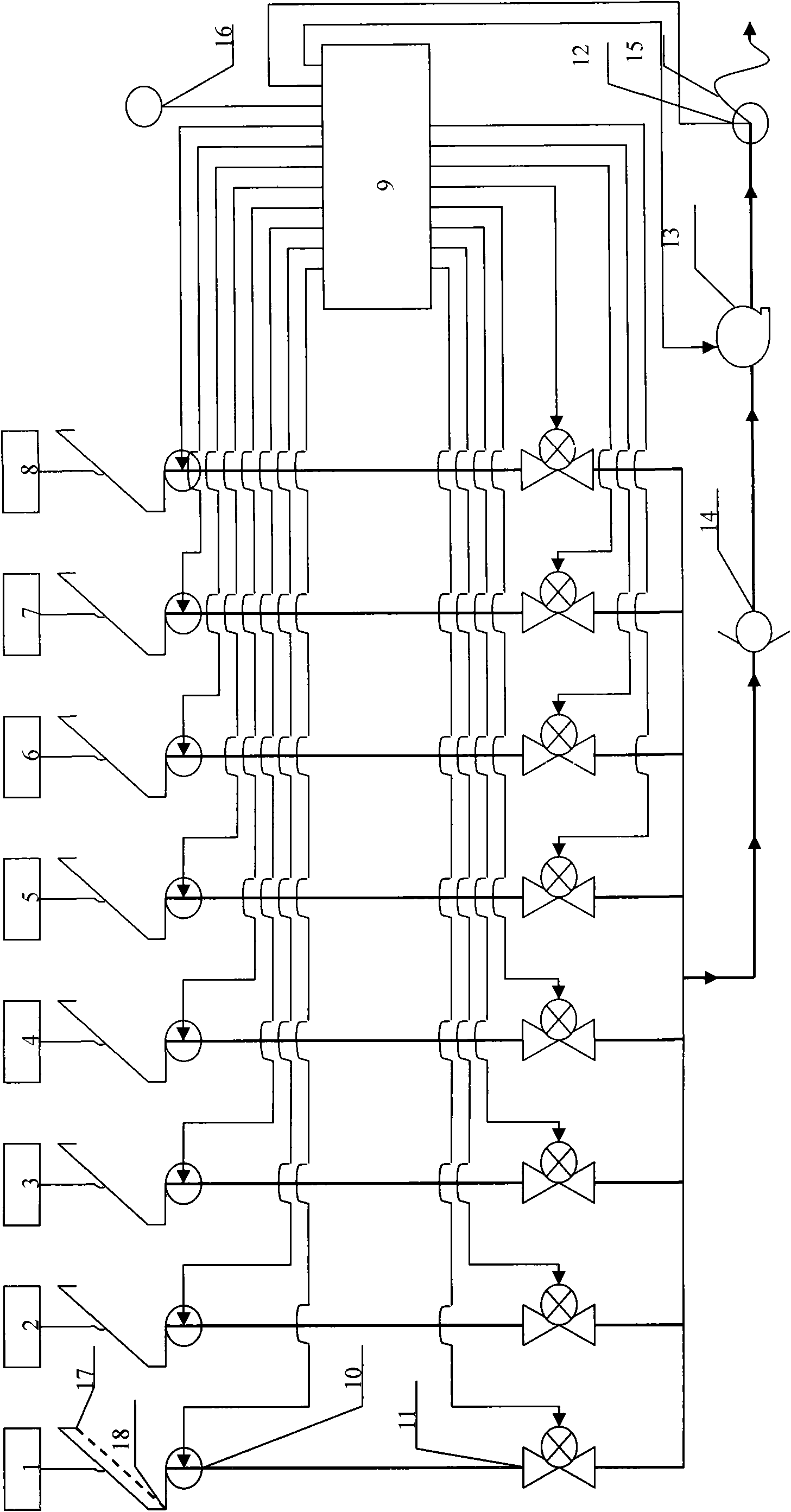

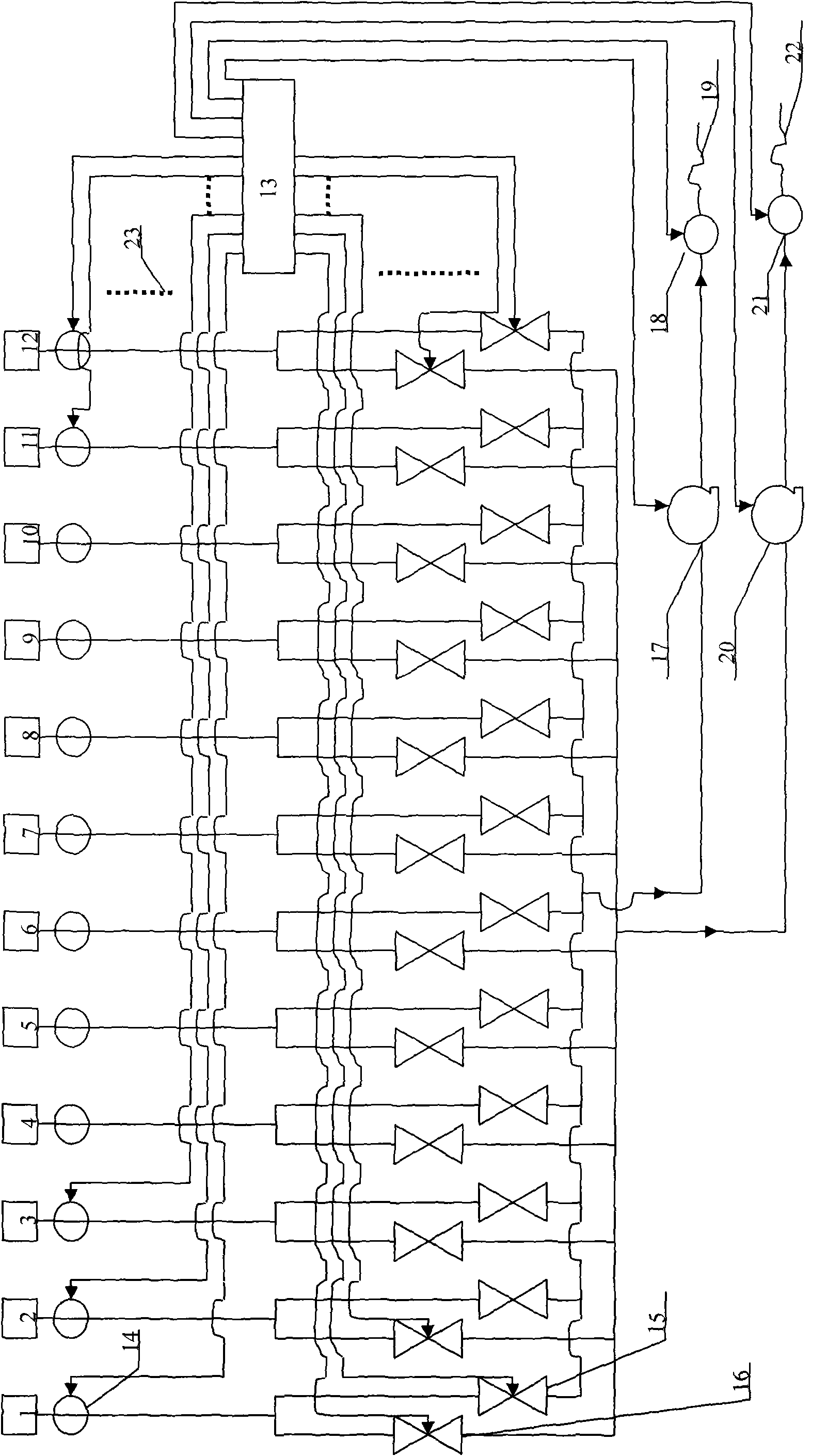

Palletizing systems and methods

InactiveUS20080131255A1Increase order filling efficiencyImprove filling efficiencyLoadersPackagingCustomer orderAutomatic guidance

Palletizing systems and methods increasing the efficiency at which pallets of mixed products are built. The systems and methods include a pallet building module for receiving customer orders and generating pallet building instructions for arranging the products on the pallets, among other functions. The pallet building module is in communication with a number of robot cells that include source products and pallet building robots for building pallets based upon instructions generated by the pallet building module. The system includes other modules for system control including conveyor controllers, forklift controllers, and automatic guided vehicle controllers, among other controllers. Methods for building pallets of mixed product from source products within more than one robot cell.

Owner:TRANSBOTICS CORPORATION

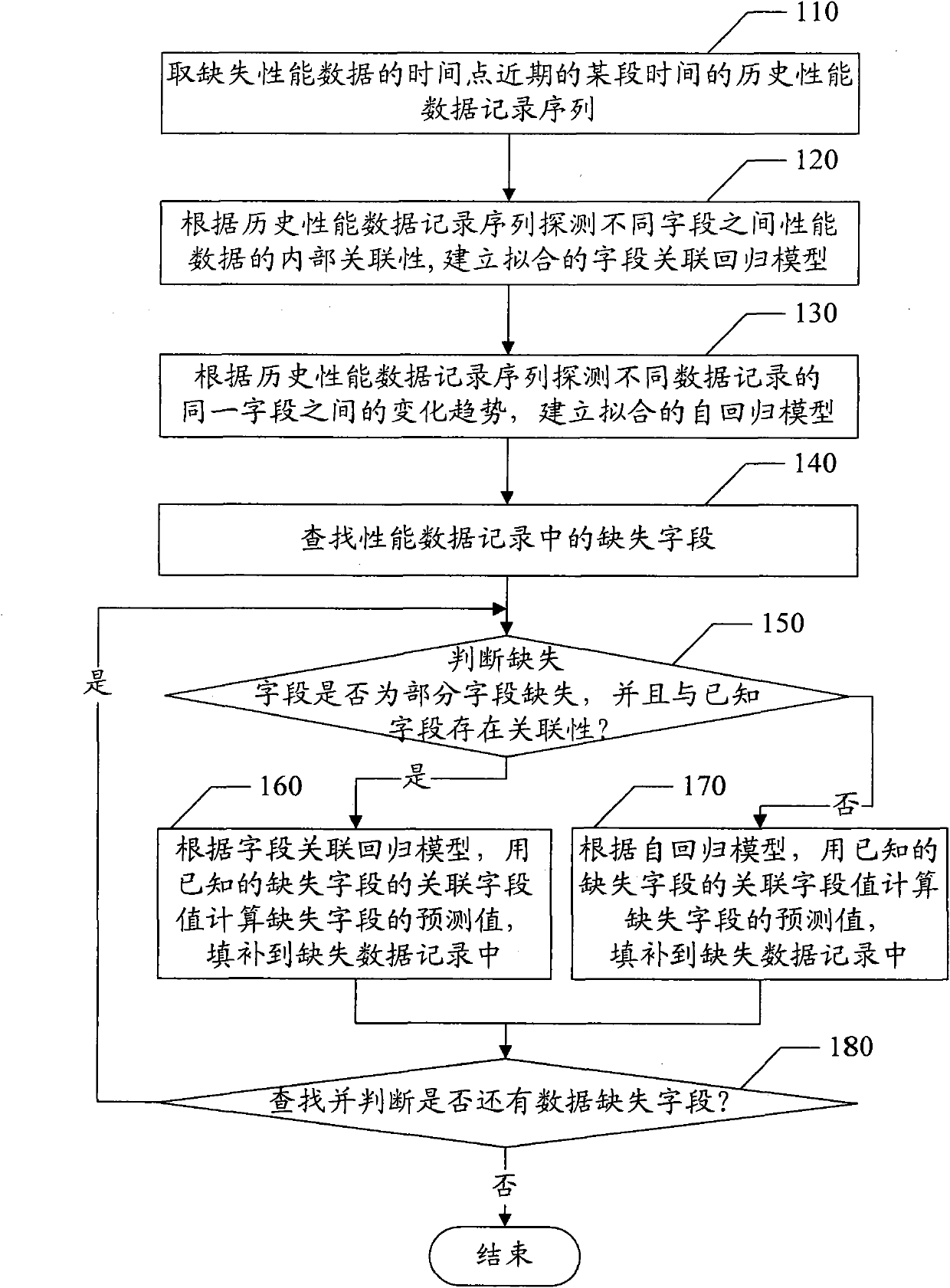

Filling method and device thereof for performance data

ActiveCN102025531AGuaranteed accuracyRealize scientificData switching networksSpecial data processing applicationsMissing dataNetwork management

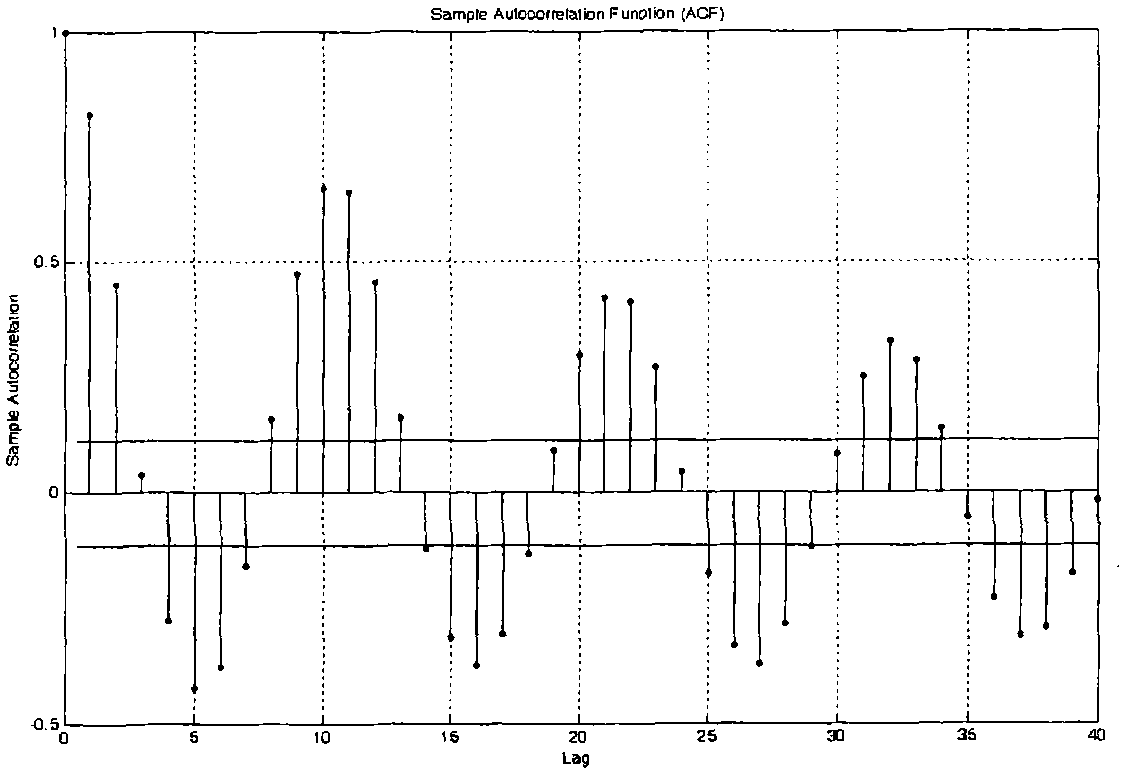

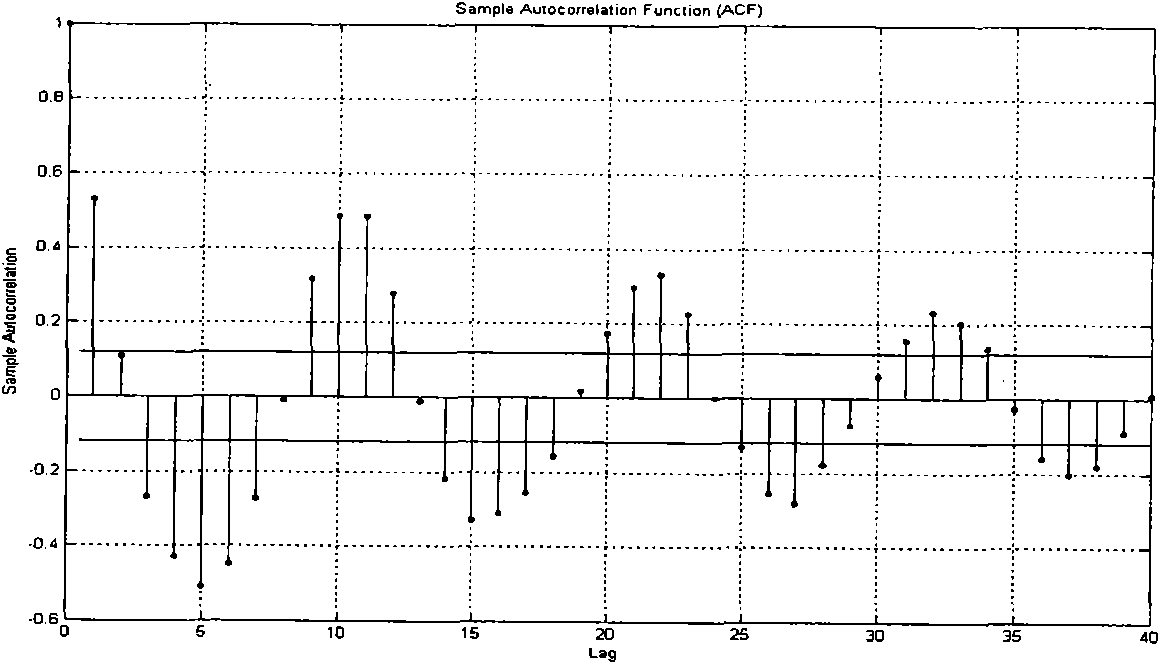

The invention provides a filing method and a device thereof for performance data, and the method comprises the following steps: getting a sequence of historical performance data records; detecting the internal association among different data items with specific relationship according to the sequence of the historical performance data records; establishing a regression model for mutual fitting for the associated data items with the internal association; and using the corresponding regression model to calculate estimation values of the data items in deletion according to the known values of the associated data items if the deletion of the data items occurs in the performance data records and filling the estimation values to the performance data records in deletion. The modeling method based on mathematical statistics and data mining technology is firstly applied in filling of the performance data in a network management system, thereby realizing scientification, intelligentization and automation of the filling method, not only effectively ensuring the accuracy of data filling, but also greatly improving the filling efficiency of the batch data in deletion.

Owner:BEIJING BOCO COMM TECH +2

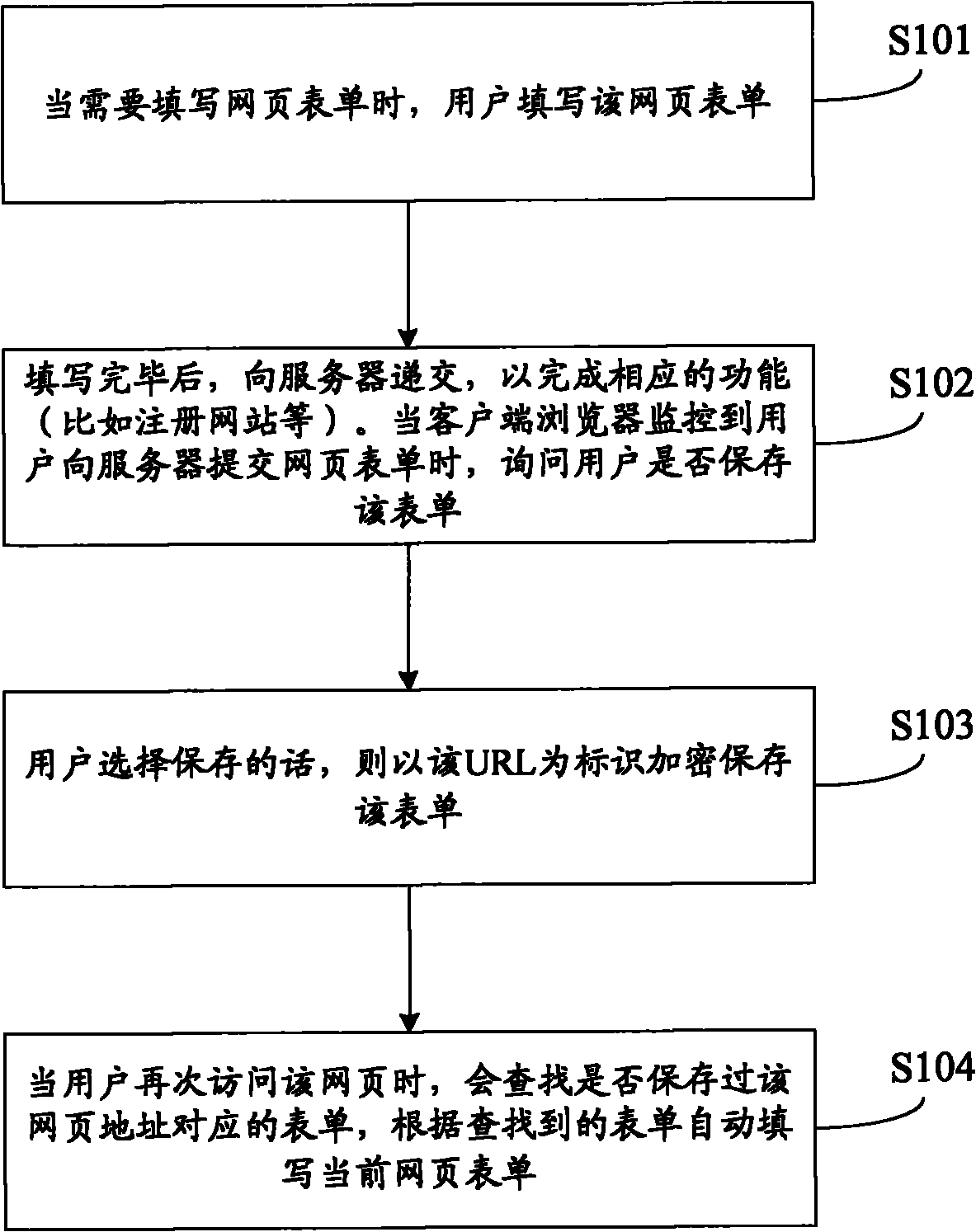

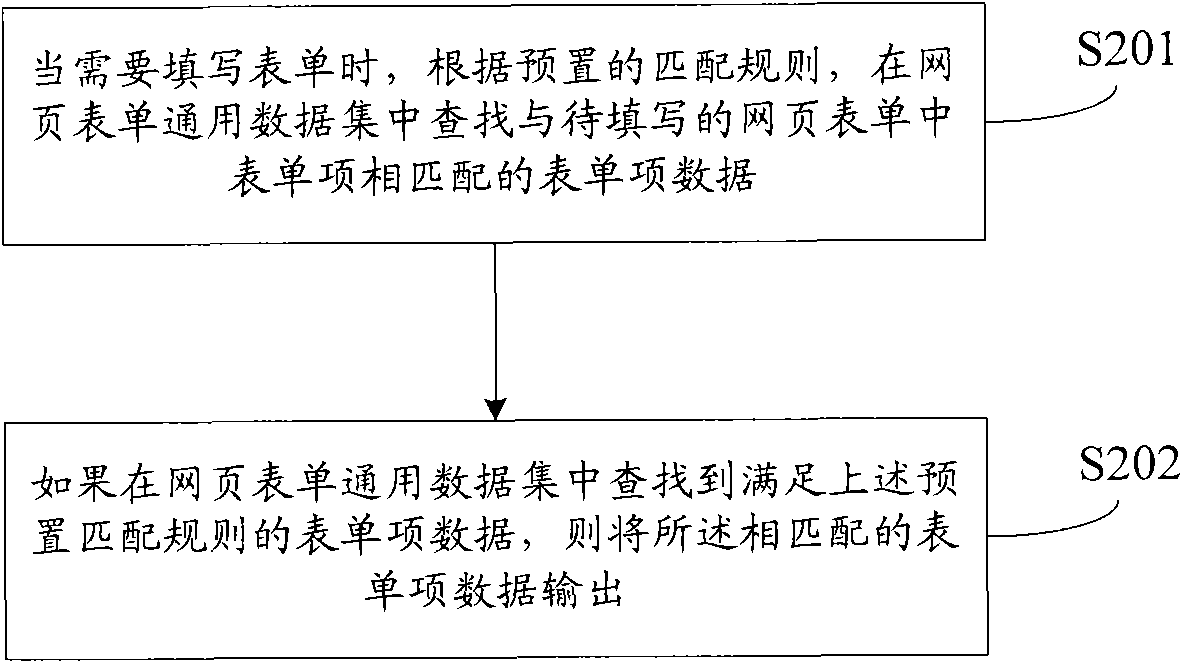

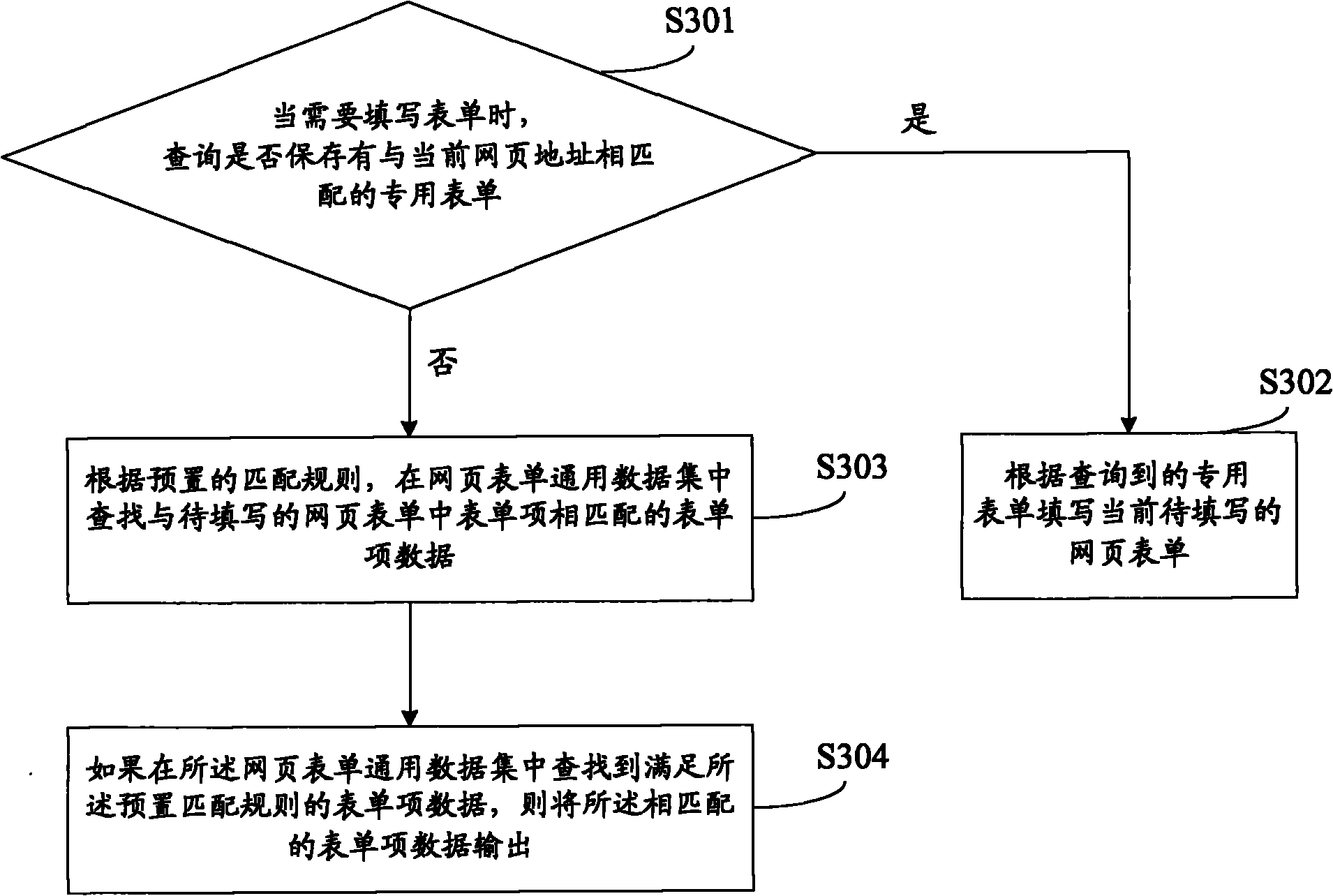

Web form data output method, device and form processing system

ActiveCN101782919AReduce workloadImprove filling efficiencyNatural language data processingSpecial data processing applicationsData setForm processing

The embodiment of the invention discloses a web form data output method, a device and a form processing system, relating to the technical field of a browser. The method comprises the steps: if trigger events output by a web form universal dataset is monitored, a form item data which is matched with the form item in the web form to be filled is found in the web form universal data set according to a preset matching rule; the web form universal data set is obtained by summarizing and analyzing the form items of at least two stored forms in advance; and if the form item data which meets the preset matching rule is found out in the web form universal data set, the matched form item data is output. The device comprises a form processing module, a matching finding module and a data output module. The system comprises a form finding module and an analyzing and summarizing module. The embodiment of the invention can increase the filling efficiency of the web form and is beneficial to improving the user experience.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

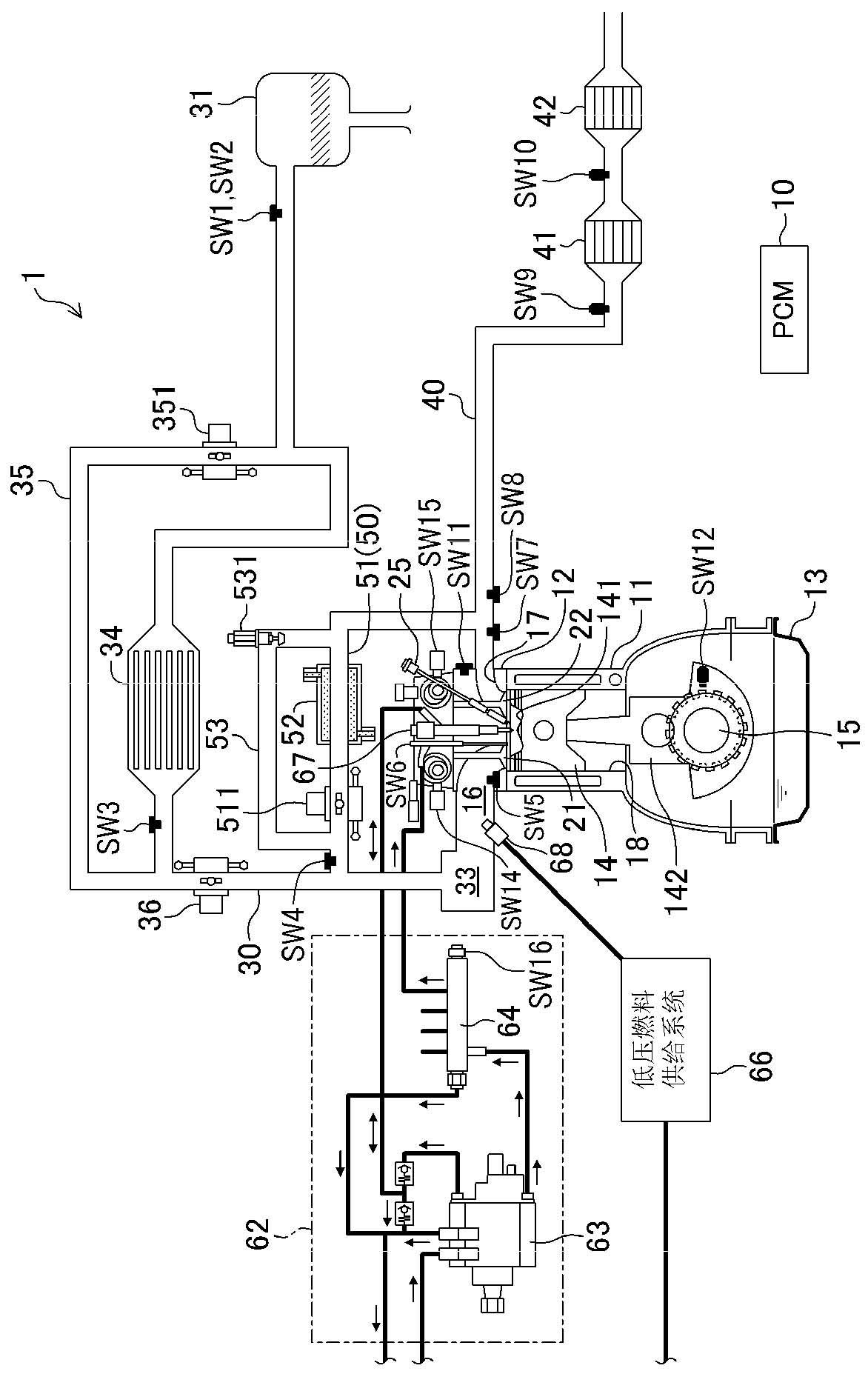

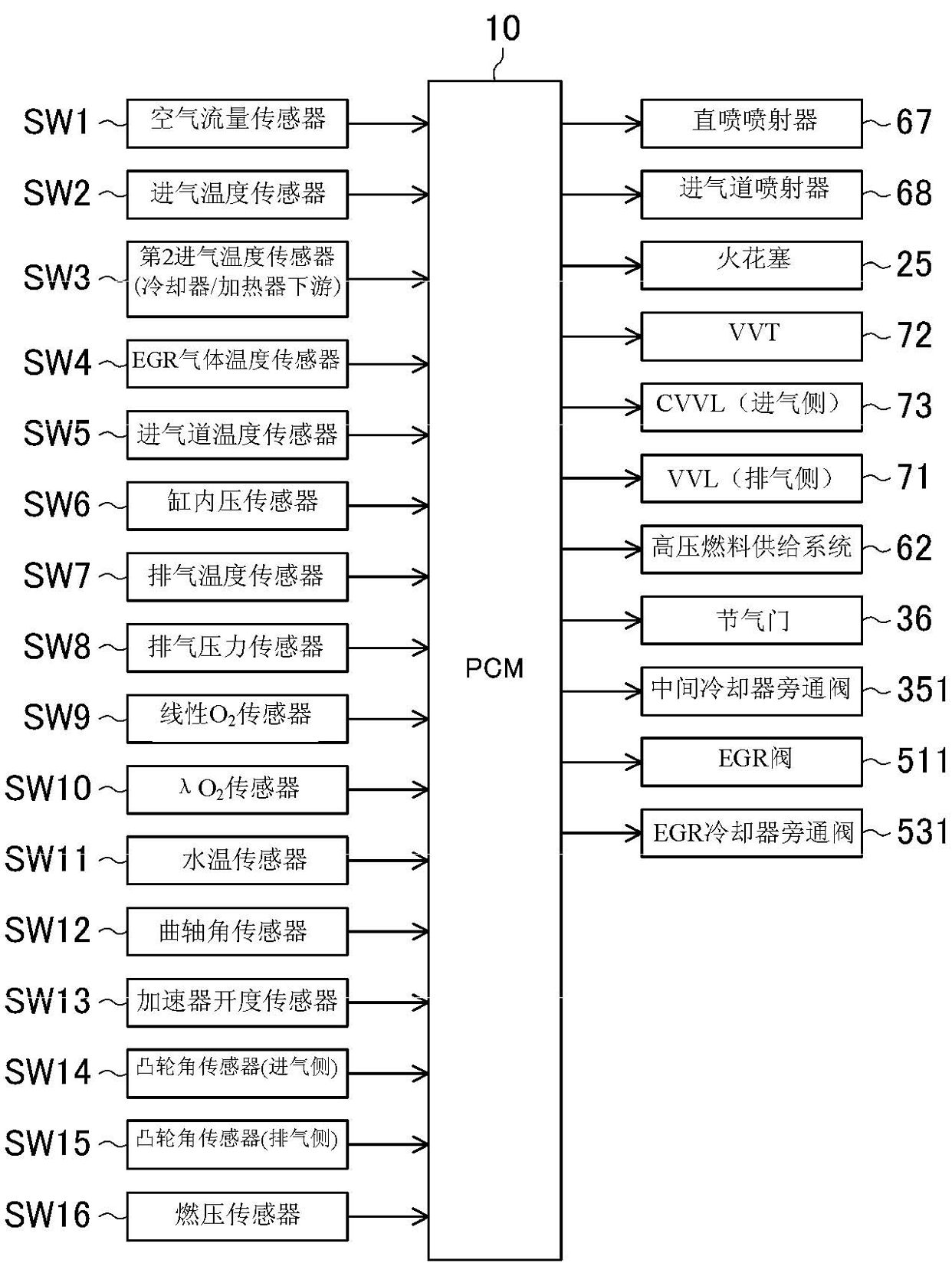

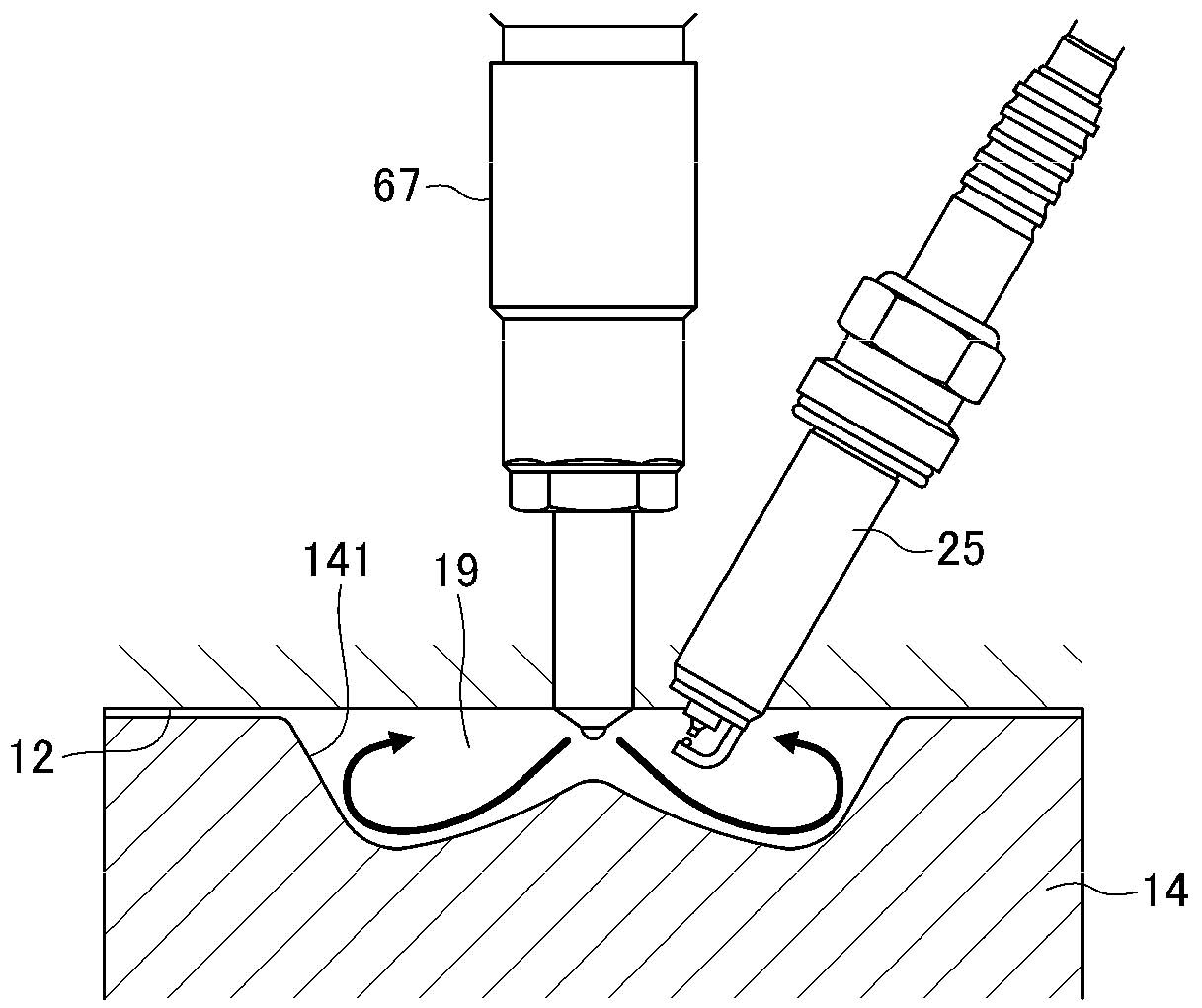

Control device of spark-ignition gasoline engine

InactiveCN102650239ALarge injection volumeShorten the formation periodElectrical controlInternal combustion piston enginesInjectorFuel supply

The disclosure provides a control device of a spark-ignition gasoline engine. According to the invention, in a spark-ignition gasoline engine (1) with a higher high compression ratio, abnormal burning in a high load area can be avoided. When an operating state of an engine body is within a low engine speed range, a controller (PCM 10) operates a fuel pressure variable mechanism (a high pressure fuel supply system 62) so that a fuel pressure is higher within a high engine load range compared to a low engine load range, the controller operates, within the high engine load range, a fuel injection mechanism to perform at least a fuel injection into the cylinder by a cylinder internal injection valve (a straight spray injector 67) at a timing during a retard period from a late stage of a compression stroke to an early stage of an expansion stroke, and the controller (10) operates, within the high engine load range, an ignition plug to ignite at a timing during the retard period and after the fuel injection.

Owner:MAZDA MOTOR CORP

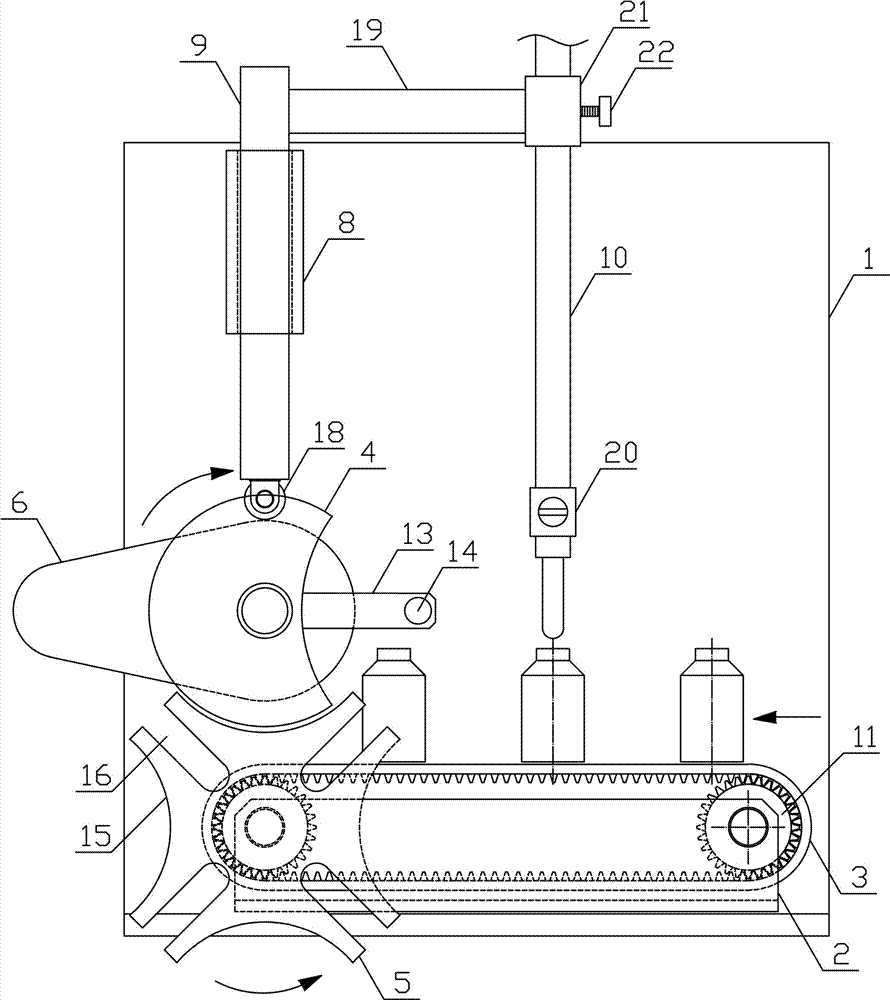

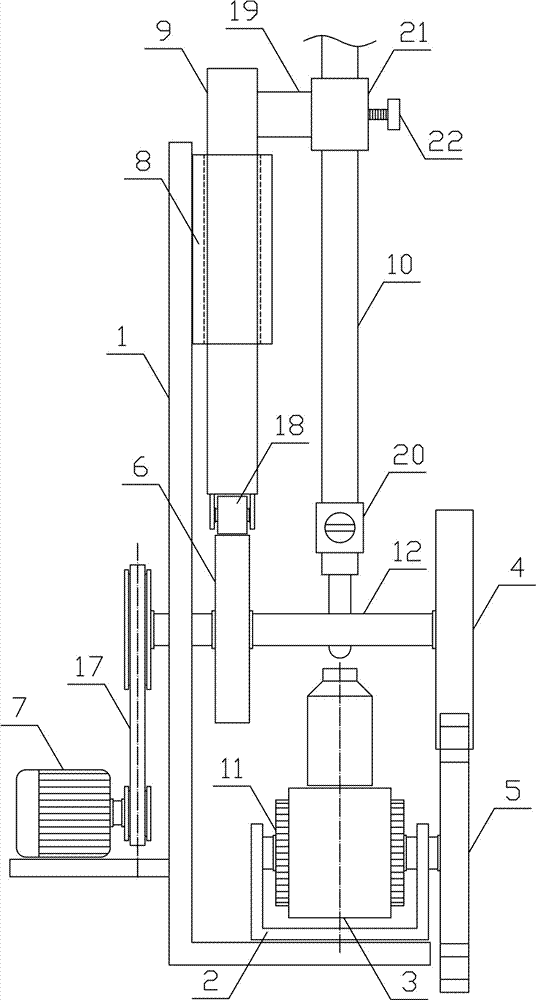

Continuous filling mechanism

InactiveCN107055439ASmooth transmissionThe conveyor belt can be moved intermittently according to the needs, and the transmission is smoothLiquid bottlingFilling materialsEngineering

The invention discloses a continuous filling mechanism, which belongs to the field of material filling machinery and equipment. The invention includes a fixed bracket, a transmission bracket, a round can conveyor belt, a rotating circular plate, a slotted rotary plate, a rotating cam, a rotating motor, a lifting sleeve, a lifting guide rod and a filling material tube, and the round can conveyor belt is horizontally arranged on the transmission bracket. On the side, the rotating circular plate is vertically arranged at one end of the rotating shaft, and the card slot rotating plate is vertically arranged on one side of the translation pulley. Between two adjacent rotating arc surfaces, there are drive slots along the radial direction of the card slot rotating plate. The rotating card slot matching the wheel, the rotating motor and the rotating shaft are connected by a transmission belt transmission, the lifting sleeve is slid along the vertical direction and a lifting guide rod is installed, and the filling material tube is vertically set at one end of the filling support plate . The invention has a reasonable structural design, can quickly, efficiently and smoothly fill the round cans one by one continuously, improves the efficiency and quality of filling, and meets the needs of production and use.

Owner:屠明州

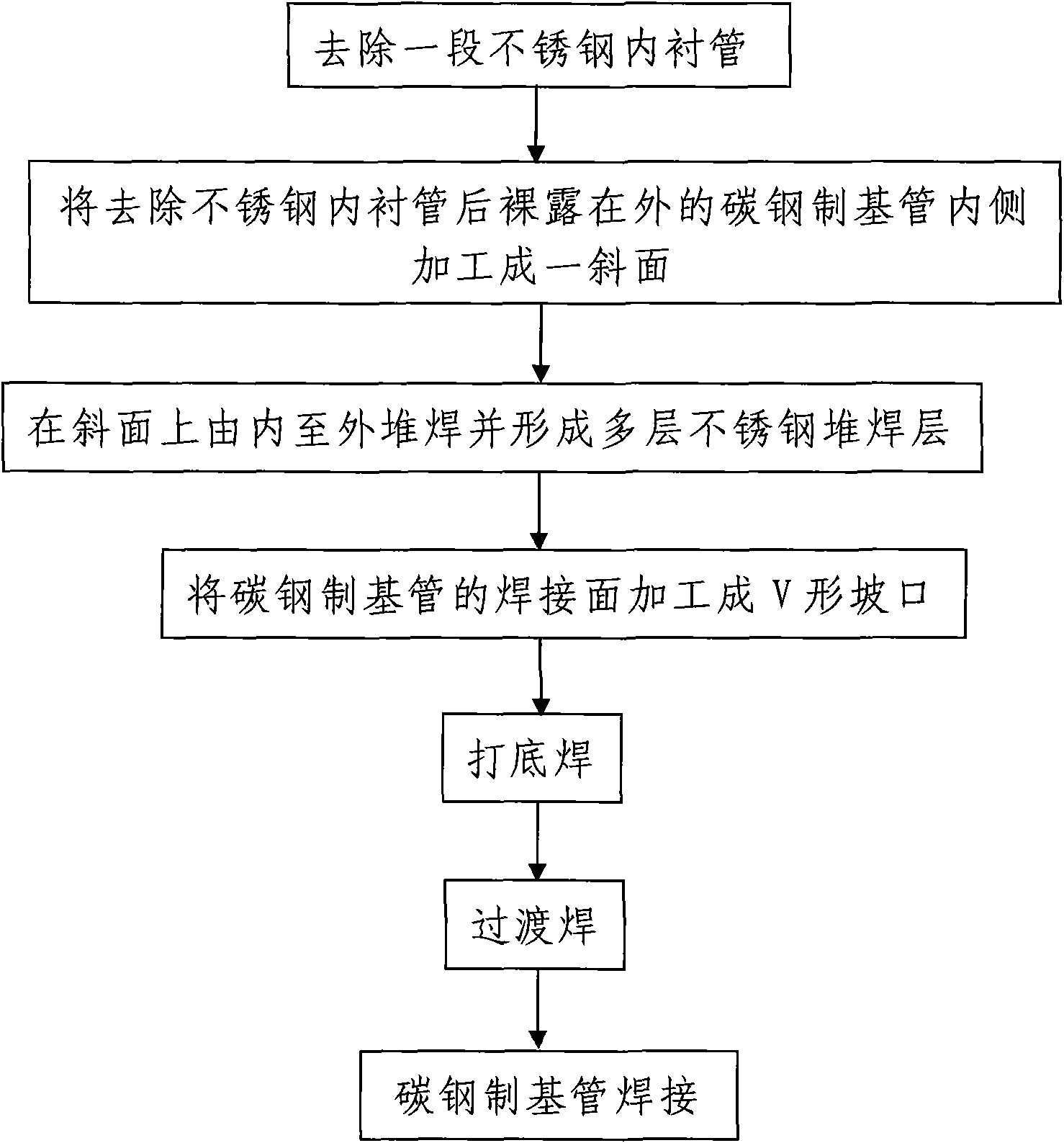

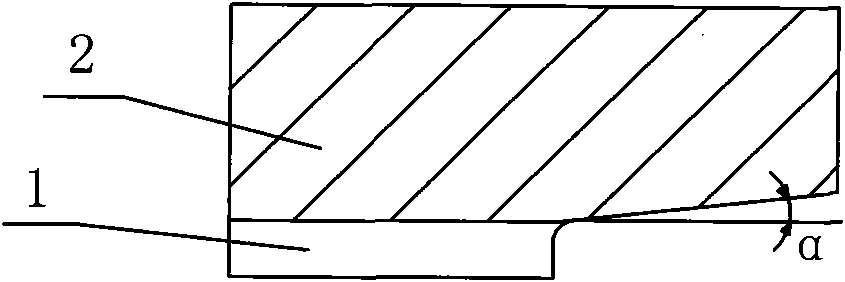

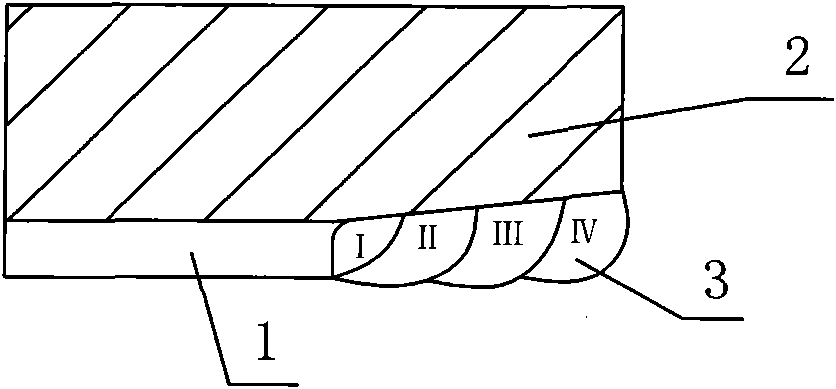

Method for welding composited tube at bonding interface of carbon steel/stainless steel machinery

ActiveCN101653855ASimple welding processExcellent weld mechanical properties and corrosion resistanceArc welding apparatusWelding/cutting media/materialsCarbon steelArc welding

The invention discloses a method for welding composited tube at the bonding interface of carbon steel / stainless steel machinery, comprising the following steps: 1. welding groove treatment as follows:removing a section of stainless steel lined tube; processing the interior of the carbon steel parent tube exposed outside after removing the stainless steel lined tube into an inclined plane inclinedinwards from exterior to interior; using a tungsten electrode argon arc welding machine to carry out bead weld on the inclined plane from interior to exterior and forming multiple stainless steel bead weld layers; processing the weld surface of the carbon steel parent tube into a V-shaped groove; 2. backing weld: when fitting up the stainless steel bead weld layers before backing weld, adopting the tungsten electrode argon arc welding machine to carry out fitting-up and fixing in a manner of spot welding; 3. transition weld; and 4. carbon steel parent tube weld. The invention features simpleprocedure steps, less used weld materials, high weld pass percentage, good welding line mechanical property, high weld quality and improved production efficiency simultaneously.

Owner:XIAN SUNWARD AEROSPACE MATERIAL

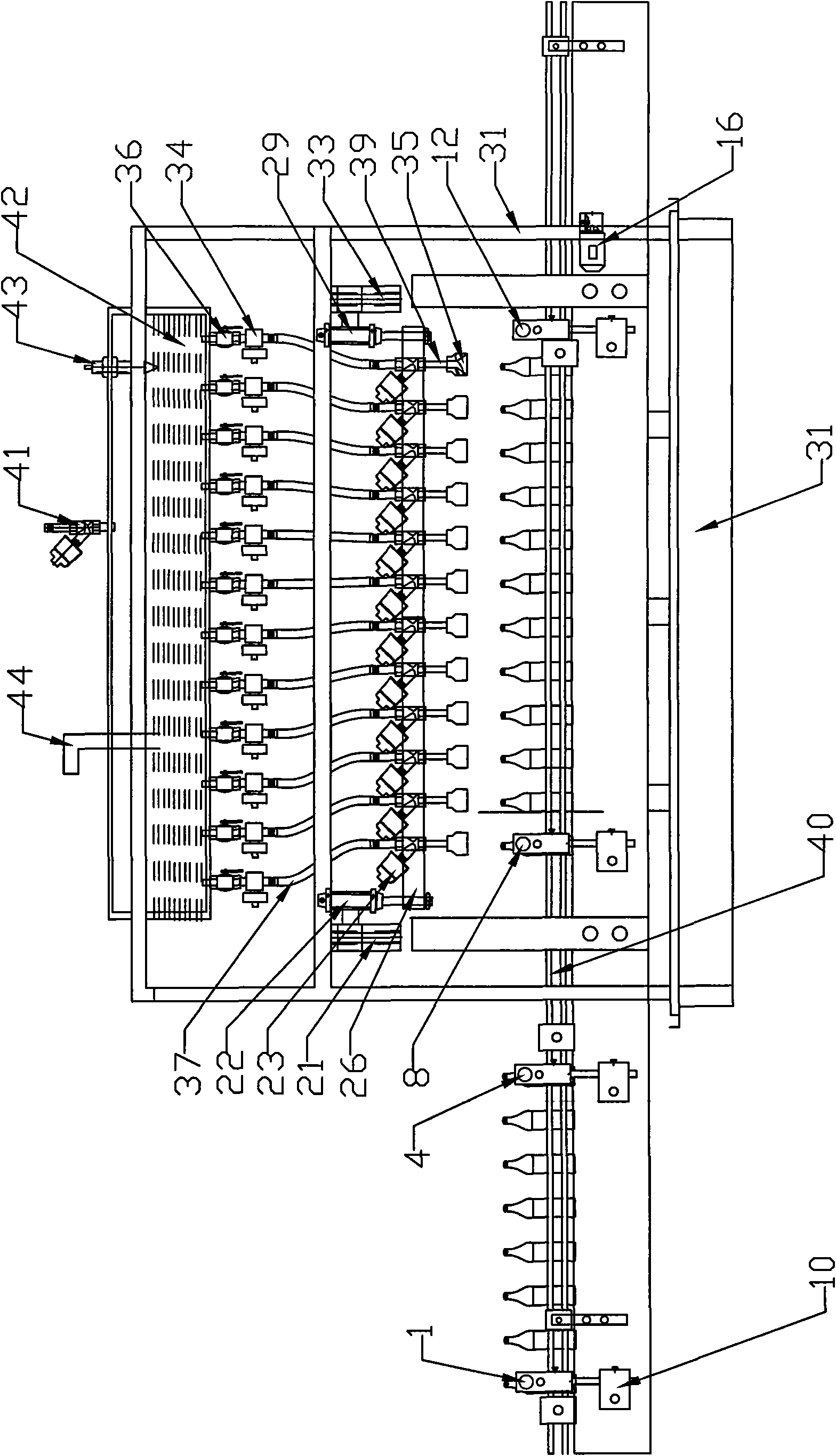

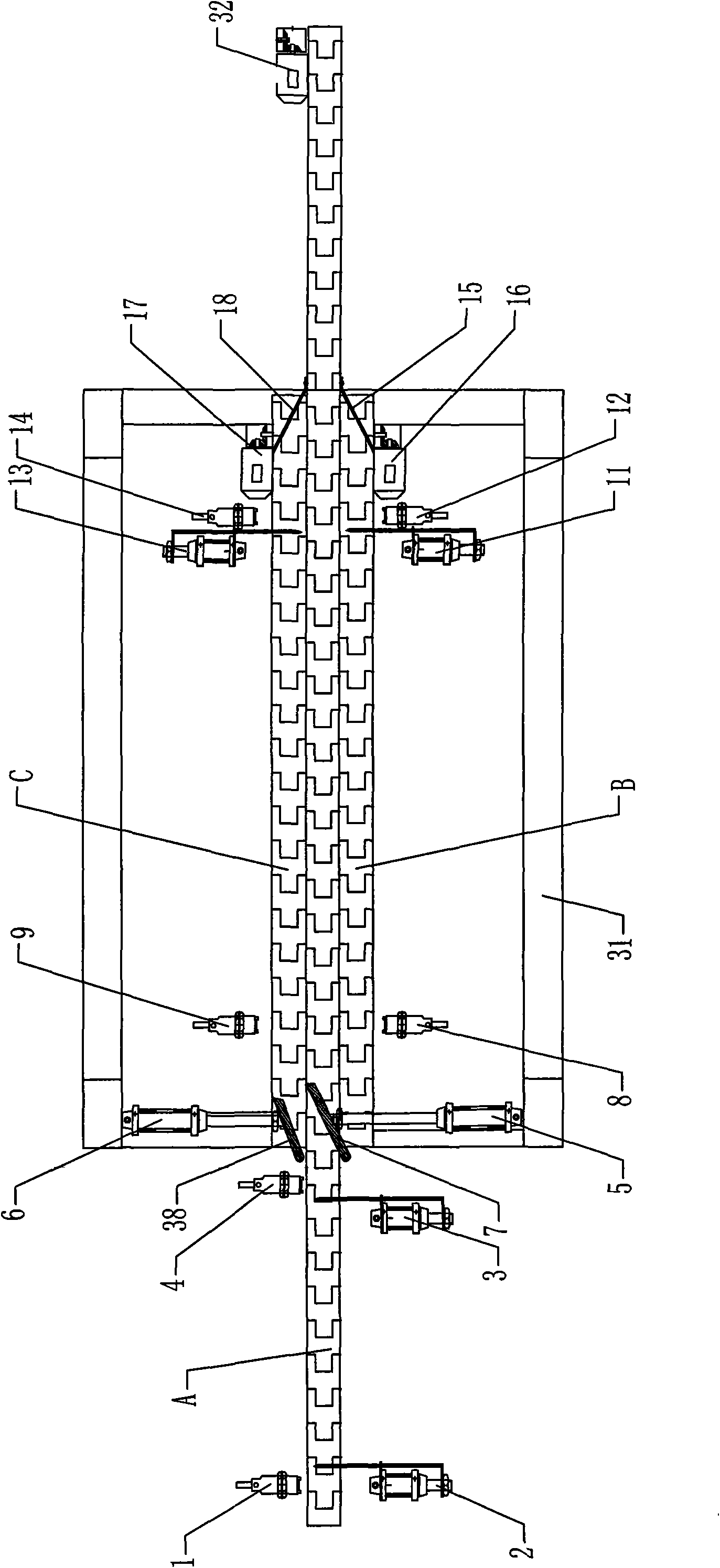

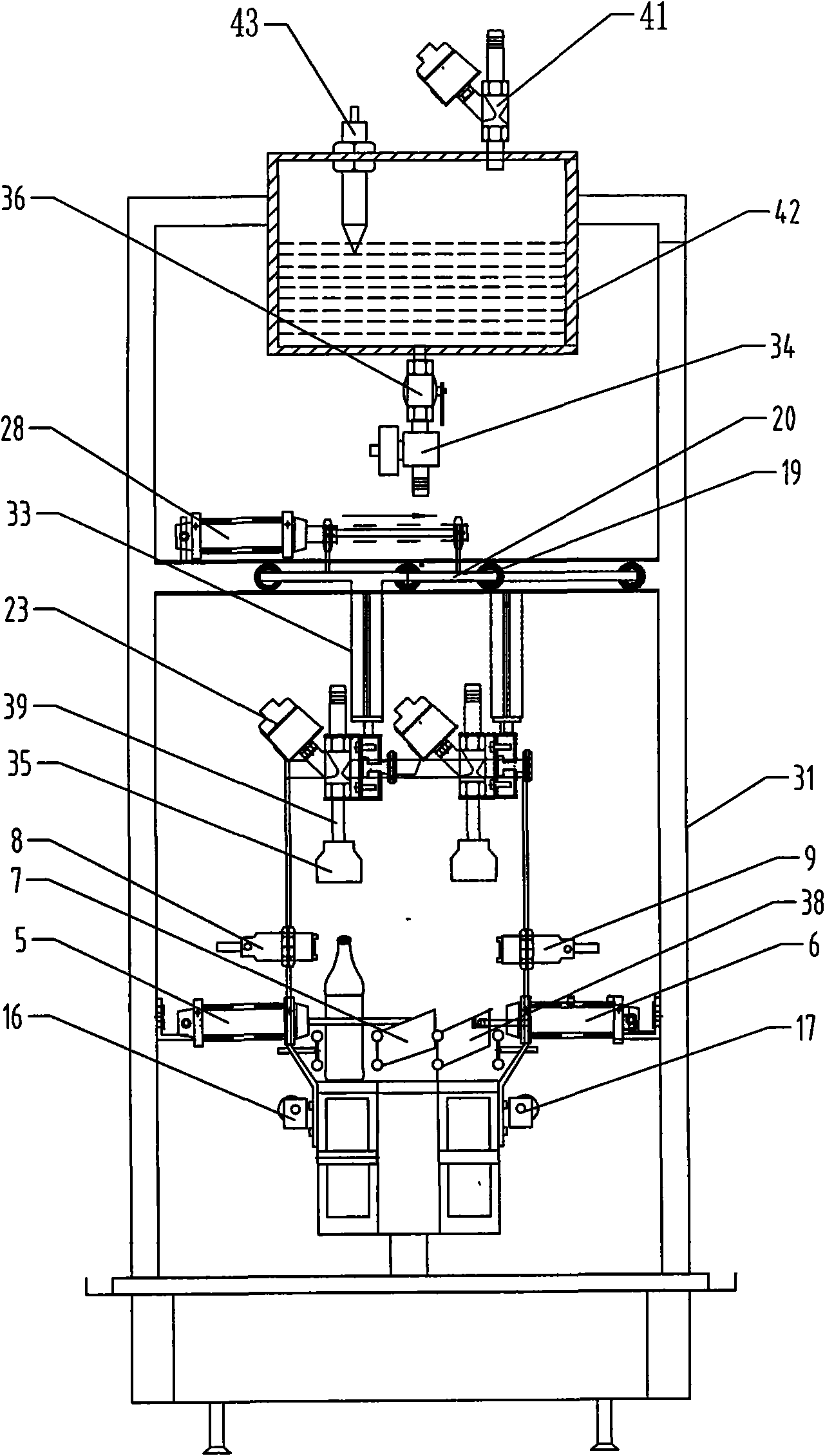

Three-row double-wire linear filling machine

InactiveCN101618845AShorten the intervalImprove filling efficiencyLiquid fillingAbnormal shapedEngineering

The invention discloses a three-row double-wire linear filling machine, comprising a frame. A bottle finishing and bottle conveying device and a liquid filling device are arranged on the frame, the bottle finishing and bottle conveying device comprises three rows of conveyer belts arranged in parallel, line exchanging devices are arranged between the three rows of conveyer belts, the bottle body can be continuously filled by carrying out line exchange on the bottle body, thereby overcoming the defect that the feeding of bottle needs to be waited when filling the bottle body by a traditional filling machine, shortening interval time between fed bottles and improving filling efficiency; the filling machine has the advantages of reasonable structure, high degree of automation, high precision, no drop leak, no discharge, simple capacity set, no bottle piling, strong applicability to abnormal shapes and high stability.

Owner:李真中

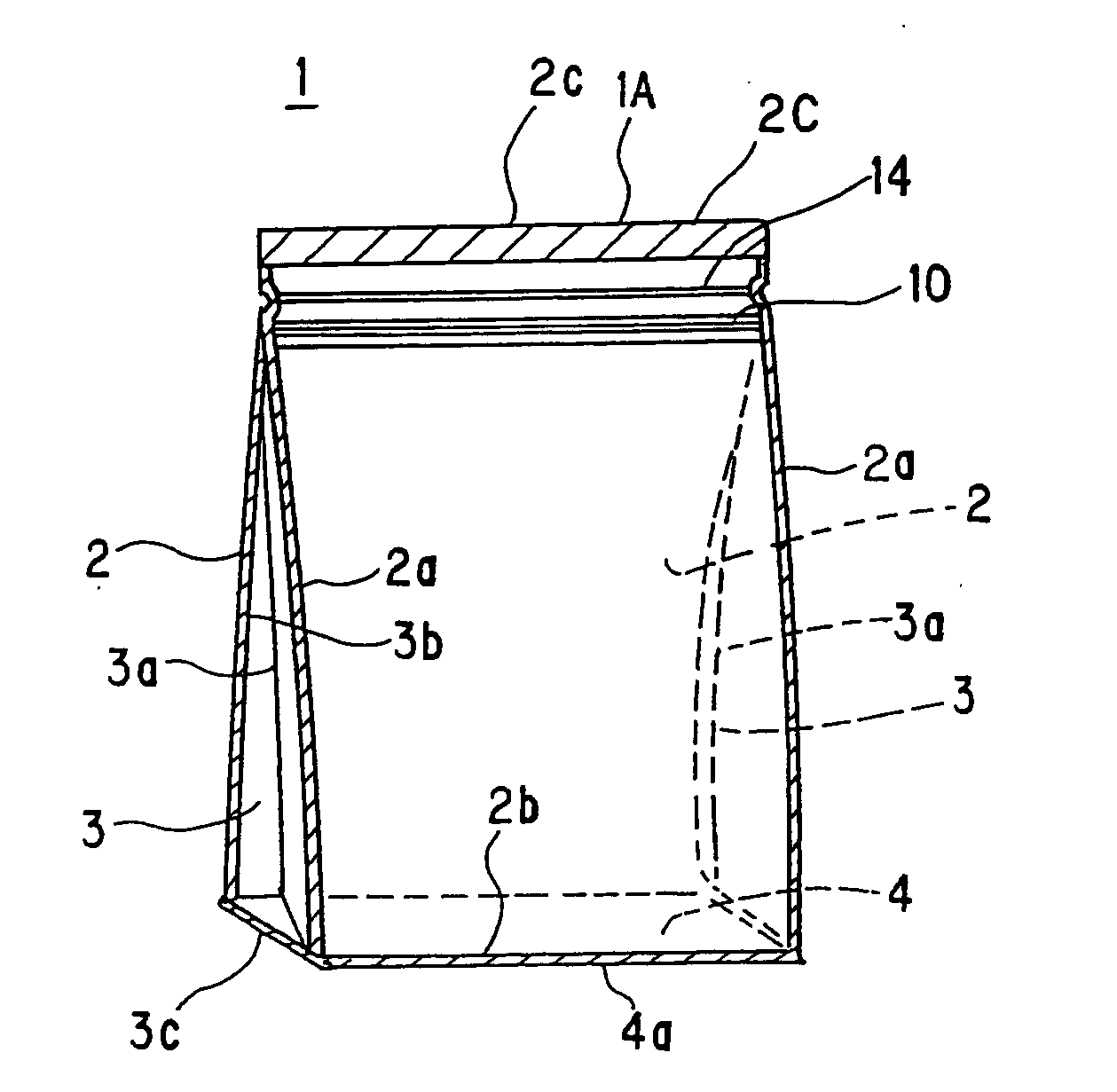

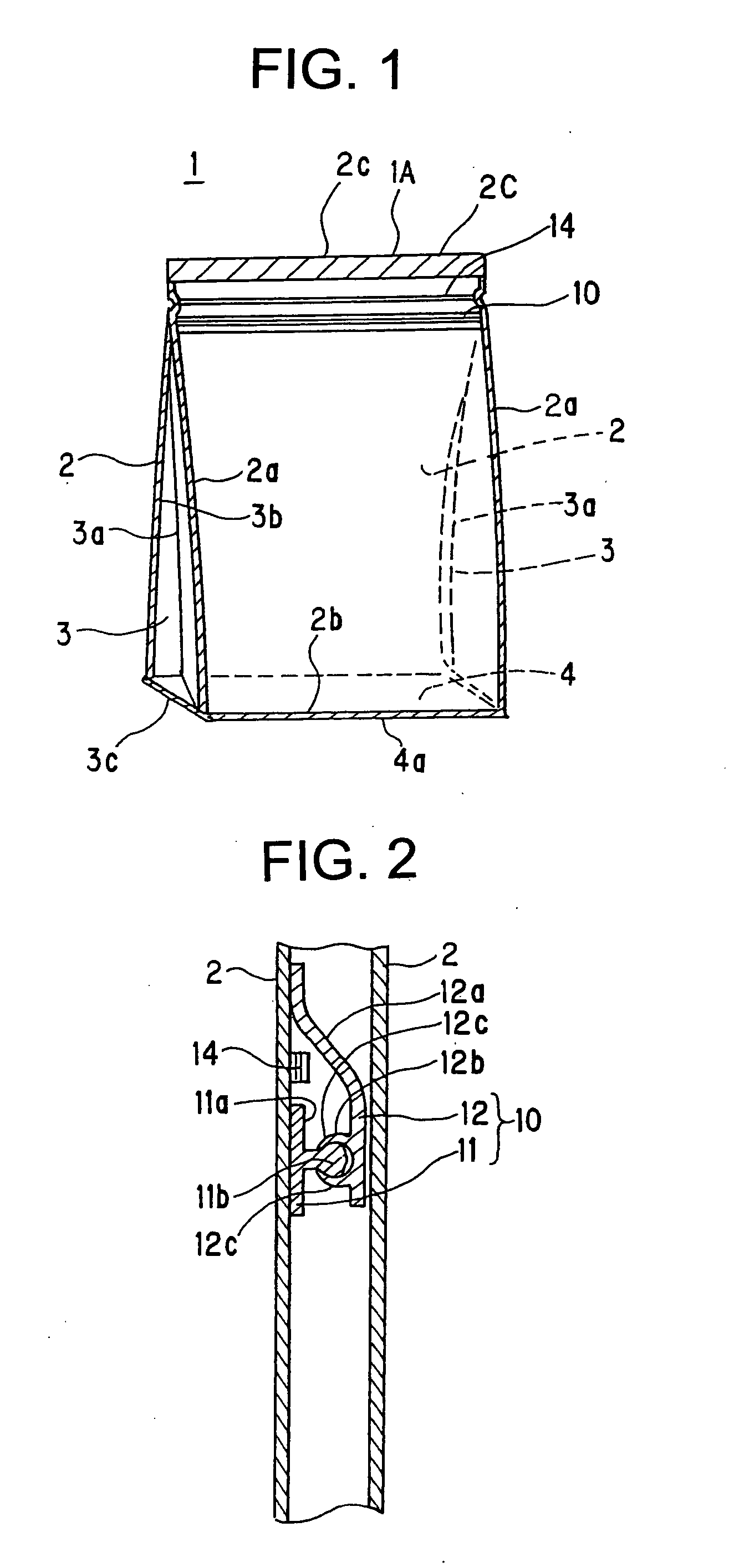

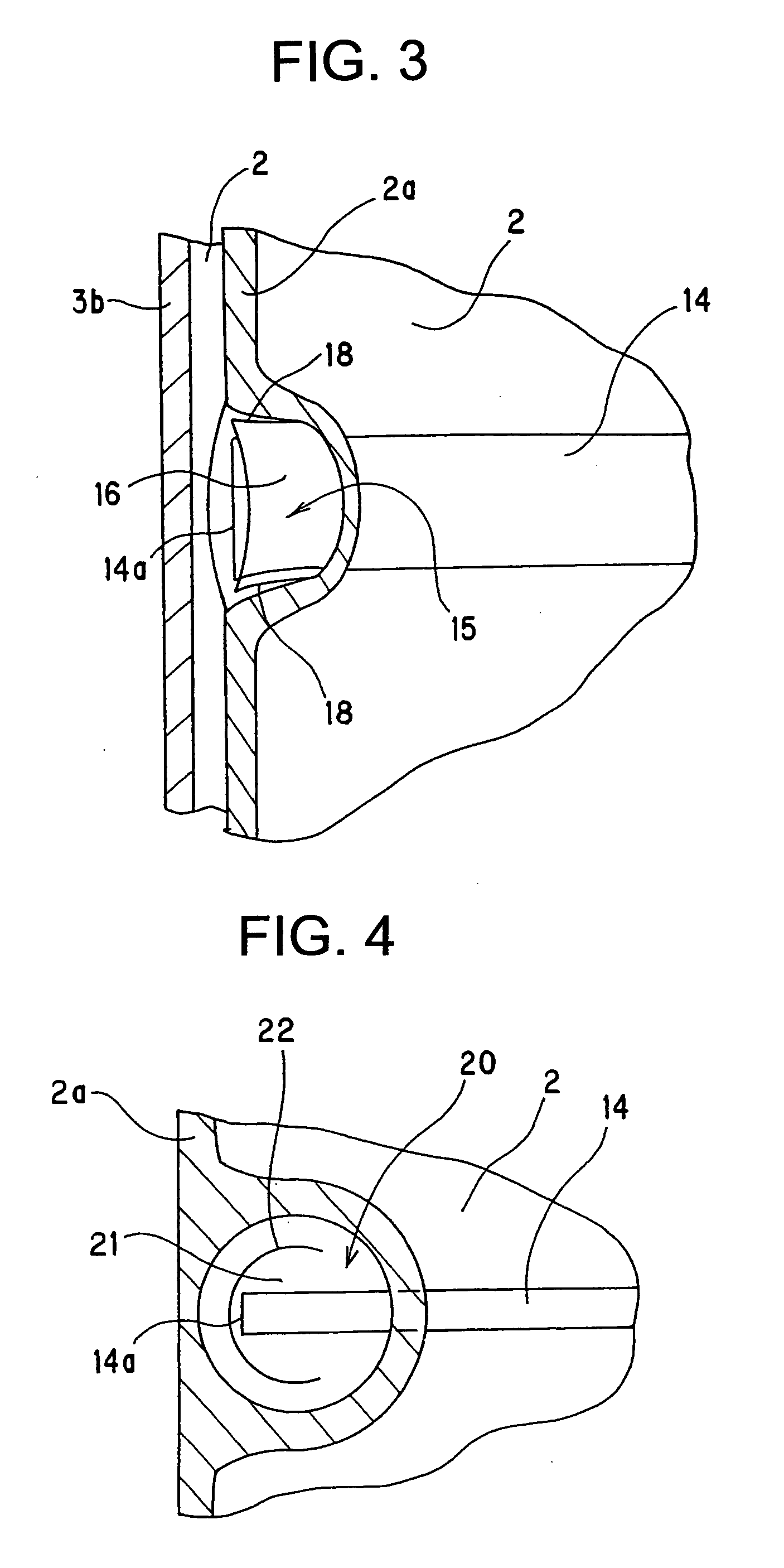

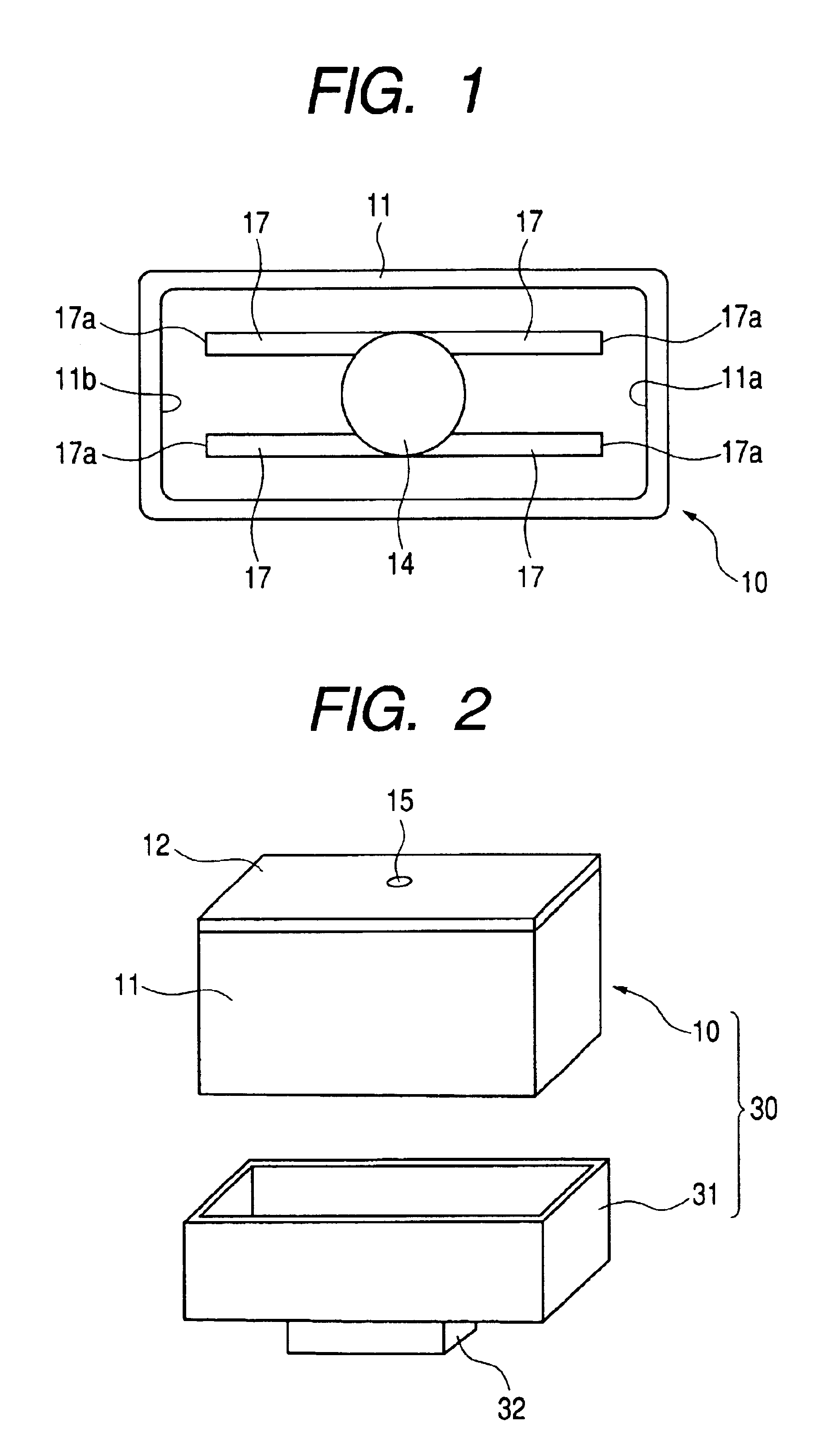

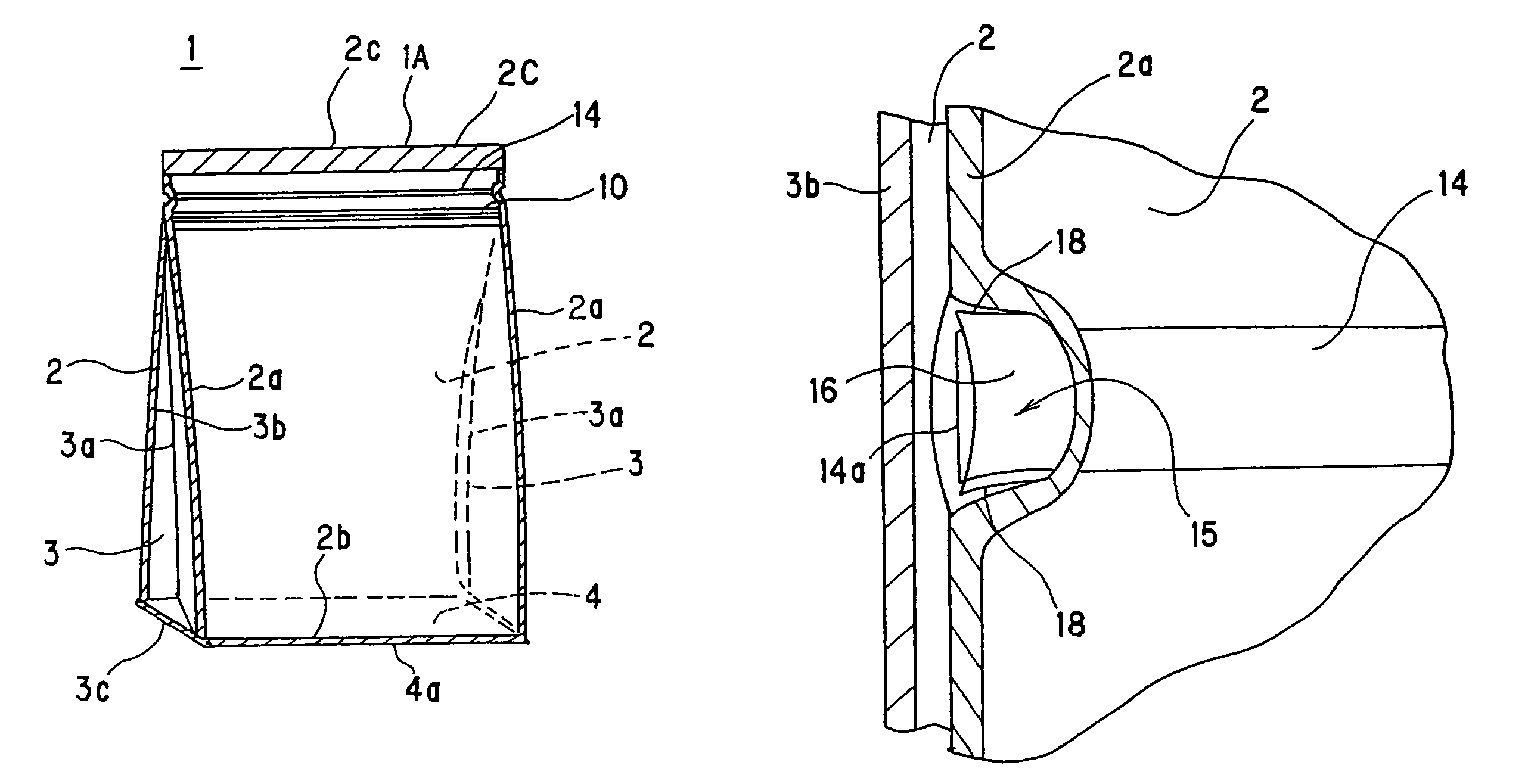

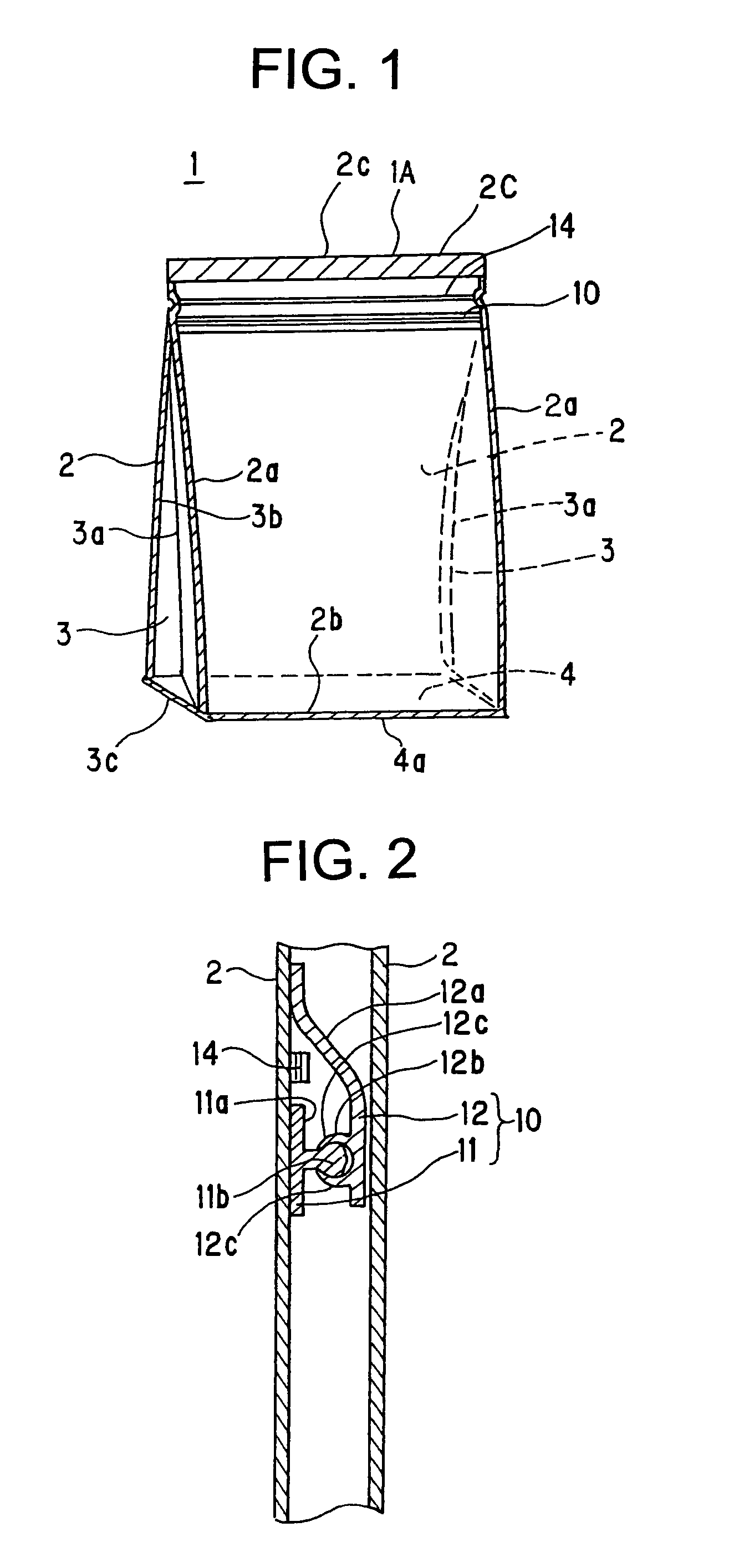

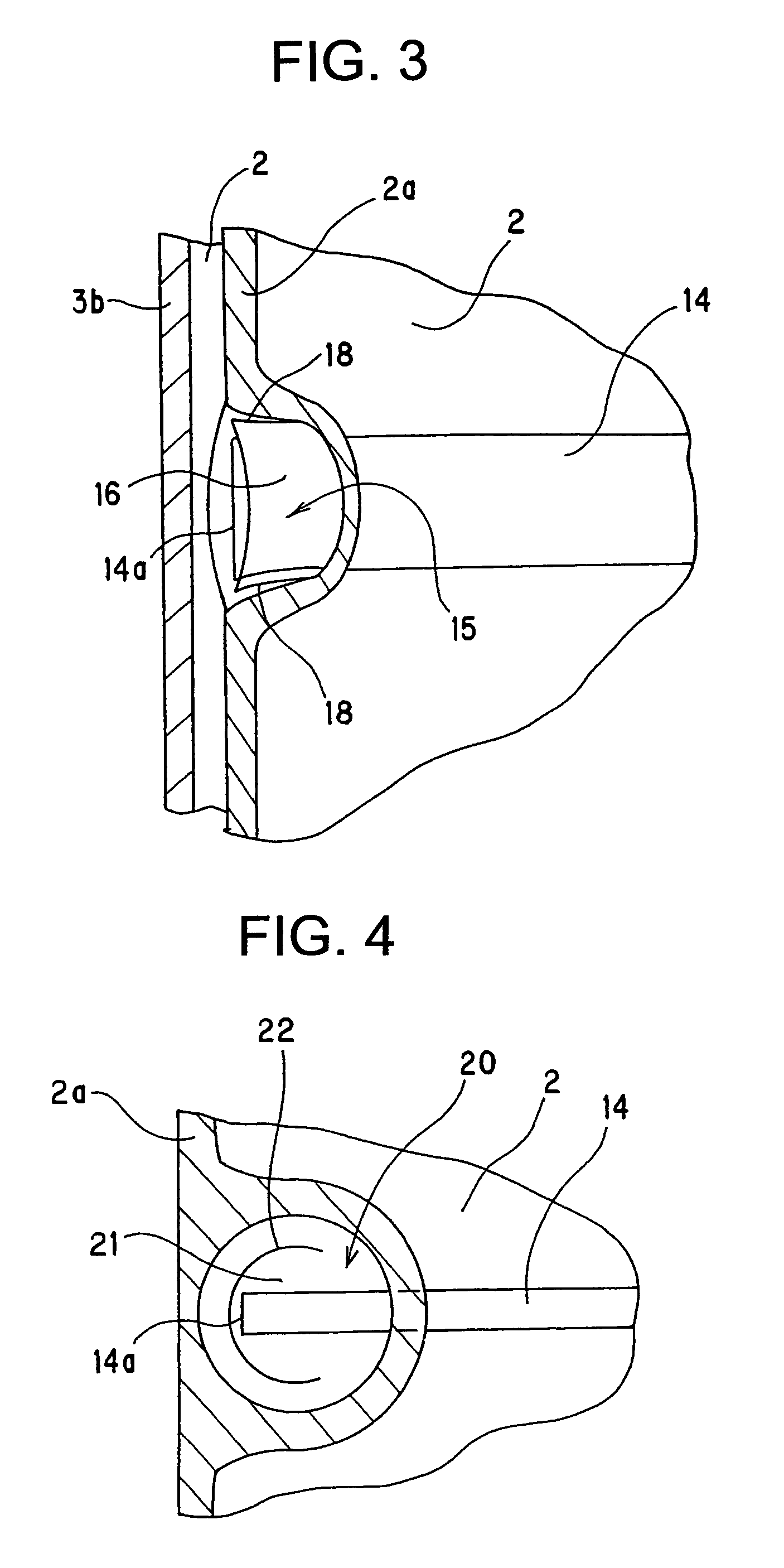

Fastener bag

ActiveUS20060104550A1Easy to openPrevent oxidationFlexible coversWrappersFastenerBiomedical engineering

There is provided a fastener bag capable of improving working efficiency for the filling of inner content and surely forming a bag cut-starting portion. The faster bag 1 is formed as gusset-type packaging bag, to which a fastener 10 for freely opening or closing the packaging bag is attached. The fastener 10 is composed of a male portion 11 to which a projected thread 11b is formed and a female portion 12 to which a groove 12b is formed so as to be engaged with the projected thread 11b. Base portions 11a and 12a of both the portions 11 and 12 are attached to an inner surface of one of the flat surface portions 2 or side surface portions 3 so that the projected thread 11b and the groove 12b face each other. A cut-tape 14 for separating the flat surface portion 2 into the male portion side and the female portion side is provided between the base portions 11a and 12a.

Owner:HOSOKAWA YOKO CO LTD +1

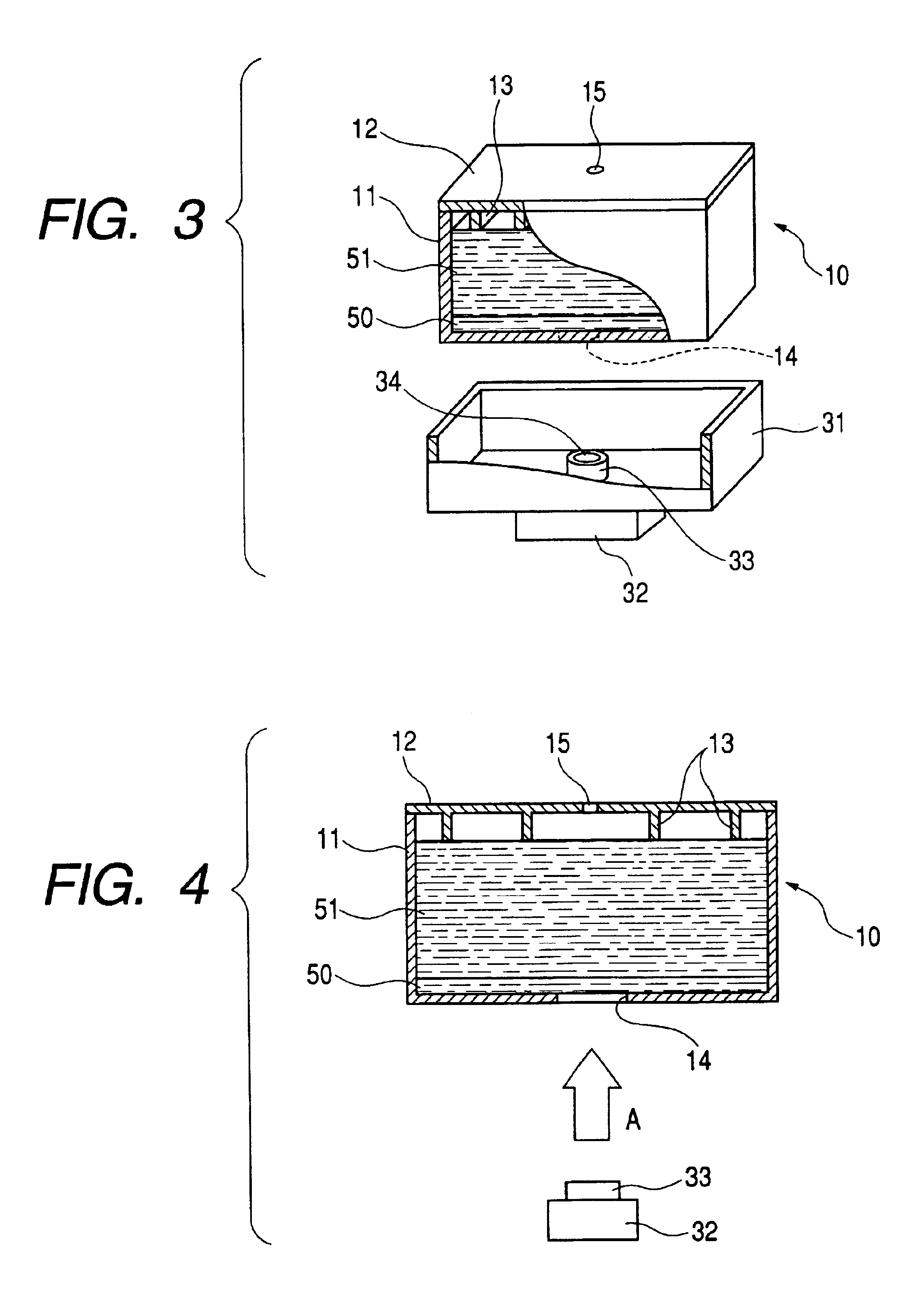

Ink tank

ActiveUS6942326B2Use of internal spaceEfficient use ofPrintingElectrical and Electronics engineering

Owner:CANON KK

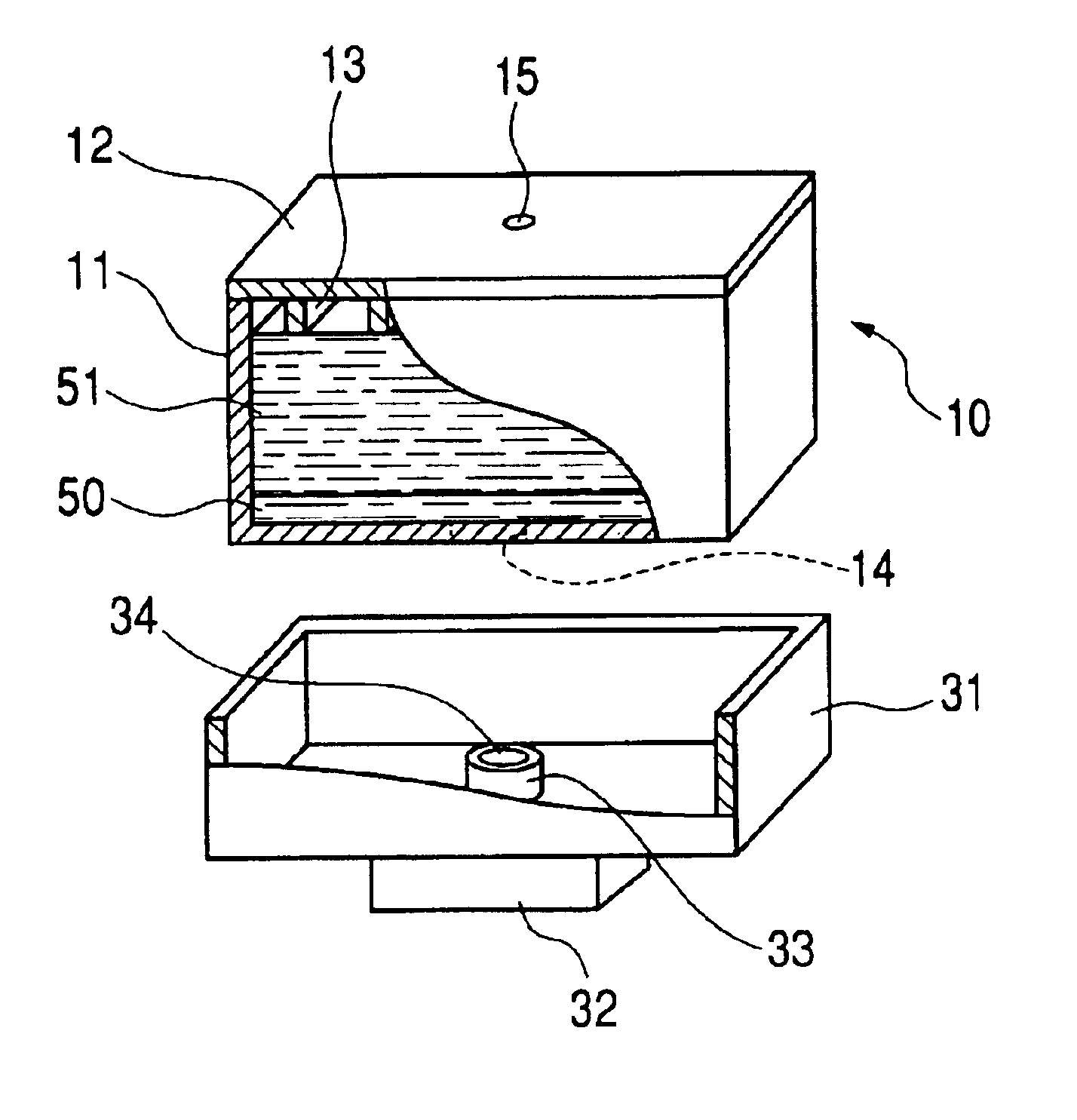

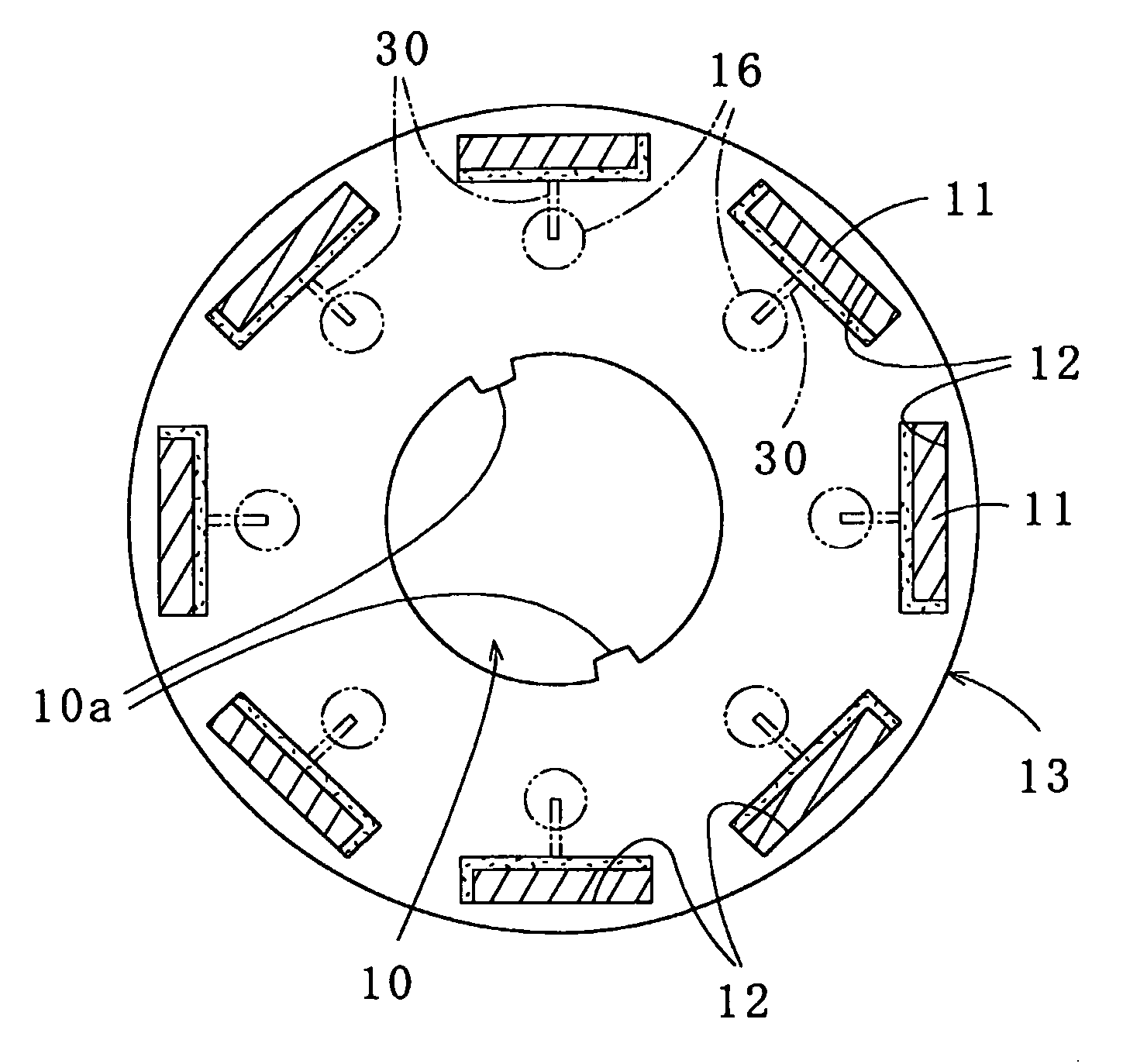

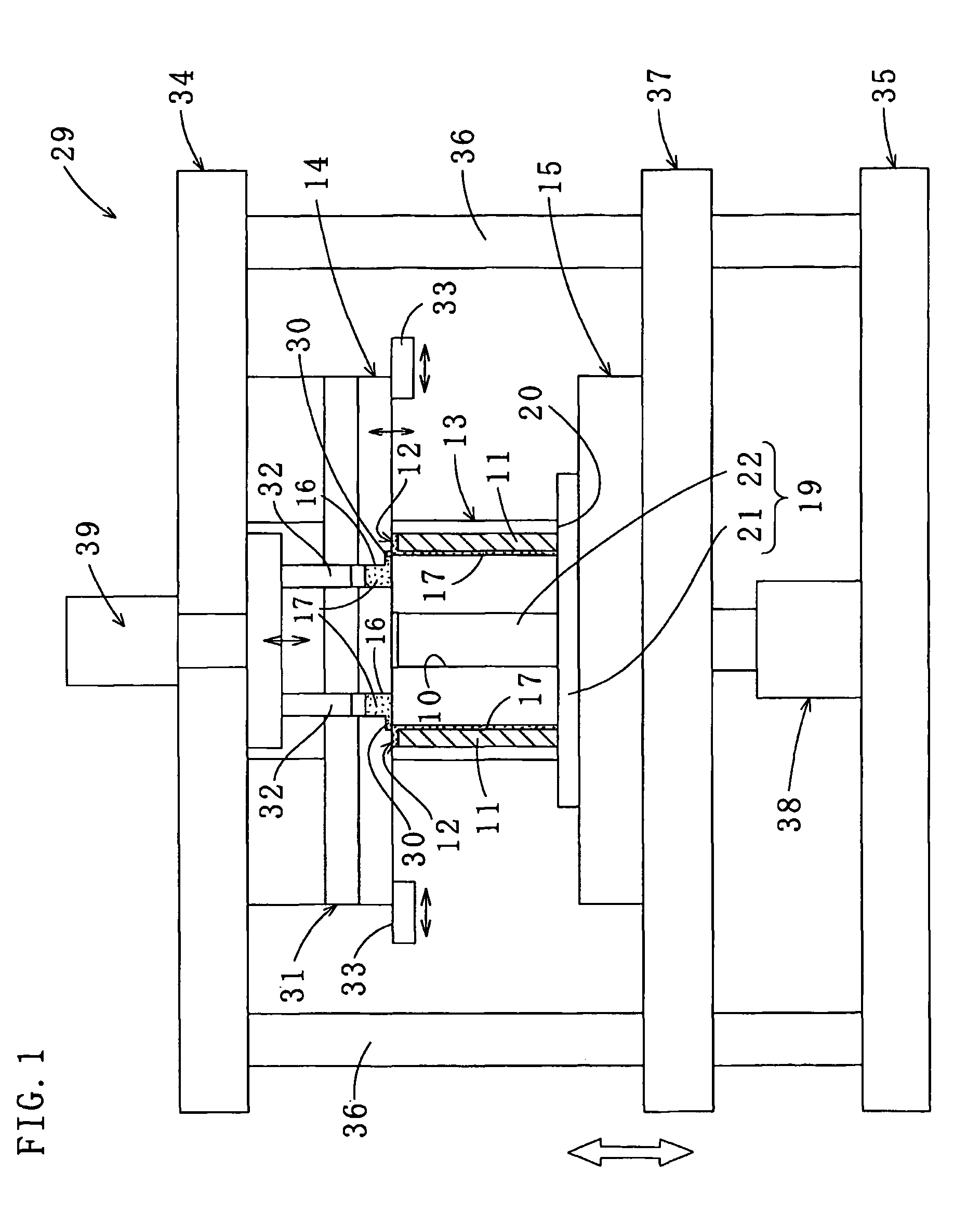

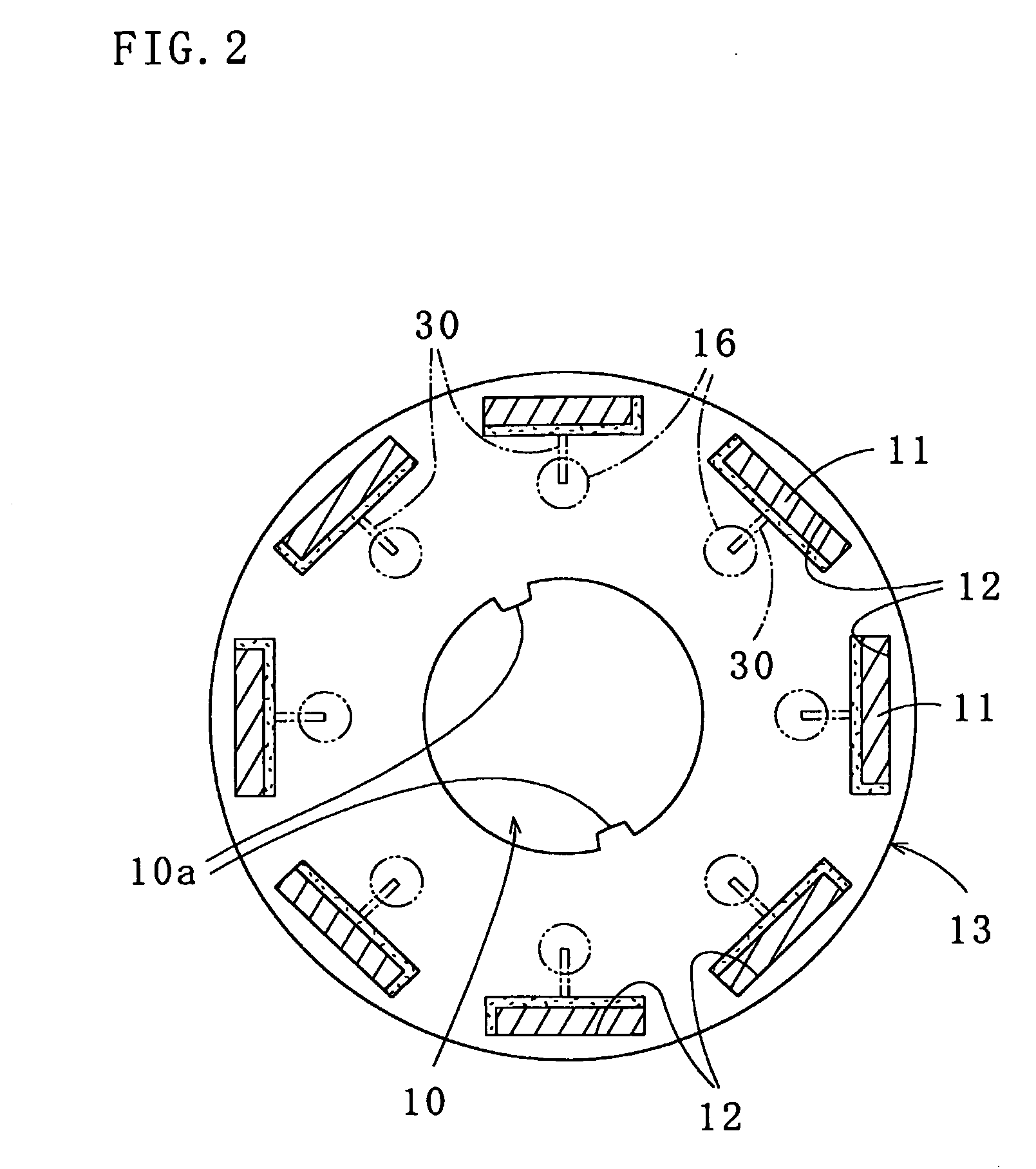

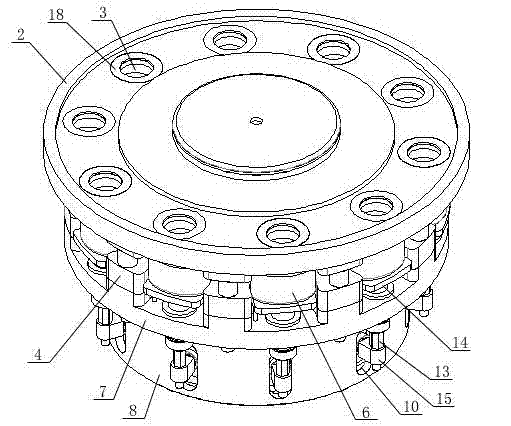

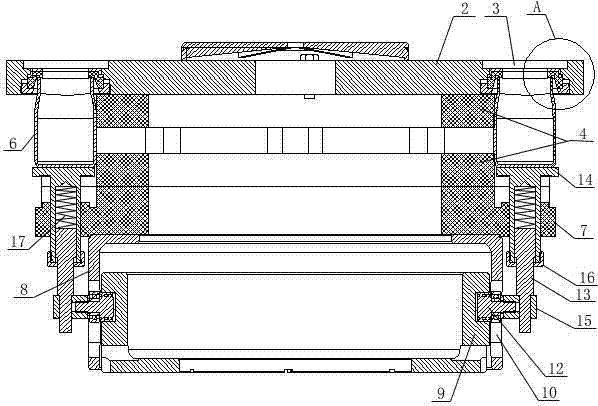

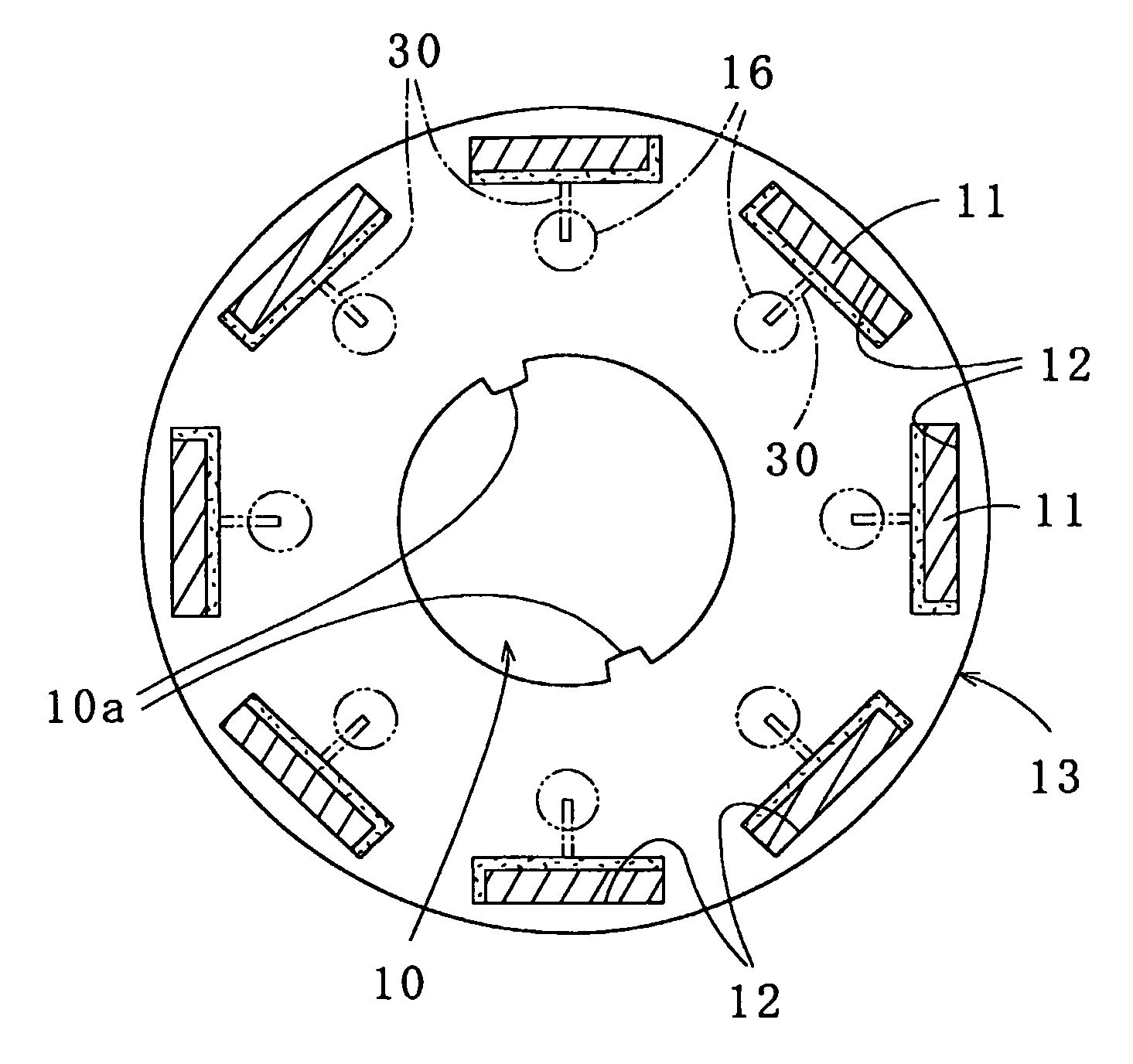

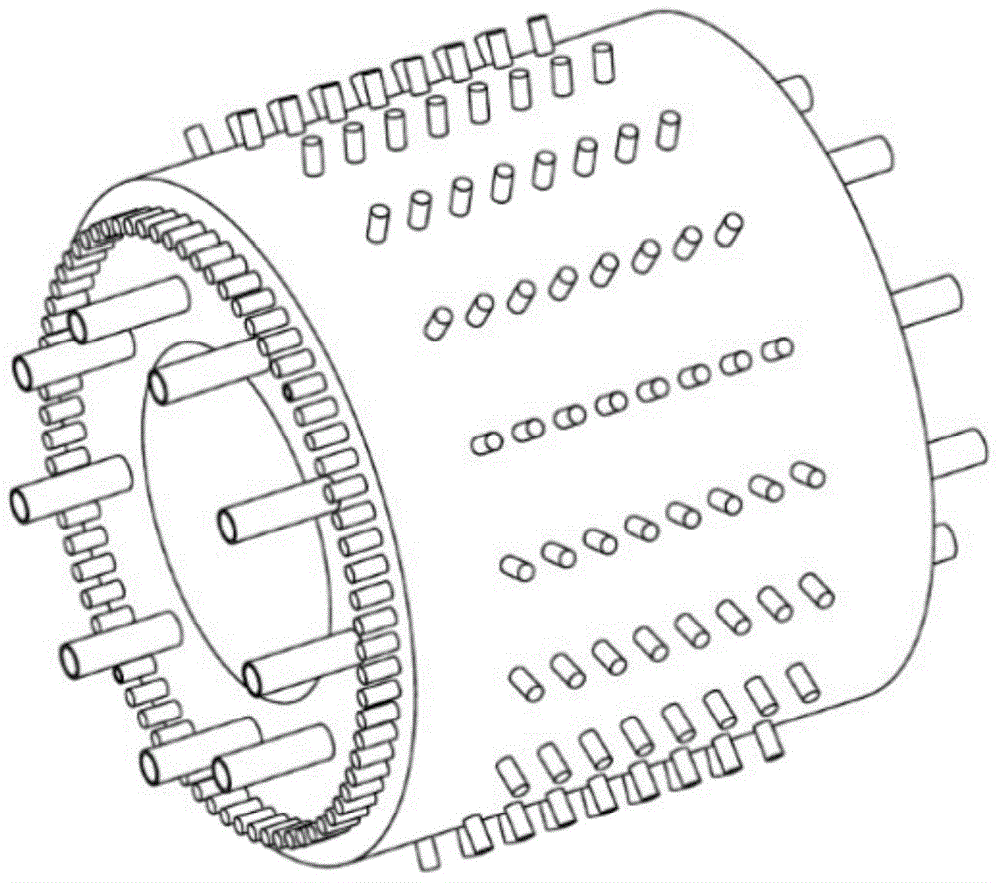

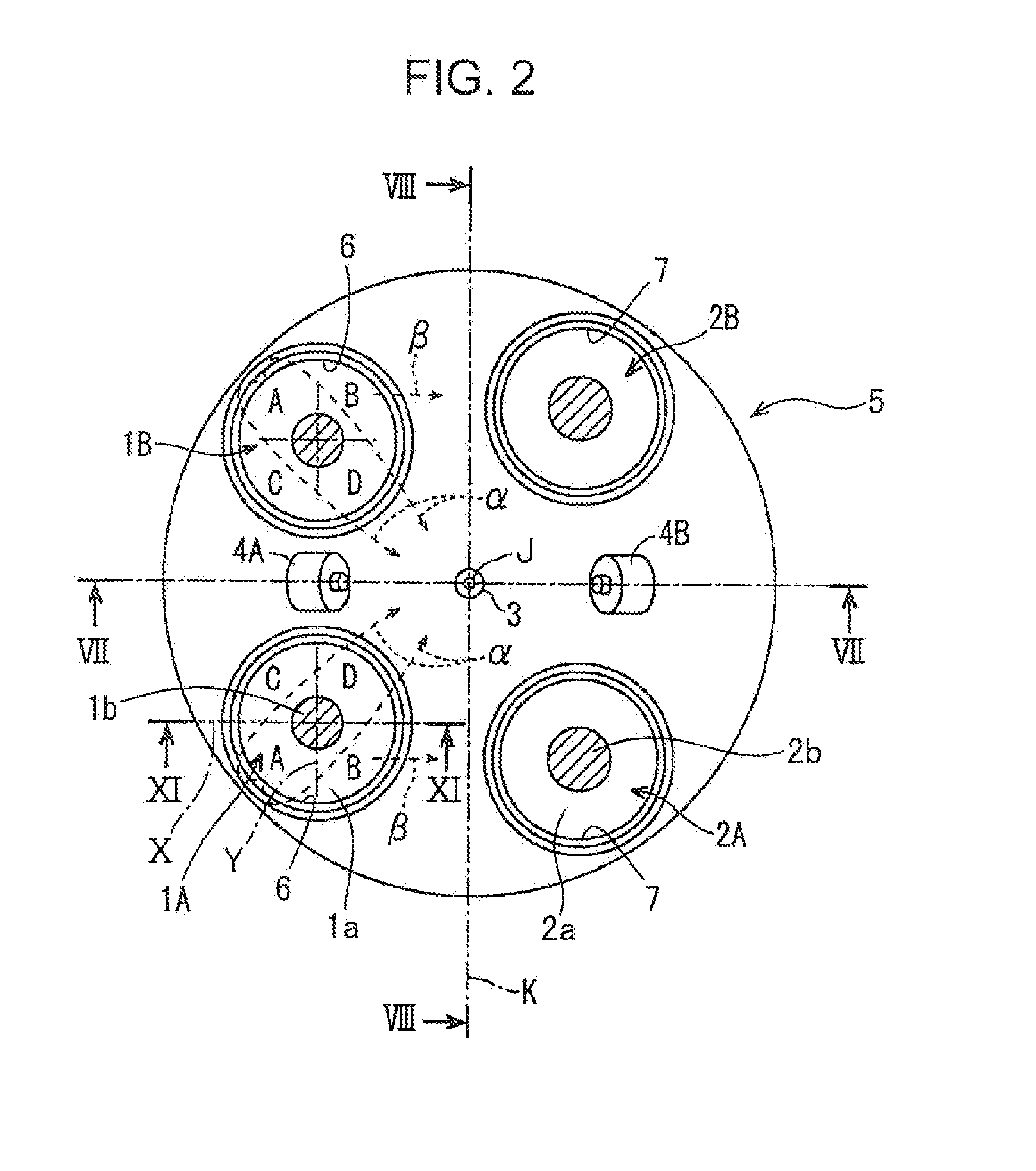

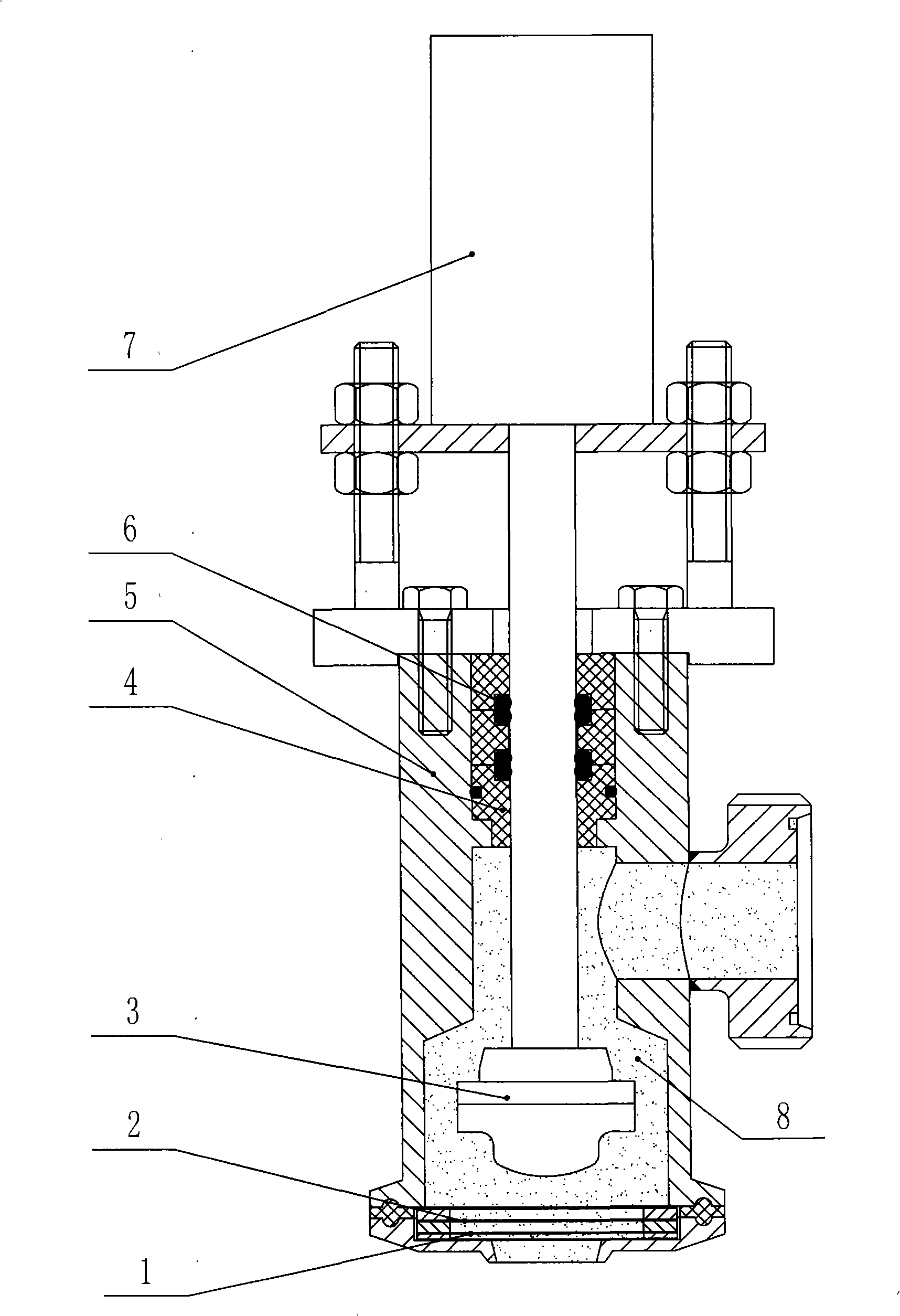

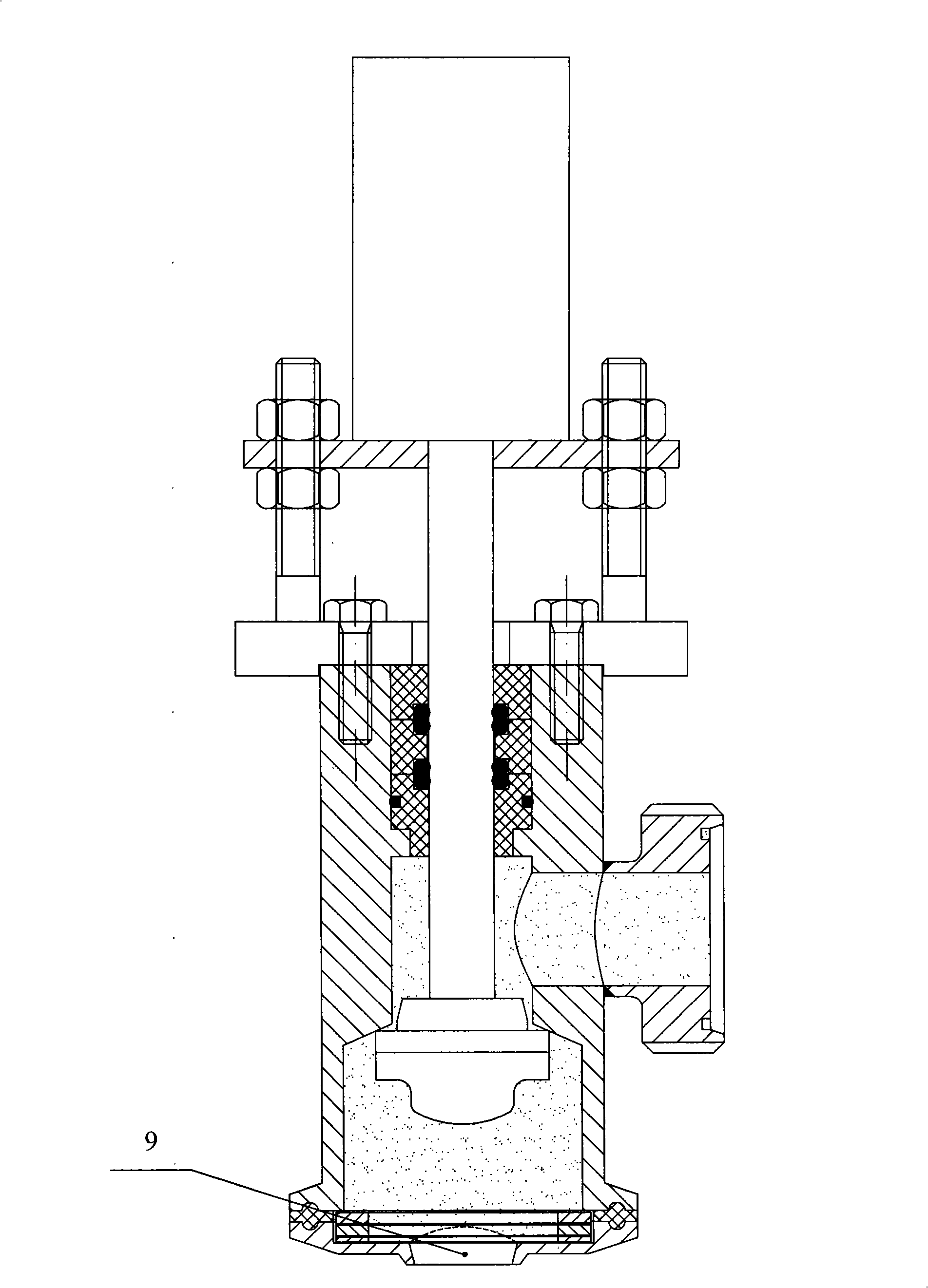

Method of Resin Sealing Permanent Magnets in Laminated Rotor Core

ActiveUS20080276446A1Improve filling efficiencyLess affectedMagnetic circuitInductances/transformers/magnets manufacturePlungerMagnet

A method comprising: a first process of placing a laminated rotor core (13) in a preheating device (18) to preheat the laminated core (13); a second process of removing the preheated laminated core (13) from the preheating device (18) and disposing the laminated core (13) between upper and lower dies (14, 15) of a resin sealing apparatus (29); a third process of pressing the laminated core (13) by the upper and lower dies (14, 15) and liquefying resin material (17) in resin reservoir pots (16) by heating; and a fourth process of ejecting the liquefied resin material (17) from the pots (16) into the magnet insertion holes (12) by plungers (32) inserted and moving vertically in the pots (16) and thermally curing the resin material (17). The method improves efficiency of resin sealing the permanent magnets (11) in the laminated core (13).

Owner:MITSUI HIGH TEC INC

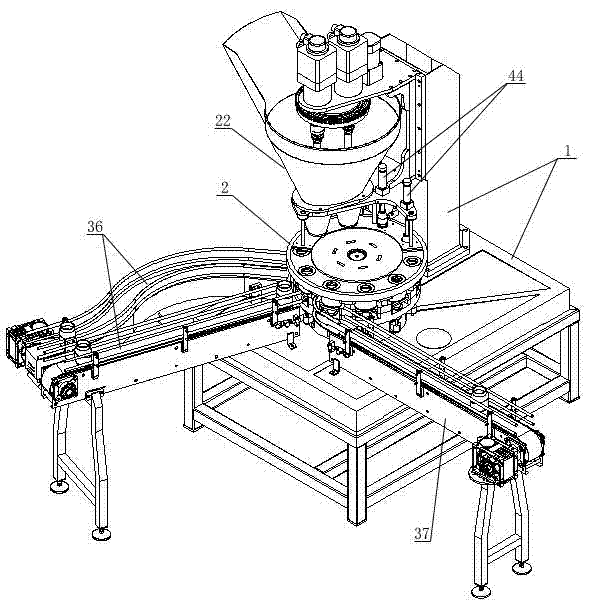

Full-automation filling machine

The invention discloses a full-automation filling machine which comprises a rack, a discharging device, a rotation plate device, a baiting device and a conveying device, wherein the discharging device, the rotation plate device, the baiting device and the conveying device are arranged on the rack. The rotation plate device comprises a rotation plate and multiple baiting through holes. A bottle clamping plate is arranged below the rotation plate, multiple bottle clamping grooves are formed in the periphery of the bottle clamping plate and a bottle ejecting mechanism is arranged below the ejector rod fixing plate. The discharging device is located above the rotation plate. A discharging opening of the discharging device is communicated with the baiting through holes in the rotation plate. The baiting device is located above the rotation plate and matched with the baiting through holes corresponding to baiting stations. The conveying device corresponds to the bottle clamping grooves at bottle inlet stations and bottle outlet stations. According to the full-automation filling machine, the bottle clamping plate is used for clamping and fixing filling bottles and a bottle jacking mechanism is used for jacking the corresponding filling bottle, so that the filling bottle totally corresponds to the corresponding baiting through hole of the rotation plate. In the whole filling process, the filling bottles can rotate synchronously along with the rotation plate and the filling problem due to the fact that the filling bottles do not align with a baiting hopper in an existing structure is solved.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

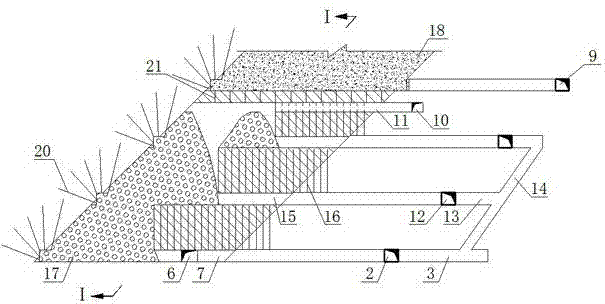

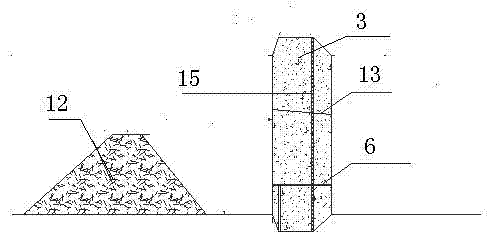

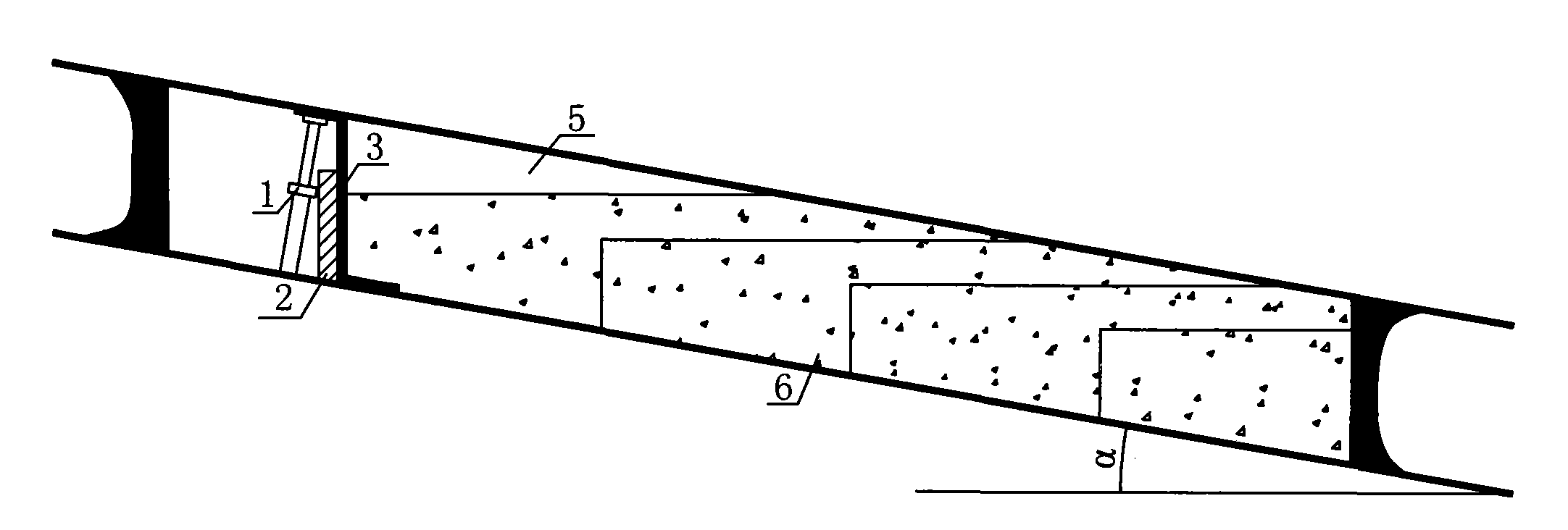

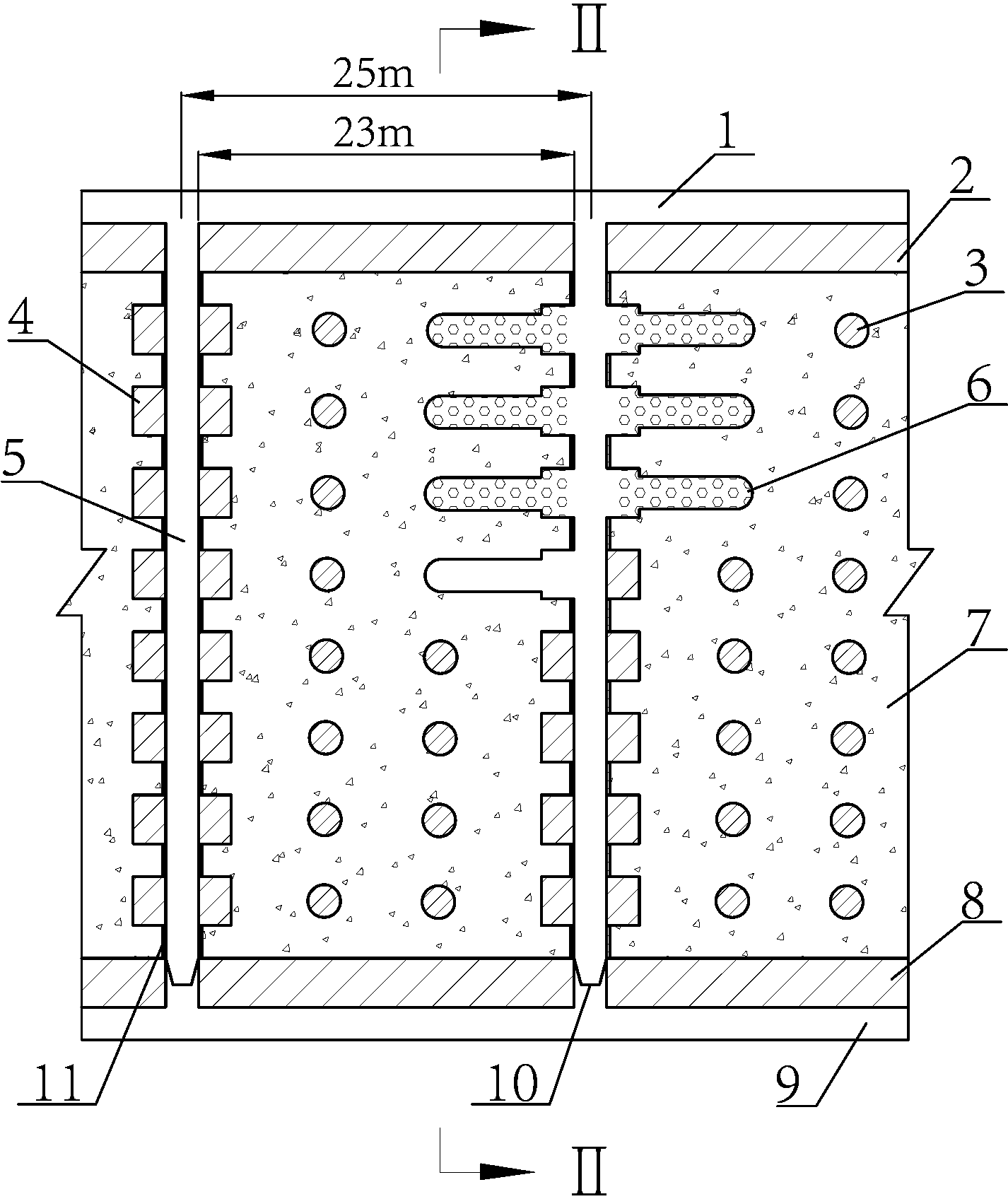

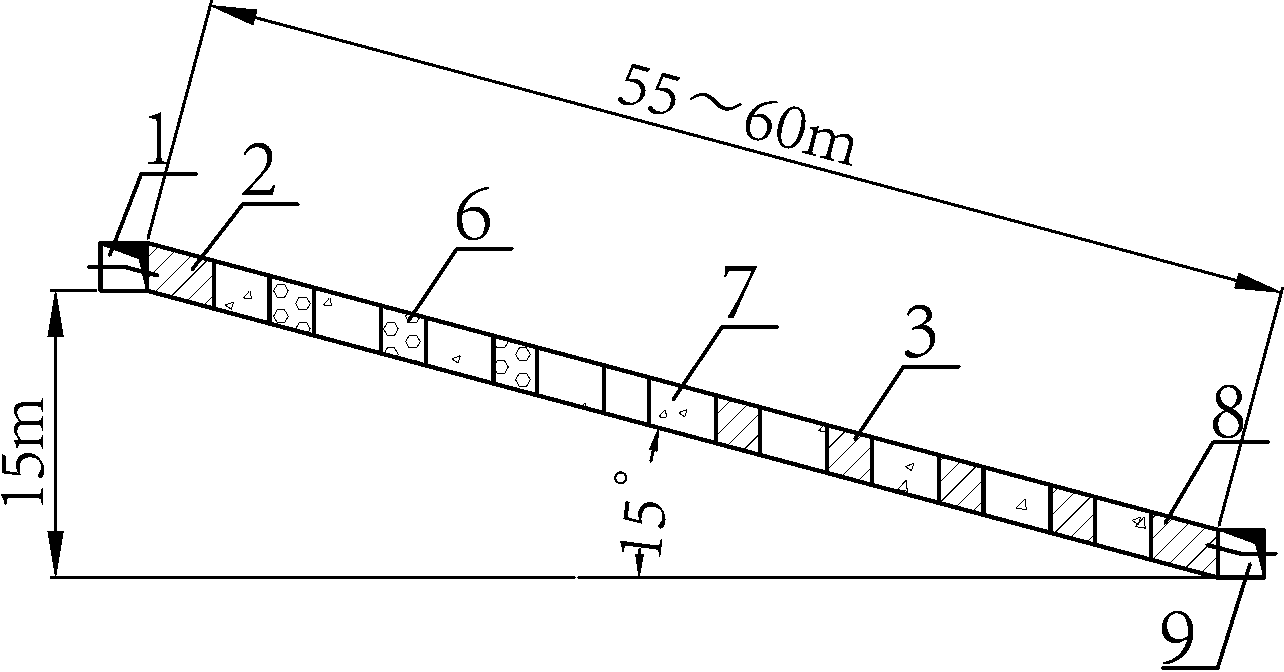

Staged rock drilling and staged mining and subsequent filling mining method

ActiveCN110644997AImprove recovery rateImprove filling efficiencyUnderground miningSurface miningMining engineeringRock cutting

The invention discloses a staged rock drilling and staged mining and subsequent filling mining method. A last-stage ore room and a next-stage ore room share a bottom ore drawing structure of the next-stage ore room, and no top pillar or bottom pillar needs to be arranged between the last-stage ore room and the next-stage ore room; vertical deep holes are drilled in parallel in a rock drilling chamber of the last-stage ore room and a rock drilling chamber of the next-stage ore room; firstly the next-stage ore room is caved row by row, caved ore is shoveled and loaded in a loading roadway, thendischarged into an extra-vein ore pass or an intra-vein ore pass through a loading connecting roadway, a part of ore is reserved as a buffer cushion layer for caving the last-stage ore room; after caved ore of the last-stage ore room and the next-stage ore rooms is completely discharged, a sealing retaining wall is adopted to seal a rock drilling connecting roadway and an ore drawing connecting roadway, a goaf is filled, and the same method is adopted to carry out two-step ore pillar mining after the filling body reaches the specified maintenance strength. Continuous large-scale mining is realized, the workload of pre-mining cutting is reduced, the ore recovery rate and the production efficiency of a stope are improved, and the mining production cost is reduced.

Owner:安徽金安矿业有限公司 +1

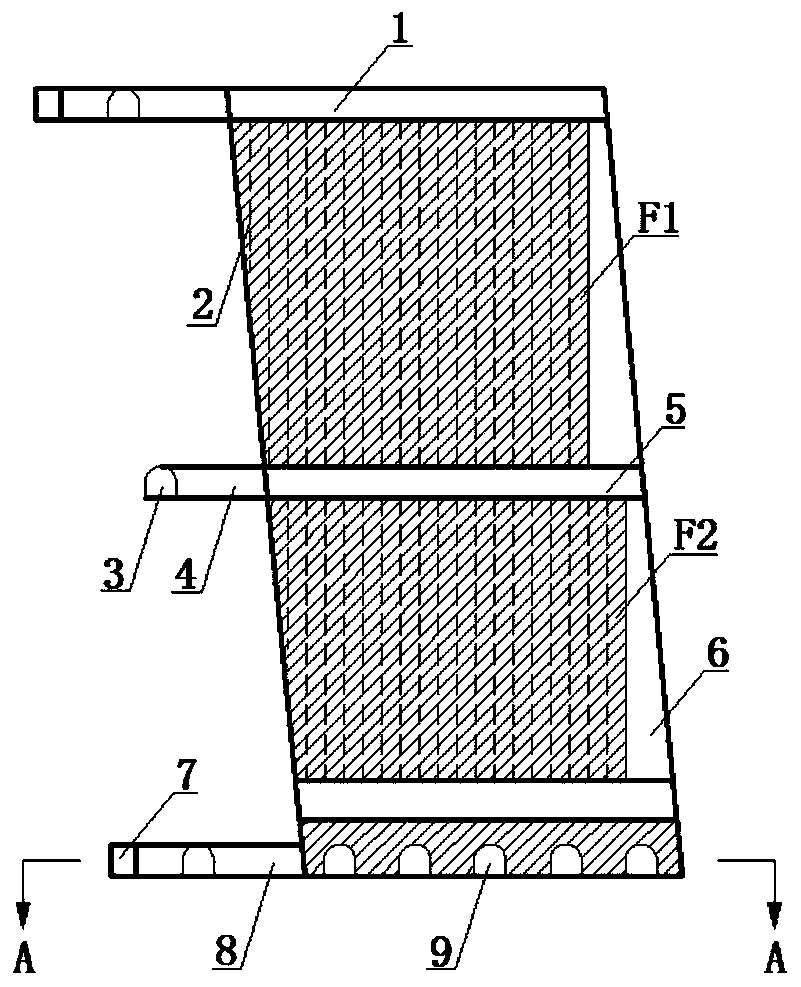

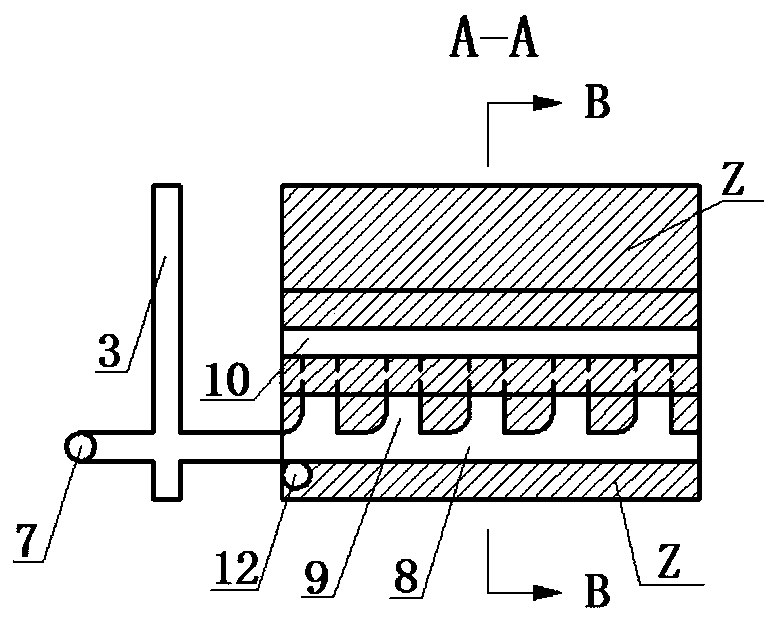

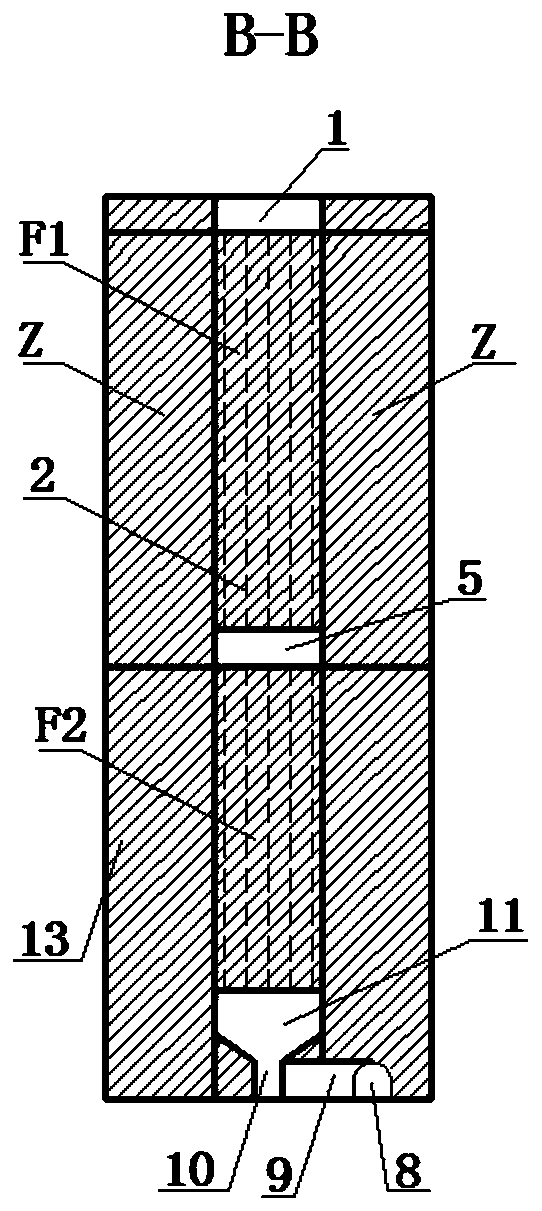

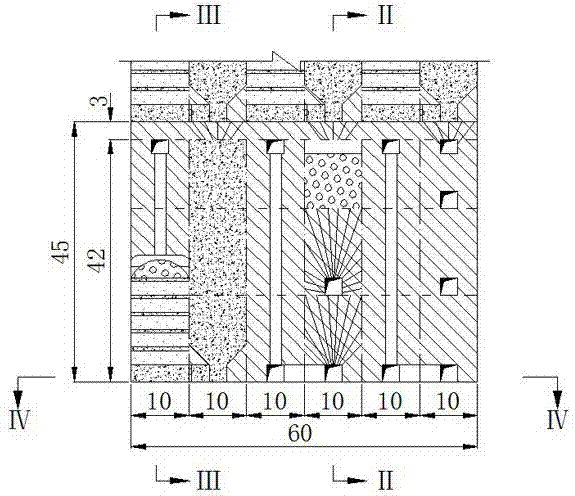

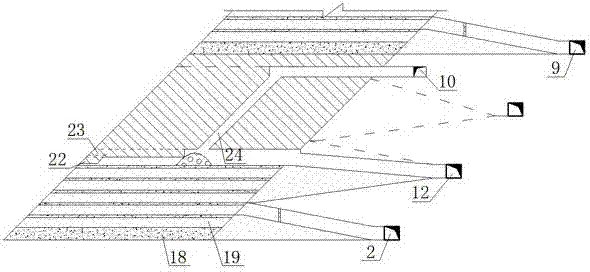

Chamber and overhand cut combined cut-and-filling stoping method in pre-roof-protecting stage

InactiveCN104847352AImprove mining safetyImprove stope production capacityUnderground miningSurface miningEngineeringCut and fill

The invention relates to a chamber and overhand cut combined cut-and-filling stoping method in a pre-roof-protecting stage. The method comprises the following steps: dividing a middle ore body into panels along the trend of the ore body, further dividing the middle section into a plurality of sections in the vertical direction, and mainly adopting a footwall out-out-pulse traceless accurate mining mode; arranging chambers and pillars in the panels at intervals; recovering the chambers first, and adopting a sublevel open stoping method with subsequent backfilling; after recovering the chambers, recovering the pillars and adopting an overhand horizontal cut-and fill method for the pillars, and before recovering the chamber in stages, pre-supporting a long cable in advance for an upper panel in a sublevel upper panel supporting lane; pre-supporting the fore-set by using an anchor rod and a metal net in an air return cross gateway below the fore-set; when the pillars are recovered in layers, stopping mining when the pillar is 3m close to the main crack of the upper panel F1 in horizontal distance and reserving the panel as an upper panel roof-protecting ore of the sub layer, and when the lower layer is recovered, fully recovering the upper panel roof-protecting ore reserved in the previous layer, and meanwhile, reserving the upper panel roof-protecting ore in the lower sub layer; and sequentially circularly recovering and reserving the upper panel roof-protecting ore. By virtue of the method provided by the invention, safe, efficient and low-cost mining can be implemented for thick and large ores which are relatively broken.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

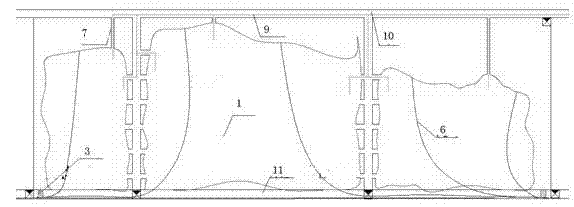

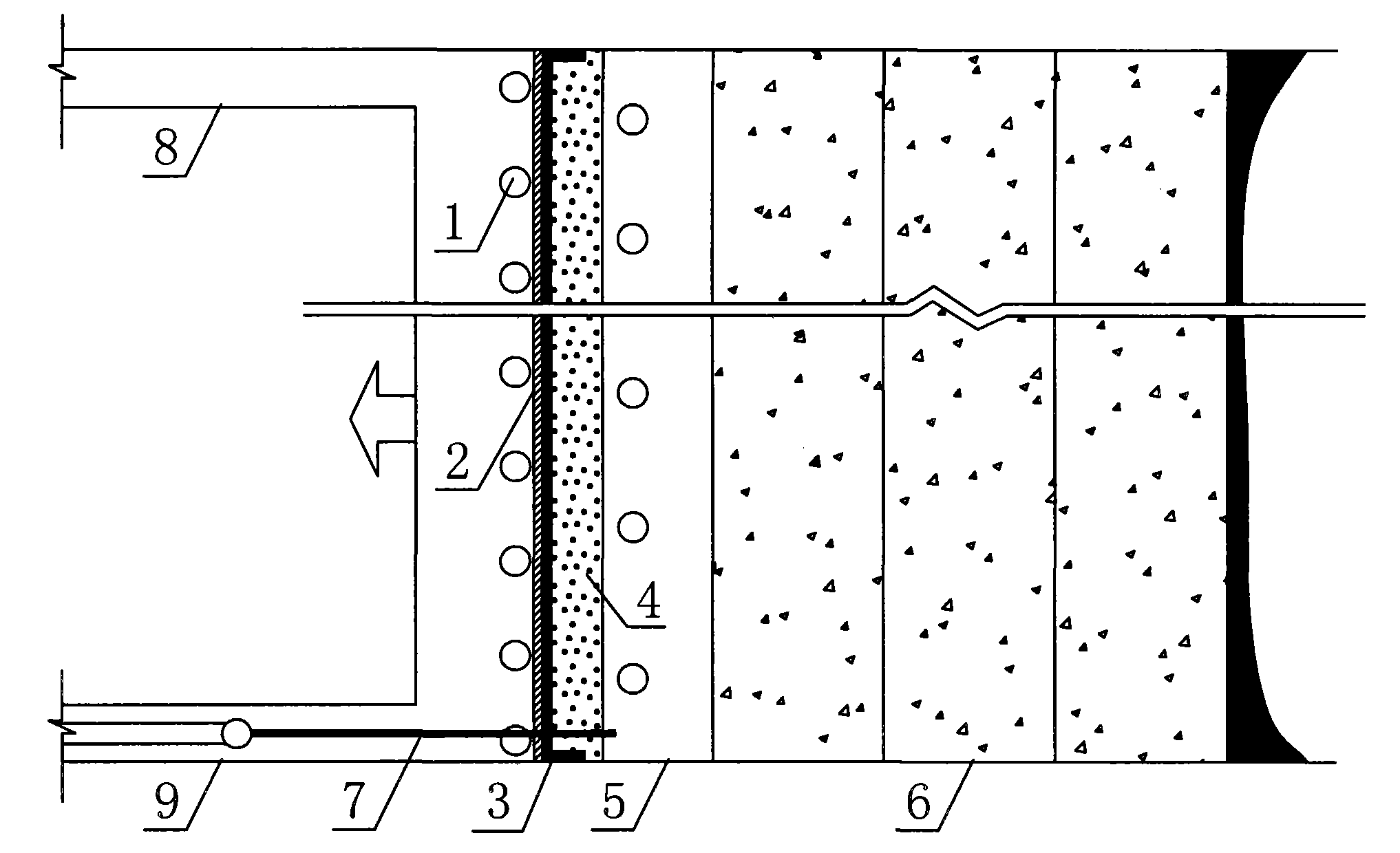

Large-range goaf group filling method

InactiveCN103046955AGuarantee normal productionSimple filling processMaterial fill-upDrainagePipeRetaining wall

The invention relates to a large-range goaf group filling method and belongs to the technical field of mining engineering. According to the technical scheme, the method includes: dividing filling units, selecting filling material, and laying out filling pipes; calculating to determine the thickness of a filling retaining wall, performing site construction, reserving drain holes and filter holes in the filling retaining wall, and stacking a hillock inverted filter layer behind the filling retaining wall; laying filter pipes, allowing the filter pipes to extend out from the drain holes of the filling retaining wall; constructing a filling borehole, 133mm-150mm in diameter, at a highest point, applying the filling borehole as an overhead discharge point, ensuring roof contact, constructing the corresponding number of filling boreholes according to practical situation, and performing alternating filling. The large-range goaf group filling method has the advantages that filling process is simplified, filling efficiency is increased, plugging amount is decreased, filling amount is decreased, filling period is shortened, filling cost is lowered, and normal mine production is guaranteed.

Owner:HEBEI IRON & STEEL GRP MINING +2

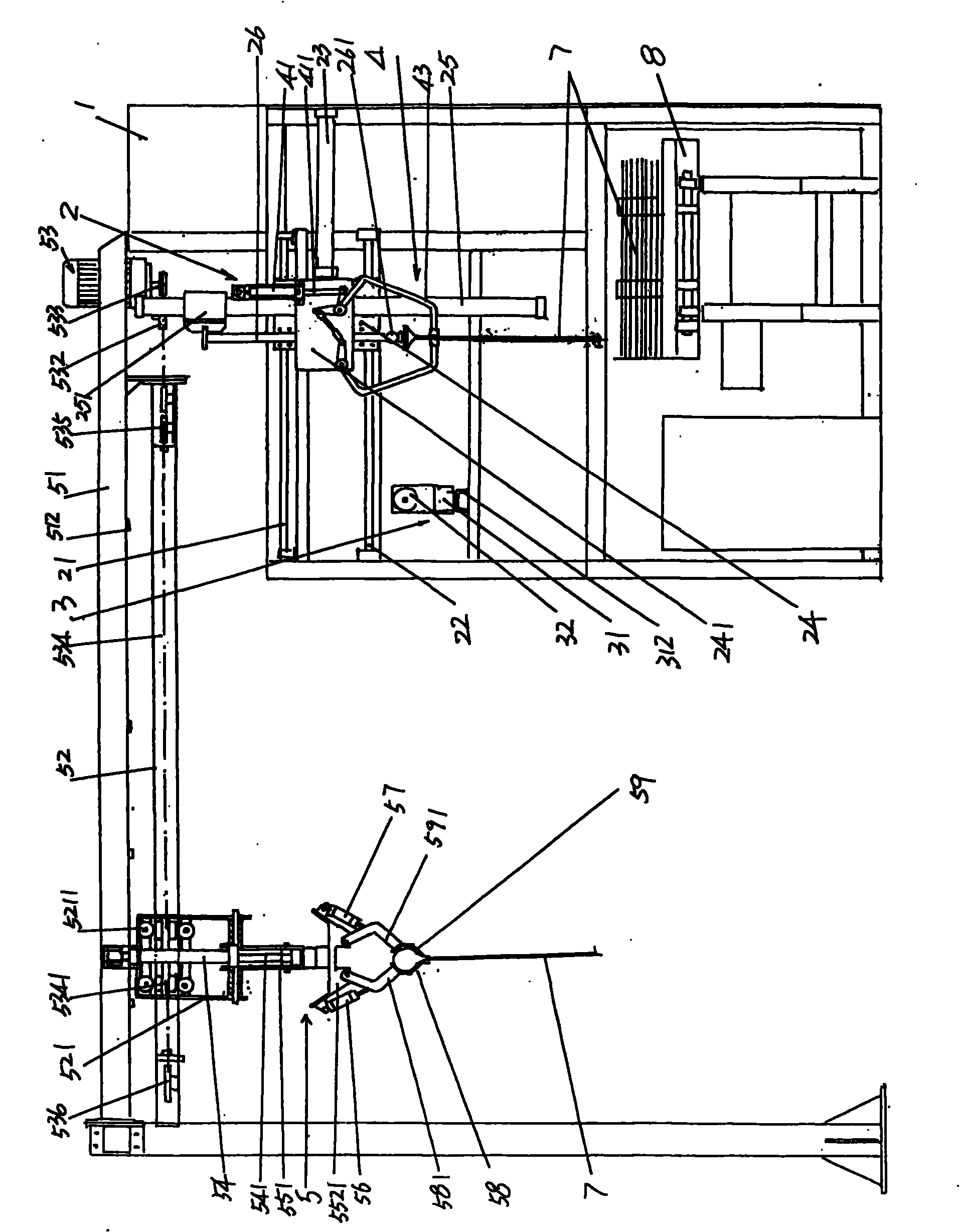

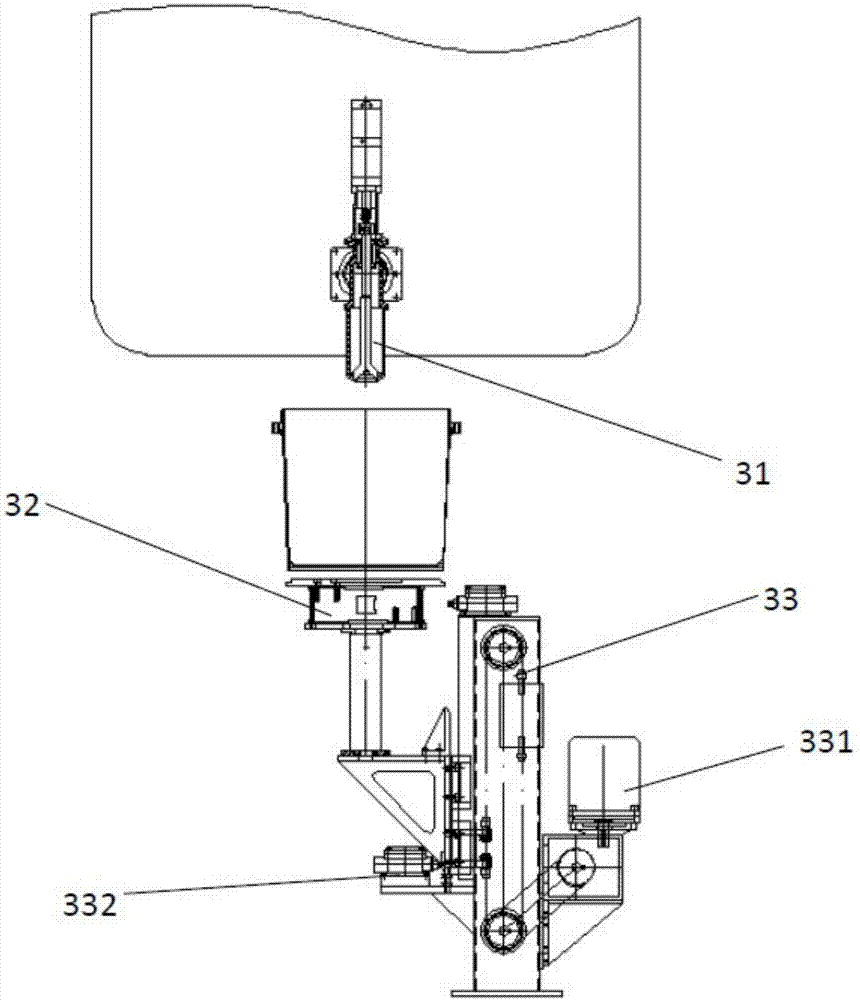

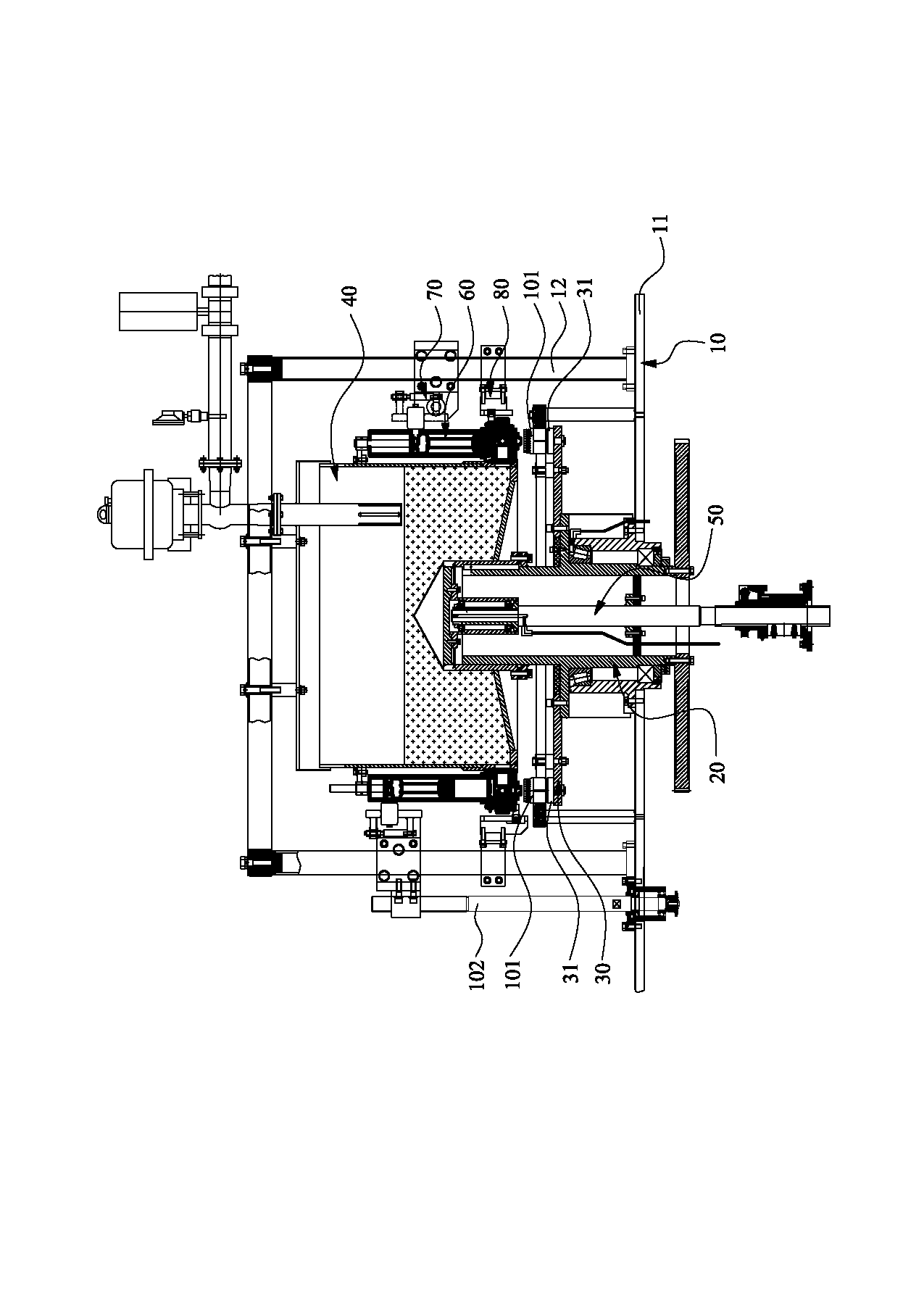

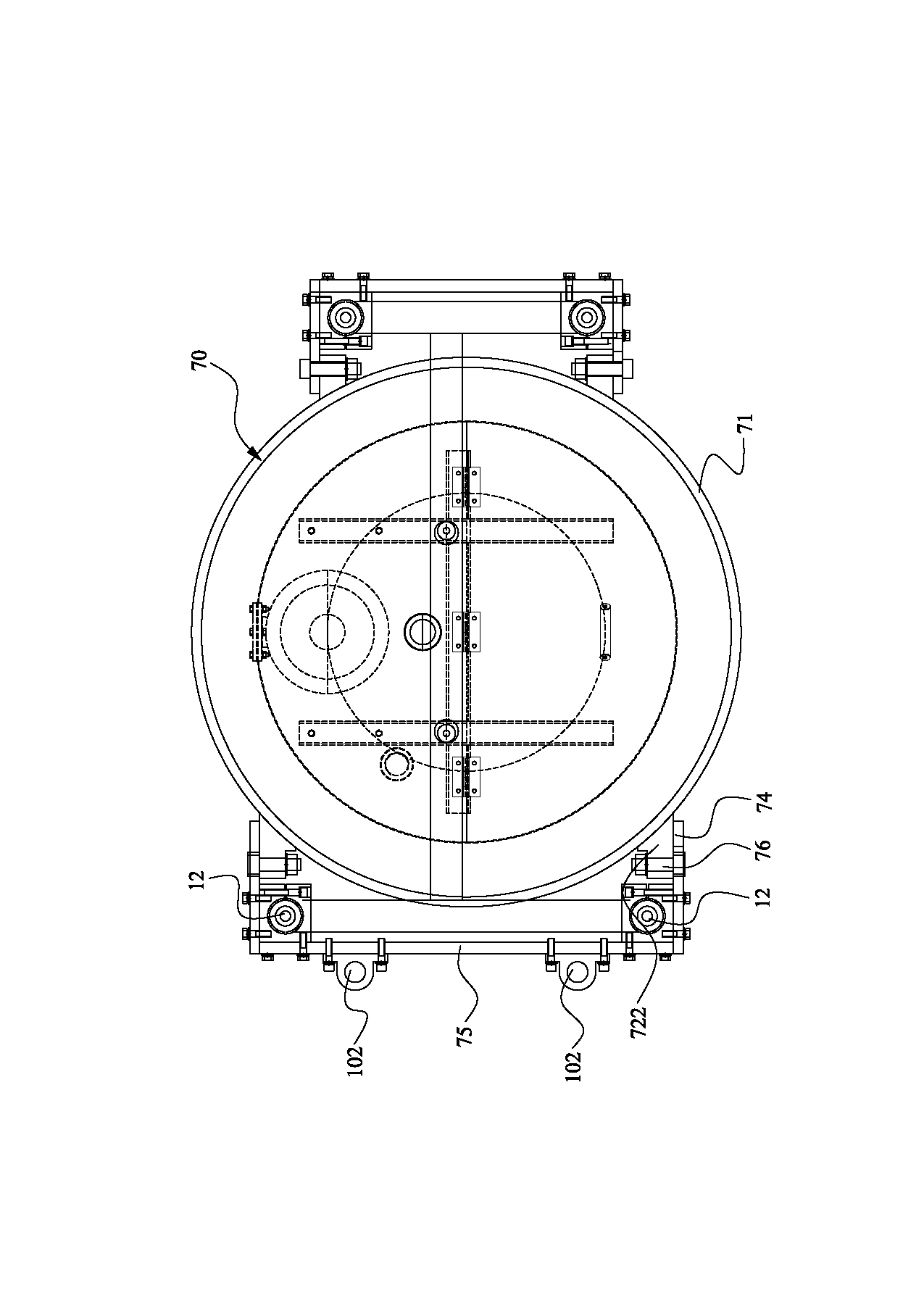

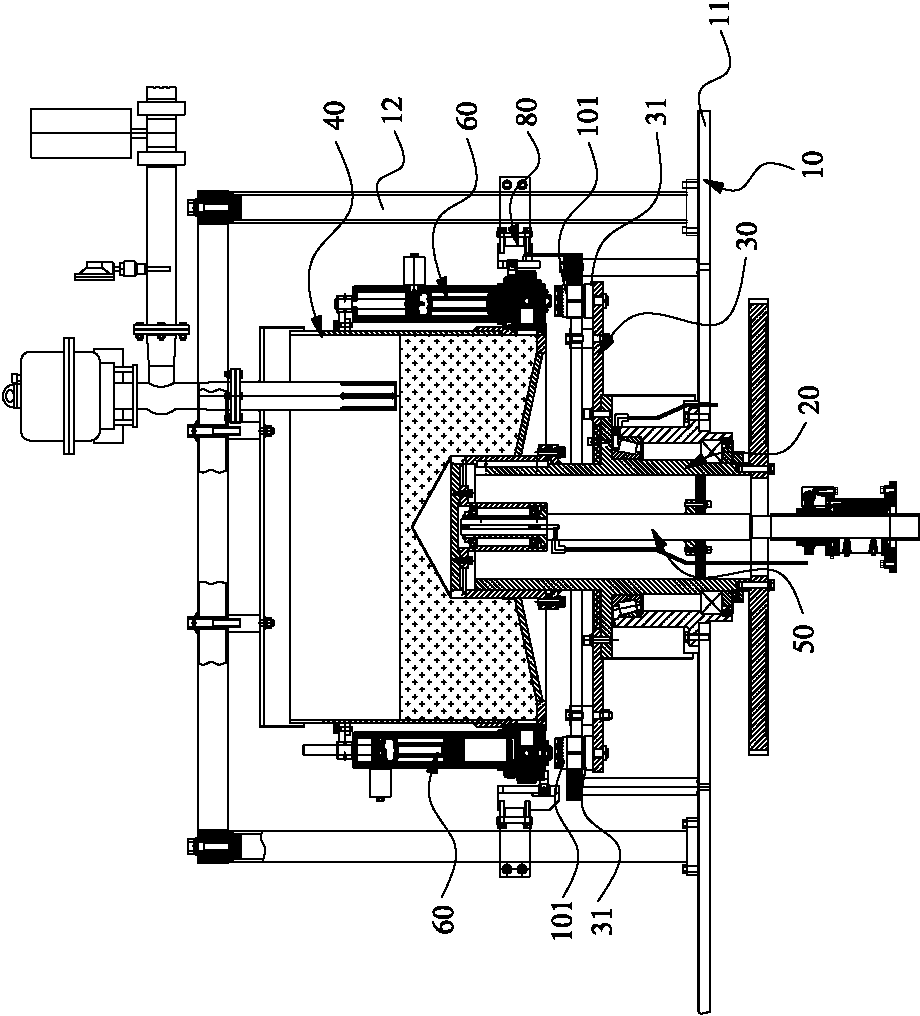

Automatic bag supplier for valve bag

ActiveCN102069925AReduce labor intensityReduce human inputPackagingEngineeringMechanical engineering

The invention relates to an automatic bag supplier for a valve bag, belonging to the technical field of packing machinery. The bag supplier comprises a frame, a valve bag picking-up mechanism, a valve bag opening clamping mechanism, a valve bag capturing mechanism and a filling machine bag feeding mechanism, wherein the frame is configured to one side of a set of filling machines with horizontal filling openings under a use state, at least two of the filling machines are arrayed linearly with each other, and the frame corresponds to the front part of the horizontal filling openings; the valve bag picking-up mechanism is in sliding fit with the frame by moving left and right; the valve bag opening clamping mechanism is arranged on the valve bag picking-up mechanism; the valve bag capturing mechanism is delivered by the valve bag picking-up mechanism to capture the valve bag, and is arranged on the frame; and the filling machine bag feeding mechanism is used for taking the valve bag captured by the valve bag capturing mechanism away from the valve bag capturing mechanism and transferring the clamped valve bag to the filling machine for filling, and is arranged on the frame by moving left and right. The automatic bag supplier for the valve bag provided by the invention has the following advantages: the human input can be reduced, the labor intensity of operators is eased, and the filling efficiency can be improved.

Owner:CHANGSHU SANHE PRECISION MACHINERY & TECH CO LTD

Fastener bag

There is provided a fastener bag capable of improving working efficiency for the filling of inner content and forming a bag cut-starting portion. The bag is formed as gusset-type packaging bag, to which a fastener for freely opening or closing the packaging bag is attached. The fastener has a male portion to which a projected thread is formed and a female portion to which a groove is formed so as to be engaged with the projected thread. Base portions of the male and female portions are attached to an inner surface of one of the flat surface portions or side surface portions so that the projected thread and the groove face each other. A cut-tape for separating the flat surface portion into the male portion side and the female portion side is provided between the base portions.

Owner:HOSOKAWA YOKO CO LTD +1

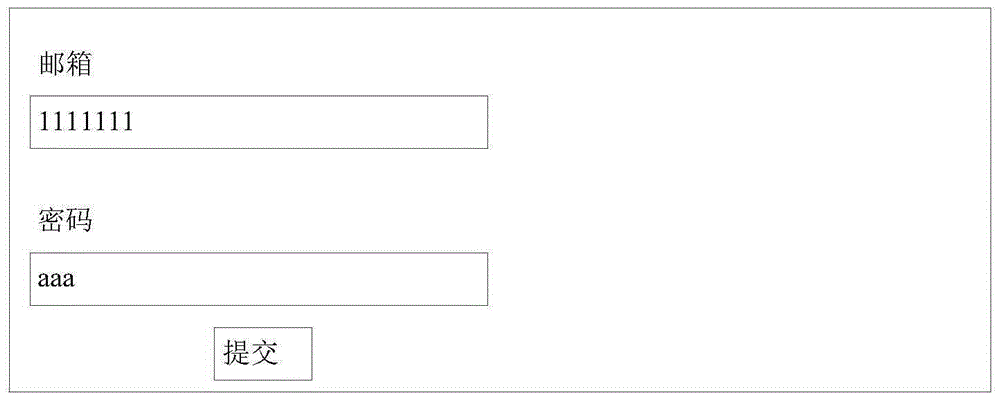

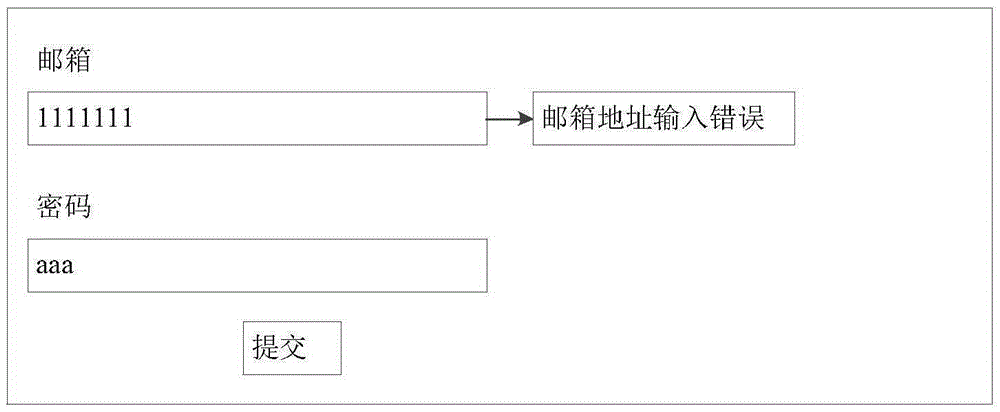

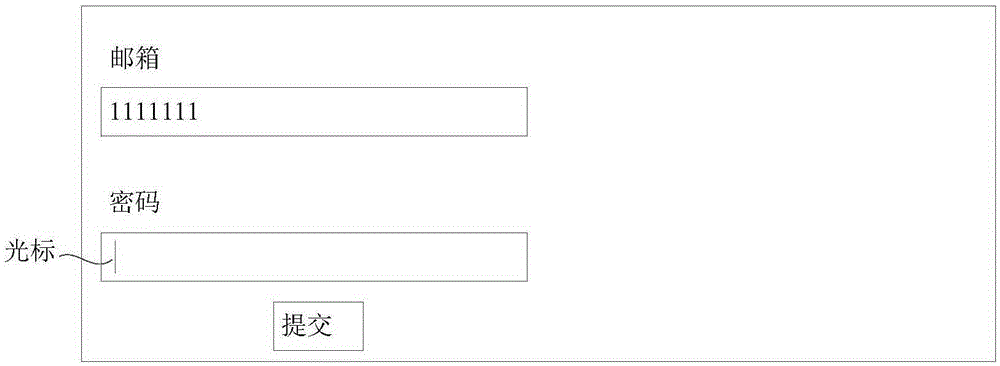

Form verification method and apparatus

InactiveCN105404620AImprove filling efficiencyShorten the timeNatural language data processingSpecial data processing applicationsComputer science

Embodiments of the present invention relate to the technical field of communication and particularly to a form verification method and apparatus that are used for improving form filling efficiency. The method comprises: monitoring a first input box of a form; when it is monitored that an operation action that enables a content in the first input box to be changed occurs in the first input box, calling a callback function corresponding to a trigger event that corresponds to the first input box; according to a first verification rule corresponding to the first input box, verifying the content in the first input box, and displaying prompt information corresponding to the first input box on a interface of the form; when a submitting command of submitting the form is received, acquiring a content of each input box in the form and a verification result obtained by verifying each input box by means of a second verification rule corresponding to each input box; processing the form according to the verification result obtained by verifying each input box. Thus, the form verification method and apparatus improve form filling efficiency and save time for the user to fill the form.

Owner:HUAWEI TECH CO LTD

Method of resin sealing permanent magnets in laminated rotor core

ActiveUS7653984B2Improve filling efficiencyLess affectedMagnetic circuitInductances/transformers/magnets manufactureEngineeringPlunger

Owner:MITSUI HIGH TEC INC

Preparation of polymer composite gelling agent for grouting and application method thereof

The invention belongs to the technical field of a gelling agent for geologic hazard control as well as filling control of goaf and waste laneway or collapse craters after exploitation of other mines, and provides a formula and a method of a novel polymer composite gelling agent for grouting. The gelling agent comprises the following components in percentage by weight: 10-25% of bentonite, 5-20% of cellulose, 5-20% of vegetable gum, 10-15% of calcium hydroxide, 10-25% of inorganic hygroscopic agent, 0.5-1.5% of inorganic dispersant, 0.5-2% of inorganic flocculent, 6-18% of organic flocculent, and 5-15% of alkali metal carbonate. The gelling agent is used for processing and crushing, mixing with water, and injecting to slurry for gelling. According to the invention, the characteristics of high-hydroscopicity mineral matters and hydroscopic synthetic resin are sufficiently absorbed and utilized, and various ion groups are introduced and adjusted to obtain specific performance, so that the gelling agent has strong water solubility, can form hydrophile and water-insoluble gel in the slurry, and has excellent adhesion force to solids and dissolved matters in the slurry, good gelling property, strong water control function, high and adjustable jelling speed, low cost and no pollution.

Owner:JICHANG XIANDAO ENG MATERIAL

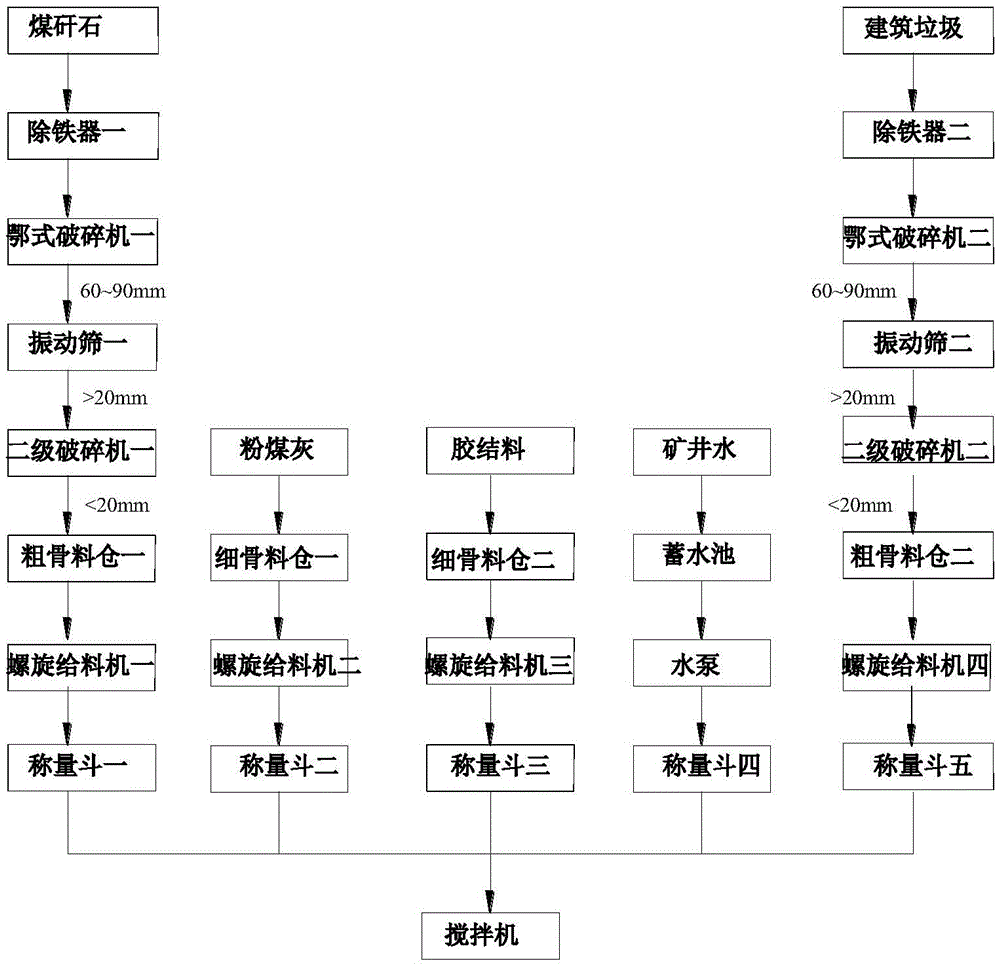

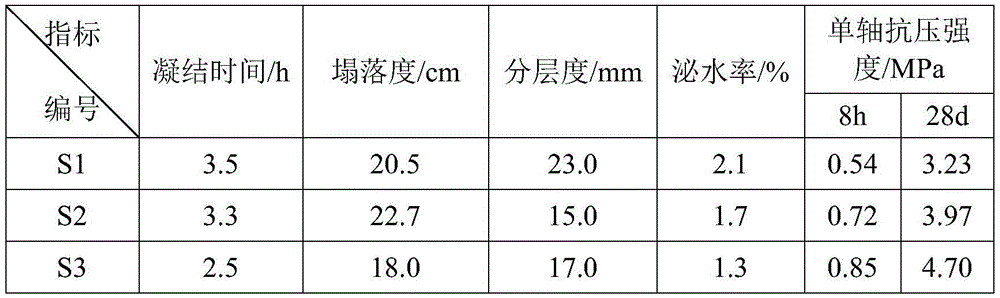

Coal mine paste-like filling material using construction waste, and preparation and filling method thereof

InactiveCN105481314AHigh strengthImprove stabilitySolid waste managementMaterial fill-upFilling materialsWater reducer

The invention provides a coal mine paste-like filling material using construction waste. The material comprises the following raw materials: a coarse aggregate containing 450-500Kg of construction waste and 400-450Kg of gangue; a fine aggregate containing 350-400Kg of fly ash and 200-250Kg of a binder; an admixture containing 6.0-12.5Kg of an accelerator and 2.0-7.5Kg of a water reducer; and 550-630Kg of mine water. According to the invention, construction waste, gangue and other wastes are used to prepare the paste-like filling material with good pumpability, low bleeding rate and degree of stratification, short setting time, high strength and stability, and low cost. The invention also provides a preparation and filling method of the coal mine paste-like filling material using construction waste.

Owner:ANHUI UNIV OF SCI & TECH

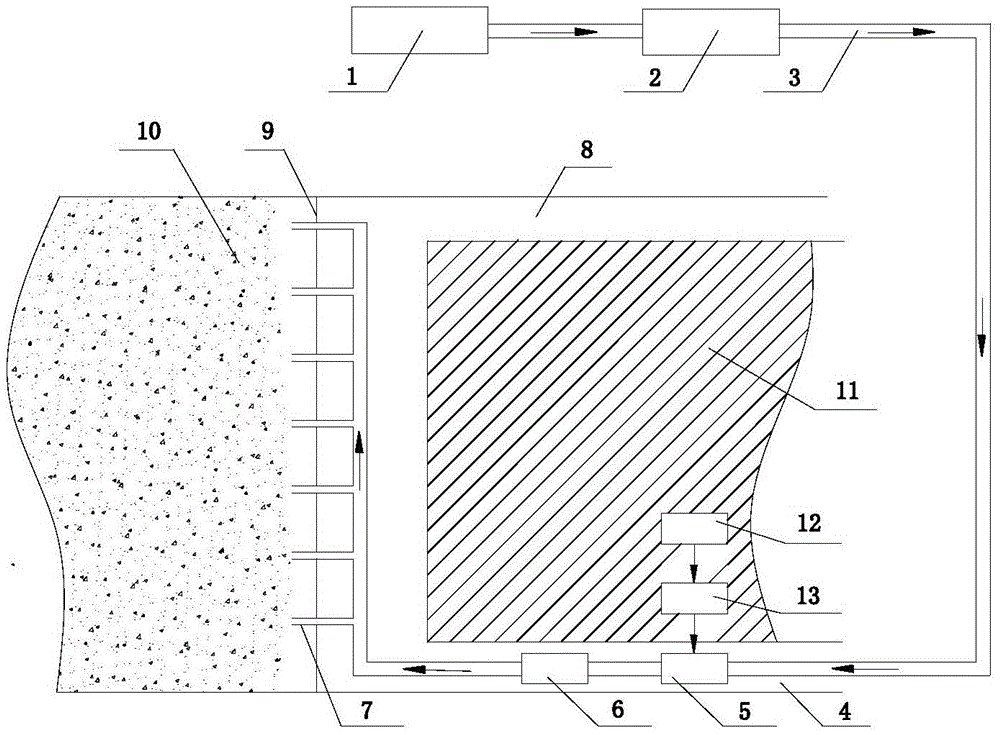

Mined out space dam-type filling method

The invention relates to a mined out space dam-type filling method; after an overhand mining working surface is pushed forward 3-5m, a baffle is arranged behind a cut top row single-body hydraulic support post in a spanning way; flexible waterproof cloth is attached on baffle and is laid and extended towards a bottom plate and two lanes of the working surface, so that a separated mined out space is formed; high-water material is filled into the separated mined out space by grouting equipment; after the high-water material is solidified, the baffle and the single-body hydraulic support post are disassembled, and one-time filling can be finished; along with the advance of a coal mining working surface, the steps are repeatedly carried out for completing the filling for a plurality of times; after the coal mining working surface finishes mining, all devices of the working surface are disassembled, a closed wall is built between a transportation roadway and a track roadway, and finally, top tight filling is carried out to complete the filling operation of the whole mined out space. As a grouting pipe is used for flood irrigation of the separated mined out space, the filling liquid level is lifted, slurry can be in top tight filling rapidly, filling is dense, the effect is visualized, and the method is simple. Therefore, the mined out space dam-type filling method is applicable to the overhand mining working surface with smaller coal seam dip angle or higher mining height.

Owner:CHINA UNIV OF MINING & TECH

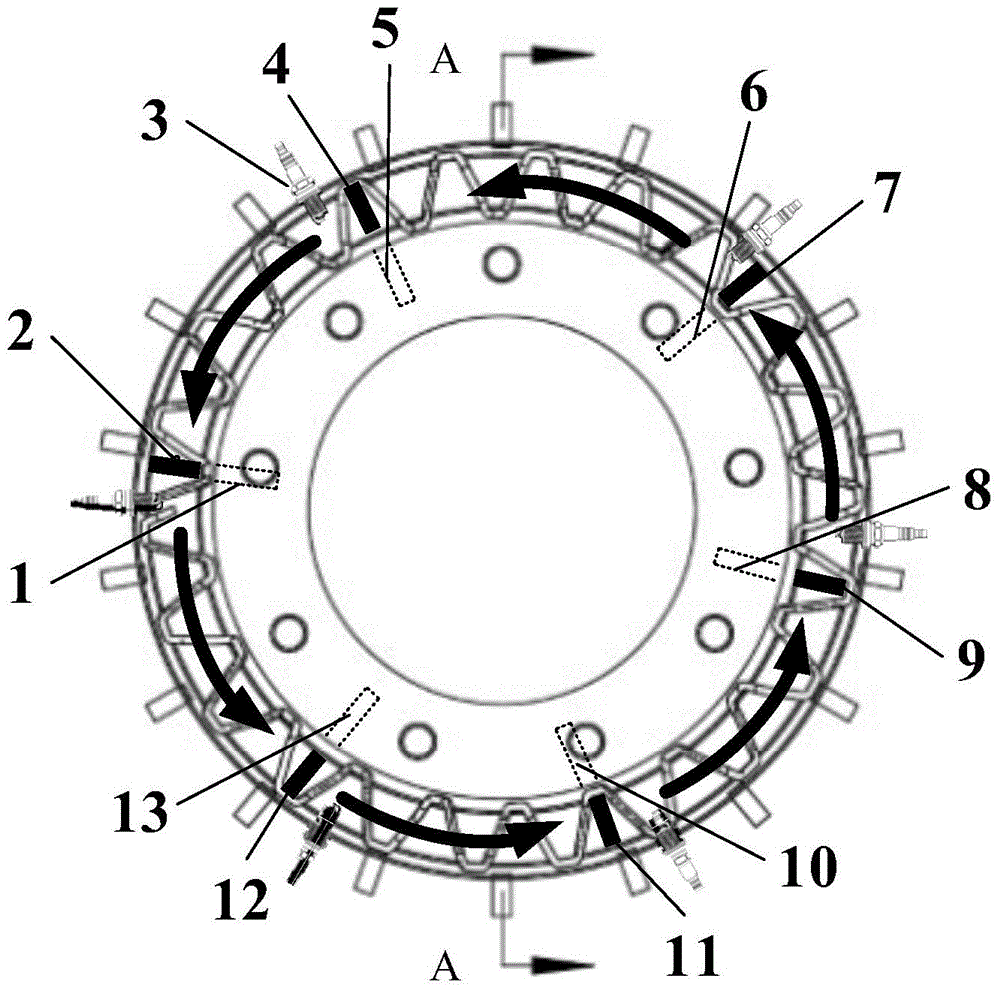

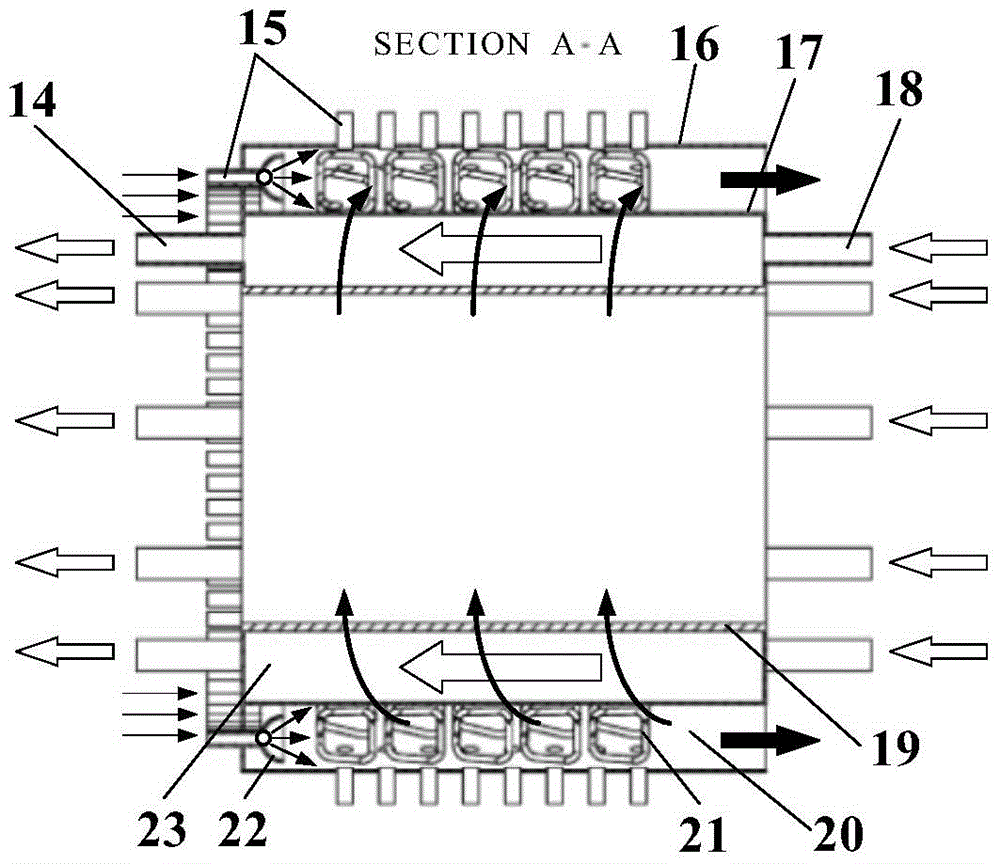

Rotating detonation combustion chamber

InactiveCN104154567AImprove self-pressurization abilityImprove stabilityContinuous combustion chamberDetonationAxial distance

The invention provides a rotating detonation combustion chamber. According to the rotating detonation combustion chamber, besides a plurality of fuel spray nozzles which are distributed on the head portion of the combustion chamber in an annular mode at equal intervals, a plurality of fuel spray nozzles are further evenly arranged in the axial direction and the circumferential direction of an outer shell of the combustion chamber, so that the annular detonation combustion chamber is divided into a plurality of small spaces; each spray nozzle is responsible for supplying fuel to the corresponding small space, and therefore filling efficiency of fuel can be improved, the filling space of fuel of the combustion chamber can be enlarged, and the combustion thermal intensity of the combustion chamber can be improved. The axial distance of rotating detonation combustion waves can be lengthened due to the fact that the filling space of fuel of the combustion chamber is enlarged, so that the rotating detonation waves penetrate through the whole combustion chamber, and meanwhile the rotating detonation waves can be prevented from degeneration and disappear which are caused by fuel shortage in the spreading process. A spiral obstacle is arranged in an annular cavity of the rotating detonation combustion chamber in the circumferential direction, and therefore the distance by which slow combustion is converted into detonation combustion in the starting process of the combustion chamber can be shortened, the intensity of the rotating detonation waves is enhanced, the overall self-pressurization capacity is improved in the combustion process of the combustion chamber, and meanwhile stability of the rotating detonation waves can be enhanced in the spreading process.

Owner:XIAN THERMAL POWER RES INST CO LTD

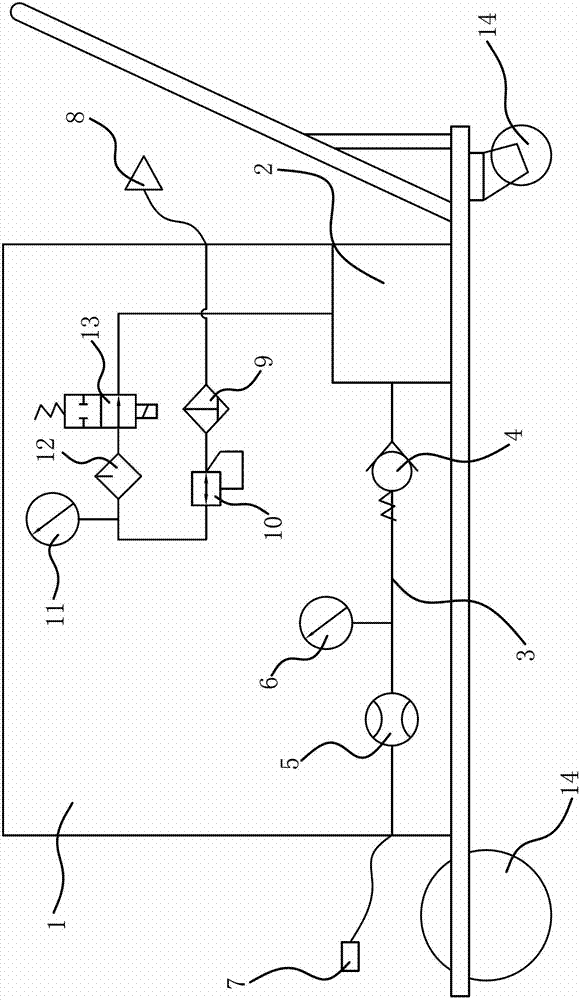

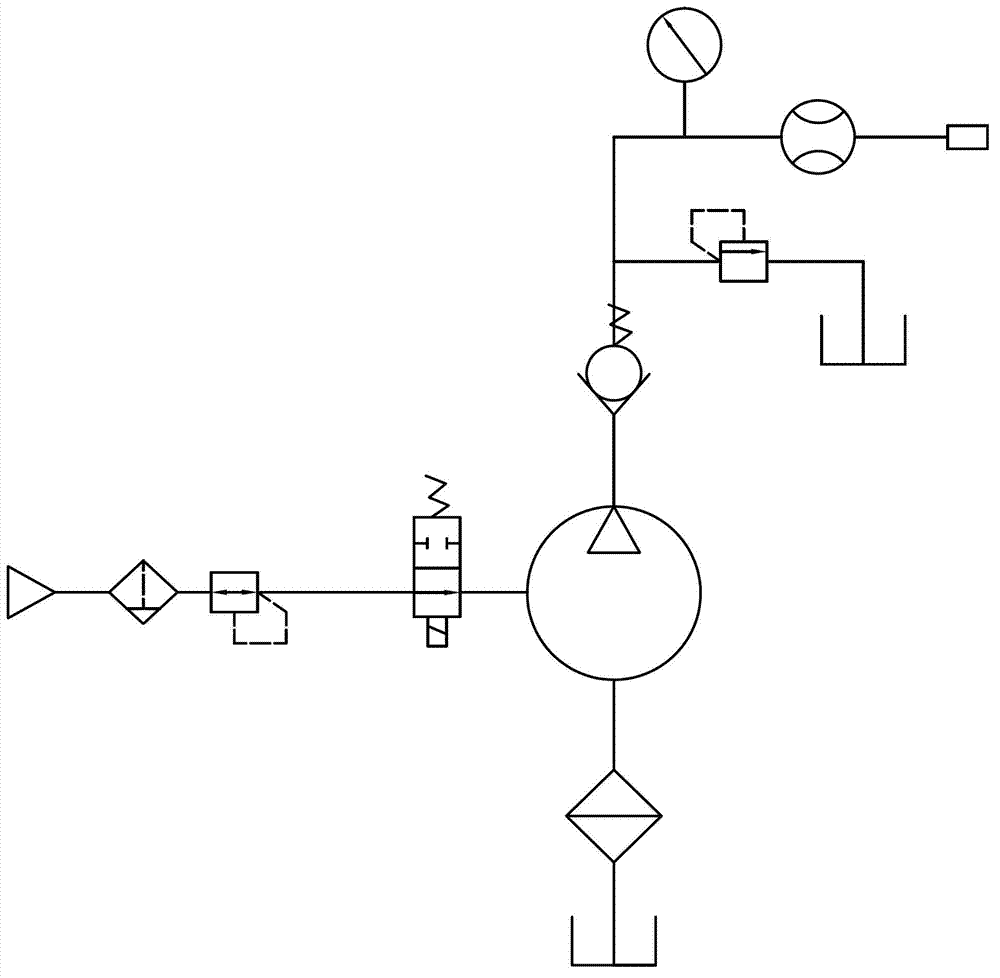

Liquid filling device

The invention provides a liquid filling device, which belongs to the technical field of operation and solves the problems of complex operation and poor performance existing in the traditional liquid filling device. The liquid filling device comprises a liquid storage box, a pneumatic diaphragm pump, a filling connector which can be communicated with a filling opening and an air inlet connector which can be communicated with an air supply opening, wherein a liquid inlet of the pneumatic diaphragm pump is communicated with the liquid storage box through a liquid inlet pipeline assembly and is positioned at the bottom part of the liquid storage box; a liquid outlet of the pneumatic diaphragm pump is communicated with the filling connector through a liquid outlet pipeline assembly; and the air inlet connector is communicated with an air inlet of the pneumatic diaphragm pump through an air inlet pipeline assembly which can be used for enabling the air to enter into the pneumatic diaphragm pump in voltage stabilization and controlling the air inlet or the air cut. The liquid filling device disclosed by the invention has the advantages of compact structure, convenience for control, high injection efficiency, and time and labor saving; and by adopting the pneumatic diaphragm pump as a power source, the liquid filling device has the advantages of safety in use, stable performance and the like.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

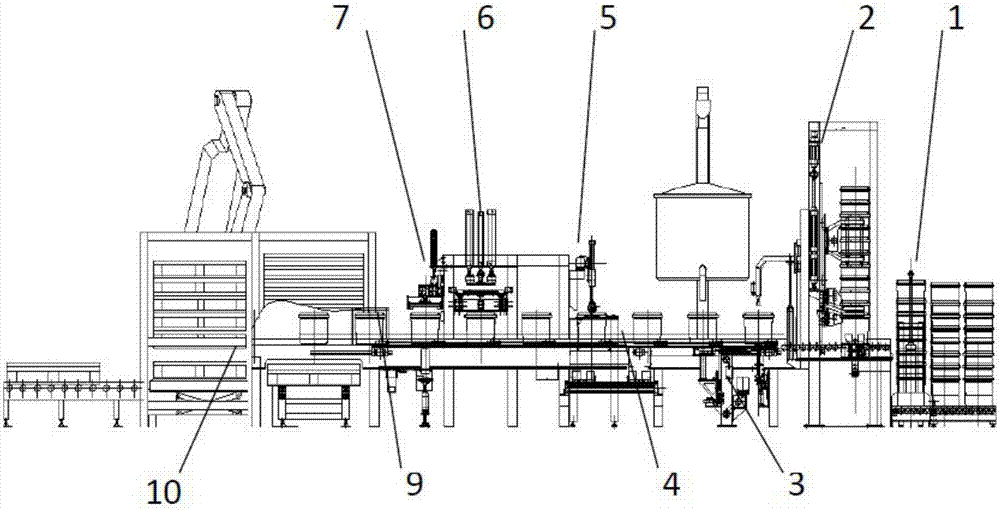

Full-automatic printing ink filling assembly line

PendingCN107298191AHigh degree of automationCompact structureLiquid materialPackaging machinesEngineeringAssembly line

The invention relates to a full-automatic printing ink filling assembly line. The full-automatic printing ink filling assembly line is characterized in that an automatic barrel distributing device is arranged at the rear of an automatic barrel loading device and is connected with an automatic filling device by a stepping line, and an integral pile of plastic barrels can be automatically separated from one another one by one along the perpendicular direction by an automatic barrel distributing machine by the aid of a barrel distributing cylinder and can be sequentially conveyed to the stepping line; filled barrels can be conveyed to an automatic film covering device by the stepping line, and a plastic film can sucked by the automatic film covering device by the aid of vacuum suckers and covers the surface of printing ink in the filled barrels; the filled barrels covered with the plastic films can be conveyed onto an automatic barrelhead loading and compressing device on a barrelhead compressing station by the stepping line, and barrelheads can be automatically extracted by the automatic barrelhead loading and compressing device and can tightly cover the barrels by the automatic barrelhead loading and compressing device; a barrelhead screwing and labeling station is arranged beside the automatic barrelhead loading and compressing device, an automatic barrelhead screwing device and an automatic labeling machine are arranged on the barrelhead screwing and labeling station, the barrelheads can be screwed by the automatic barrelhead screwing device, and bodies of the filled barrels can be labeled by the automatic labeling machine. The full-automatic printing ink filling assembly line has the advantage that the plastic barrels can be automatically filled with the printing ink with different colors.

Owner:SHANGHAI HENGTUO IND DEV

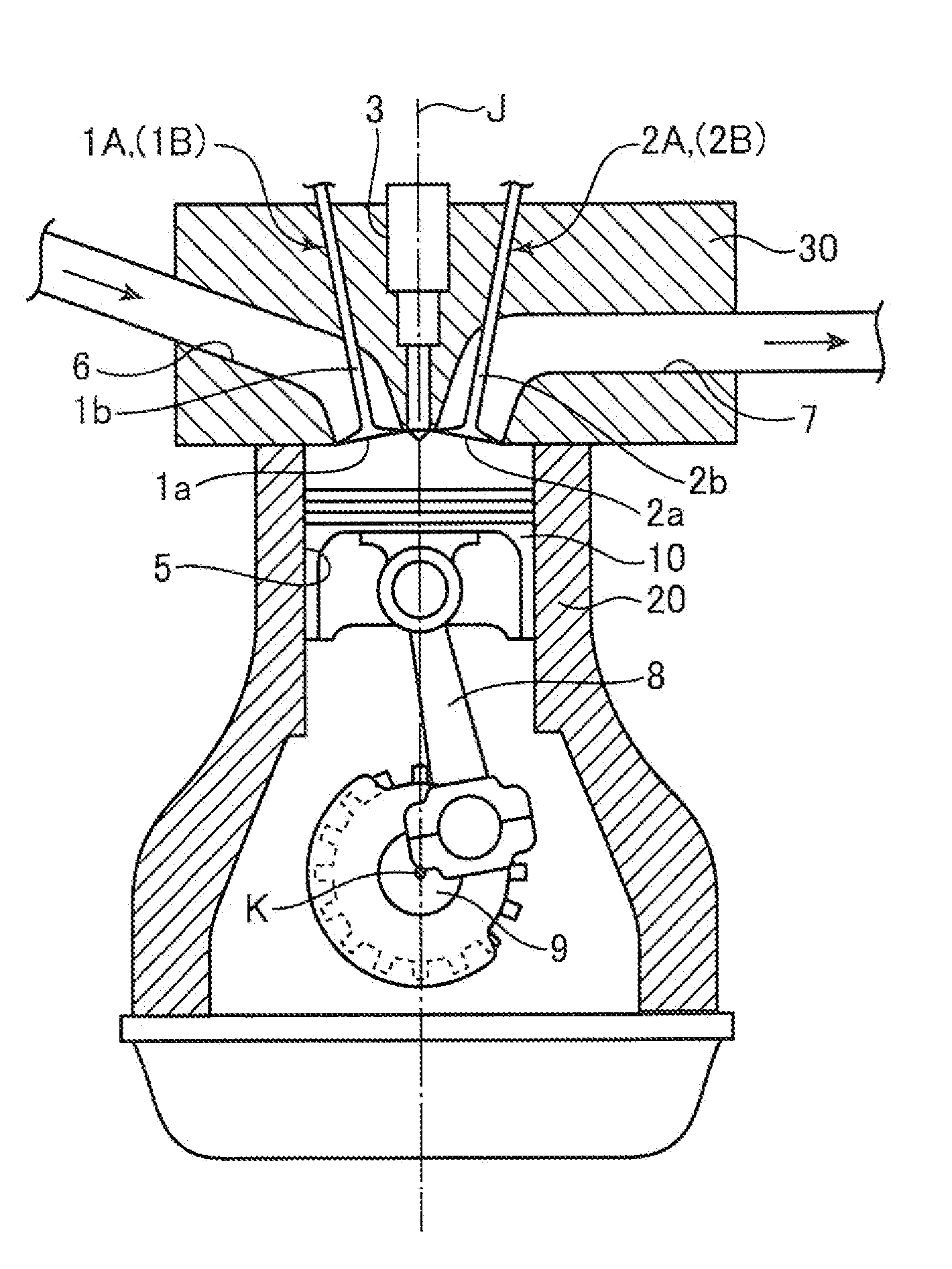

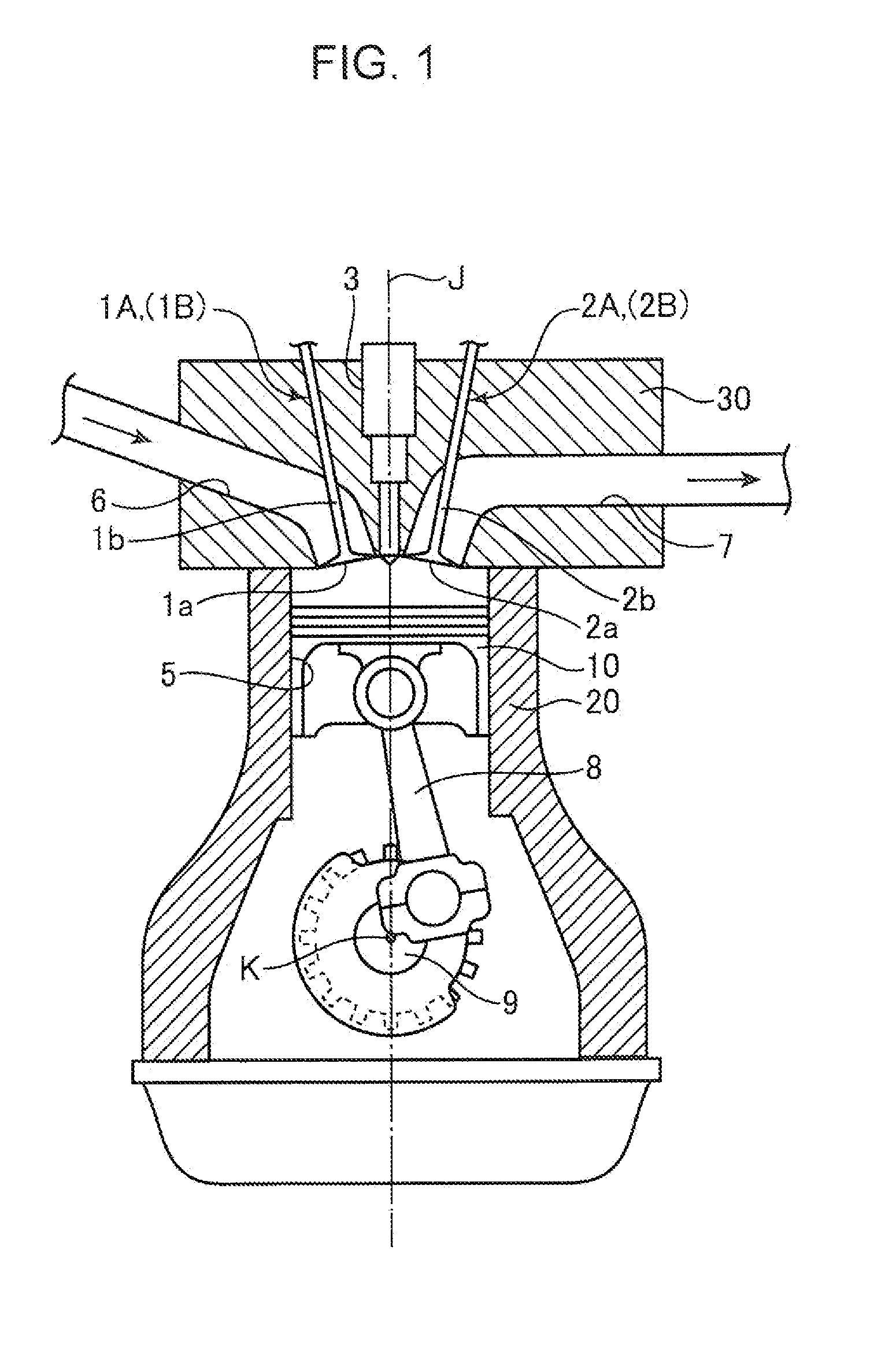

Combustion chamber structure for engine

ActiveUS20150167536A1Improve filling efficiencyInternal combustion piston enginesCylinder headsExhaust valveCombustion chamber

The axial line of an intake valve is inclined, and a gap between a piston crown surface and a valve head of the intake valve expands in accordance with the approach of the crankshaft axis. A relationship of G2>G1 is fulfilled, where G1 stands for a minimum gap between the lower surface of the cylinder head that is positioned between the intake valve and the exhaust valve facing the intake valve, with the crankshaft axis being interposed therebetween, and the piston crown surface in a top dead center, and G2 stands for a gap at a position that is the closest to the crankshaft axis, from among the gaps between the lower surface of the valve head of the intake valve and the piston crown surface at a center timing of a valve overlap period in which the intake valve and the exhaust valve are both open.

Owner:MAZDA MOTOR CORP

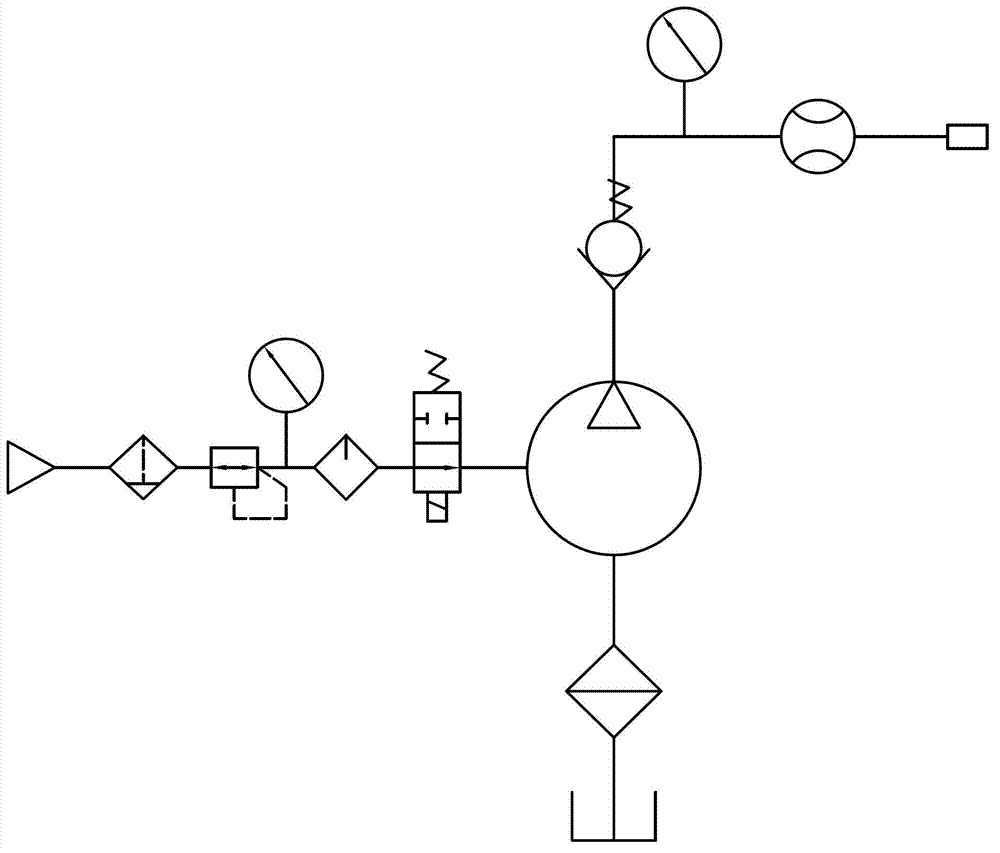

Gas dispenser and gas station composed of the same

ActiveCN101566277ASimple structureVersatileVessel mounting detailsFluid transferredGas cylinderMechanical wear

A gas dispenser is technically characterized in that a PLC firstly collects the pressure value of a pressure sensor in a gas dispersion gun, namely the pressure value in a vehicular gas cylinder. Then the pressure value is added with a preset value, wherein 0<the preset value <20. The summation is compared with the pressure value of each pressure sensor under a plurality of gas cylinder openings. The valve corresponding with the pressure value which is most approximative to and larger than the summation is opened for dispensing the gas through pressure difference. The steps are adopted again before balancing or after balancing. The steps are repeated until the value of the pressure sensor in the gas dispersion gun is the rated pressure value of the vehicular gas cylinder, wherein the rated pressure value is smaller than or equal to 20MPa. Then the valve is closed and the gas dispensation is finished. The gas station of the invention is composed of a plurality of gas cylinders and gas dispensers. The gas station is technically characterized in that the plurality of gas cylinders are used circularly for providing the high-pressure gas for satisfying the using amount of continuous gas dispensation of a single gun or a plurality of guns to the vehicular gas cylinder. The invention changes the technical route of prior gas substation. The matching of large-scale power devices of compressor and hydraulic pump is not required. The gas dispenser has no mechanical wear and extraordinarily low current consumption. The gas dispenser of the invention is the developing direction of the future.

Owner:沈军

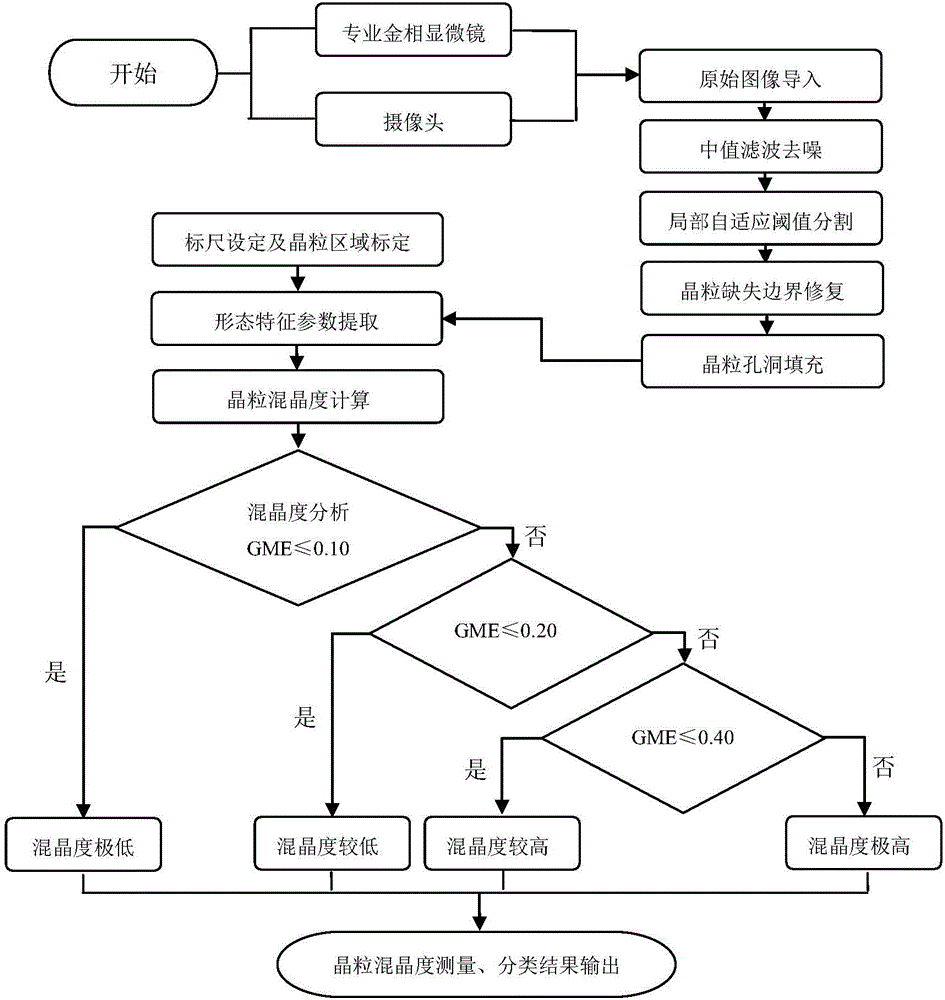

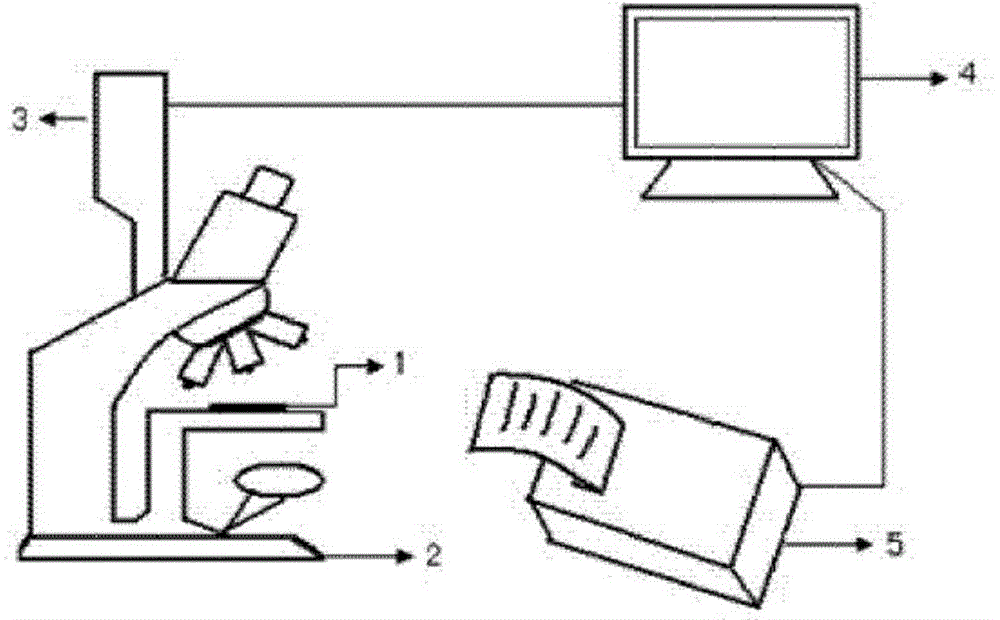

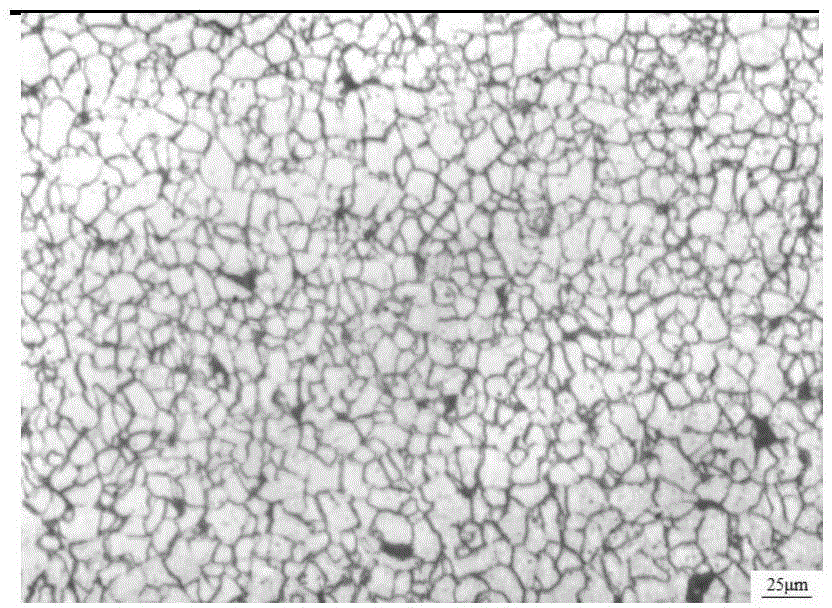

Mixed crystal degree automatic measurement and fine classification method for steel crystal grains, and system thereof

InactiveCN104880389AKeep edge informationEliminate mis-segmentationCharacter and pattern recognitionParticle size analysisCrystalliteMicroscopic scale

The invention belongs to the analysis field of quantitative metallography on all-form crystal grains in a steel material microstructure and particularly relates to an automatic measurement and fine classification method for steel crystal grains, and a system thereof. According to the method, an image acquisition device acquires the original images of to-be-measured crystal grains of the steel material firstly, and then the original images are pre-processed by an image pre-processing module. The pre-processed images are subjected to the region labeling treatment by an automatic measurement module, and then the images of to-be-measured crystal grains can be obtained. After that, the geometry characteristic parameters of the images of to-be-measured crystal grains are extracted, and then the characteristic morphological parameters of target crystal grains are measured through the random field area algorithm. The area of crystal grains is obtained, and then the grain size of crystal grains and the mixed crystal degree (GME) of crystal grains can be figured out. The mixed crystal degree (GME) of crystal grains is automatically classified by an automatic classification module according to a most suitable threshold. In this way, the blank in measuring and classifying the mixed crystal degree of steel crystal grains in the prior art can be filled up. Meanwhile, the characterization precision of the images of steel crystal grains is up to plus / minus 0.001 [mu]m. Therefore, by adopting the above method and the above system, the characterization precision of the images of steel crystal grains is highest during the steel metallographic structure analysis process.

Owner:JIANGSU UNIV

Inverse pumping type anti-leakage pouring valve

InactiveCN101403445ASimple structureSolve the problem of dripping backSpindle sealingsOperating means/releasing devices for valvesWire gauzeEngineering

The invention discloses a reverse pumping type anti-drip filling valve; the filling valve comprises a cylinder arranged in a valve body; a piston rod of the cylinder is fixed by a positioning ring of a valve core; the position of the material outlet of the valve body is provided with at least one layer of wire gauze; the valve core is in the valve body and above the wire gauze; on the positioning ring of the valve core, a sealing ring is arranged between the piston rod of the cylinder and the valve body; the amount of the wire gauze is two layers comprising a first layer wire gauze and a second layer wire gauze; the mesh amount of the first layer wire gauze and / or the second layer wire gauze is 20-30. The filling valve has simple structure, and solves the drip returning problem existing in the low-viscosity or high-viscosity fluid filling process reliably; moreover, the time for pumping the vacuum or blowing the residual materials after the filling is finished is not needed, and therefore the filling efficiency is improved.

Owner:FOSHAN HAITIAN FLAVOURING & FOOD CO LTD +1

Quantitative filling machine of viscous material

ActiveCN102838069AImprove filling efficiencyEasy to installFilling using counterpressureEngineeringBottle

The invention discloses a quantitative filling machine of a viscous material. The quantitative filling machine comprises a rack, a revolving seat, a revolving platform and a material cylinder, wherein the circumferential face of the material cylinder is provided with a filling valve; a track which is arranged slantwise is constituted by an upper ring and a lower ring; a piston is controlled to alternately suck the material into a material cavity or press the material in the material out and fill in a bottle by using the track; meanwhile, a sensor is cooperatively used for controlling work of a driving mechanism, so that an ascending passage is opened or closed by a swing rod, thereby communicating a feed port and the material cavity by a feeding passage or communicating a filling port and the material cavity by a filling passage, effectively controlling output of the material and preventing a mistaken filling phenomenon; and thus, inlet and outlet of the material of all filling valves can be simultaneously and effectively controlled by using a piston control device and a switching control device, the quantitative filling machine has a simple structure and is convenient to operate, mount, debug and maintain, the degree of automation of the machine is greatly improved, and the filling efficiency of the material is effectively increased.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

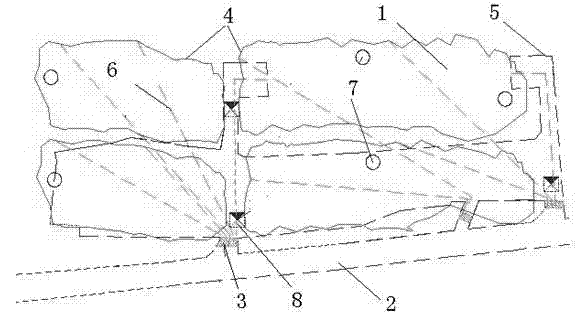

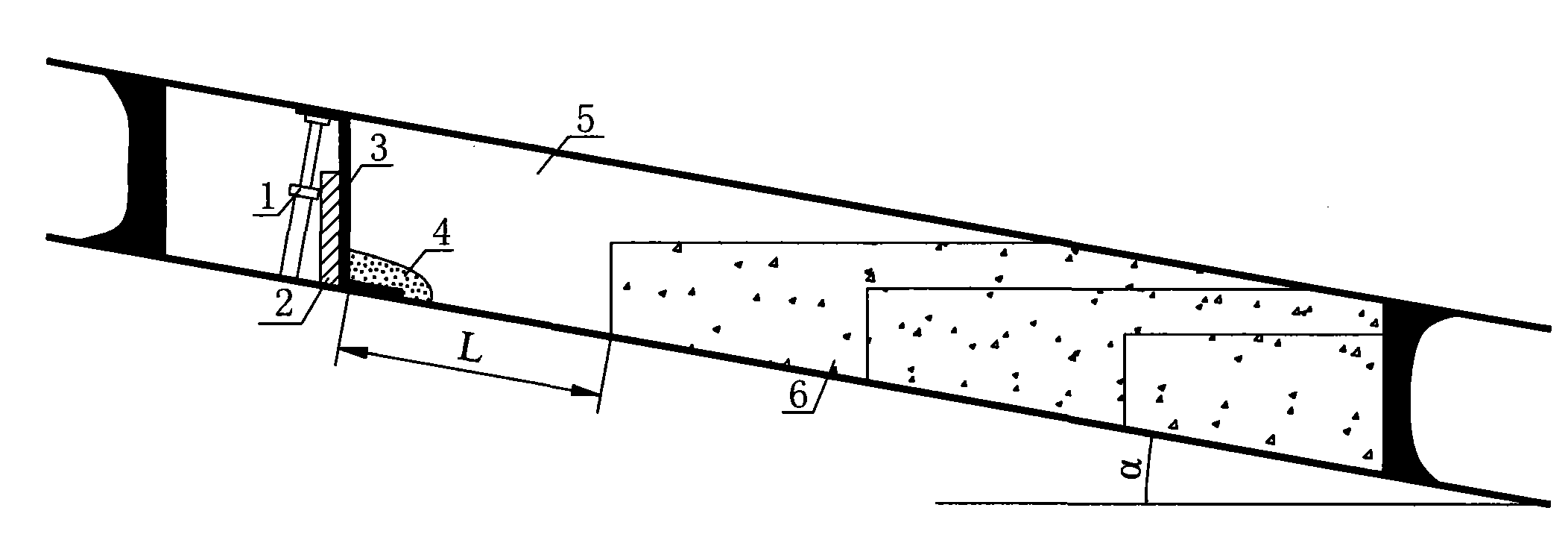

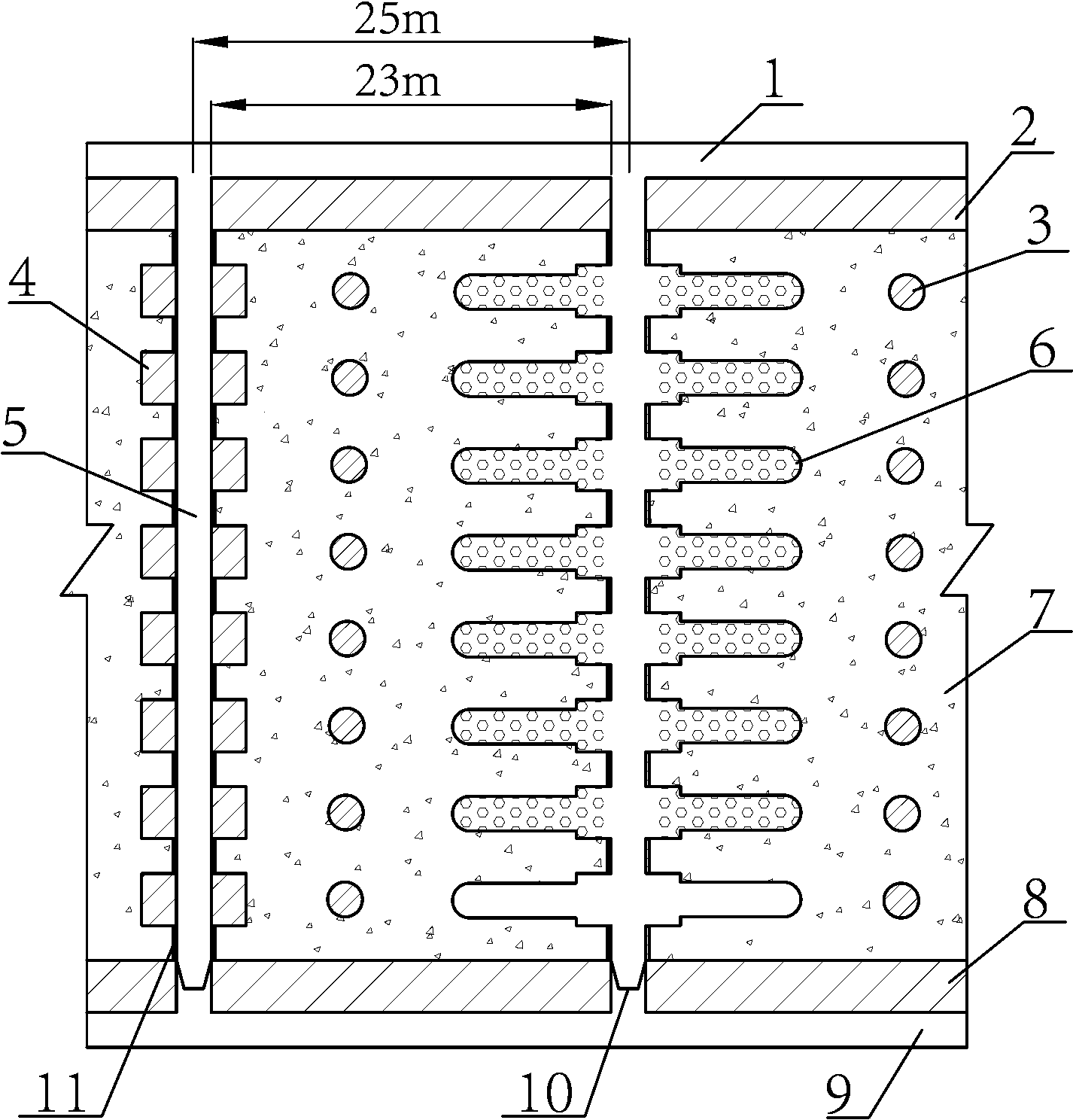

Pillar mining method for gentle dip thin ores

ActiveCN103967493AImprove filling efficiencyReduce filling cyclesUnderground miningSurface miningRoom and pillar miningComputer science

The invention discloses a pillar mining method for gentle dip thin ores. The method comprises the following steps: A, filling the goaf (except upward roadways on the studding side) among top pillars, bottom pillars and studding in an open-stope room-and-pillar method stope (in which stoping is finished) with cementing tailings to form a cemented filling mass; B, firstly stoping pillars in the goaf; then moving tailings and waste stone (dug in the process of stoping the first row of pillars) out of the stope and backfilling the goaf for stoping adjacent upper rows of pillars with tailings and waste stone (dug in the process of stoping other pillars); C, after pillars in the goaf are all stoped, filling the upper roadways and the goaf of pillars by one-time operation; D, after pillars and middle pillars in the whole middle section of the goaf are all stoped, remaining essential airways; for the sake of safety, transporting roadway frontals from the middle section, then going back for stoping top pillars and bottom pills according to a method of drift stroping with backfill, and carrying out alternative stoping and tightened filling. By virtue of the method disclosed by the invention, pillars reserved in the open-stope room-and-pillar method can be stoped safely and efficiently at low cost.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com