Quantitative filling machine of viscous material

A filling machine and material technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of low degree of automation, inconvenient installation, debugging and maintenance, and easy to cause wrong filling, etc., to achieve strong use flexibility, debugging And the maintenance is convenient, and the effect of eliminating the wrong filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

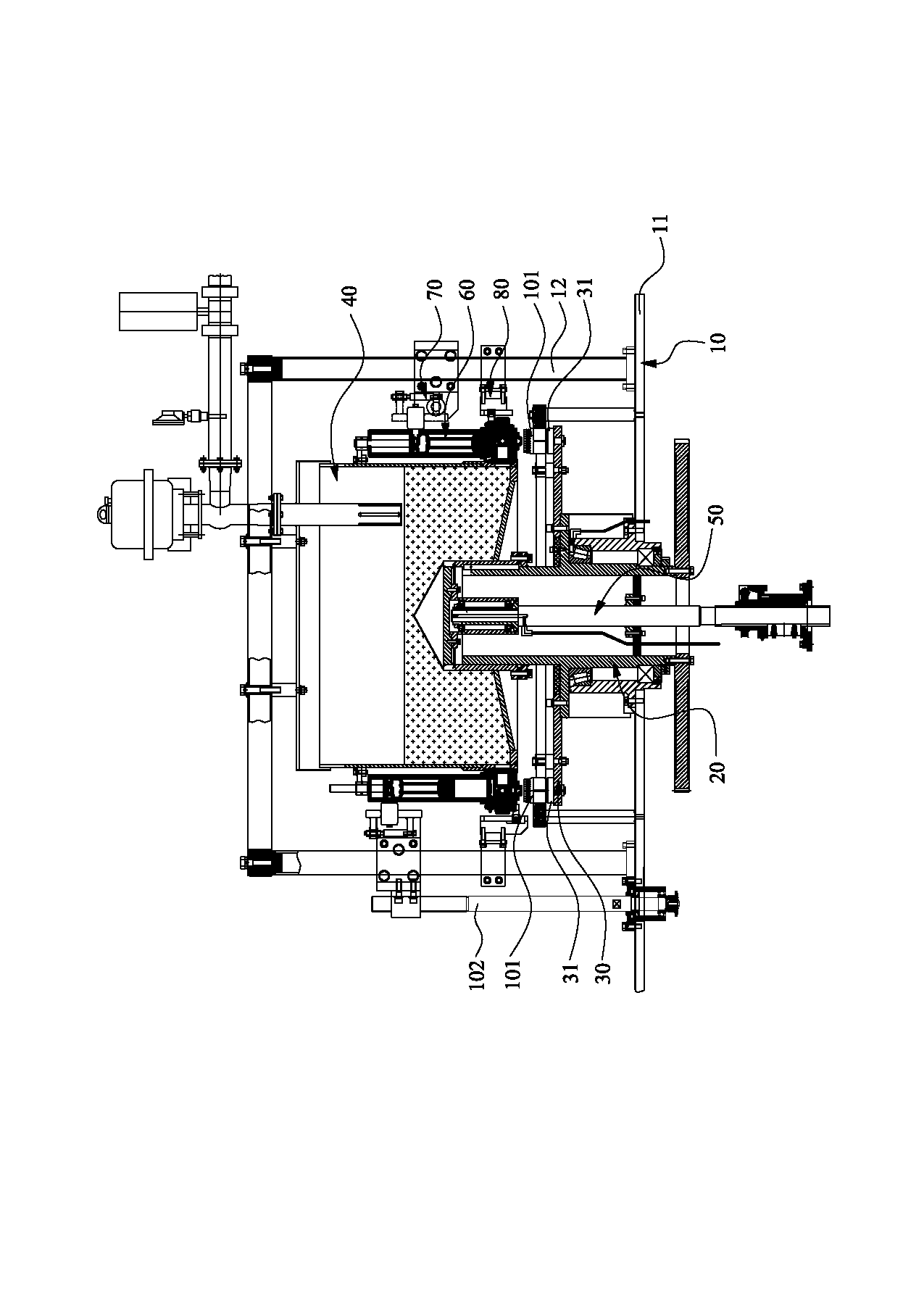

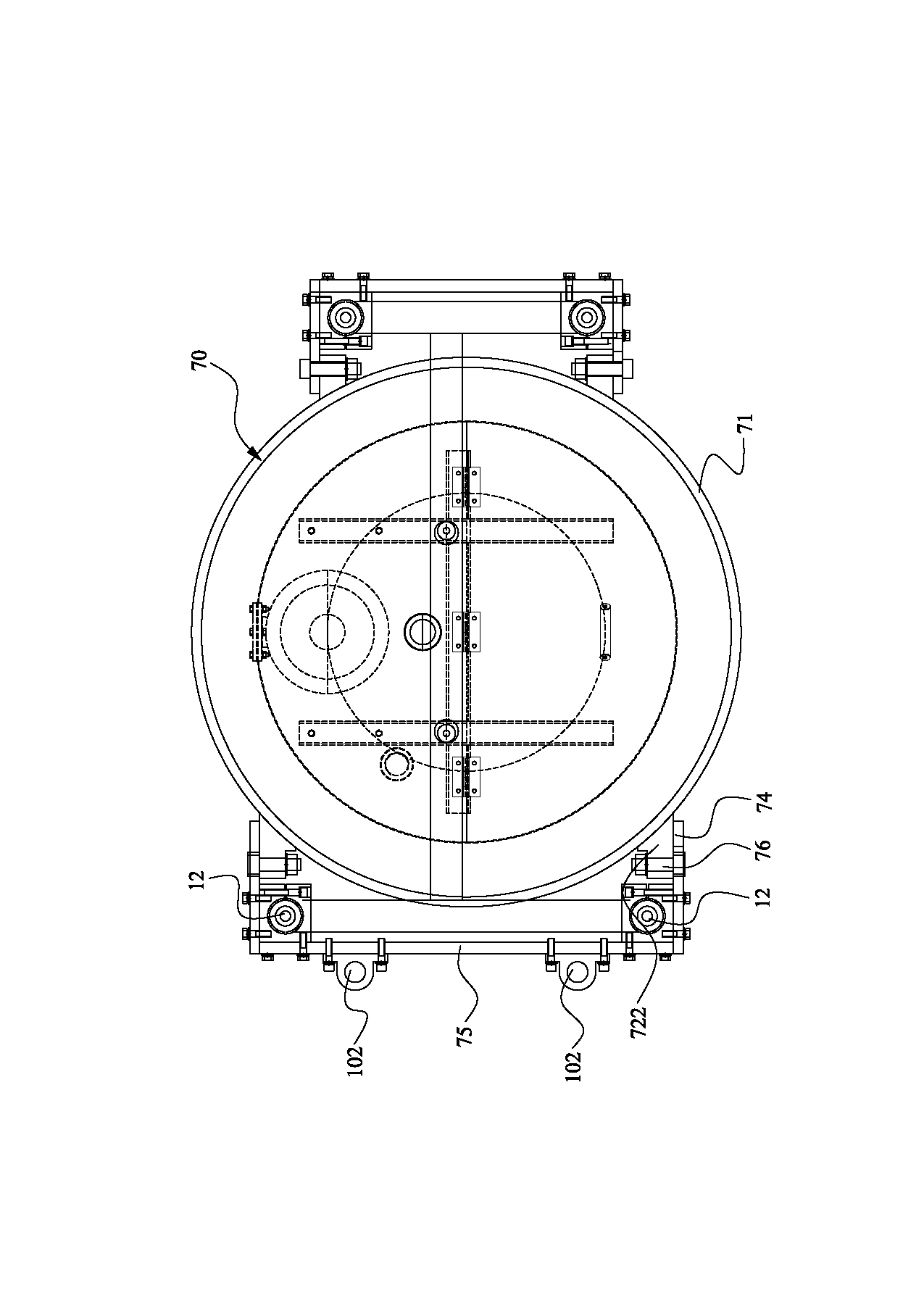

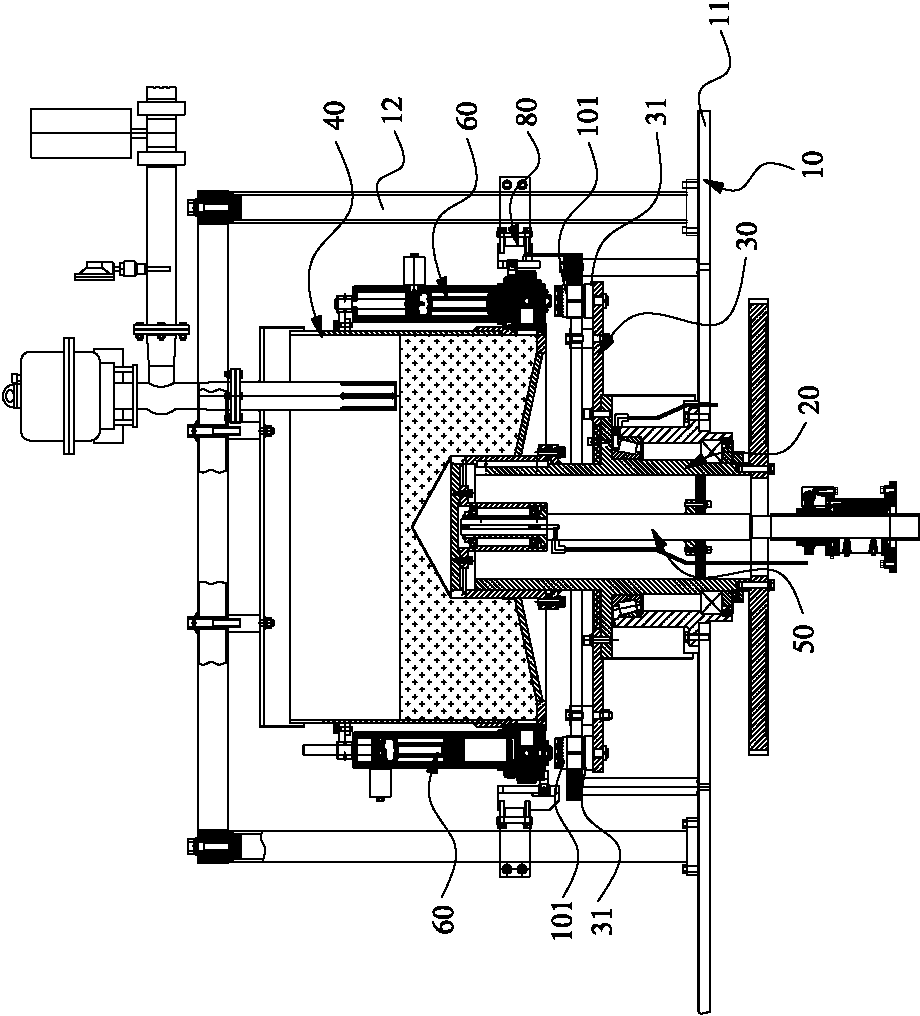

[0067] Please refer to Figure 1 to Figure 16 Shown, it has shown the concrete structure of preferred embodiment of the present invention, comprises frame 10, is used for inputting the bottle-feed channel (not shown in the figure) of empty bottle, is arranged on frame 10 and is driven by external driving device The rotary base 20 driven to rotate and the rotary platform 30 and the material cylinder 40 arranged on the rotary base 20 to rotate synchronously with the rotary base 20 .

[0068] Wherein, the frame 10 includes a platform 11 and a plurality of columns 12 arranged on the platform 11 .

[0069] The revolving base 20 can rotate around its own center line relative to the frame 10. A lifting mechanism 50 that drives the revolving platform 30 to move up and down is provided between the revolving base 20 and the revolving platform 30. Center of rotation distribution.

[0070] The periphery of the rotary platform 30 is provided with a plurality of bottle holders 31 for plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com