Pillar mining method for gentle dip thin ores

A thin ore body, mining method technology, applied in surface mining, underground mining, special mining and other directions, can solve the problems of large safety hazards, large roof stress, rock movement, etc. The effect of impoverishment and reduction of loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0026] The first embodiment of a kind of gently inclined thin ore body pillar mining method of the present invention comprises the following steps:

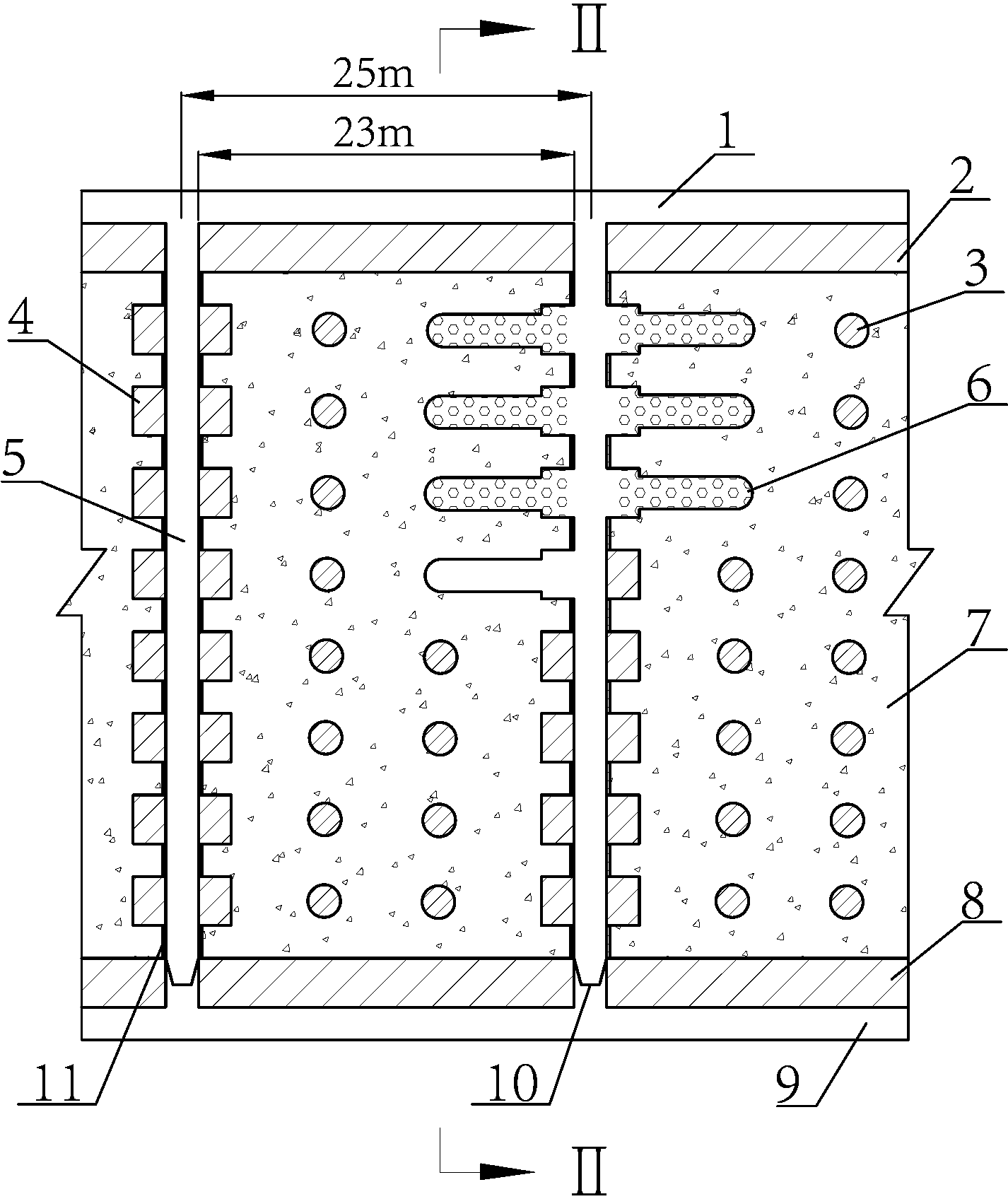

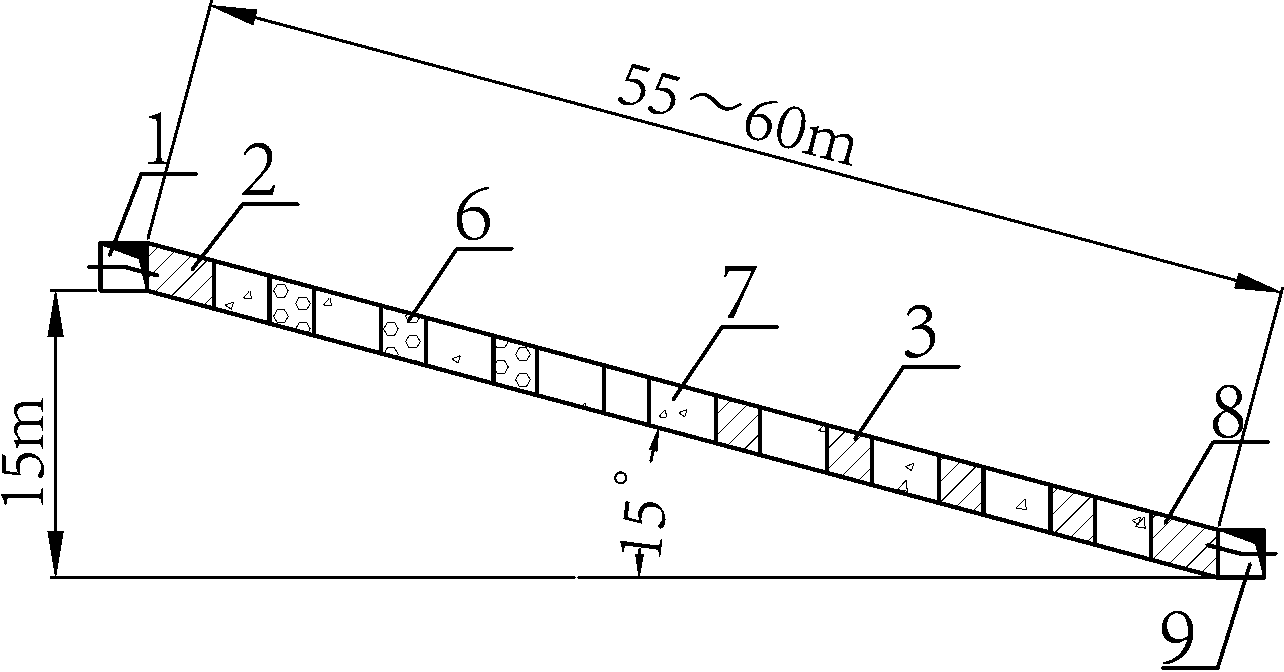

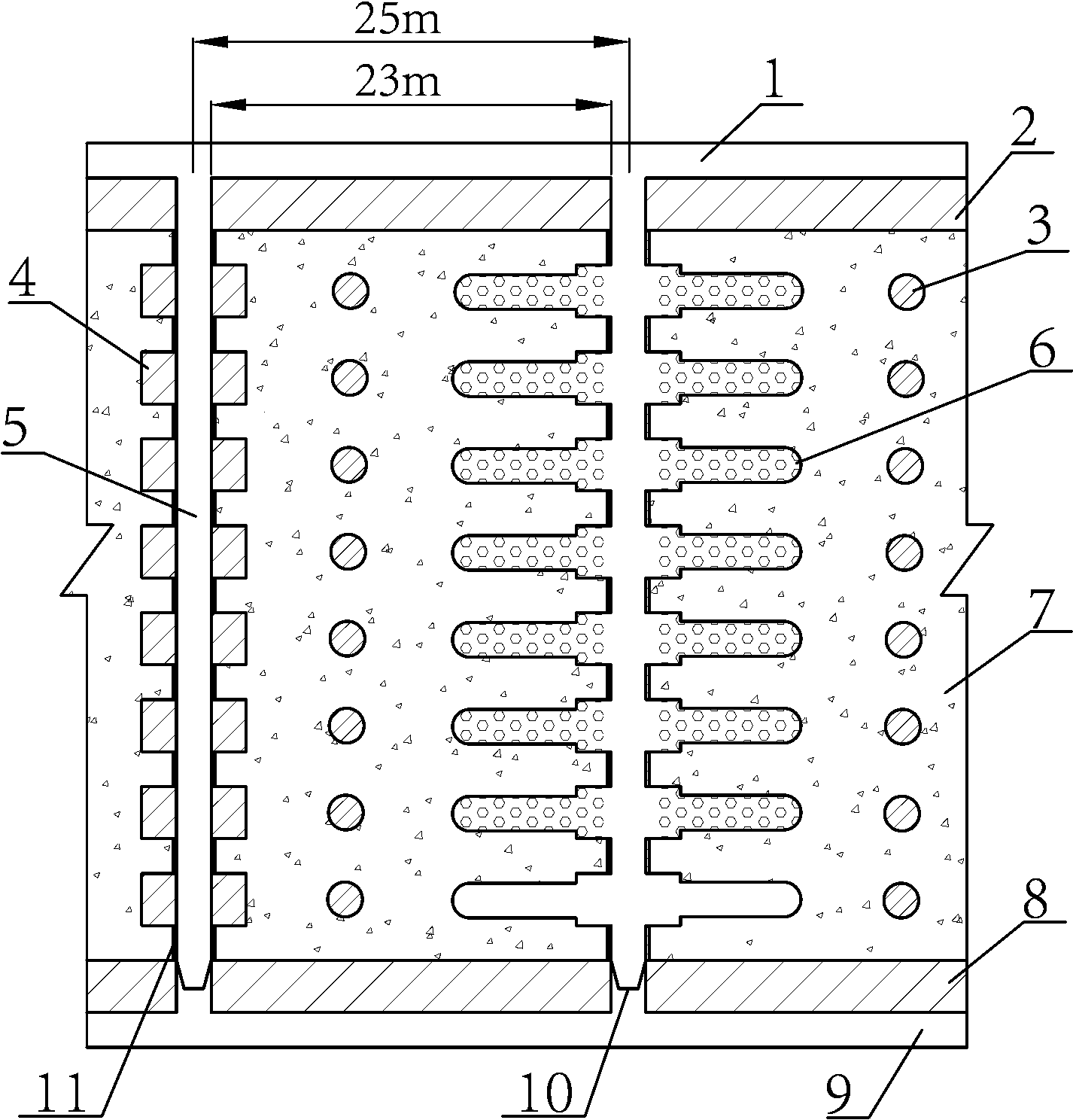

[0027] 1) The structural parameters of the original empty-pit room-and-pillar method stope are the stope strike width 25m, the inclined length of the stope 55-60m, and the section height 15m. 1. Between the bottom column 8 and the inter-column 4, all goafs except the upper hill 5 on the side of the inter-column are filled with glue-tailed sand to form a cemented filling body 7, as figure 1 As shown; in order to prevent leakage of the filling material, geotextiles and filling retaining walls 11 are used to seal the adjacent inter-columns tightly. Within the 6m area of column 8, the material-cement-sand ratio for staged filling is 1:4, and the material-cement-sand ratio for other stages of filling is 1:8.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com