Coal mine paste-like filling material using construction waste, and preparation and filling method thereof

A technology for construction waste and filling materials, which is applied in the fields of filling, mining equipment, earthwork drilling, etc. Strict and scientific grading, prolonged pumping time and improved filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

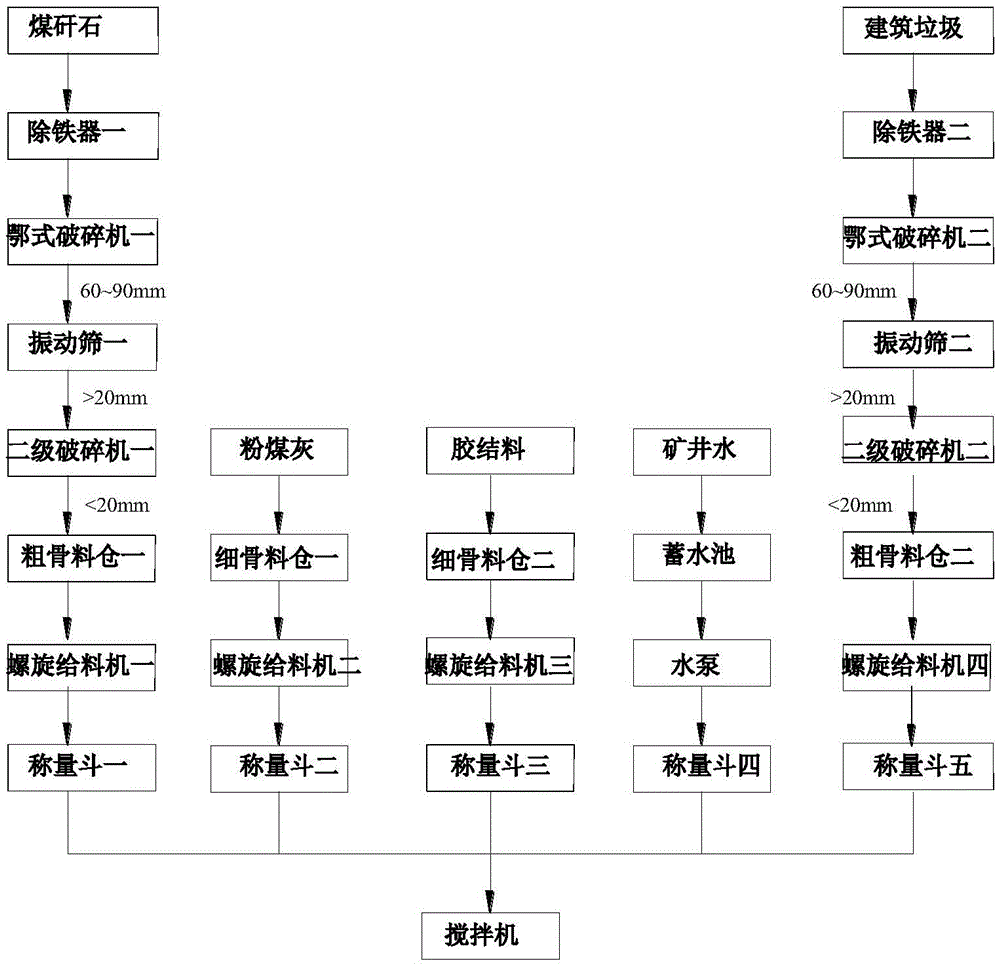

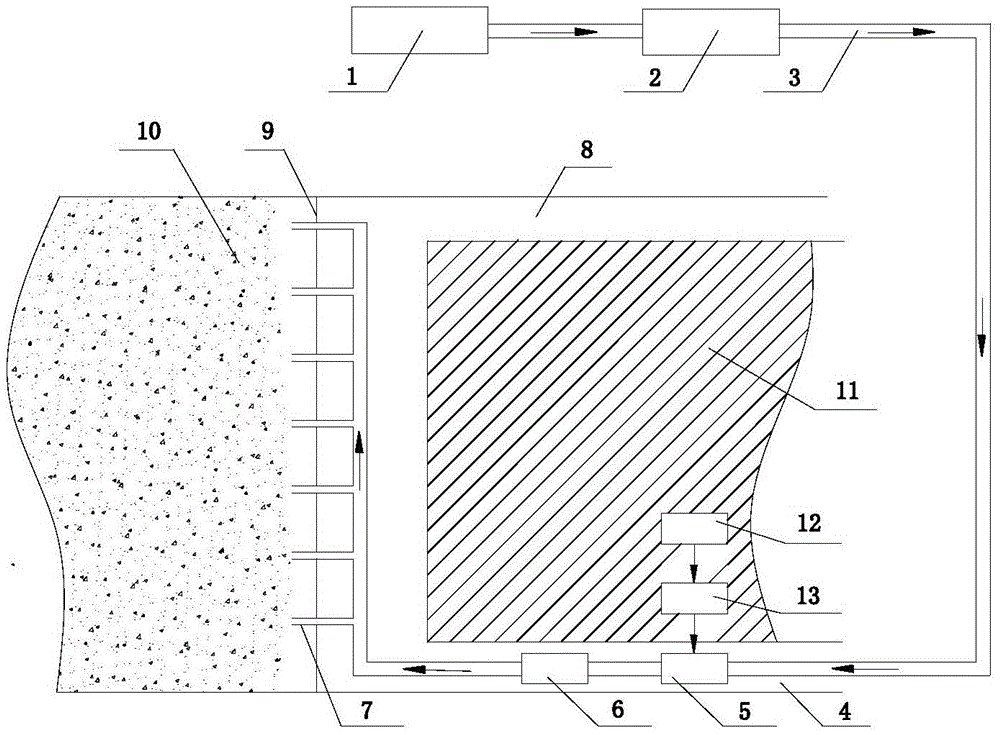

Method used

Image

Examples

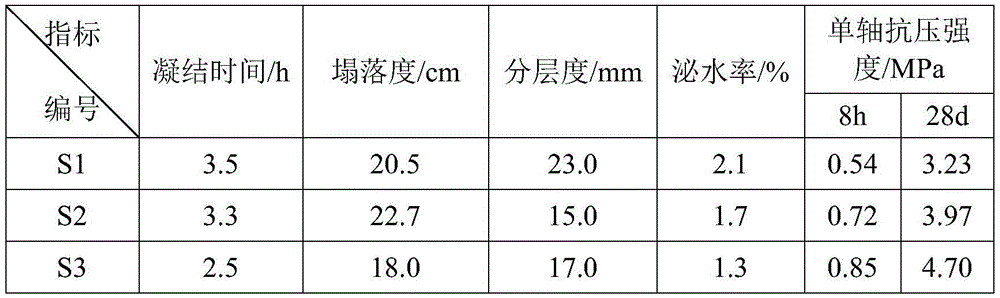

Embodiment 1

[0033] A kind of coal mine paste-like filling material using construction waste, every 1m 3 The filling material consists of the following raw materials: coarse aggregate: construction waste 500Kg and coal gangue 450Kg, fine aggregate: fly ash 400Kg and cementitious material 250Kg, admixture: accelerator 12.5Kg and water reducing agent 7.5Kg, mine water 630Kg.

[0034] The construction wastes are waste concrete blocks, waste sand and gravel, waste bricks and tiles, waste stone materials, ceramic fragments and waste tiles with a particle size of less than 20 mm after secondary crushing, which are produced due to construction, decoration and demolition. 16mm-20mm accounted for 4.32%, particle size 13.5mm-16mm accounted for 3.66%, particle size 9.5mm-13.5mm accounted for 10.82%, particle size 5mm-9.5mm accounted for 21.51%, particle size 1mm ~5mm accounted for 29.05%, particle size 0.3mm~1mm accounted for 14.89%, particle size 0.1mm~0.3mm accounted for 8.76%, particle size 0.075...

Embodiment 2

[0048] A paste-like filling material for coal mines utilizing construction waste, each 1 m3 of the filling material is composed of the following raw materials: coarse aggregate: construction waste 475Kg and coal gangue 425Kg; fine aggregate: fly ash 375Kg and cementation Material 225Kg; admixtures: accelerator 9.5Kg and water reducing agent 5.5Kg; mine water 630Kg.

[0049] The construction wastes are waste concrete blocks, waste sand and gravel, waste bricks and tiles, waste stones, ceramic fragments and waste tiles with a particle size of less than 20mm after secondary crushing, which are produced due to construction, decoration and demolition. 5% are 16mm~20mm, 2% are 13.5mm~16mm, 15% are 9.5mm~13.5mm, 25% are 5mm~9.5mm, 1mm are ~5mm accounted for 25%, particle size 0.3mm~1mm accounted for 15%, particle size 0.1mm~0.3mm accounted for 6%, particle size 0.075mm~0.1mm accounted for 5%, 0~0.075mm 2%;

[0050] The coal gangue is the raw coal mine gangue waste with a particle s...

Embodiment 3

[0060] A paste-like filling material for coal mines utilizing construction waste, each 1 m3 of the filling material is composed of the following raw materials: coarse aggregate: construction waste 450Kg and coal gangue 400Kg; fine aggregate: fly ash 350Kg and cementation Material: 200Kg; Admixture: 6.0Kg of accelerator and 2.0Kg of water reducing agent; 550Kg of mine water.

[0061] The construction wastes are waste concrete blocks, waste sand and gravel, waste bricks and tiles, waste stone materials, ceramic fragments and waste ceramic tiles with a particle size of less than 20mm after secondary crushing, and the particle size is 16mm~20mm 1%, 13.5mm~16mm 5%, 9.5mm~13.5mm 10%, 5mm~9.5mm 20%, 1mm~1mm 5mm accounted for 35%, particle size 0.3mm~1mm accounted for 10%, particle size 0.1mm~0.3mm accounted for 10%, particle size 0.075mm~0.1mm accounted for 4%, 0~0.075mm accounted for 5%.

[0062] The coal gangue is the raw coal mine gangue waste with a particle size of less than 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com