Liquid filling device

A technology of filling device and liquid, applied in liquid distribution, conveying or transfer device, distribution device, special distribution device, etc., can solve the problems of reduced air pressure of liquid sealed container, inconvenient filling of lubricating oil, and reduced filling speed, etc. , to achieve the effect of safe use, improved structure compactness and firmness, and high filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

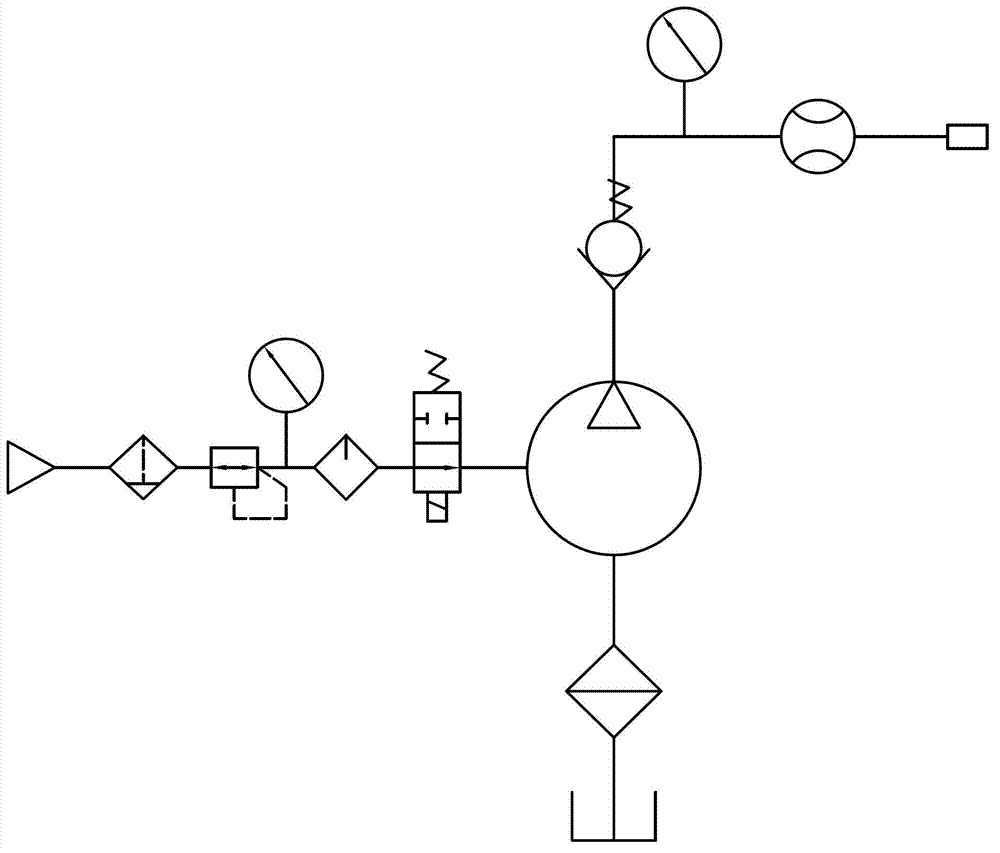

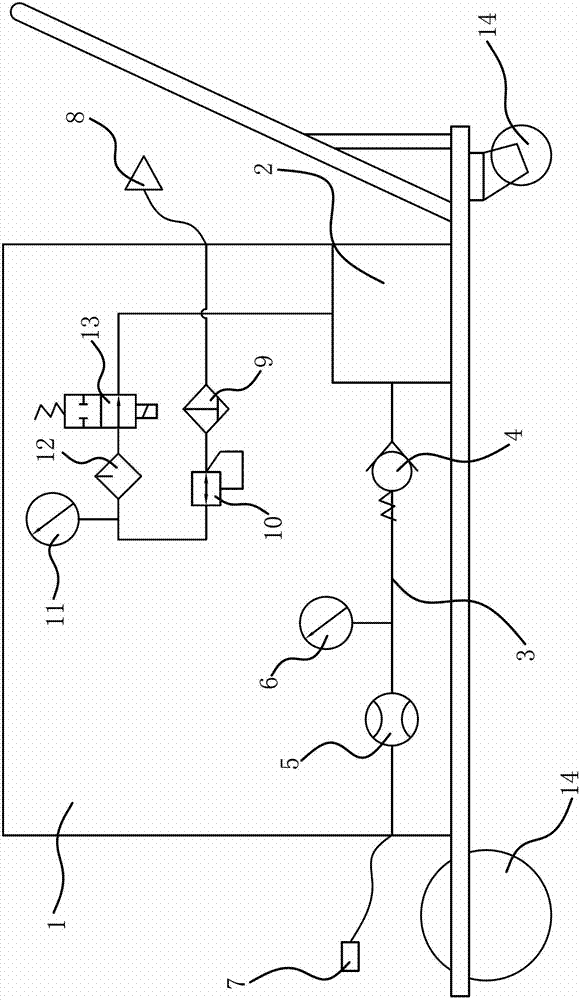

[0034] Such as figure 1 with figure 2 As shown, the liquid filling device includes a liquid storage tank 1, a pneumatic diaphragm pump 2, a filling joint 7 that can communicate with the filling port, and an air intake joint 8 that can communicate with the air supply port. The liquid inlet of the pneumatic diaphragm pump 2 is connected to the liquid storage tank 1 through the liquid inlet pipe assembly and the connection is located at the bottom of the liquid storage tank 1; the liquid outlet of the pneumatic diaphragm pump 2 is connected to the filling joint through the liquid outlet pipe 3 assembly 7 is connected; the air inlet joint 8 is connected with the air inlet of the air-operated diaphragm pump 2 through the air-inlet pipe assembly that can make the gas enter the air-operated diaphragm pump 2 in a stable pressure and can control the air intake or cut-off.

[0035] Specifically, 3 to 4 casters 14 are fixed at the bottom of the liquid storage tank 1; Connected drain v...

Embodiment 2

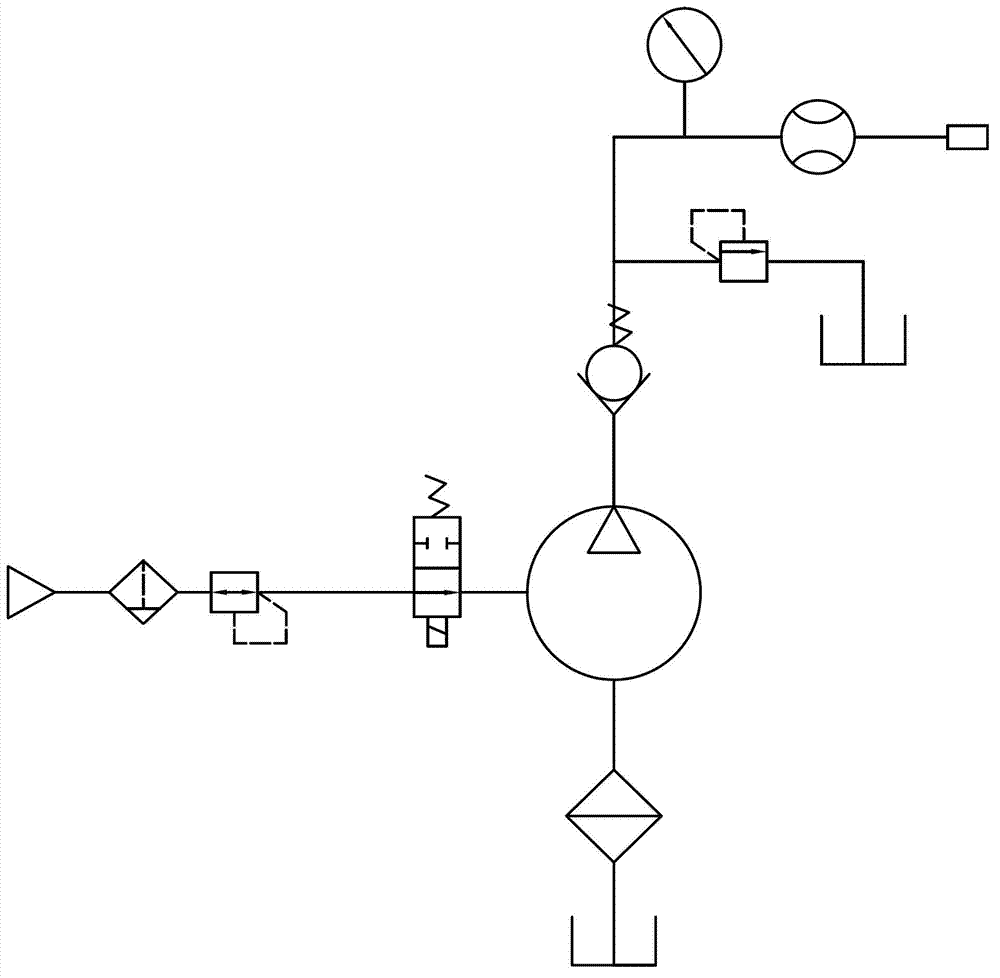

[0040]The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: image 3 As shown, the liquid outlet pipe 3 assembly includes a liquid outlet pipe 3, a one-way valve 4 and a flow meter 5 connected in series on the liquid outlet pipe 3 in sequence from the liquid outlet of the pneumatic diaphragm pump 2 to the filling joint 7; The outlet pipe 3 is also connected with a liquid pressure gauge 6 and an overflow valve. The one-way valve 4, overflow valve and flowmeter 5 are all fixed on the outer wall of the liquid storage tank 1.

Embodiment 3

[0042] The structure and principle of this embodiment are basically the same as that of Embodiment 1 or Embodiment 2, the difference is that: image 3 As shown, the intake pipe assembly includes an intake pipe, a gas filter 9 , a pressure reducing valve 10 and a control switch 13 connected in series on the intake pipe in sequence from the intake joint 8 to the air inlet of the pneumatic diaphragm pump 2 . The gas filter 9 , pressure reducing valve 10 and control switch 13 are all fixed on the outer wall of the liquid storage tank 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com