Formaldehyde absorption tower

A formaldehyde absorption tower and absorption tower technology, applied in separation methods, organic chemistry, dispersed particle separation, etc., can solve problems such as formaldehyde polymerization, and achieve the effects of large processing capacity, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

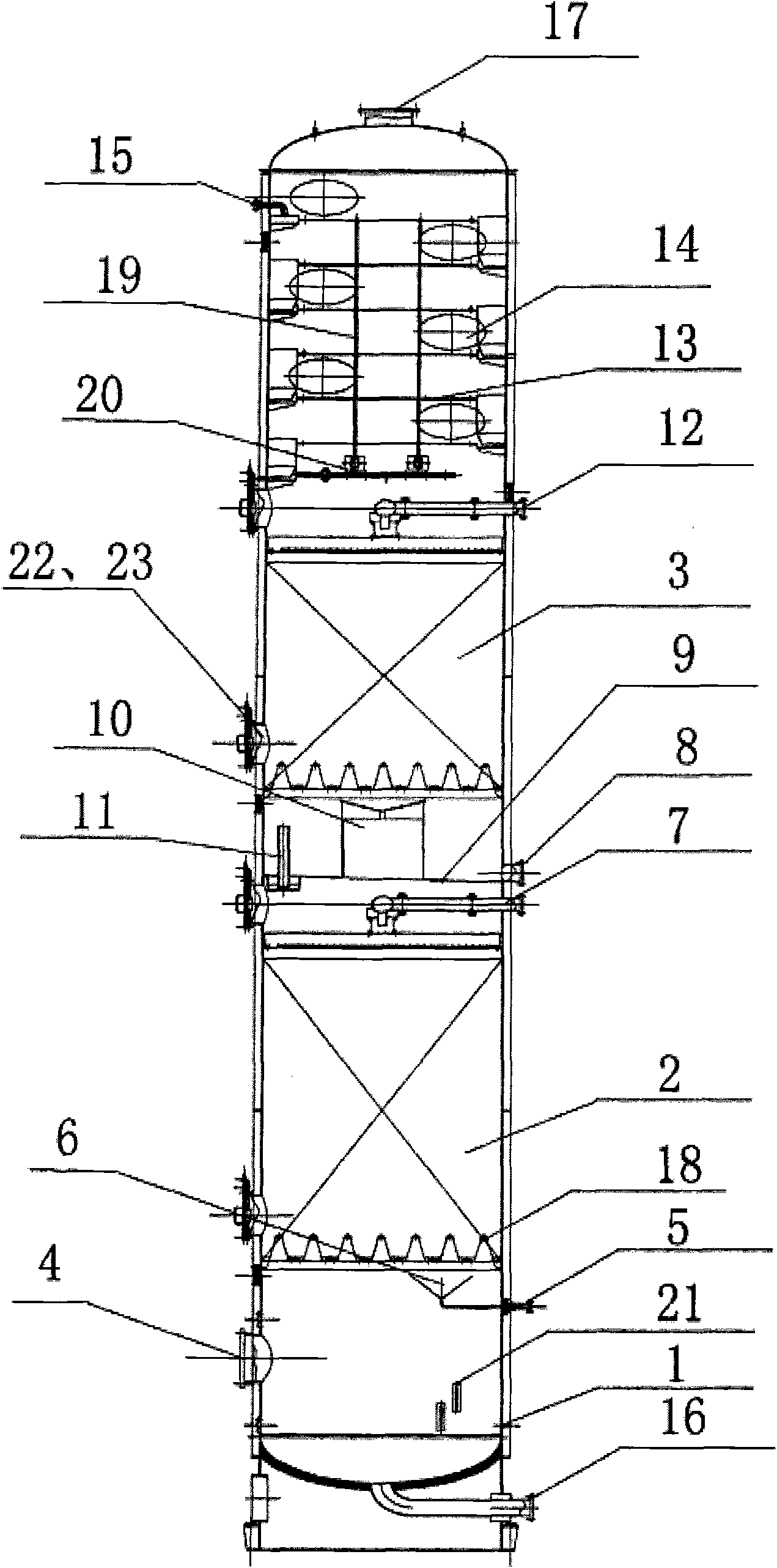

[0026] A formaldehyde absorption tower, the absorption tower includes a tower still 1, a first packing layer 2 and a second packing layer 3 are arranged in the tower still 1, on the tower still wall below the first packing layer 2 A first air inlet 4 and several nozzle installation ports 5 are provided, and a nozzle 6 is installed through a pipeline on the nozzle installation port 5, and the nozzle 6 is installed inside the tower kettle 1 with the nozzle upward; The first liquid inlet pipe 7 and the first liquid outlet 8 are arranged on the tower still wall between the first packing layer 2 and the second packing layer 3, and the first liquid inlet pipe 7 and the first liquid outlet 8 A partition 9 is arranged between them, and a gas phase pipe 10 for the gas under the partition 9 to flow upward is arranged on the partition 9, and a gas phase pipe 10 for the liquid on the partition 9 to overflow to the partition The overflow pipe 11 to the lower layer of the plate; the second ...

Embodiment 2

[0028] On the basis of Embodiment 1, a preferred embodiment of the present invention is to install the first packing layer 2 and the second packing layer 3 on a support plate 18 that combines a beam type and a gas injection type.

Embodiment 3

[0030] On the basis of Example 2, the preferred embodiment of the present invention also includes that the first packing layer 2 is a high-concentration formaldehyde-absorbing packing layer, and the high-concentration formaldehyde-absorbing packing layer selects Φ50 Pall rings, and the The second packing layer 3 is a second-high concentration formaldehyde-absorbing packing layer, and the second-high concentration formaldehyde-absorbing packing layer is selected from Φ25 Pall rings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com