Preparation method of polysaccharide-zinc complex and zinc supplement

A compound and polysaccharide technology, applied in the field of zinc supplement preparation, can solve the problems of low absorption efficiency and availability, high molecular weight, low zinc supplement yield, etc., to optimize reaction time, improve yield, and solve absorption problems. Effects of low efficiency and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

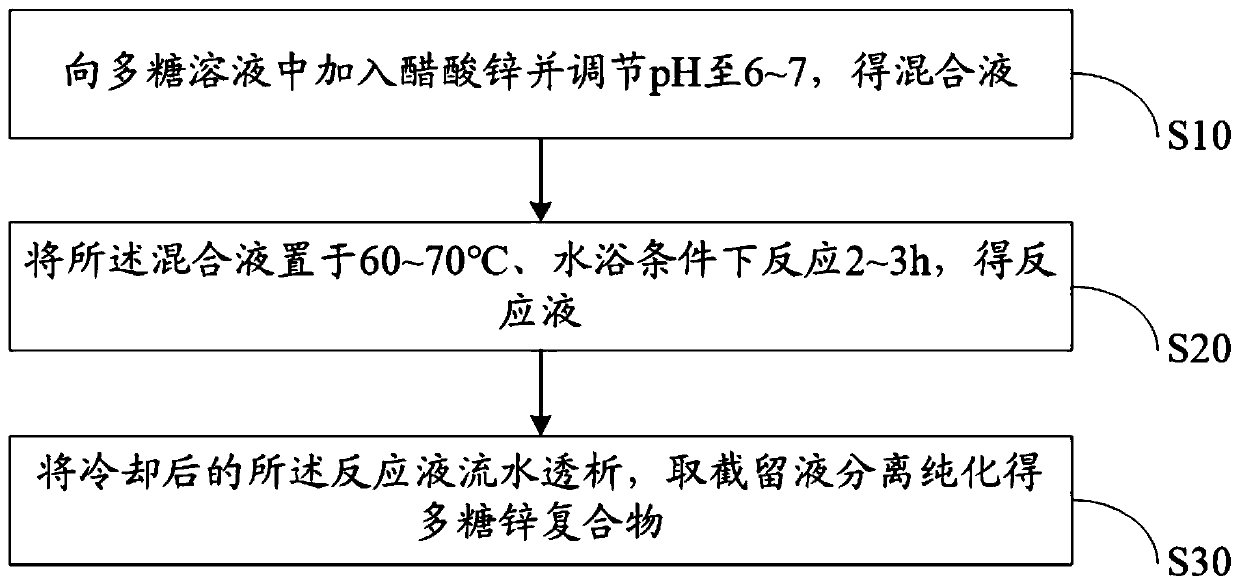

[0049] Based on this, the present invention also proposes a method for preparing a polysaccharide zinc complex. The preparation method can be used to prepare Codonopsis pilosula polysaccharide-zinc complex and carboxymethyl tuckahoe polysaccharide with high zinc content, the codonopsis polysaccharide-zinc complex and the Carboxymethyl tuckahoe polysaccharide can be used to prepare the above zinc supplement. figure 1 Is an embodiment of the preparation method of the polysaccharide zinc complex of the present invention, combined figure 1 It can be known that the preparation method of the polysaccharide zinc complex includes the following steps:

[0050] Step S10, adding zinc acetate to the polysaccharide solution and adjusting the pH to 6-7 to obtain a mixed solution.

[0051] Step S20: Place the mixed solution at 60-70°C and react for 2 to 3 hours under water bath conditions to obtain a reaction solution.

[0052] Step S30: Dialyze the cooled reaction solution with flowing water, and ...

Embodiment 1

[0085] Take carboxymethyl tuckahoe polysaccharide and dissolve it in water at a material-to-liquid ratio of 3:500 to obtain a carboxymethyl tuckahoe polysaccharide solution; add zinc acetate to the carboxymethyl tuckahoe polysaccharide solution and adjust the pH to 6 to obtain a mixed solution; The mixed solution was reacted for 2 hours at 60°C in a water bath to obtain a reaction solution; the cooled reaction solution was placed in a dialysis bag with a molecular weight cut-off not greater than 3500, and dialyzed under running water for 24 hours to collect the retentate; Add 95% ethanol to the retentate until the volume concentration of ethanol in the retentate is 70-75%, let stand for 24 hours, and collect the precipitate; after the precipitate is dissolved in water, the precipitate is treated with alcohol, and the precipitate is taken at 30°C Under vacuum drying, polysaccharide zinc complex.

Embodiment 2

[0087] Take carboxymethyl tuckahoe polysaccharide and dissolve it in water according to a material-to-liquid ratio of 4:400 to obtain a carboxymethyl tuckahoe polysaccharide solution; add zinc acetate to the carboxymethyl tuckahoe polysaccharide solution and adjust the pH to 7 to obtain a mixed solution; The mixed solution was reacted at 70°C in a water bath for 3 hours to obtain a reaction solution; the cooled reaction solution was placed in a dialysis bag with a molecular weight cut-off not greater than 3500, and dialyzed under running water for 48 hours to collect the retentate; Add 93% ethanol to the retentate until the volume concentration of ethanol in the retentate is 70-75%, let stand for 30 hours, and collect the precipitate; after dissolving the precipitate in water, perform alcohol precipitation treatment and take the precipitate at 28°C Under vacuum drying, polysaccharide zinc complex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com