Composite scale and rust cleaning agent

A cleaning agent and composite technology, applied in the field of chemical cleaning agents, can solve the problems of high cost, corrosion and damage to equipment, and low cost, and achieve the effects of simple preparation process, improved heat exchange efficiency, convenient and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Prepare compound scale and rust cleaner according to the following formula:

[0015] component name

weight percentage (%)

Mass concentration 36.67% hydrochloric acid

7

Mass concentration 70% glycolic acid

1.5

Commercially available Ningjin Kaizer Chemical Company naphthenic acid imidazoline corrosion inhibitor

0.3

500PPM nonylphenol ethoxylates

0.05

water

91.15

[0016] The quality index of this compound scale rust cleaning agent is as follows:

[0017] project

Quality Index

Exterior

light brown transparent liquid

Solution pH value

1

Density (g / ml)

1.035±0.005

Dissolved scale g(CaCO 3 ) / Kg

110

Corrosion rate to A3 carbon steel (35℃±1℃)

0.250g / (m 2 h)

Corrosion rate to copper (35℃±1℃)

0.230g / (m 2 h)

Corrosion rate to 304 stainless steel (35℃±1℃)

0.200g / (m 2 h)

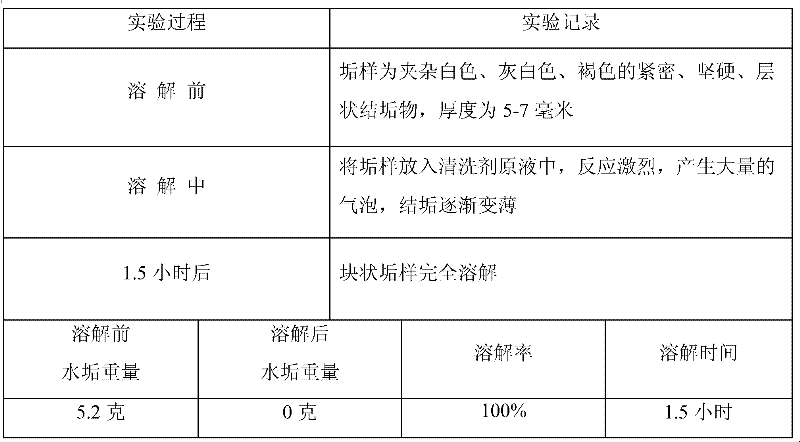

[0018] The e...

Embodiment 2

[0021] Prepare compound scale and rust cleaner according to the following formula:

[0022] component name

weight percentage (%)

Mass concentration 37.2% hydrochloric acid

8

Mass concentration 99% glycolic acid

1.5

Commercially available Ningjin Kaizer Chemical Company naphthenic acid imidazoline corrosion inhibitor

0.3

700PPM nonylphenol ethoxylates

0.05

water

90.15

[0023] The quality index of this compound scale rust cleaning agent is as follows:

[0024] project

Quality Index

Exterior

light brown transparent liquid

Solution pH value

1

Density (g / ml)

1.040±0.005

Dissolved scale g(CaCO 3 ) / Kg

120

Corrosion rate to A3 carbon steel (35℃±1℃)

0.270g / (m 2 h)

Corrosion rate to copper (35℃±1℃)

0.246g / (m 2 h)

Corrosion rate to 304 stainless steel (35℃±1℃)

0.218g / (m 2 h)

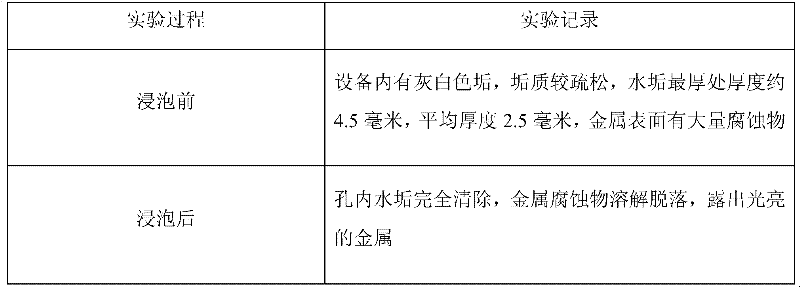

[0025] The ex...

Embodiment 3

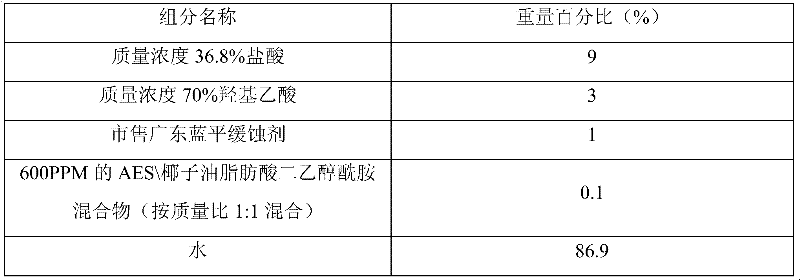

[0028] Prepare compound scale and rust cleaner according to the following formula:

[0029] component name

[0030] The compound scale rust cleaning agent quality index is as follows:

[0031] project

[0032] For the comparative experiment of this embodiment, refer to Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com