Method for synthesizing methyl propionate by ethylene

A technology for methyl propionate and ethylene, applied in the field of ethylene oxo synthesis of methyl propionate, can solve the problems of no commercial application prospect, harsh reaction conditions, poor selectivity, etc., and achieve good catalytic activity and selectivity, good selectivity , the effect of good commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

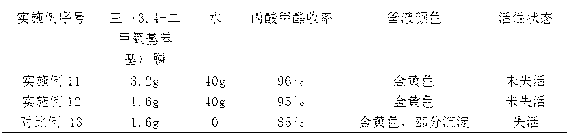

Examples

Embodiment 1

[0027] Weigh 400.0 g of methanol, 0.1605 g of palladium acetate, 0.0160 g of nickel acetate, 6.40 g of triphenylphosphine, 9.60 g of benzenesulfonic acid, and 40.0 g of distilled water, and put them into a 1000 mL autoclave for sealing. n (CO): n (C 2 H 4 )=1:1, stirring speed 400r / min, reaction temperature 80°C, reaction pressure 3.0MPa, reaction for 120 minutes, based on ethylene, the yield of methyl propionate is 96%. The kettle liquid is a golden yellow transparent liquid.

Embodiment 2

[0029] Weigh 400.0 g of methanol, 18.0 g of concentrated sulfuric acid, 8.00 g of tris (3,4-dimethoxyphenyl) phosphine, 0.1604 g of palladium acetate, 0.0160 g of ruthenium acetate, and 20.0 g of distilled water, and add them to a 100 mL autoclave for sealing. n (CO): n (C 2 H 4 )=2:1, stirring speed 400r / min, reaction temperature 110°C, reaction pressure 2.5MPa, reaction for 120 minutes, based on ethylene, the selectivity to methyl propionate is 95%. The kettle liquid is a golden yellow transparent liquid.

Embodiment 3

[0031] Weigh 400.0 g of methanol, 22.0 g of salicylic acid, 6.40 g of triphenylphosphine, 0.1604 g of palladium acetate, 0.0210 g of ruthenium acetate, and 40.0 g of distilled water, and put them into a 100 mL autoclave for sealing. n (CO): n (C 2 H 4 )=5:1, stirring speed 400r / min, reaction temperature 90℃, reaction pressure 1.5MPa, reaction for 120 minutes, based on ethylene, the selectivity to methyl propionate is 95%. The kettle liquid was earthy yellow and turbid, with black granular sediments, and there were many powdery sediments in the lower layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com