Foamer and foam gas flooding method

A foaming agent and gas technology, which is applied in the field of foam flooding, can solve the problems that the corrosion of injection equipment and oilfield injection-production system is difficult to control and affect the development of air foam flooding technology, and achieves strong foaming, good adaptability, and improved The effect of spillover efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In a second aspect, the present invention provides a method for preparing a foaming agent, the method comprising: under stirring conditions, mixing the components of the foaming agent until they are completely dissolved.

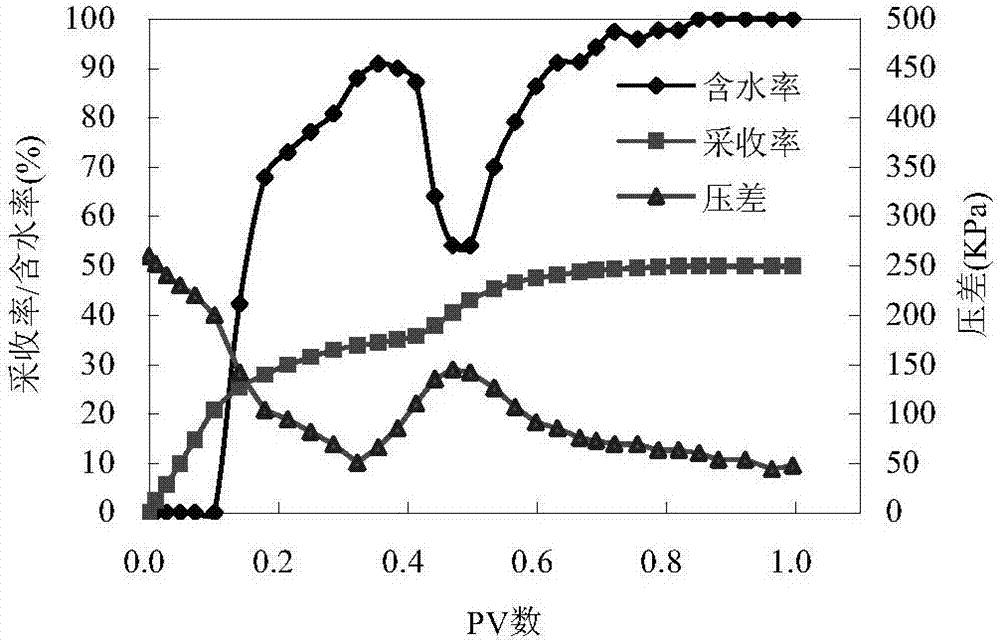

[0053] In the third aspect, the present invention provides a foam gas flooding method, the method comprising: injecting a foaming agent containing a weak cationic amphoteric surfactant and gas into the oil reservoir for foam profile control and oil displacement.

[0054] In the method of the present invention, preferably, the foaming agent contains a weak cationic amphoteric surfactant and water, and based on the weight of the foaming agent, the content of the weak cationic amphoteric surfactant is 0.05-3 wt. %, the content of water is 97-99.95% by weight; further preferably, based on the weight of the foaming agent, the content of weak cationic amphoteric surfactant is 0.25-1% by weight, and the content of water is 99-99.75% by weight %.

[0055] Fo...

Embodiment 1

[0071] (1) Add 5g of dodecyldimethylamine oxide, 1.5g of dodecyltrimethylammonium chloride, 1.5g of dodecyldimethylbetaine, and 0.25g of lauryl alcohol into distilled water to 500mL, Stir for 30 minutes until completely dissolved to obtain 500 mL of foaming agent.

[0072] (2) Take 100mL to measure the foaming volume and foam half-life of the foaming agent. The foaming volume of the foaming agent is 860mL, and the foam half-life is 225min; take another 300mL foaming agent and 300mL distilled water to measure the corrosion rate respectively, and the corrosion rates of distilled water and foaming agent are 6.137g / (m 2 .h) and 0.0072g / (m 2 .h), the corrosion inhibition rate of the blowing agent is 99.88%.

Embodiment 2

[0074] (1) Add 2.5g octadecyldimethylamine oxide, 0.8g dodecyltriethylammonium chloride, 0.8g tetradecyldimethylbetaine, and 0.15g n-decyl alcohol into distilled water until 500mL, stirred for 30min until completely dissolved to obtain 500mL foaming agent.

[0075] (2) Take 100mL to measure the foaming volume and foam half-life of the foaming agent. The foaming volume of the foaming agent is 850mL, and the foam half-life is 190min; take another 300mL foaming agent and 300mL distilled water to measure the corrosion rate respectively, and the corrosion rates of distilled water and foaming agent are 6.137g / (m 2 .h) and 0.0081g / (m 2 .h), the corrosion inhibition rate of the blowing agent is 99.87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com