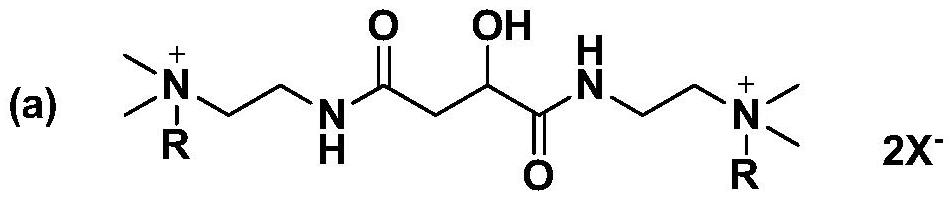

A kind of oligomeric cationic quaternary ammonium salt surfactant synergistic oil displacement agent

A surfactant and polycation technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of loss of foaming ability, reduced foaming agent performance, corrosion, etc. foam performance and enhanced oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

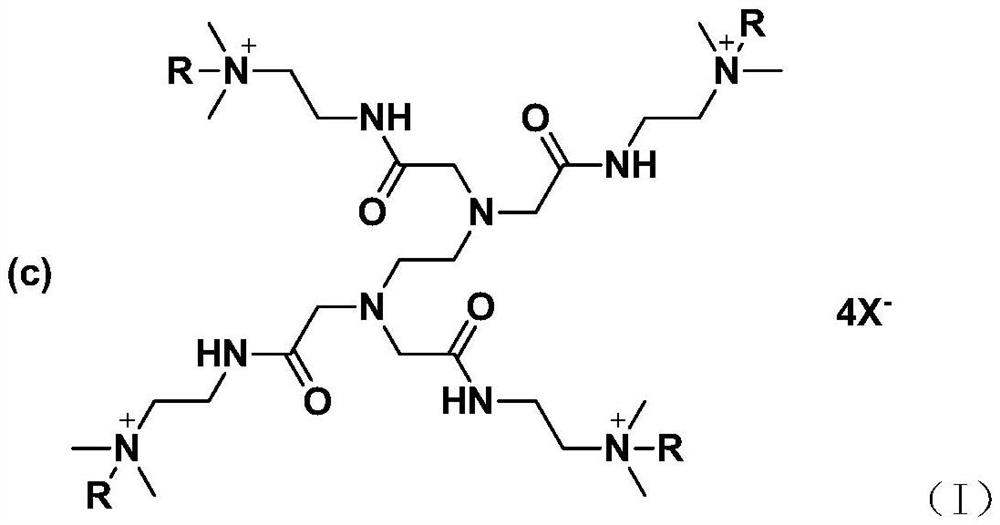

Method used

Image

Examples

preparation example Construction

[0037] (2) Preparation of dimer quaternary ammonium salt surfactant: get intermediate 1.6g (6.0mmol), 1-bromododecane 6.0g (24.0mmol) (the number of carbon atoms n of the alkyl chain R of compound A is For other values, when X is other options, select the corresponding raw material to replace 1-bromododecane) Dissolve in methanol / acetone mixed solvent, react at 40°C for 72h. The solvent was removed by rotary evaporation, and the crude product was recrystallized in methanol / ethyl acetate to obtain a powdery product, Compound A.

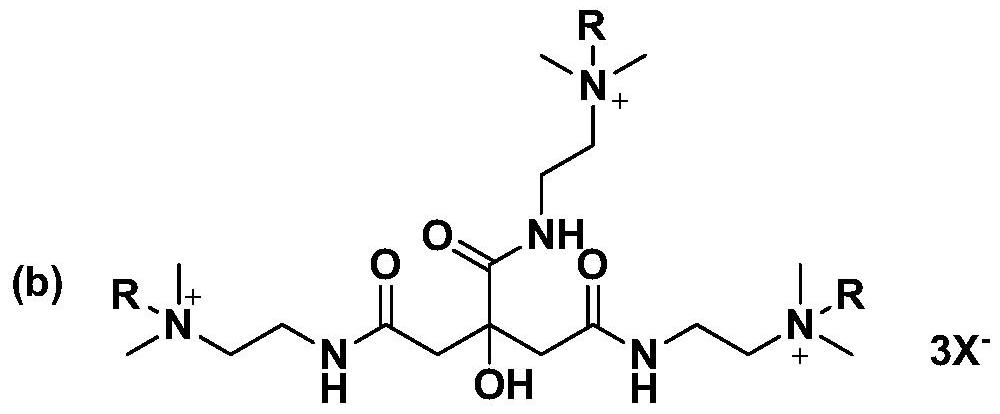

[0038] Specifically, the preparation method of compound B (the carbon number n of the alkyl chain R is 12, and X is Br) is as follows:

[0039] (1) Synthesis of intermediate tripolyamide: 10.6 g (120.0 mmol) of N,N-dimethylethylenediamine was added to 2.3 g (10.0 mmol) of trimethyl citrate, and refluxed at 106° C. for 3 h. After the reaction, use a rotary evaporator to remove excess N,N-dimethylethylenediamine to obtain the intermediate;

[0040] (2)...

Embodiment 1

[0042] Preparation of embodiment 1 oil displacing agent and use effect evaluation

[0043] (1) Weigh 5g dodecyl dimethyl amine oxide, 0.3g Malic-2C 12 , 1.5g dodecyl dimethyl betaine, 0.25g soluble starch; add distilled water to 500mL, stir for 30min until completely dissolved, and get 500mL oil displacing agent.

[0044] (2) Take 100mL of oil displacement agent, and measure the foaming volume and foam half-life. The foaming volume of the oil-displacing agent is 1080mL, and the half-life of the foam is 560min; another 300mL of oil-displacing agent and 300mL of distilled water are taken to measure the corrosion rate respectively. The corrosion rates of distilled water and oil displacing agent are 6.10g / (m 2 h) and 0.0077g / (m 2 h), the corrosion inhibition rate of the oil displacement agent reaches 99.9%.

[0045] It can be seen that the oil displacing agent of the present invention has a good anti-corrosion effect.

Embodiment 2

[0046] Preparation of embodiment 2 oil displacing agent and use effect evaluation

[0047] (1) Weigh 1.25g dodecyl dimethyl amine oxide, 0.1g Malic-2C 12 , 0.25g dodecyl dimethyl betaine, 0.06g soluble starch; add distilled water to 500mL, stir for 30min until completely dissolved, and get 500mL oil displacing agent.

[0048] (2) Take 100mL of oil displacement agent, and measure the foaming volume and foam half-life. The foaming volume of the oil-displacing agent was 705mL, and the half-life of the foam was 375min; another 300mL of oil-displacing agent and 300mL of distilled water were taken to measure the corrosion rate respectively. The corrosion rates of distilled water and oil displacing agent are 6.04g / (m 2 h) and 0.025g / (m 2 h), the corrosion inhibition rate of the oil displacement agent reaches 99.6%.

[0049] It can be seen that the oil displacing agent of the present invention has a good anti-corrosion effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com