Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

281results about How to "Strong foaming ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane rigid foam and preparation method thereof

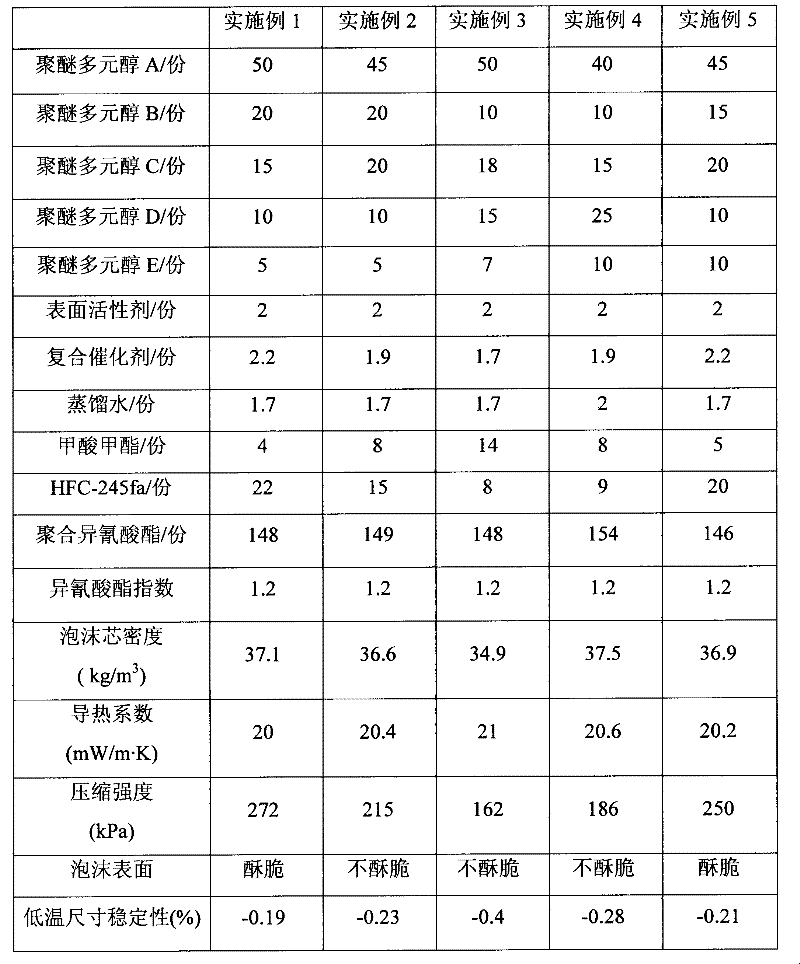

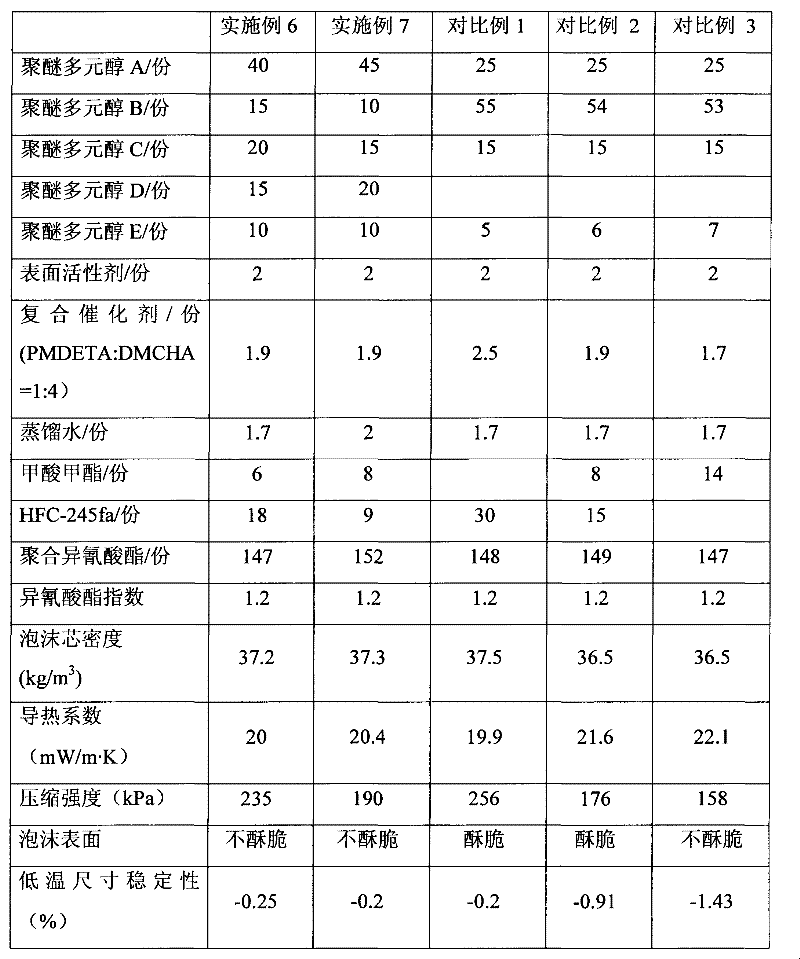

The invention discloses polyurethane rigid foam and a preparation method thereof, wherein foam plastic is prepared from the following raw materials by a high pressure foaming machine in parts by weight: 100 parts of combined polyether, 1.5-3 parts of surfactant, 1.5-3 parts of complex catalyst, 1-3 parts of water, 16-26 parts of mixed foaming agent and 140-170 parts of polymerized isocyanate, wherein the mixed foaming agent consists of methyl formate and 1,1,1,3,3-pentafluoropropane (HFC-245fa). The prepared polyurethane foam has low heat conductivity, good dimensional stability and proper cost.

Owner:万华化学(佛山)容威聚氨酯有限公司 +2

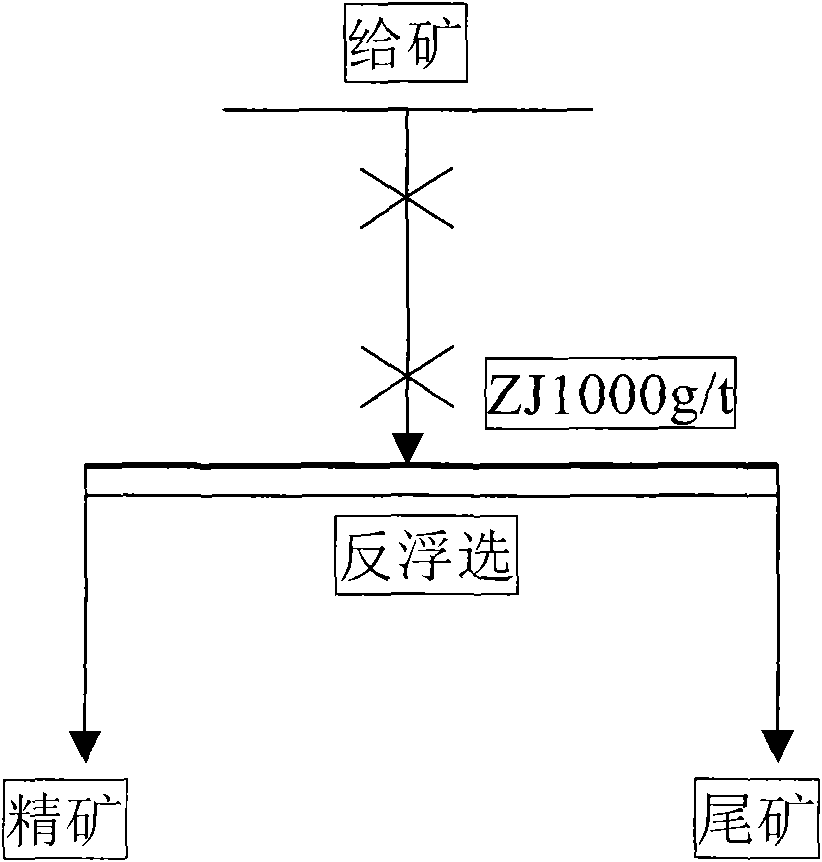

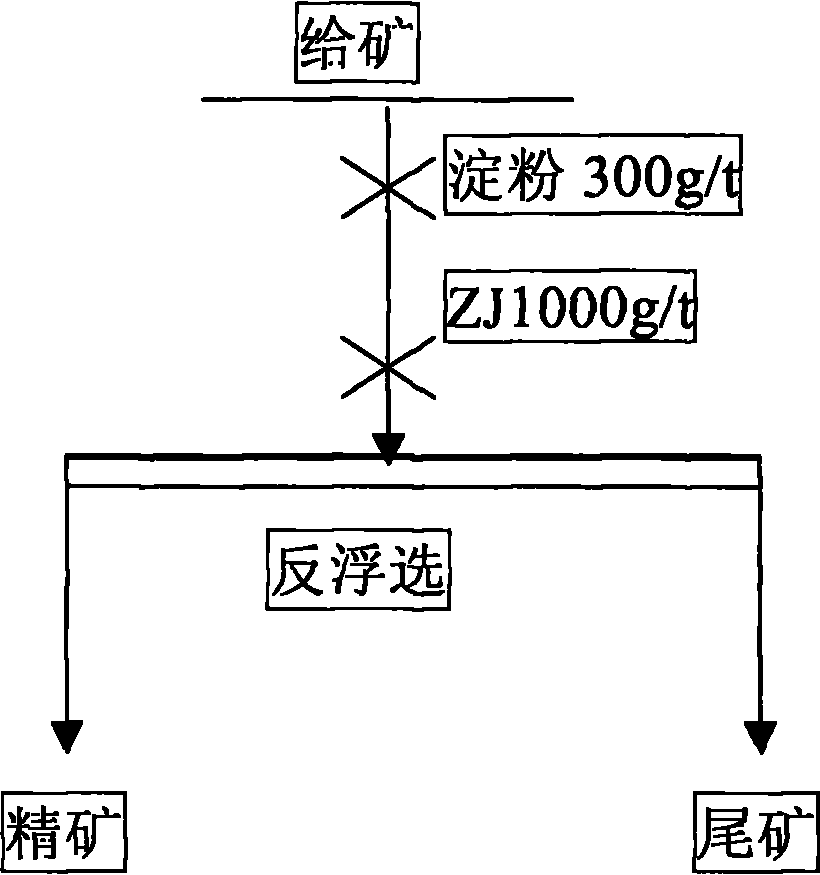

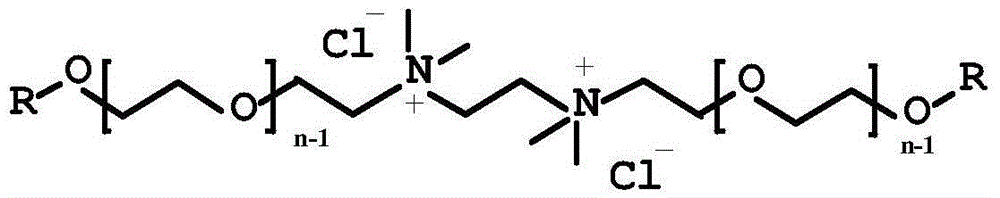

Environmentally-friendly amine cationic collector and using method thereof

InactiveCN101816981ASave on heating costsPracticalOrganic compound preparationFlotationSURFACTANT BLENDToxicity

The invention discloses an environmentally-friendly amine cationic collector and a using method thereof. The collector ZJ is ester group-containing quaternary ammonium salt cationic surfactant and has a plurality of alkyl groups, wherein an R alkyl group has 6 to 18 carbon atoms; an R1 alkyl group has 1 to 4 carbon atoms; the number of ester groups is 1 or two; and the number of the quaternary ammonium group is 1. The collector is obtained by esterification and quaternarization. As a hydrophobic chain has a carbonyl structure, the collector can hydrolyze easily into nonsurfactant fragments, and is a surfactant with high biodegradability, small toxicity and high performance. The collector is used in ore flotation for the first time and demonstrates high collecting capacity and selectivity.The collector forms fine and fragile foam that is low temperature resistant. The collector can be used under the condition that the pH value of ore pulp is 7 without corroding equipment. The preparation process of the collector is simple and easy in operation. And the collector is easy to biodegrade and is environmentally-friendly.

Owner:WUHAN UNIV OF TECH

Foaming agent for plugging gas channeling in displacement of reservoir oil by using CO2

ActiveCN103881683AEnhanced overall recoveryOil displacement effect is goodDrilling compositionFoaming agentSURFACTANT BLEND

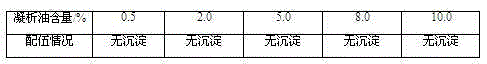

The invention provides a foaming agent for plugging gas channeling in displacement of reservoir oil by using CO2. The foaming agent is composed of the following components in percentage by weight: 0.12%-0.30% of anionic surfactant, 0.06%-0.15% of imidazoline-derived ampholytic surfactant, 0.12%-0.30% of lycine-derived ampholytic surfactant, 0.02%-0.04% of foam stabilizer and the balance of water. The foaming agent for plugging gas channeling in displacement of reservoir oil by using CO2 is characterized in that the anionic surfactant, the imidazoline-derived ampholytic surfactant, the lycine-derived ampholytic surfactant and the foam stabilizer are combined so that the obtained foaming agent is capable of forming stable foam with the CO2, and thus is strong in foaming capacity and high in stability; the foaming agent has high plugging selectivity and can be used for plugging CO2 channeling in the displacement of reservoir oil by using CO2, and therefore, the plugging effects of plugging water rather than oil and plugging large rather than small can be achieved, and the oil recovery factor and the effect of the displacement of reservoir oil by using CO2 can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Guar gum fracturing fluid

The invention discloses guar gum fracturing fluid. The guar gum fracturing fluid is characterized by comprising a base solution, a gel breaker and a crosslinking agent, wherein the base solution comprises the following components by weight percent: 0.2-0.4% of guar gum, 0.01-0.3% of bactericide, 0.2-1% of clay stabilizer, 0.01-0.2% of pH modifier, 0.5-1% of cleanup additive, 0.1-0.15% of temperature stabilizer, and the balance of water, wherein the gel breaker is 0.05-0.3% of weight of the base solution; the crosslinking agent is 0.1-0.8% of weight of the base solution. By using the novel foaming cleanup additive, the guar gum fracturing fluid is low in surface tension, and strong in foaming power, and gel breaking liquid can be smoothly discharged out of stratum, so as to achieve the target of cleaning downhole accumulated liquid. Thus, the water lock effect of the downhole is reduced, and meanwhile, a part of densifier scraps can be carried by the gel breaking liquid, so as to further reduce the damage.

Owner:四川川庆井下科技有限公司

Fracturing liquid

InactiveUS20030168217A1Easily degradableStrong foaming capabilityFluid removalFlushingAlcoholAdditive ingredient

A subterranean fracturing fluid, which is relatively harmless to both the environment and subterranean formations includes an amphoteric surfactant, specifically a betaine surfactant and an organic electrolyte or an alcohol in an aqueous medium. Depending upon the proportions of the ingredients, the fluid can be foamed.

Owner:TRICAN WELL SERVICE

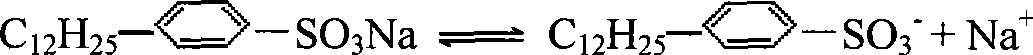

Foaming concrete for foam agent

The invention discloses a foaming agent for foam concrete. The foaming agent is prepared by uniformly mixing and stirring the following raw materials at room temperature, by weight : 5-10 parts of sodium dodecyl benzene sulfonate, 2-4 parts of sodium alcohol ether sulphate, 1-2 parts of sodium lauroyl sarcosinate, 1-2 parts of cocamidopropyl betaine, 0.2-0.6 part of polyethylene glycol (120) methyl glucoside dioleate, 0.3-0.5 part of triethanolamine, 0.5-1 part of polyacrylamide, 1-2 parts of hydroxyethyl cellulose, and 60-70 parts of water. The invention has advantages of easily available raw materials, low cost and simple preparation process; and the produced foaming agent has advantages of good stability, no deterioration, easiness for long-term preservation, prolonged shelf-life, good foaming power, good peaceability with various foam concrete substrates, no defoaming and unrestricted range of usage.

Owner:安徽艾柯泡塑股份有限公司

Non-pollution well detergent

A non-pollution flushing fluid for oil field and oil well hot bath consists of poly-amine polyoxytrimethylene polyethenoxy ether 2.5-6.8 wt%, aliphatic alcohol polyethenoxy ether sodium sulfate 12-20 wt%, alcohol ether sulpho-succinic monoester di-sodium salt 5-8 wt%, FC-NO1 fluorocarbon surface activator 0.05-0.15 wt% and water 66-80 wt%. Non-pollution flushing fluid 0.1-0.5 wt% is added into oil well hot-bath water, it has strong flushing bubbling ability, less pollution for stratum, better activity and washing function for paraffin, gum and asphalt; Fine foam is injected by stratum air pressure and flushing pressure difference, which makes liquid density lower and level raise, it increases draining and carrying abilities, and decreases oil pipeline gum, asphalt and was adsorption.

Owner:PETROCHINA CO LTD

Solid foaming agent

The industrial solid foaming agent composition is used in foaming deairing well drilling and provides excellent foaming performance and foaming stability. The solid foaming agent composition features that the solid foaming agent has anionic surfactant as main material accounting for over 25 wt% and contains also stabilizer, tackifier, co-solvent, chelating agent and other components, and all the components are mixed homogeneously and extruded to form the solid foaming agent. When used, the solid foaming agent added into water at 25-100 deg.c to form the foam liquid. The solid foaming agent has the advantages of high foaming performance, high resistance to high calcium ion water, etc.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

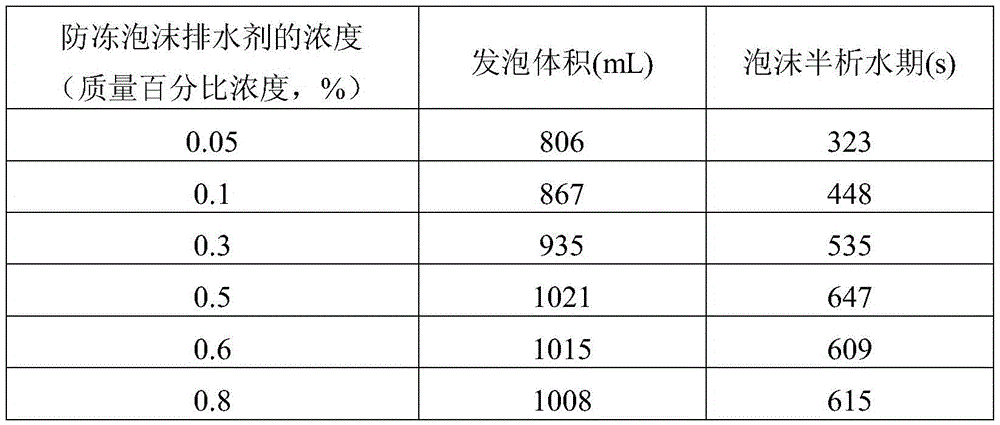

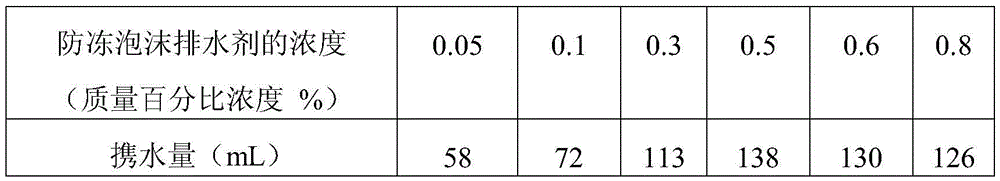

Antifreezing foaming drainage agent, and preparation method and application thereof

ActiveCN105670591AGood thermal stabilityImprove foaming efficiencyFluid removalDrilling compositionUreaChemistry

The invention provides an antifreezing foaming drainage agent, and a preparation method and application thereof. The antifreezing foaming drainage agent is prepared from the following raw materials in percentage by weight: 20-35% of fatty alcohol polyethenoxy ether phosphate sodium salt, 10-20% of sodium alpha-olefin sulfonate, 2-3% of polyanionic cellulose, 1-2% of coco fatty acid diethanol amide, 2-4% of alcohol, 1-1.5% of potassium carbonate, 1-1.5% of sodium chloride, 0.5-1% of urea, 0.5-1% of sodium acetate and the balance of water. The preparation method comprises the following step: sequentially adding the raw materials into a reaction vessel while stirring. The antifreezing foaming drainage agent provided by the invention has the advantages of excellent oil resistance, excellent salt tolerance, excellent foaming capacity, excellent water carrying capacity and low solidifying point (-30 DEG C), and is suitable for drainage and gas recovery operation of natural gas wells under severe cold conditions.

Owner:PETROCHINA CO LTD

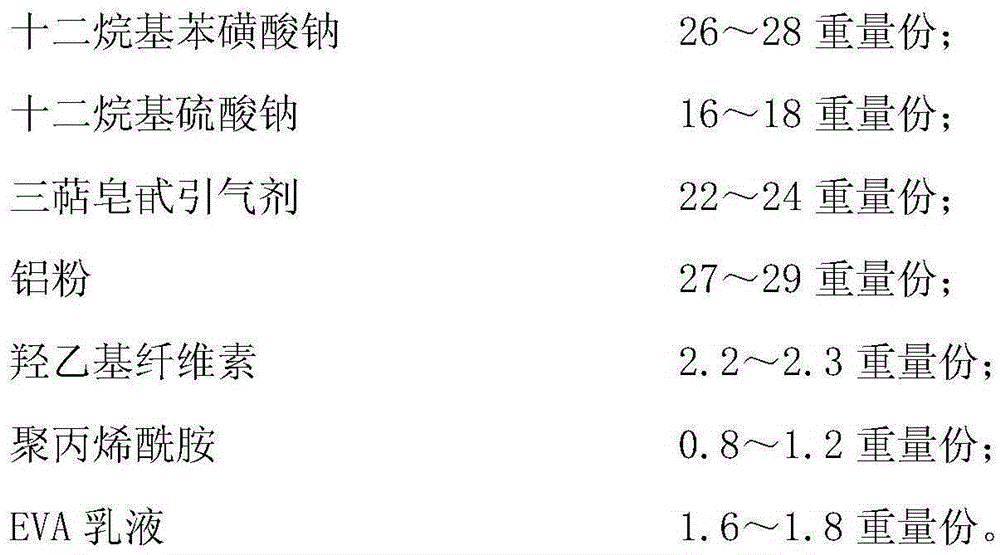

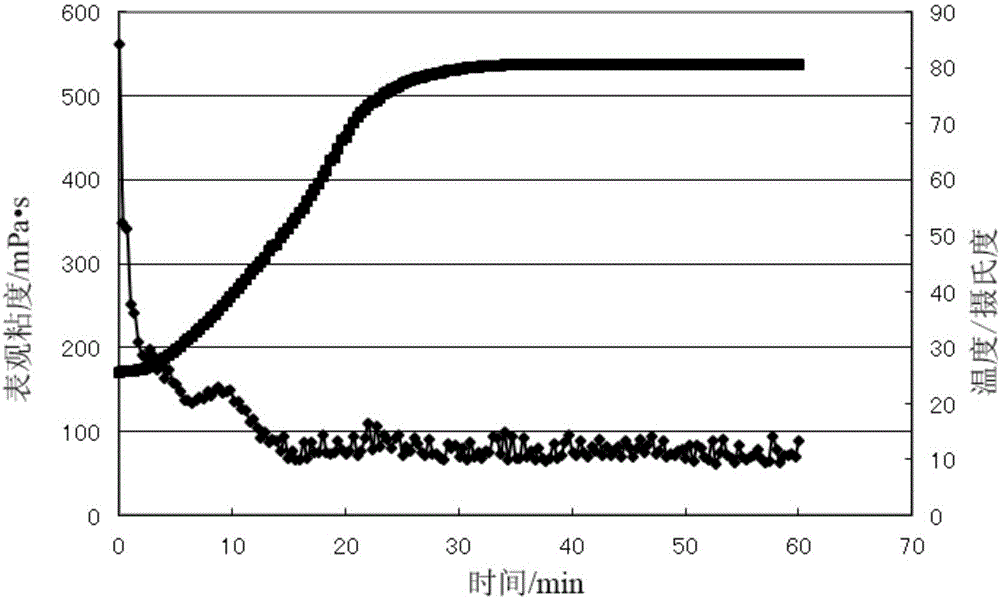

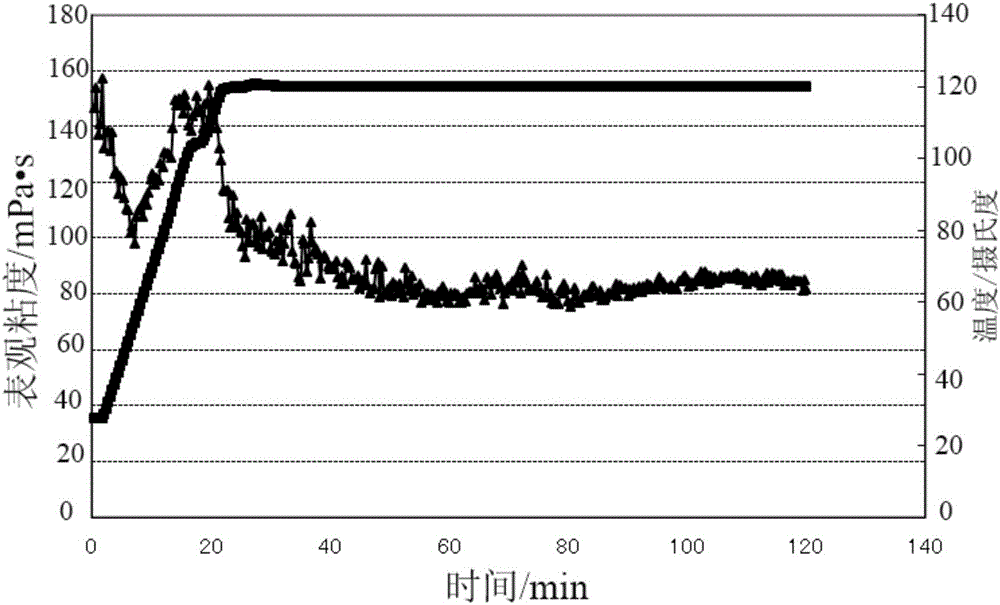

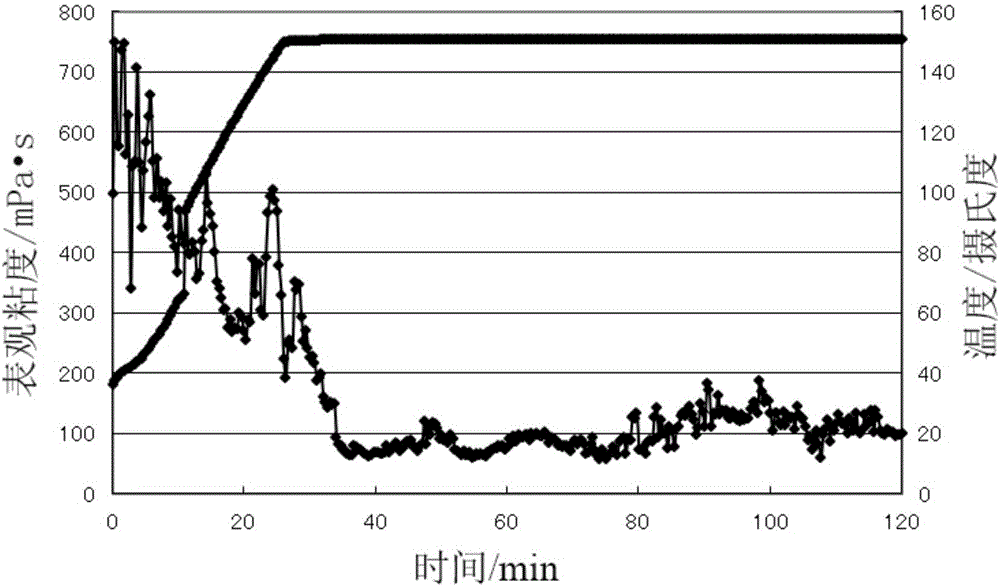

Foam concrete foaming agent and application thereof

ActiveCN105330196AProduct quality cannot be guaranteedImprove stabilityCeramicwareFoam concreteHydroxyethyl cellulose

The invention discloses a foam concrete foaming agent and application thereof. The foam concrete foaming agent is prepared from anionic surfactant, a chemical foaming agent and a foam stabilizing agent, wherein the chemical foaming agent is aluminum powder, and the foam stabilizing agent is selected from one or two or three of hydroxyethyl cellulose, polyacrylamide and EVA emulsion. The anionic surfactant is prepared from sodium dodecyl benzene sulfonate, sodium dodecyl sulfate and a triterpenoidal saponin air entraining agent. The quality of a foam concrete product can be well ensured by using aluminum powder for forming for supplementing foam in an early stage through compounding. Cellulose, starch and other foam stabilizing agents are usually adopted as ingredients of a foam stabilizing agent in a foaming agent on the current market and are likely to form flocculent matter when mixed with a solution, and the foam stabilizing performance of the foam stabilizing agent is affected. By means of performance comparison, the mode of compounding cellulose ester and the EVA emulsion is adopted, so that the probability of generating the flocculent matter is reduced, and thus the stability of the foam stabilizing agent is improved.

Owner:TIANYUAN CONSTR GROUP +2

High-temperature resistant CO2 foam cleaning and associated fracturing fluid and preparation method and application thereof

ActiveCN106675546AFast water solubilityEasy to prepareFluid removalDrilling compositionCross-linkPolymer science

The invention provides high-temperature resistant CO2 foam cleaning and associated fracturing fluid and a preparation method and application thereof. The high-temperature resistant CO2 foam cleaning and associated fracturing fluid comprises a fracturing fluid base solution, a cross-linking agent, a gel breaker and liquid CO2, wherein the cross-linking agent and the gel breaker account for 0.3%-0.8% and 0-0.05% of the fracturing fluid base solution in parts by weight separately; and the liquid CO2 accounts for 30%-70% of total volume of the CO2 foam cleaning and associated fracturing fluid. The high-temperature resistant CO2 foam cleaning and associated fracturing fluid provided by the invention has the characteristics of being few in additive types, simple in preparation, controllable in crosslinking, low in residue, low in damage, low in friction, high in foaming efficiency, high in flowback rate and resistant to high temperature.

Owner:PETROCHINA CO LTD

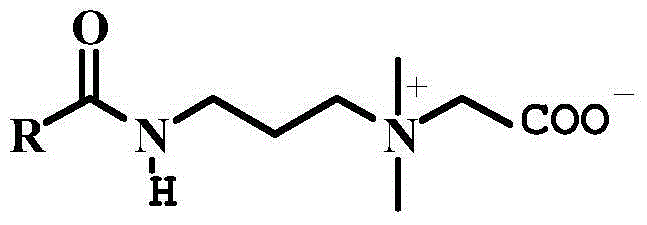

Environmental-friendly type foam water-draining agent and preparation method thereof

ActiveCN106244127AEasy to operateGood drainageDrilling compositionCocamidopropyl dimethylamineBetaine

The invention discloses an environmental-friendly type foam water-draining agent and a preparation method thereof. The environmental-friendly type foam water-draining agent adopts a biodegradable material; and the foam water drainage refers to discharging liquid accumulated at the bottom of a well out of the well by utilizing the water containing performance of foam and the own capability of the well bottom so as to realize the purpose of increasing the yield of the natural gas well. In a field experiment, the foam water-draining agent disclosed by the invention has the advantages that the foam water drainage gas producing process can be met by good foaming capability, foam stabilizing capability and liquid carrying capability, and the foam water-draining effect can be achieved. The environmental-friendly type foam water-draining agent is characterized by comprising the following components of: cocamidopropyl dimethylamine hydroxysultaine, dodecyl dimethyl betaine, alkyl glycoside, cocamidopropyl betaine, lauramidopropyl betaine, dodecyl dimethyl ammonium oxide, hexadecyl trimethyl ammonium chloride, fatty alcohol polyoxyethylene ether, urea and water.

Owner:北京众博达石油科技有限公司

Environmental-friendly foam drainage bar, and preparation method thereof

ActiveCN106244128AEasy to carrySimple filling processDrilling compositionSodium bicarbonatePolyethyleneglycol stearate

The invention discloses an environmental-friendly foam drainage bar, and a preparation method thereof. The environmental protection performance of the environmental-friendly foam drainage bar is used for referring that the environmental-friendly foam drainage bar is prepared from biodegradable raw materials. Foam drainage is used for referring discharging of well bottom accumulated water or accumulated liquid out of wells via utilization of water-containing or fluid-carrying capability of foam, so that gas recovery factor of gas wells is increased fully. The environmental-friendly foam drainage bar is capable of satisfying requirements of foam draining gas recovery and achieving excellent foam draining effect in field tests because of the excellent foaming ability, foam stabilizing ability, and liquid carrying capacity of the environmental-friendly foam drainage bar. The environmental-friendly foam drainage bar comprises following raw materials: cocamidopropyl betaine, sodium lauryl oxyethyl sulfonate, sodium lauroyl glutamate, fatty alcohol polyoxyethylene ether, polyethylene glycol monostearate, urea, citric acid, sodium bicarbonate, and sodium carbonate.

Owner:北京众博达石油科技有限公司

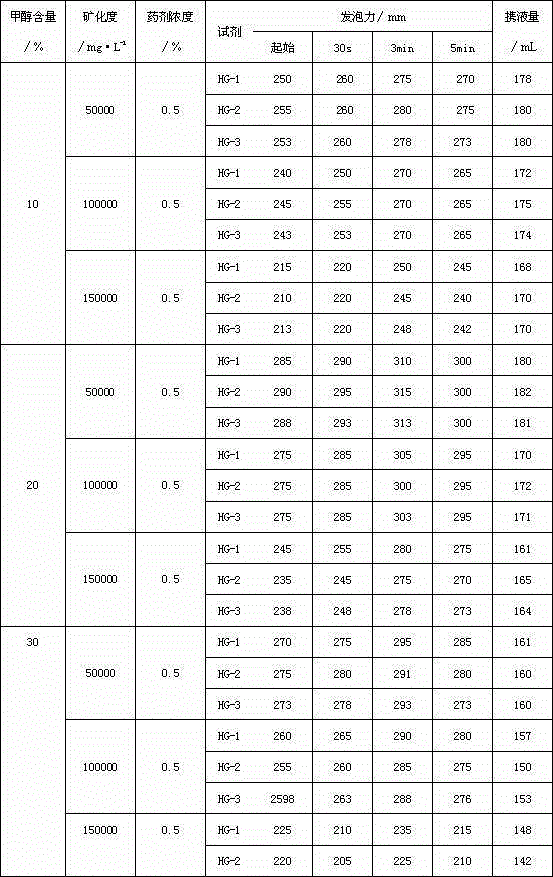

High-temperature resistant, hypersalinity resistant and gas condensate resistant foam scrubbing agent and preparation method thereof

ActiveCN105199701AEasy to operateReduce dosageDrilling compositionFluorocarbonTemperature resistance

The invention provides a high-temperature resistant, hypersalinity resistant and gas condensate resistant foam scrubbing agent and a preparation method thereof. The foam scrubbing agent is prepared from the following components in parts by weight: 30 to 50 percent of anionic surfactant, 10 to 2 percent of ampholytic surfactant, 1 to 2 percent of fluorocarbon surfactant, 0.5 to 1.5 percent of foam stabilizer, 0.2 to 0.5 percent of triethanolamine, 0.2 to 0.5 percent of glycol, 3 to 5 percent of sodium salt and the balance of water. The foam scrubbing agent has good water-carrying and foaming effects, can meet the process requirements of gas recovery by water drainage and has high-temperature resistance, hypersalinity resistance and gas condensate resistance.

Owner:西安长庆化工集团有限公司

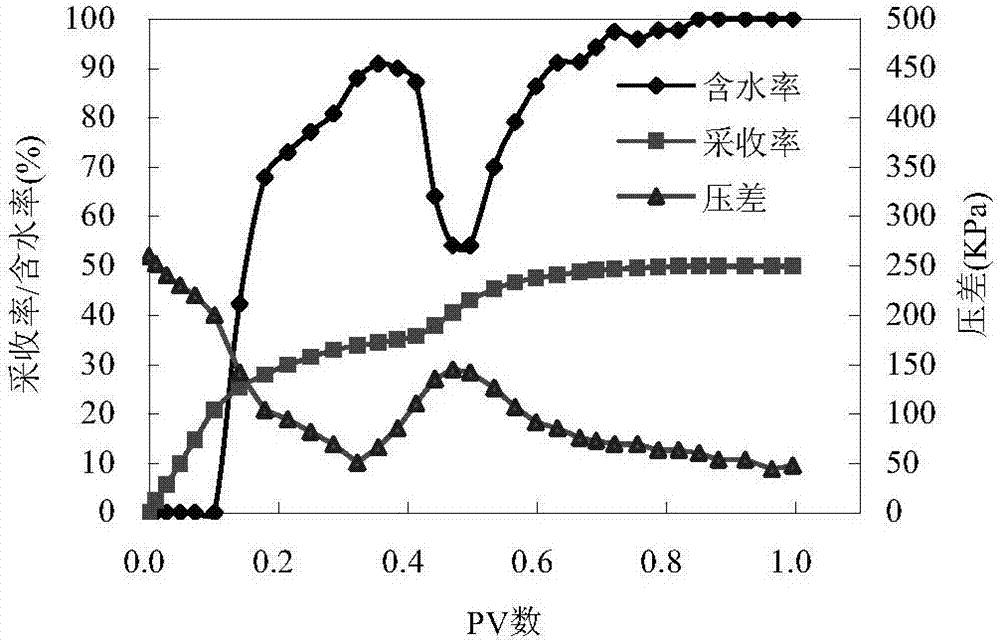

Foamer and foam gas flooding method

ActiveCN107227147APlugged channelingFoaming fastFluid removalDrilling compositionAlcoholInjection equipment

The invention relates to the field of foam flooding and discloses a foamer and a foam gas flooding method. The foamer comprises a weak-cationic amphoteric surfactant, water and at least one of cationic surfactant, amphoteric surfactant and alcohol. The foam gas flooding method comprises the steps of injecting the weak-cationic amphoteric surfactant containing foamer and gas into an oil reservoir, and carrying out foam profile control and oil displacement. According to the foamer and the method, disclosed by the invention, the foamer has high foamability, stability and profile control and oil displacement capability, so that the corrosion action on injection equipment and an oilfield injection-production system caused by air foam in an air foam flooding profile control and oil displacement process can be obviously lowered; and the foamer not only can be applied to a foam profile control and oil displacement process of ordinary strata, but also can be applicable to the foam profile control and oil displacement process under the condition that stratum water is high in degree of mineralization and high in calcium and magnesium ion content.

Owner:CHINA PETROLEUM & CHEM CORP +1

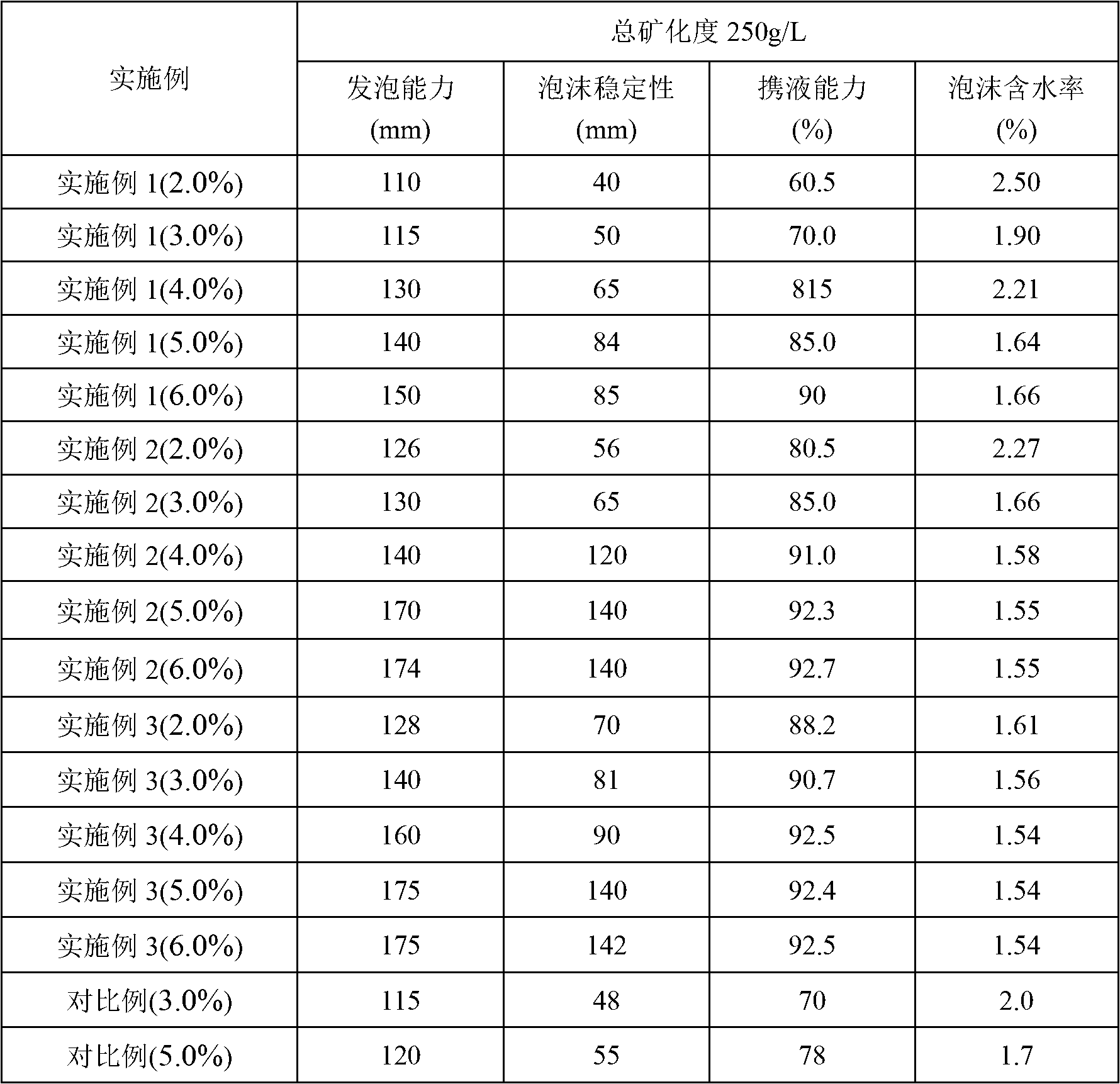

Foam water-drainage agent and its aqueous solution

ActiveCN103059826APromote degradationHigh resistance to mineralizationDrilling compositionChemical reactionTemperature resistance

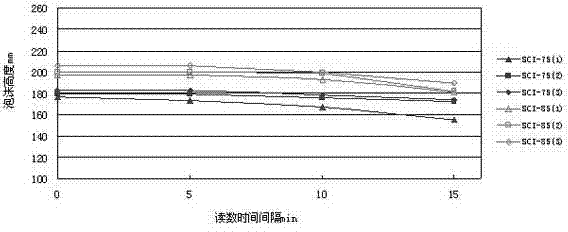

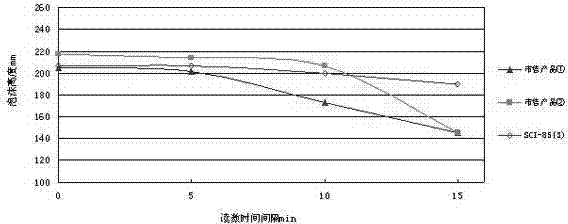

The invention discloses a foam water-drainage agent and its aqueous solution, and belongs to the technical field of the oilfield chemical engineering. The foam water-drainage agent is composed of 50-80 parts by weight of a Sapindus mukurossi Gaertn extract, 20-40 parts of fatty alcohol polyoxyethylene ether AEO18, 1-5 parts by weight of polyacrylamide and 5-10 parts by weight of triethanolamine. The foam water-drainage agent has the characteristics of strong foaming capability after meeting water, good foam stability, and high liquid carrying capability and high mineralization resistance of foams, and is suitable for the use in natural gas wells containing gas condensate and having a high mineralization and a large water output; the foam water-drainage agent has a foam stability of 170mm, has a foam water content of not more than 2.0%, has a mineralization resistance of 250g / L, has a gas condensate resistance of 30%, has a temperature resistance of 90DEG C, is non-toxic, is easy to degrade, and does not pollute the environment; and the foam water-drainage agent has the advantages of compatibility with chemicals comprising methanol, a corrosion inhibitor, a scale inhibitor and the like, no chemical reaction with gas or liquid components, no increase to the toxicities of gases or combustion products, and no corrosion to equipment or pipelines.

Owner:CHINA PETROLEUM & CHEM CORP +1

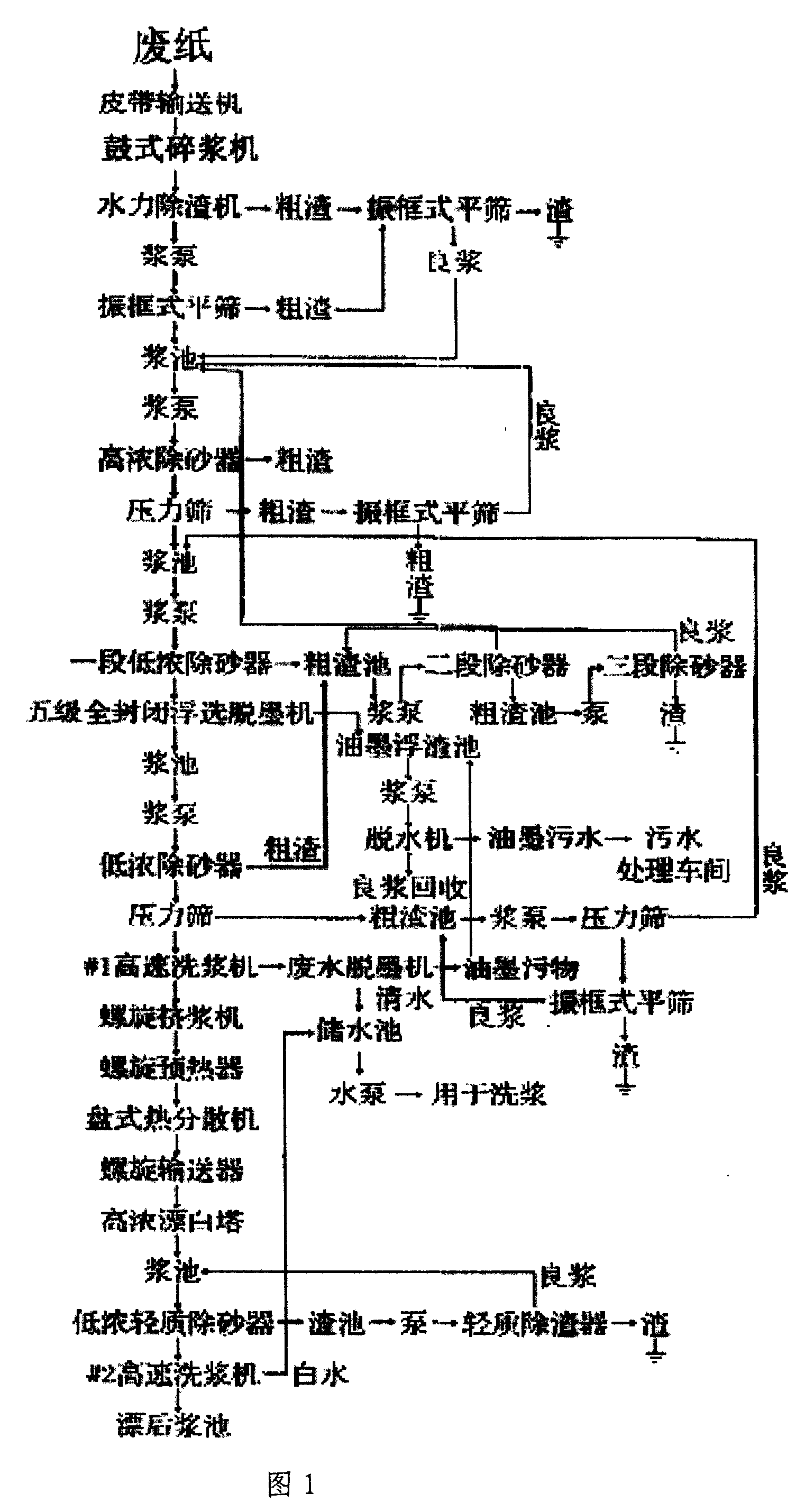

Deinking agent

InactiveCN101177558AStrong foaming abilityFine bubblesChemical paints/ink removersChemistryPrinting ink

The invention relates to a special deinking agent for old newspaper (ONP), containing polyoxyethylene alkyl ether, polyoxyethylene polyol ester, fatty salt, lauryl sulfate, sodium lignosulfonate and inorganic matter; the deinking agent has good biodegradability, which greatly reduces environment pollution. As appropriate amount of foam can be maintained during processing, the deinking agent provides good practicability. High quality reclaimed pulp with high whiteness and low amount of residual printing ink can be obtained when the deinking agent is used. The deinking agent is liquid, usage and storage is convenient, and cost for deinking is low, thereby reducing processing cost.

Owner:SHANDONG TAIYANGZHIYE

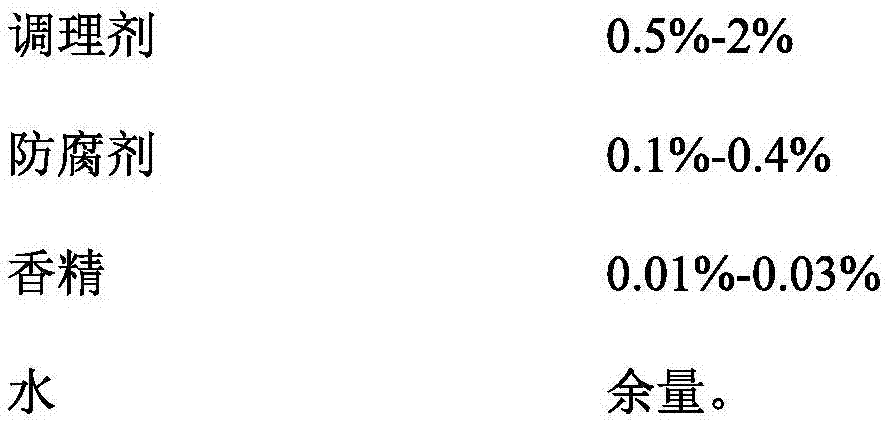

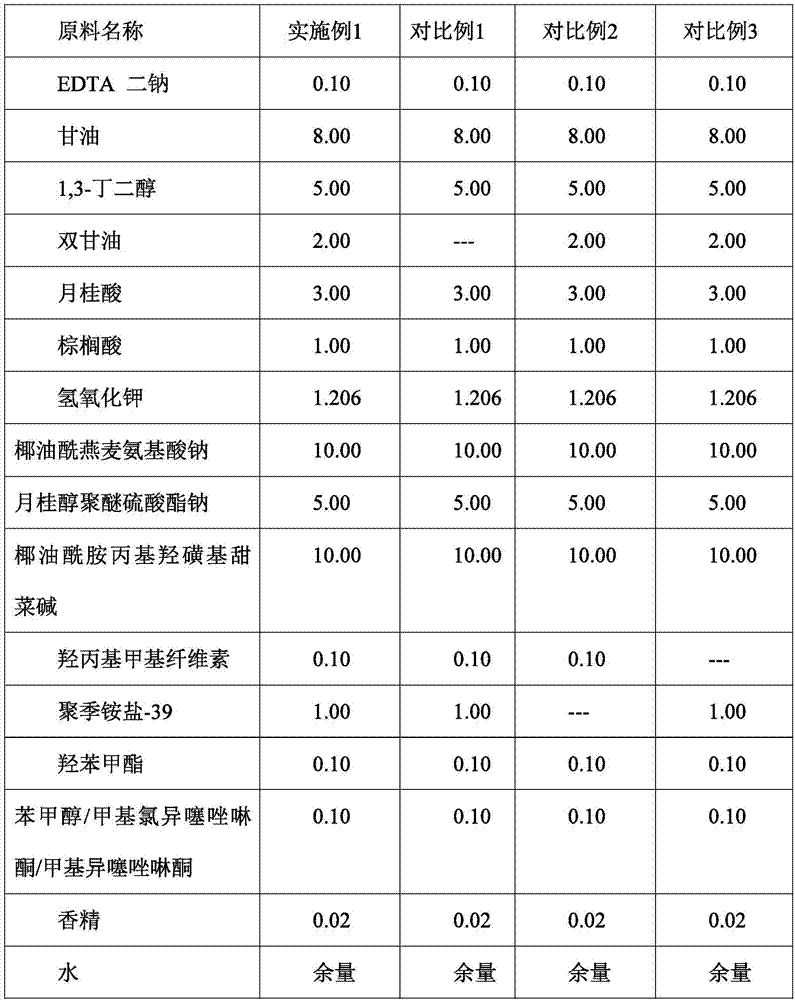

Gentle cleansing foam and preparation method thereof

ActiveCN107260579ARich and fine foamStrong foamingCosmetic preparationsToilet preparationsPromotion effectChemistry

The invention discloses gentle cleansing foam. The gentle cleansing foam comprises the following components in percentages by weight: 0.05-0.1% of a chelating agent, 9-21% of polyol, 1.5-6% of fatty acid, 0.5-1.5% of alkali, 10-23% of a surfactant, 8-15% of glycine betaine, 0.05-0.2% of cellulose, 0.5-2% of a conditioner, 0.1-0.4% of a preservative, 0.01-0.03% of essence and the balance of water. Compared with the prior art, the gentle cleansing foam has the advantages that the amino acid surfactant is perfectly matched with a soap base, while skin is cleaned, visual experience of the product can be implemented, and the foam is exquisite and abundant, lasting and compact. Sodium cocoyl apple amino acids which are sourced naturally are low in odor, low in chromaticity and high in foaminess. The foam is soft and abundant, and is gentle to eyes and skin. The soap base neutralized by fatty acid and alkali not only has abundant stable foam, but also has the characteristic of deep cleaning. By matching of glycerinum, 1,3-butanediol and diglycerol, the gentle and long-lasting moisturizing effect for the skin can be achieved, furthermore, the foam promotion effect is achieved, the foam is delicate, and the lasting time is long.

Owner:广州蜜妆生物科技有限公司

High liquid absorption rate acrylic acid water-absorbent resin and its preparation method and use

ActiveCN106279494AHigh specific surface areaStrong foaming abilityCoatingsAbsorption rateStorage material

The invention provides high liquid absorption rate acrylic acid water-absorbent resin and its preparation method and use. The high liquid absorption rate acrylic acid water-absorbent resin is prepared from acrylic acid, an alkali, water, a cross-linking agent, a high temperature-resistant foaming agent, a copolymerization monomer, a reducer and an initiator. A mass ratio of the acrylic acid, alkali to water is (25-45): (7-22): (33-68) and based on the acrylic acid mass, a use ratio of the cross-linking agent is in a range of 0.001-1wt%, a use ratio of the high temperature-resistant foaming agent is in a range of 0.01-2wt%, a use ratio of the copolymerization monomer is in a range of 0-10wt%, a use ratio of the reducer is in a range of 30-500ppm and a use ratio of the initiator is in a range of 0.001-1wt%. A high liquid absorption rate of the acrylic acid water-absorbent resin is 15-40s. The acrylic acid water-absorbent resin can be used as a liquid absorption material in fields of paper diapers, baby diapers and sanitary napkins in the health care industry and can also be used as a water absorption and storage material in industries of desert treatment, water blockage in an oil field and agricultural and forestall water retention.

Owner:WANHUA CHEM GRP CO LTD

Preparation method for peanut bioactive peptide

ActiveCN102250998AHas antibacterial activityHas good antibacterial activityFermentationSolubilityHydrolysate

The invention discloses a preparation method for peanut bioactive peptide. The method comprises the following steps: adding peanut protein powder to distilled water, carrying out stirring, followed by standing and microwave treatment to obtain peanut protein powder suspension liquid; adjusting a pH value of the peanut protein powder suspension liquid through a hydrochloric acid solution, then adding compound plant hydrolase Viscozyme L, followed by carrying out the microwave treatment to secondarily carry out enzymolysis to obtain a enzymatic hydrolysate, then killing the enzymes and carryingout cooling to a room temperature; adjusting a pH value of the enzymatic hydrolysate through a sodium hydroxide solution or the hydrochloric acid solution, then adding protease and carrying out the microwave treatment to secondarily carry out the enzymolysis, then killing the protease and carrying out cooling to the room temperature, followed by carrying out centrifugating and freeze drying to obtain the peanut bioactive peptide. The prepared peanut bioactive peptide product provided by the present invention has functional properties of high dissolubility, high emulsibility, strong foamability, good emulsion stability, good foam stability and the like. In addition, the method provided by the present invention is applicable for the industrial production.

Owner:SHANDONG PEANUT RES INST

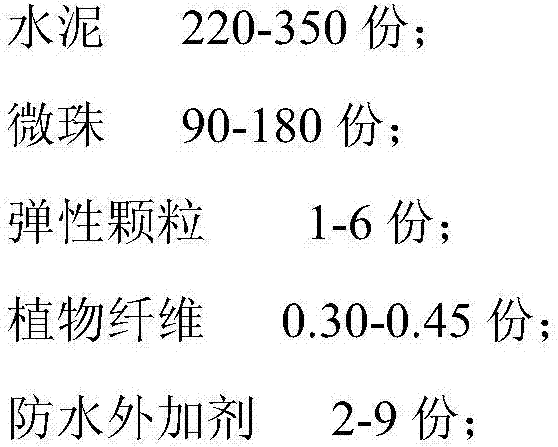

Waterproof crack-resistant foam concrete and manufacture method

The invention discloses waterproof crack-resistant foam concrete and a manufacture method thereof. The waterproof crack-resistant foam concrete is formed by mixing and stirring of raw materials including, by weight, 220-350 parts of cement, 90-180 parts of microspheres, 1-6 parts of elastic particles, 0.30-0.45 parts of palm filaments, 60-160 parts of water, 2-9 parts of waterproof admixtures and foam. The waterproof crack-resistant foam concrete and the manufacture method thereof have the advantages that the raw materials such as industrial by-products, tailings powder or waste rubber powder and the palm filaments are adopted, and the multi-scale toughening principle on compounding of the elastic particles and fibers is followed, so that strength and crack resistance of the foam concrete are improved, and waste resource utilization is benefited; the adopted waterproof admixtures are highly compatible with other materials, and accordingly, water resistance and durability of the foam concrete are improved effectively; by the prepared foam which is fine, uniform and high in stability, anti-permeability and thermal performance of the foam concrete are improved; the foam concrete is applicable to heat insulation of building walls and roofs and roadbed refilling materials for highways in regions with soft soil and high water level.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

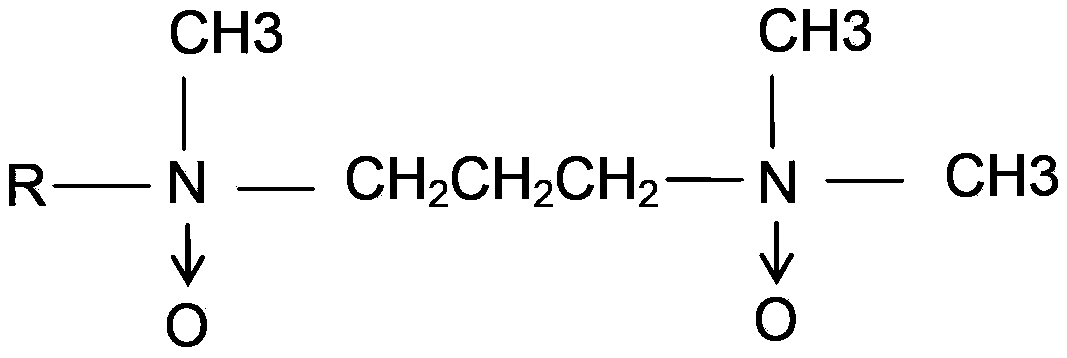

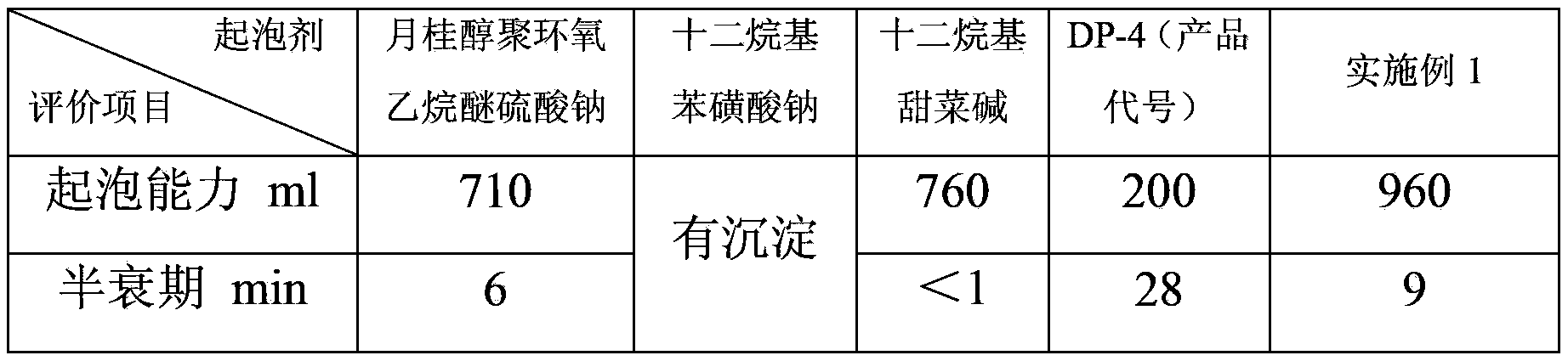

Foaming agent suitable for high-temperature and high-salinity oil reservoir and preparation method thereof

ActiveCN104109520ASolve the problem of low ability evaluationStrong foaming abilityDrilling compositionFoaming agentDistilled water

The invention discloses a foaming agent suitable for a high-temperature and high-salinity oil reservoir and a preparation method thereof. The foaming agent includes 50-70 wt% of alkyl sulfonate, 10-15 wt% of alkyl amine oxide, and the balance distilled water; the pH value of the foaming agent is 7-9. The method includes the steps: successively adding alkyl sulfonate, alkyl amine oxide and distilled water into a reaction kettle while stirring, and mixing uniformly to obtain the foaming agent, wherein the temperature of the reaction kettle is 30-70 DEG C. The foaming agent has the advantages of strong foaming ability, high salinity resistance, high calcium and magnesium ion resistance and good compatibility with formation water.

Owner:CHINA PETROLEUM & CHEM CORP +1

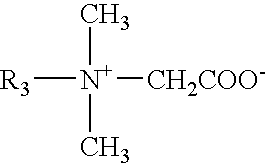

Salt-resistant and acid-resistant concentrated foaming agent as well as preparation method and application thereof

InactiveCN104130767AImprove stabilityGood compatibilityDrilling compositionSalt resistanceFoaming agent

The invention discloses a salt-resistant and acid-resistant concentrated foaming agent as well as a preparation method and application thereof. The foaming agent consists of 20-45 percent of a zwitterionic surfactant, 1-10 percent of a cation surfactant and water. The preparation method comprises the following steps: adding the components of the weight percentages into a reaction kettle respectively in sequence; stirring the mixture at the normal temperature for 2-3 hours; and fully reacting the materials in the reaction kettle to obtain the salt-resistant and acid-resistant concentrated foaming agent. The salt-resistant and acid-resistant concentrated foaming agent has the advantages of high foaming ability, high foam stability, salt resistance, acid resistance, wide temperature range and the like at a low use concentration, is suitable for a foam fracturing process as well as the processes of oil production, gas production, drainage and the like of oil-gas coproduction wells and gas-water coproduction wells, and is applied to well repair and sand wash operation. The preparation method has the advantages of adoption of readily-available raw material, easiness and convenience in operation, low requirements on the environment and equipment, and easiness in realizing industrial production and large-scale application.

Owner:安徽奔马先端科技有限公司

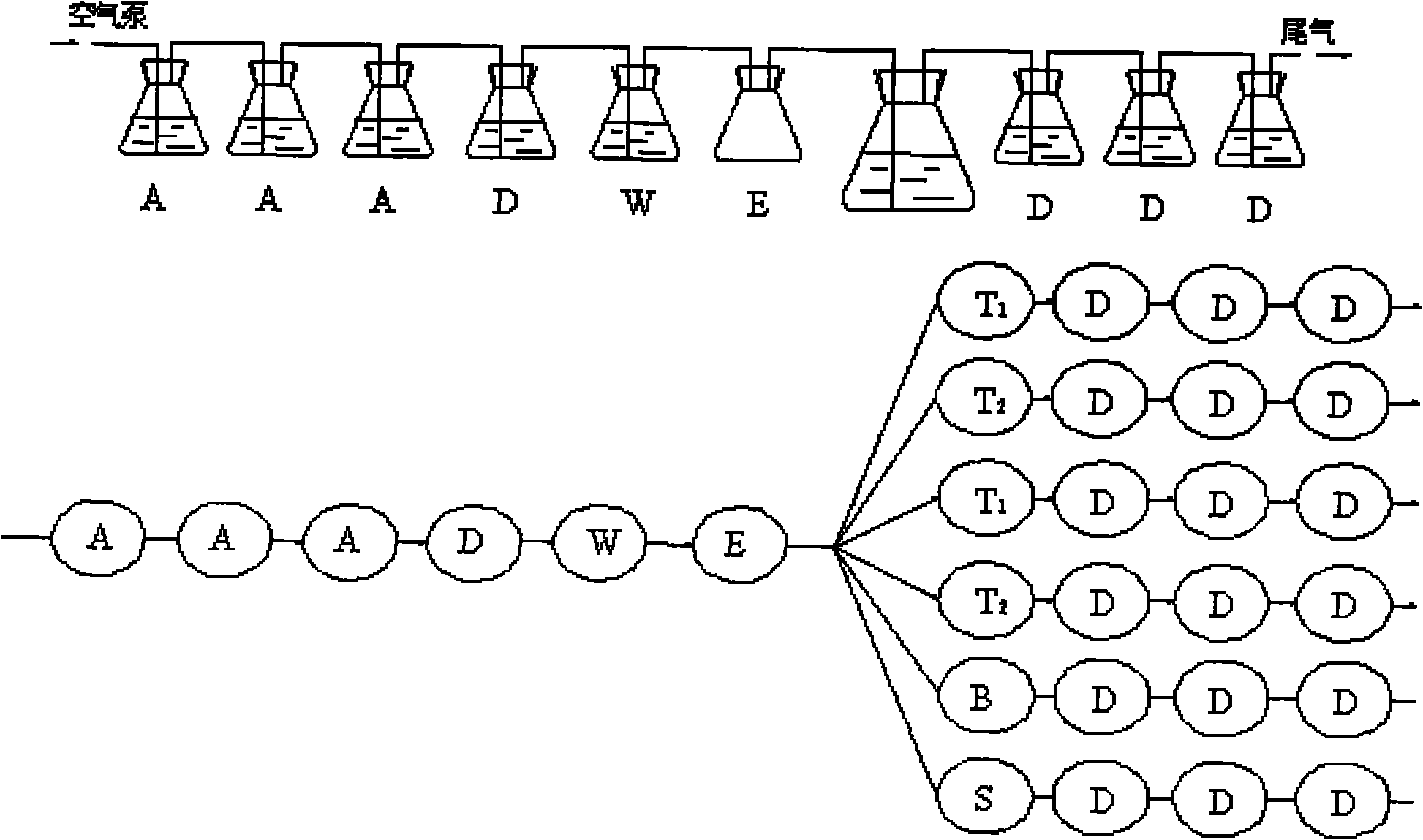

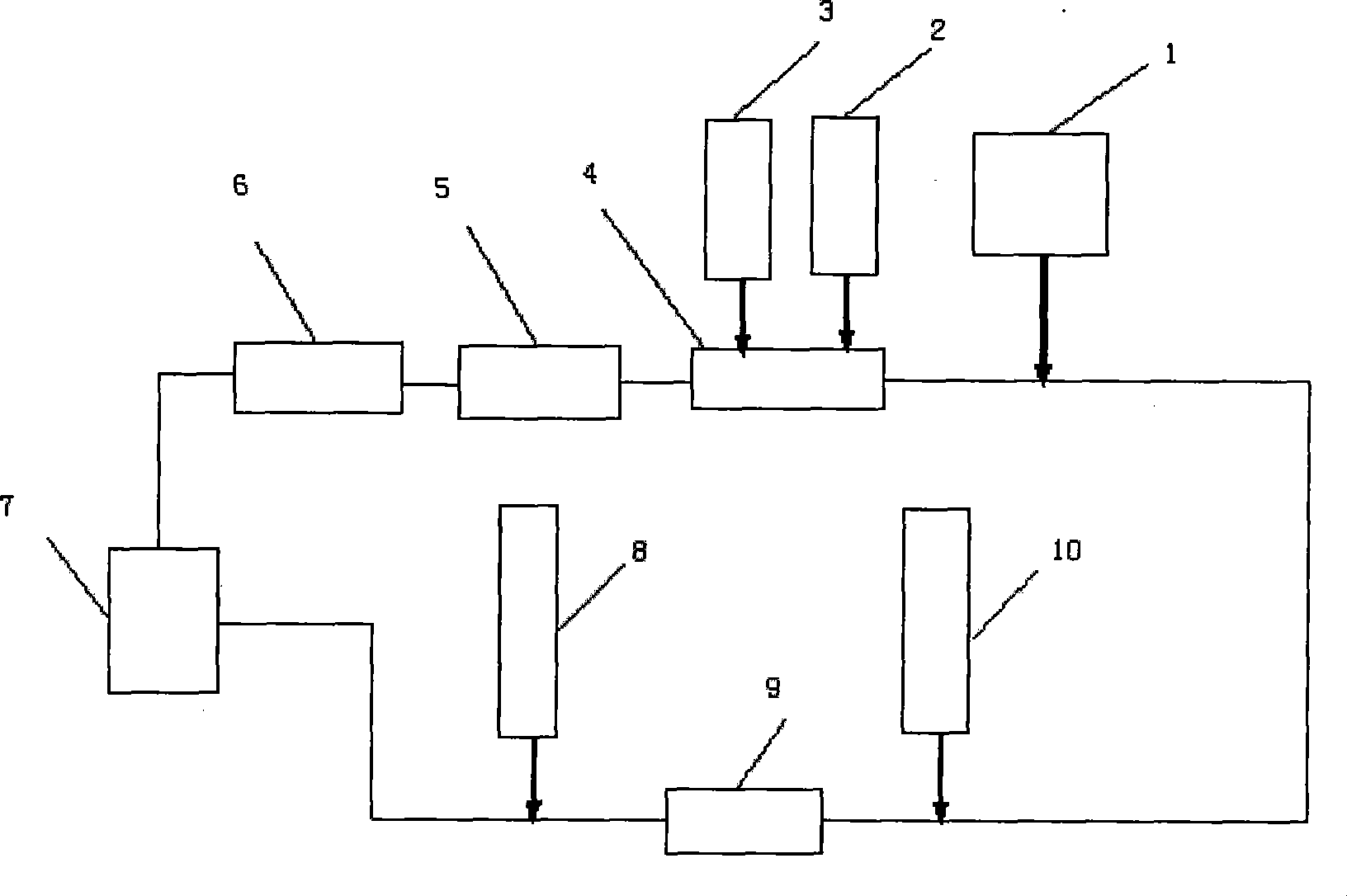

Foam cyclic utilization method used for under balance drilling

InactiveCN101463714AImprove stabilityAchieve recyclingFlushingDrilling compositionFoaming agentWell drilling

The invention relates to a method for cyclically utilizing foam, which is used for oil and gas exploitation, mining and non-excavation ground drilling and for the underbalanced well drilling and can increase the service efficiency of vesicant and reduce the environmental pollution and the cost of drilling fluids. The technical scheme is as follows: a cyclic foam system consists of a foam base fluid-CaCl2-Na2CO3; the foam base fluid comprises crisp foam, or stable foam, or three-phase foam; a water solution with anionic surfactant is used for the crisp foam, a water solution with the anionic surfactant and foam stabilization tackifier is used for the stable foam, and a water solution with the anionic surfactant, the foam stabilization tackifier and swell soil is used for the three-phase foam; the air input and the quantity of the foam base fluid are adjusted firstly to gain the foam, and a valve is opened to inject the foam into a well; after being cyclically led out from the mouth of the well, the foam is added with a CaCl2 water solution for defoaming; after drill chips are removed, a Na2CO3 solution is added to restore the foamability; and then the solution is led into a generator for foaming again. The method can realize multiple times of cyclic utilization of the foam base fluid, and has simple process and convenient operation.

Owner:SOUTHWEST PETROLEUM UNIV

Degradable highly-elastic sponge and preparation technology thereof

The invention relates to degradable highly-elastic sponge and a preparation technology thereof. The degradable highly-elastic sponge and the preparation technology thereof have the advantages that thedegradable highly-elastic sponge is made of green, natural and healthy materials according to the environment-friendly preparation technology, harmless to human bodies and capable of avoiding resource waste and environment pollution, and its mechanical properties including rebound resilience and compression set value are in compliance with the international standards; through adoption of recyclable pineapple fibers, resource waste is reduced and physical properties of low-density sponge with natural latex matrixes are improved to comply with the international standards; sodium alcohol ether sulphate and sodium lauryl sulfate which serve as foaming agents substitute for traditional pollutional ones to further avoid pollution; the high-performance low-density sponge with the excellent mechanical properties can be produced at a low preparation cost; the preparation technology is safe, simple and environment friendly.

Owner:德清舒华泡沫座椅有限公司

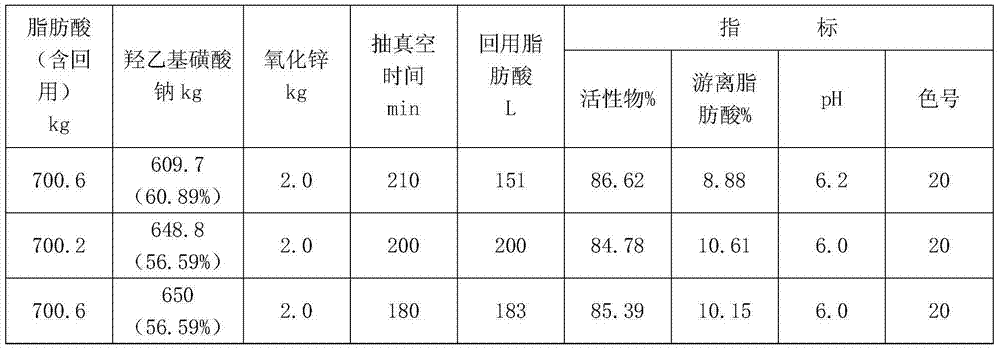

Preparation method of sodium hydroxyethyl sulfonate fatty acid ester

ActiveCN103483228ARich sourcesReduce pollutionSulfonic acids salts preparationVacuum pumpingIodo fatty acid

The invention relates to a preparation method for synthesizing esters from fatty acid and sodium hydroxyethyl sulfonate and particularly relates to a preparation method of sodium hydroxyethyl sulfonate fatty acid ester. According to the method, a finished product of sodium hydroxyethyl sulfonate fatty acid ester is prepared by adopting coconut oil acid, sodium hydroxyethyl sulfonate and zinc oxide as raw materials through performing preparation of the raw materials, esterification reaction, vacuum-pumping operation and other process steps. The preparation method provided by the invention has the advantages of simple process, rich sources of the raw materials, reproducibility, very low environmental pollution of a production process and no other wastes and byproducts, and is suitable for industrial mass production. The product is easy to be crushed into powder with the particle size of 200 meshes through a crushing machine and can be added into face washing powder, and experiments prove that the product has strong foamability and hard water resistance.

Owner:JILIN AEGIS CHEM

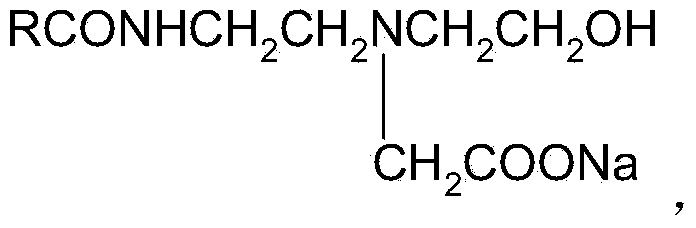

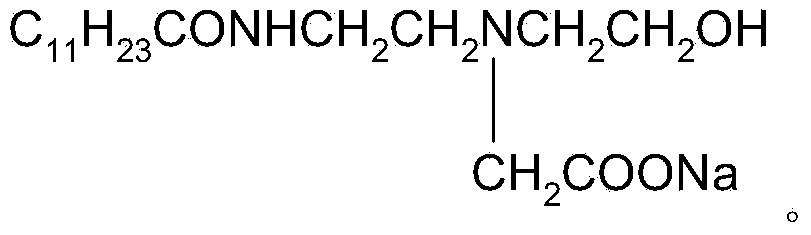

Foaming agent for CO2 oil displacement system and preparation method thereof

The invention discloses a foaming agent for a CO2 oil displacement system and a preparation method thereof. The foaming agent is prepared from the following ingredients in parts by weight: 0.05 to 0.4 part of dodecyl hydroxypropyl phosphate betaine, 0.05 to 0.5 part of surface active agents with star-shaped molecular structures and 95 to 100 parts of water, wherein the surface active agent is any one of R2N[R1N(R1NH2)2]2, R3[N(R1NH2)2]2 and N[CH2CH2N(R1NH2)2]3; the R1 is -CH2CH2CONHCH2CH2-; the R2 is CnH2n+1-, and the n is 12 to 18; the R3 is -CnH2n-, and the n is 4 to 8; the surface active agents are prepared by enabling primary amine, diamine or triamine to react with methyl acrylate and ethylenediamine. The foaming agent provided by the invention has high foaming capability, and the formed foam has high stability.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

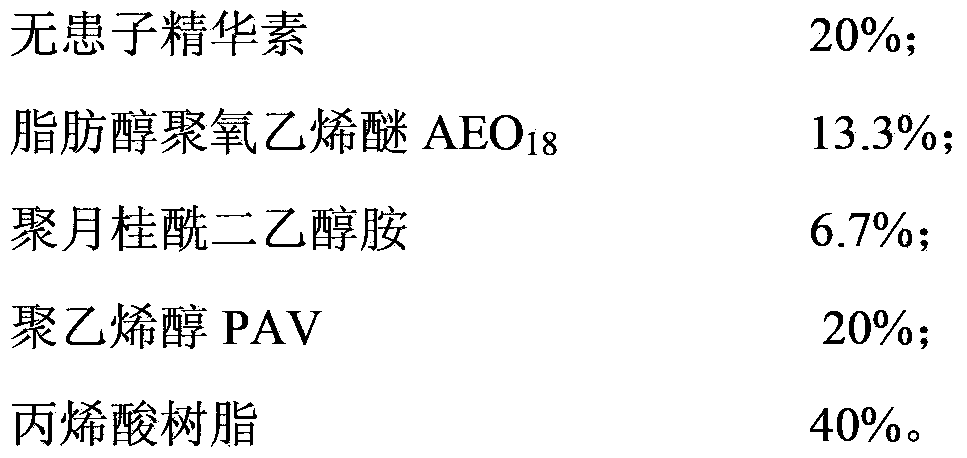

Sustained-release foaming agent

ActiveCN104342096AStrong foaming abilityImprove stabilityDrilling compositionChemical reactionFoaming agent

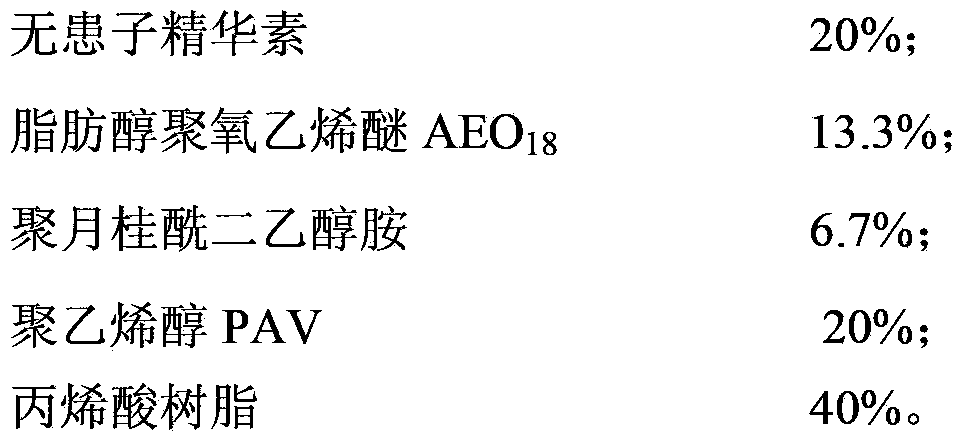

The invention relates to a sustained-release foaming agent which is composed of the following components, by weight: 20% of Chinese soapberry fruit essence, 13.3% of fatty alcohol-polyoxyethylene ether AEO18, 6.7% of polylauroyl diethanolamide, 20% of polyvinyl alcohol PAV, and 40% of acrylic resin. The sustained-release foaming agent provided by the invention has high foaming capacity when contacting water, and the foam has good stability. Liquid carrying and anti-mineralization capacities of foam are high. The foam is suitable for use in condensate-oil-containing natural gas wells with high mineralization and large water yield. The foaming capacity can reach 175mm, the anti-mineralization capacity reaches 250g / L, the condensate-oil-resistant capacity reaches 30%, the temperature resistance reaches 90 DEG C, and a dissolution time exceeds 72h. The agent has a long effective period. According to field tests, the foam scrubbing success rate is higher than 90%. The product is non-toxic and is easy to degrade. The product does not pollute the environment, does not chemically react with gas and liquid components, and does not corrode equipment and pipes.

Owner:PETROCHINA CO LTD

Phosphogypsum flame retardant foaming agent

The invention discloses a phosphogypsum flame retardant foaming agent. The technical scheme is characterized in that the phosphogypsum flame retardant foaming agent is composed of phosphogypsum, high-viscosity attapulgite clay powder, active attapulgite clay, sodium bicarbonate, sodium alkyl benzene sulfonate, sodium polyacrylate, sodium pyrophosphate, ammonium polyphosphate and zinc borate which are dehydrated; and all the ingredients of the phosphogypsum flame retardant foaming agent are stirred, ground and packaged to obtain a finished product of the phosphogypsum flame retardant foaming agent. After water is added into the phosphogypsum flame retardant foaming agent and the mixture is stirred at a high speed, a great amount of gases are rapidly released, and thus, porous foam sludge is formed; the foam slurry is directly used for extinguishing a fire after being sprayed by using a high-pressure water gun; the foam slurry is stably covered on the surface layer of a combustible material to form a foam slurry film which can be used for rapidly isolating the contact of the combustible material and the air and preventing the combustible material from continuing combusting, and thus, the aims of flame retarding and fire extinguishing are achieved; and the phosphogypsum flame retardant foaming agent is suitable for producing flame retarding and fire extinguishing products, light boards, light walls and silencing and noise reducing products.

Owner:李兴乐

Preparation method of composite protein foaming agent

ActiveCN107549443AImprove adaptabilityStrong foaming abilityVegetable proteins working-upAnimal proteins working-upProtein solutionFoaming agent

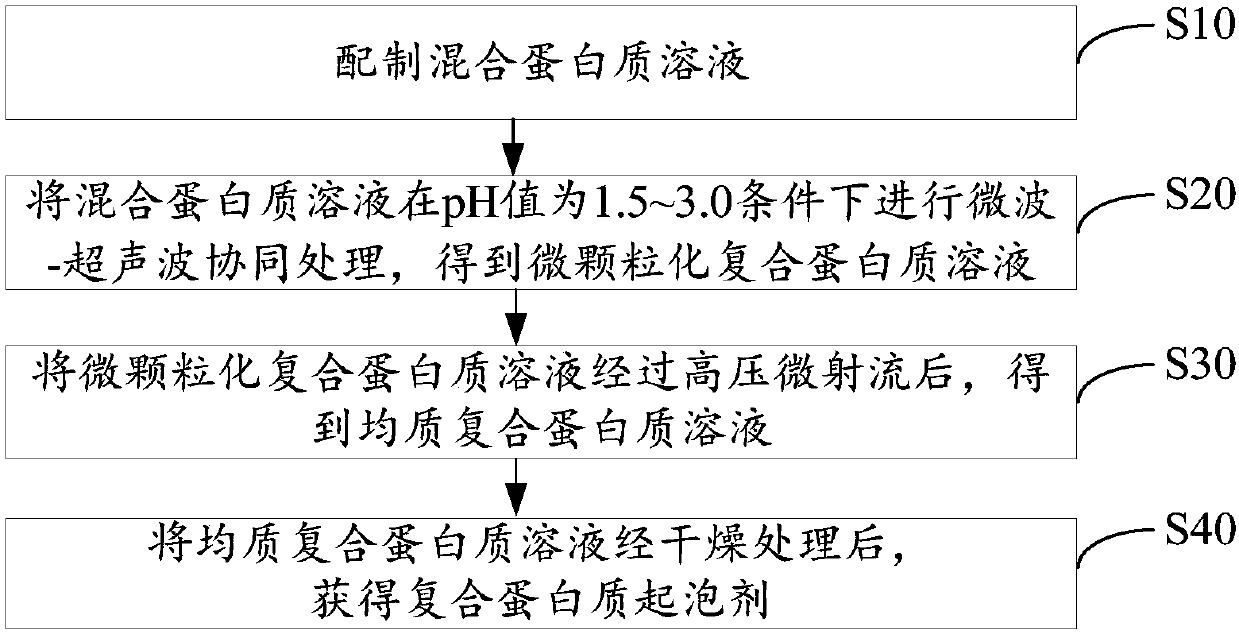

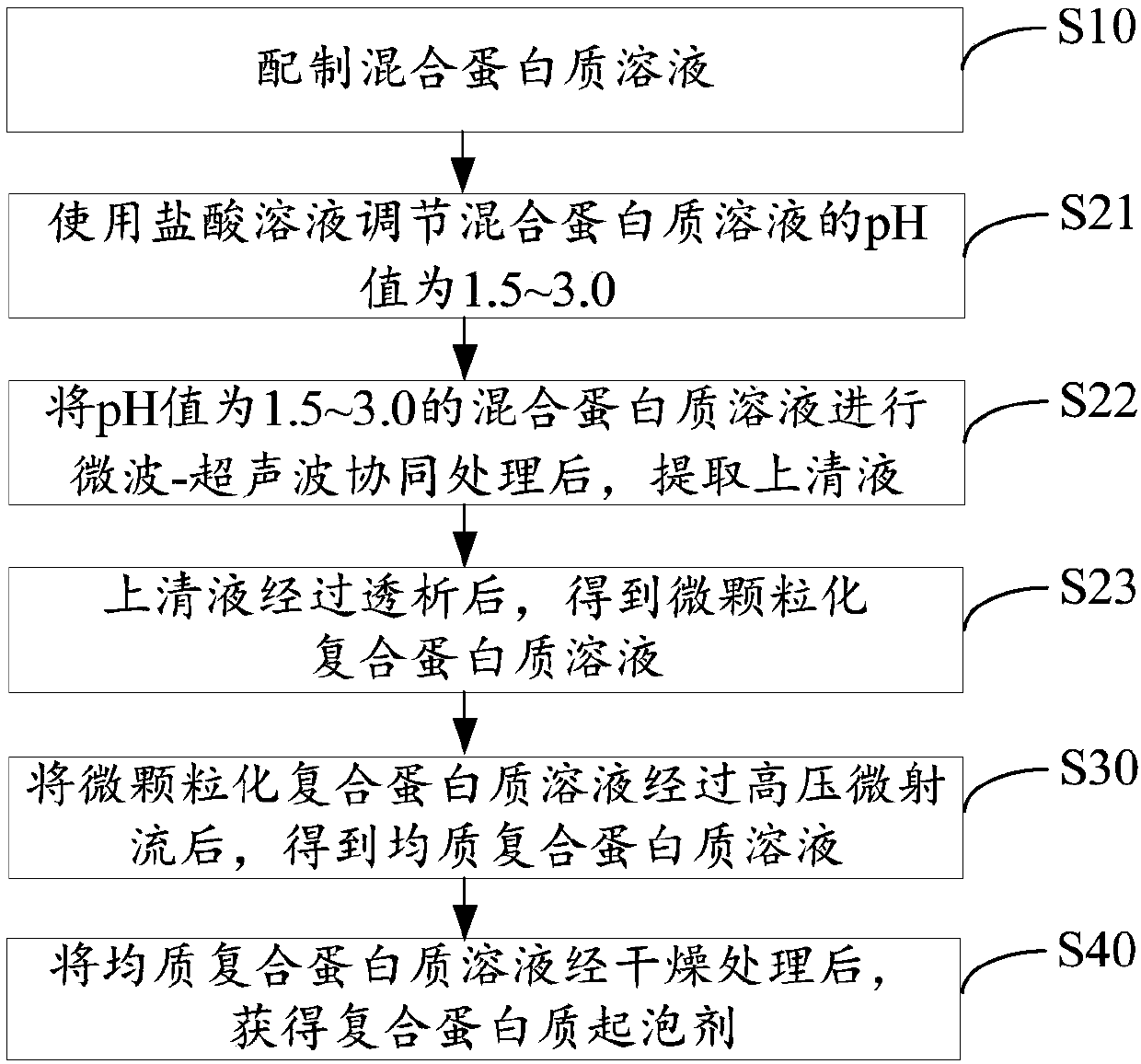

The invention discloses a preparation method of a composite protein foaming agent. The method comprises: preparing a mixed protein solution; performing microwave and supersonic wave cooperative treatment to the mixed protein solution at the pH value of 1.5-3.0 to obtain a micro-granulated composite protein solution; performing high-pressure microjet to the micro-granulated composite protein solution to obtain a homogeneous composite protein solution; and drying the homogeneous composite protein solution to obtain the protein foaming agent. Through a microwave and supersonic wave cooperative effect, heterogenous protein is induced to undergo aggregation and recombination, thereby forming specific composite protein aggregate particles. Further, the particle size of the composite protein aggregate particles is regulated with the assistance of high-pressure microjet. The adaptability to the environmental condition of the composite protein foaming agent is improved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com