Foam cyclic utilization method used for under balance drilling

An underbalanced drilling and foam technology, which is applied in drilling compositions, chemical instruments and methods, and earth-moving drilling, etc., can solve the problem that natural defoaming occupies a large area, cannot handle a large amount of foam, and consumes a large amount of defoamer. and other problems, to achieve the effect of convenient on-site operation, reduced drilling operation cost, and strong foaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

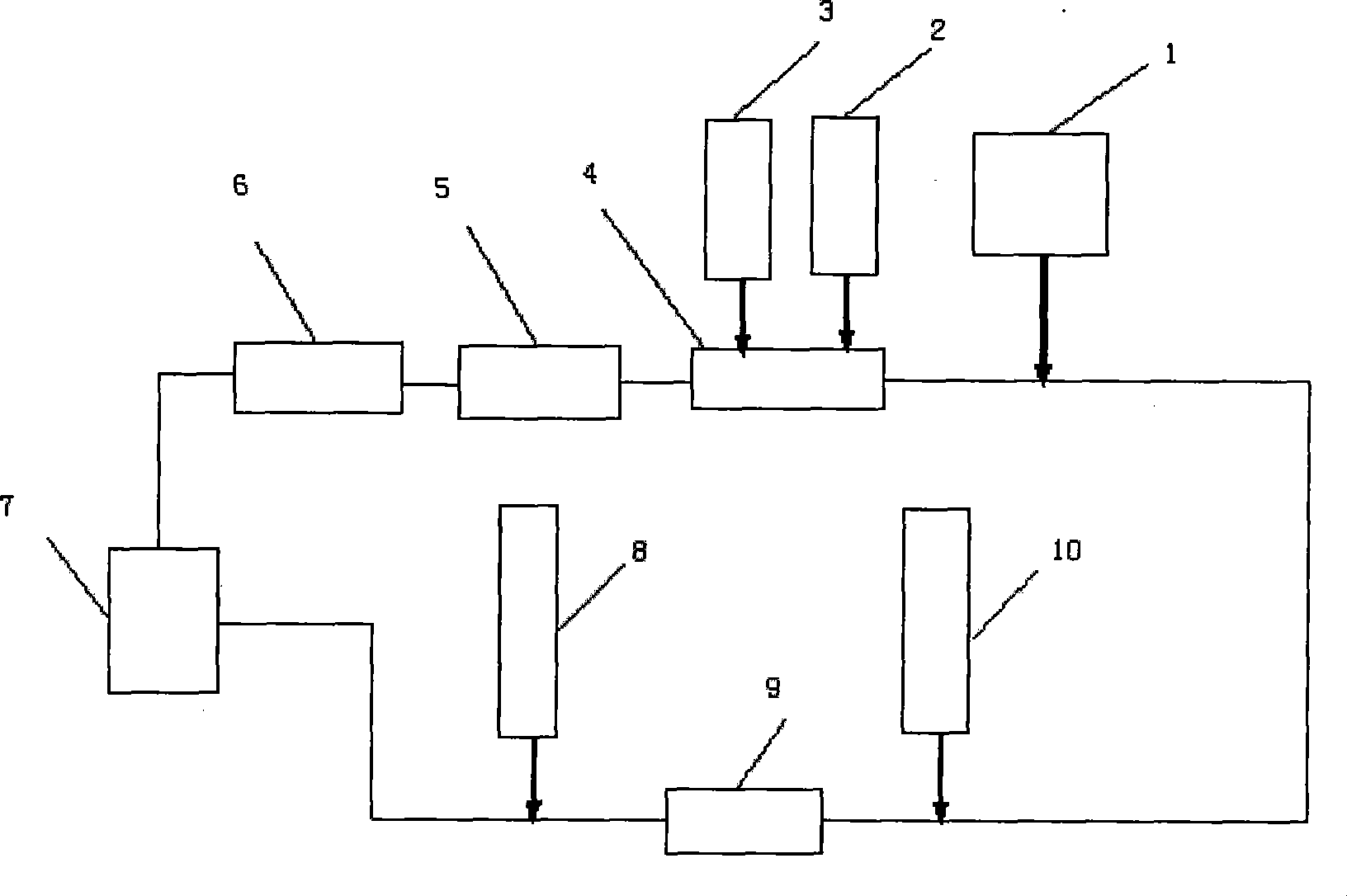

[0023] Embodiment 1, brittle foam base fluid circulation experiment

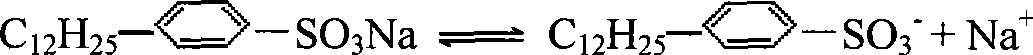

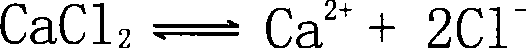

[0024] The brittle foam base fluid formula is prepared by mass: 0.6% ABS+tap water. The prepared brittle foam base liquid is injected into the base liquid tank 2 and the base liquid replenishment tank 1, and the air intake volume and the foam base liquid volume of the air supply system 3 and the base liquid tank 2 are respectively adjusted on the ground, and foam generation is monitored through the foam parameter monitoring system 5 The foam generated in the foam generator 4, after the foam quality and half-life in the foam generator 4 meet the requirements, open the well entry valve 6 to inject foam into the well 7, and after the foam carrying cuttings returns to the wellhead, it is added through the additive addition system A8 The mass percentage concentration is 20%~30% CaCl 2 solution to achieve the first defoaming; the defoamed liquid is removed through the debris removal system 9, and then Na 2 CO 3...

Embodiment 2

[0027] Embodiment two, stable foam cycle experiment

[0028]The formula of stable foam base liquid is prepared by mass: 0.4% ABS+0.3% SDS+0.2% XC+0.2% CMC+tap water. Adjust the air intake and foam base fluid volume on the ground, monitor the foam quality and half-life through the foam parameter monitoring system, and open the well valve to inject foam into the well after the foam quality and half-life meet the requirements, and the foam carrying cuttings will circulate back to the wellhead , add CaCl2 solution with a mass percentage concentration of 40% through the additive addition system A to achieve the first defoaming, the defoamed liquid removes cuttings through the debris removal system, and then adds the mass percentage through the additive addition system B The Na2CO3 solution with a concentration of 50% restores the foaming ability of the foaming agent, and the foam liquid enters the foam generator again for foaming. After the foam quality and half-life meet the requi...

Embodiment 3

[0031] Embodiment three, three-phase foam circulation experiment

[0032] The formula of the three-phase foam base liquid is prepared according to the mass: 0.5% SDS+0.2% XC+0.3% CMC+5.0% bentonite+tap water. Adjust the air intake and foam base fluid volume on the ground, monitor the foam quality and half-life through the foam parameter monitoring system, and open the well valve to inject foam into the well after the foam quality and half-life meet the requirements, and the foam carrying cuttings will circulate back to the wellhead , add CaCl with a mass percentage concentration of 50% through additive addition system A 2 Solution, to achieve the first defoaming, the defoaming liquid removes cuttings through the debris removal system, and then adds Na with a mass percentage concentration of 50% through the additive addition system B 2 CO 3 solution to restore the foaming ability of the blowing agent, and the foam liquid enters the foam generator again to re-foam. After the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com