Slurry for chemical mechanical polishing of cobalt

a technology of mechanical polishing and slurry, which is applied in the field of microelectronics technology, can solve the problems of copper and cobalt easily suffering from dissolution in acidic solution containing oxidants, ta/tan is not suitable anymore, and the cobalt barrier/adhesion layer stack is not suitable anymor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

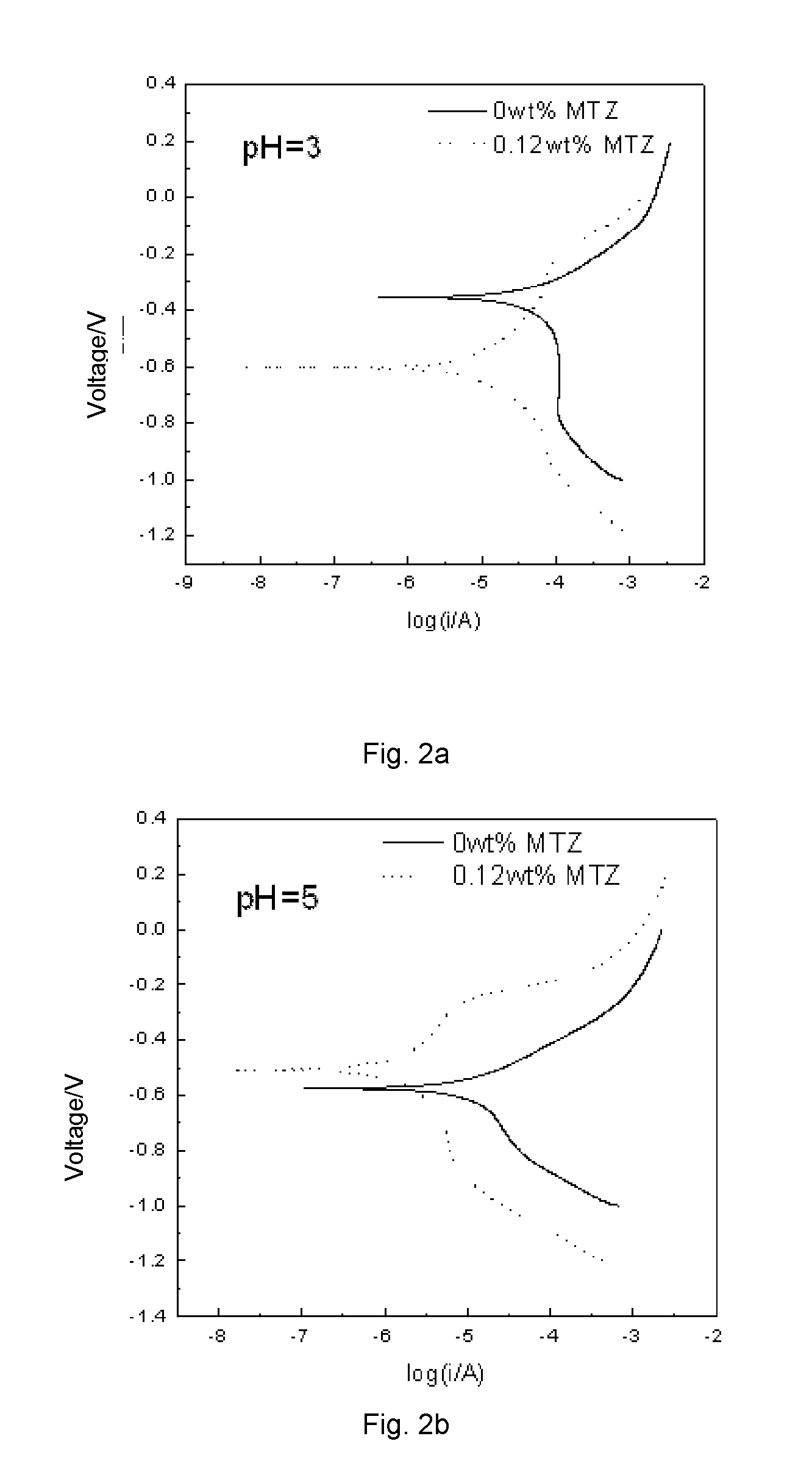

[0022]The components of slurries: 1 wt % colloidal SiO2; 0.75 wt % glycine; 0.12 wt % 2-mercaptothiazole; and the rest of water. Using the diluted nitric acid and potassium hydroxide to adjust the pH value to 3.

[0023]The polishing equipment and mechanical parameters: the polisher is CP-4 bench top polisher made by CETR Company in this embodiment. The polishing pressure is 2 psi, flow rate is 100 ml / min, and rotation rate is 150 rpm for both of polishing head and platen.

Contrast 1

[0024]The slurries is the same as those in embodiment 1 except without 2-mercaptothiazole; The polishing equipment and mechanical parameters are also the same as those in embodiment 1.

[0025]Table 1 lists the corrosion rate and polishing rate of Co in embodiment 1 and Contrast 1.

TABLE 1corrosion rate and polishing rate of Co in embodiment 1 and contrast 12-mercaptothiazole0 wt % 2-0.12 wt %mercaptothiazole2-mercaptothiazoleCorrosion rate of Co□nm / min□50Polishing rate of Co□nm / min□7327

[0026]Shown in table 1, ...

embodiment 2

[0028]The components of slurries: 5 wt % colloidal SiO2; 0.5 wt % H2O2; 0.75 wt % glycine; 0-0.24 wt % Benzotriazole; and the rest of water. The pH value of the slurry is adjust to 5. The concentrations of Benzotriazole are controlled to 0.06 wt %, 0.12 wt %, 0.18 wt %, 0.24 wt % for all the slurries.

[0029]The polishing equipment and mechanical parameters: the polisher is CP-4 bench top polisher made by CETR Company in this embodiment. The polishing pressure is 2 psi, flow rate is 100 ml / min, and rotation rate is 150 rpm for both of polishing head and platen.

[0030]Table 2 lists the corrosion rate of Co in the slurries with different concentrations of Benzotriazole.

TABLE 2corrosion rate of Co in embodiment 2Concentrations ofBenzotriazole□wt %□00.060.120.180.24Corrosion rate of Co5014962(nm / min)

[0031]From the data in table 2, we can see that the corrosion rate of Co is decreased as the increase of concentration of Benzotriazole. When the concentration of Benzotriazole is up to 0.24 wt...

example 3-8

[0033]The components of the slurries (the rest is water) and the experimental data of embodiments 3-8 are listed in table 3.

TABLE 3components of the slurries and experiment results of embodiments 3-8embodiment 3embodiment 4embodiment 5embodiment 6embodiment 7embodiment 8Inhibitor wt %BenzotriazoleBenzotriazole / Benzotriazole / Benzotriazole / Benzotriazole / imidazo / 0.3 %imidazole2-Aminobenz2-Mercaptob2-MercaptobenBenzotriazole / 1:1)imidazoleenzimidazolezimidaz (1.:1)2-mercaptoth0.7%(1:1)(1:1)1.2%iazole (1:1:1)1%2%1.8%Oxidant wt %H2O2(NH4)2S2O8KIO4KClO4(NH4)2S2O8 / H2O2 / 0.1% 5%1%4%H2O2 (1.:2)KIO4 (3:1) 2%0.6%AbrasiveColloidalColloidalCeO2Al2O3Colloidal SiO2 / Colloidalwt %SiO2SiO23.5% 10% CeO2SiO2 / Al2O3 / 1%0.1%(1.:1)Ce02(3:1:1) 7%5.2%Complexingglycine / citric arginineCitric acidGlutamic acidglycine / glycine / agent wt %acid (1.:1)0.4%2%6%Glutamic acidarginine / 0.1%(3.:1)Citric acid10%(1.:1:4)0.8%pH value3.04.05.04.03.03.0Corrosion1.553552rate of Co□nm / min□Polishingrate 458510022012060of Co□nm / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com