Cleaning agent for automobile cooling system

A car cooling and cleaning agent technology, which is applied in the field of organic acid cleaning agents, can solve problems such as corrosion of metal parts, and achieve the effect of reducing metal corrosion, reducing dilution ratio, and less impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

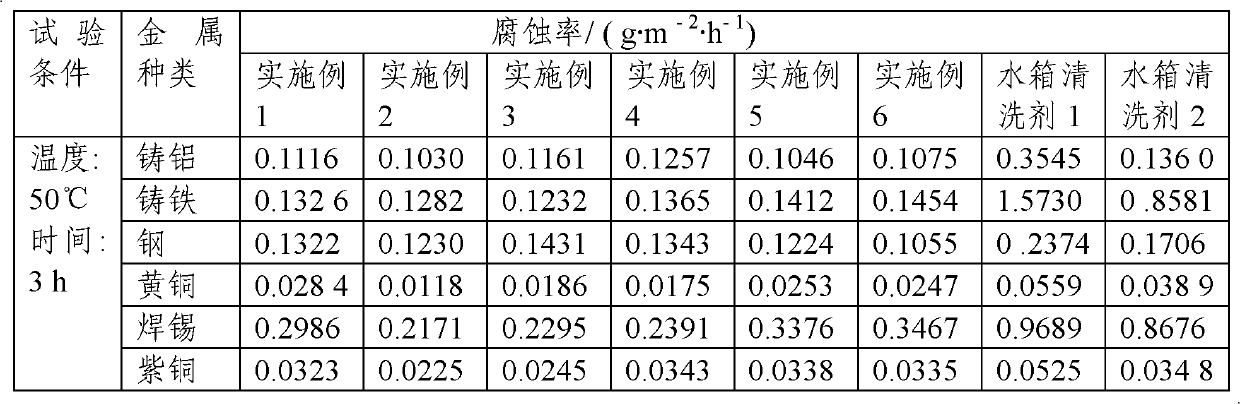

Examples

Embodiment 1

[0023] The components of the automobile cooling system cleaning agent of the present embodiment are: glycolic acid 1.0kg, methanesulfonic acid 0.7kg, citric acid 0.3kg, ammonium citrate 0.1kg, morpholine 0.3kg, AEO-9 (purchased from Hangzhou Gate Sa Chemical Co., Ltd.) 0.01kg, deionized water 7.59kg.

Embodiment 2

[0025] The components of the automobile cooling system cleaning agent of the present embodiment are: glycolic acid 1.0kg, methanesulfonic acid 0.5kg, citric acid 0.5kg, ammonium citrate 0.1kg, morpholine 0.5kg, AEO-90.01kg, deionized water 7.39 kg.

Embodiment 3

[0027] The components of the automobile cooling system cleaning agent of the present embodiment are: glycolic acid 1.1kg, methanesulfonic acid 0.5kg, citric acid 0.3kg, ammonium citrate 0.3kg, N-methylmorpholine 0.4kg, JFC (purchased from Jiangsu Haian Petrochemical Plant) 0.15kg, deionized water 7.25kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com