Acidic chemical and mechanical polishing composition

A polishing composition, chemical-mechanical technology, applied in polishing compositions containing abrasives, other chemical processes, chemical instruments and methods, etc., can solve the adverse effects of CMP overall performance, low-k dielectric layer mechanical strength decline, low-k Film delamination and other problems, to achieve excellent polishing effect, increase polishing removal rate, and optimize surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The raw silica sol flows through the regenerated cation exchange resin column and anion exchange resin column at a flow rate of 1-10 m / hour in sequence to obtain deionized silica sol, and adjust the pH value to After 10.0°C, heat to 50-60°C, slowly drop 0.6wt% of γ-methacryloxypropyltrimethoxysilane under stirring, keep stirring for 6 hours, add water to dilute to 50nm with effective solid content of 30%. Silica Hydrosol.

[0034] Add 10 grams of aminoacetic acid, 0.1 gram of benzotriazole and 0.1 gram of polyalkylene glycol into 800 grams of deionized water in sequence, stir to dissolve, and after uniformity, slowly stir and add 100 grams of refined and modified carbon dioxide Silica hydrosol.

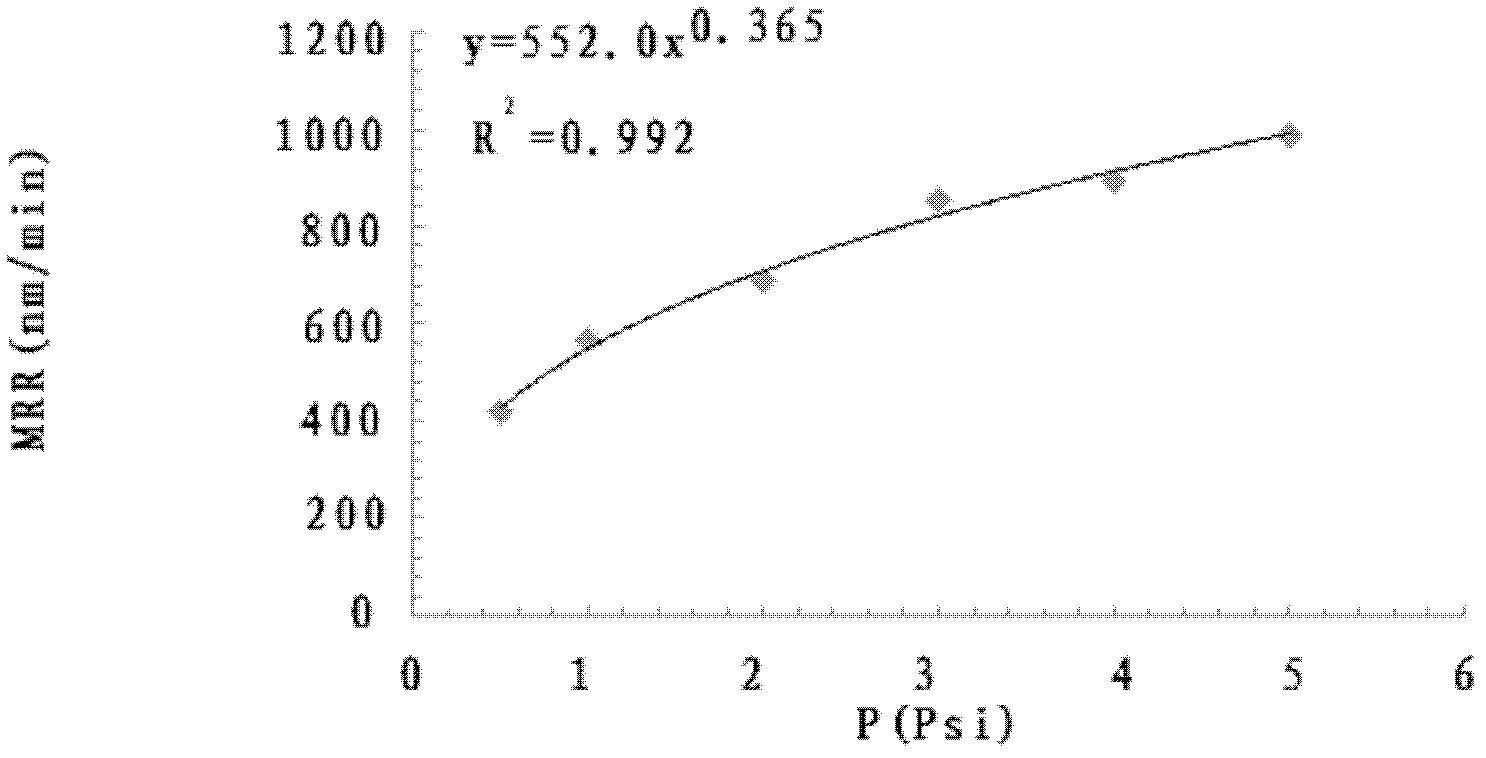

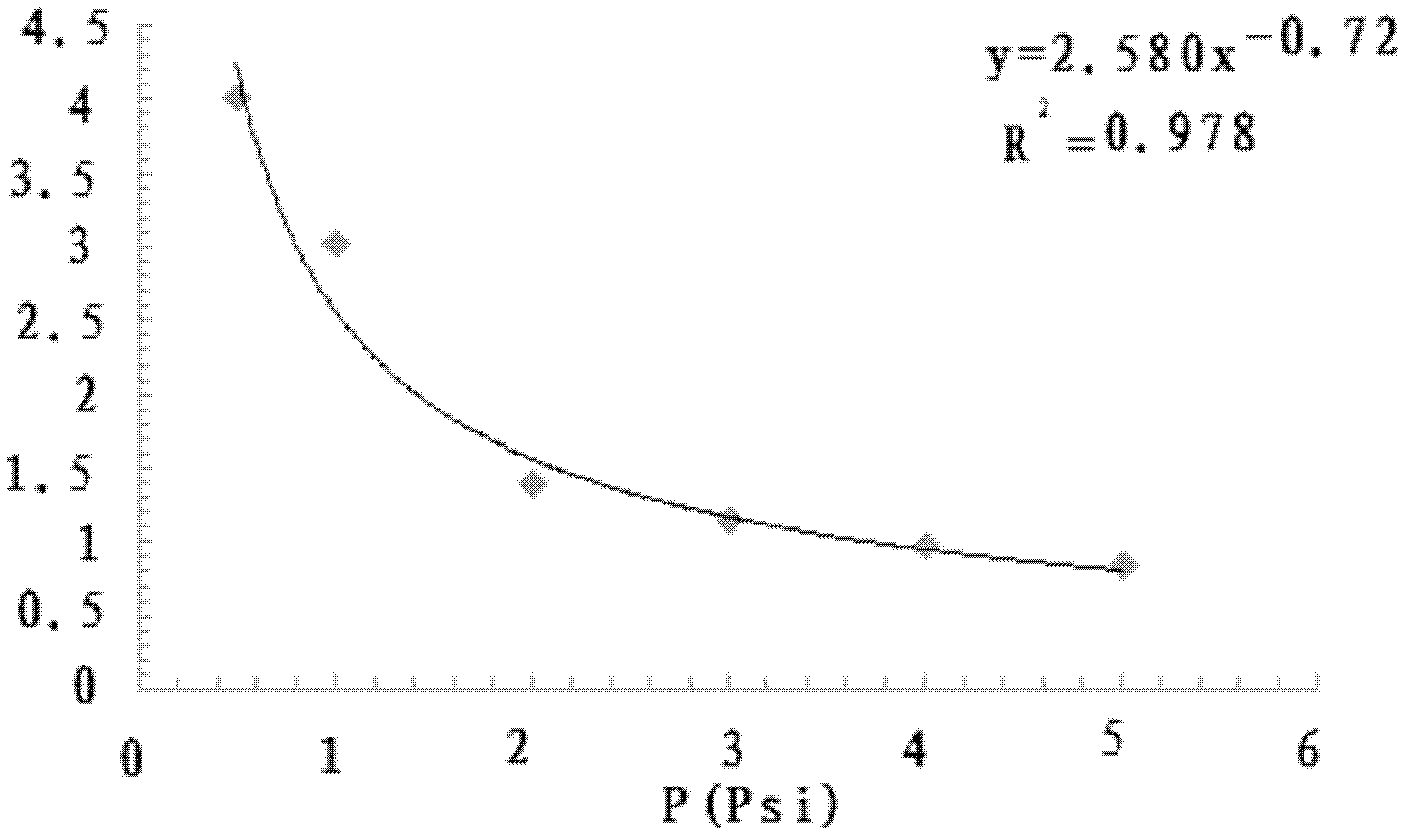

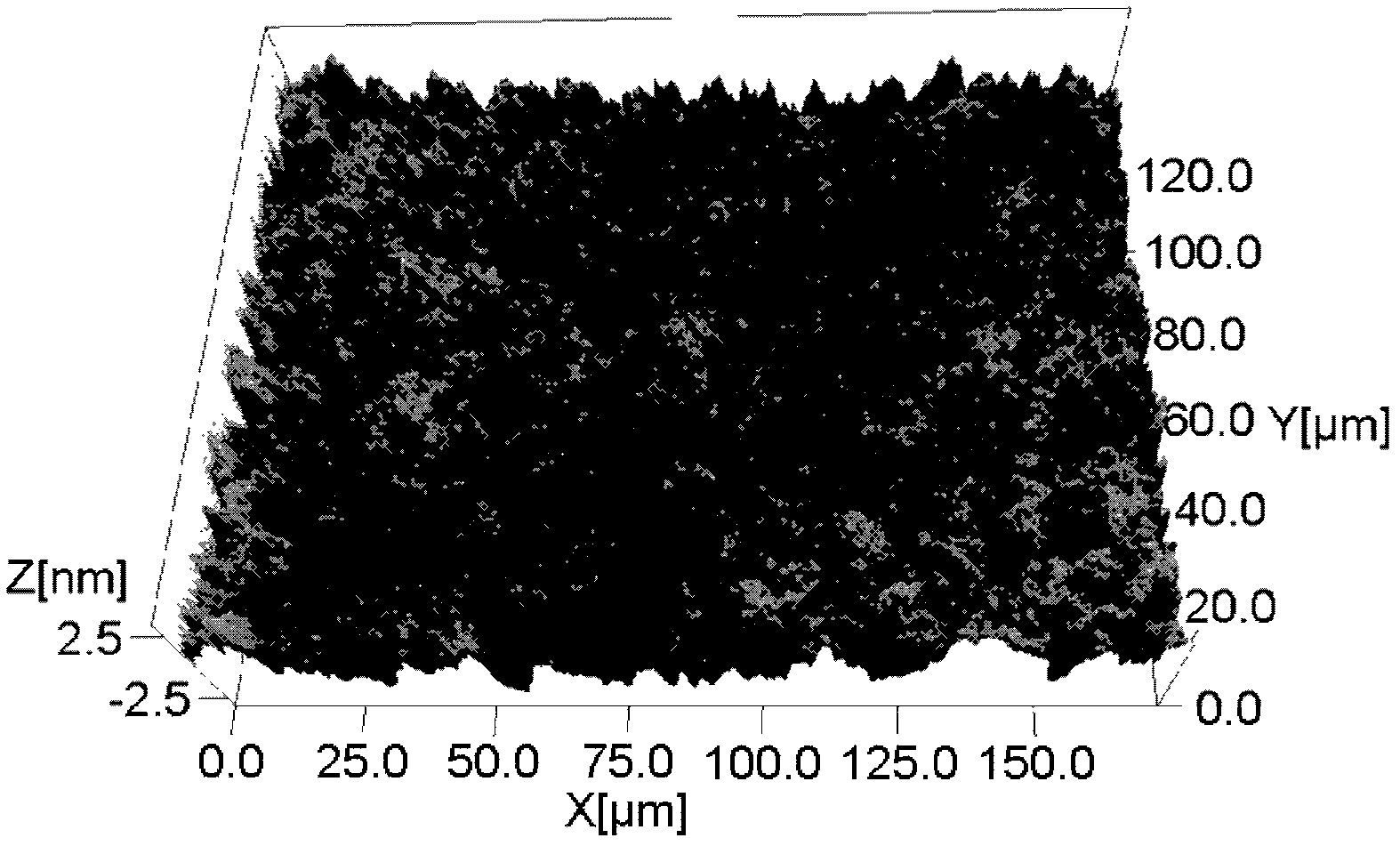

[0035] Add 100 grams of 30% oxidant hydrogen peroxide solution before polishing, and use H 2 SO 4 Calibrate the pH value to 4.0, and finally add water to make up 1000 grams and stir evenly, then immediately perform copper polishing under the pressure of 0.5Psi, the polishing...

Embodiment 2

[0037] The raw silica sol flows through the regenerated cation exchange resin column and anion exchange resin column at a flow rate of 1-10 m / hour in sequence to obtain deionized silica sol, and adjust the pH value to After 10.0°C, heat to 50-60°C, slowly drop 0.6wt% of γ-methacryloxypropyltrimethoxysilane under stirring, keep stirring for 6 hours, add water to dilute to 50nm with effective solid content of 30%. Silica Hydrosol.

[0038] Add 10 grams of aminoacetic acid, 0.1 gram of benzotriazole and 0.1 gram of polyalkylene glycol into 800 grams of deionized water in sequence, stir to dissolve, and after uniformity, slowly stir and add 100 grams of refined and modified carbon dioxide Silica hydrosol.

[0039] Add 100 grams of 30% oxidant hydrogen peroxide solution before polishing, and use H 2 SO 4 Calibrate the pH value to 4.0, add water to make up 1000 grams and stir evenly, then immediately perform copper polishing under 1.0Psi pressure, the polishing removal rate MRR i...

Embodiment 3

[0041] The raw silica sol flows through the regenerated cation exchange resin column and anion exchange resin column at a flow rate of 1-10 m / hour in sequence to obtain deionized silica sol, and adjust the pH value to After 10.0°C, heat to 50-60°C, slowly drop 0.6wt% of γ-methacryloxypropyltrimethoxysilane under stirring, keep stirring for 6 hours, add water to dilute to 50nm with effective solid content of 30%. Silica Hydrosol.

[0042] Add 10 grams of aminoacetic acid, 0.1 gram of benzotriazole and 0.1 gram of polyalkylene glycol into 800 grams of deionized water in sequence, stir to dissolve, and after uniformity, slowly stir and add 100 grams of refined and modified carbon dioxide Silica hydrosol.

[0043] Add 100 grams of 30% oxidant hydrogen peroxide solution before polishing, and use H 2 SO 4 Calibrate the pH value to 4.0, add water to make up 1000 grams and stir evenly, then immediately perform copper polishing under 2.0Psi pressure, the polishing removal rate MRR i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com