A camping oil heating stove

A heating furnace and oil-fired hearth technology, which is applied in the heating field, can solve the problems that affect field workers' night rest, generator noise is loud, and combustion is incomplete, so as to shorten the chemical reaction time, increase the thermal load limit, and reduce the heat of combustion loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

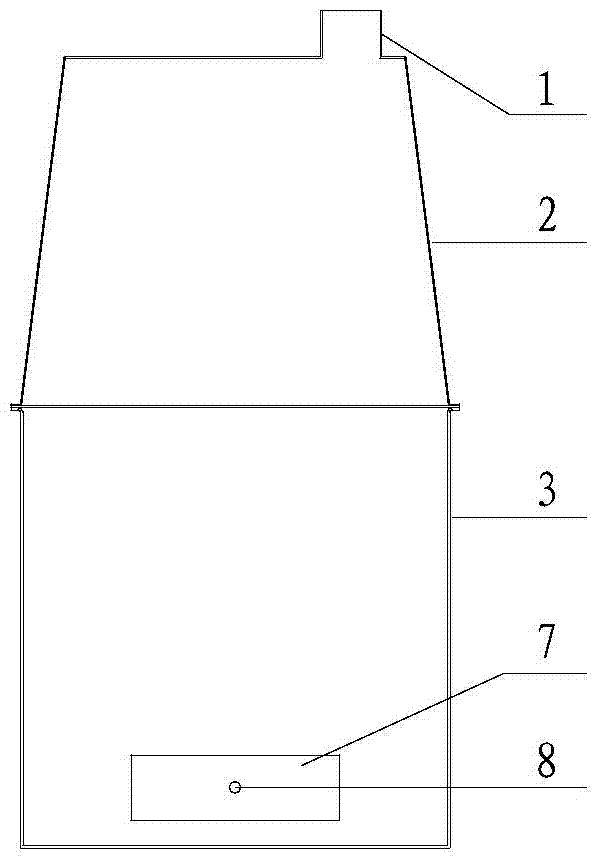

[0024] Such as figure 1 with 2 As shown, the present invention comprises body of heater 3, is provided with fuel burner hearth 4 in the body of heater 3, is provided with some air inlet holes 10 on the wall surface of fuel oil furnace hearth 4, and the diameter of air inlet hole 10 is 1.5~5mm, and some air inlet holes 10 The total area accounts for 0.1~1% of the surface area of the fuel furnace 4 barrels.

[0025] The fuel furnace 4 is provided with a vaporization device for evaporating fuel; specifically, the vaporization device is fixed in the fuel furnace 4 through a steady flow plate. The steady flow plate includes an upper steady flow plate 5 and a lower steady flow plate 6 , and the overheating pipe includes a lower end of the overheating pipe arranged below the lower steady flow plate 6 .

[0026] Vaporization device comprises vaporization cap 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com